Everything posted by Carl Beck

-

Need help getting right Blue Color

Is the original color code sticker still on the car? If what type of paint does it list? Carl

-

New to the Forum

Hi Jack T: I've been with the Hagerty for about 25 years now... I did have a claim... it was a wonderful experience. I'd highly recommend them, they are real "car people". They have taken care of the Classic Z Car Community for many many years - way ahead of the other Classic, Collectible and Special Interest auto insurance carriers. You do have to have a pretty good driving record... To replace that car today, you'd most likely need $20K. FWIW, Carl B.

-

ZCCA Convention 2009

They usually pick the next year's convention location - at the current convention.

-

New to the Forum

Looks pretty nice in the pictures... if you bought it two years ago, and the things you list are all you've done - it was most likely a very good purchase. When you are restoring Z's it's always that last 5% that gets you:stupid: As always - Make sure you have it properly insured!!! FWIW, Carl B.

-

Good Luck to the Z Racers at the Solo Nationals!

Way to go JT - the only thing better than winning, is winning when there is stiff competition. Fiddle with the Z if it makes you feel better, but I think most of us know that in this case it's 90% the DRIVER and perhaps 10% the car. Good car with a great driver plus several years of experience makes a very hard combination to beat. None-the-less we love to see that old Z carry you to victory. FWIW, Carl B.

-

What's in YOUR garage?

She's young by todays standardsLOL If you had told me, when I was 49 that I'd be having kids again, I would have told you that you were nuts. Lucky that we never know what life will hold for us tomorrow. At 50 I had my first Daughter - quite a surprise - and completely different than raising the boys (now 39 and 36). My wife was 41 and more surprised than me. My Daughter has been a complete joy..... You never know... Carl B.

-

What's in YOUR garage?

JimmyZ/Poindexter: Way off topic - but what the heck.. I built models of all the WW-II planes in the mid to late 50's. I was 10 to 15 years old then. My father had gone to Emery-Riddle Flight School in the 20's and I used to have his Bearskin Flying Gloves. (lost them somehow during my homeless days). By the mid 60's I was in college - and got my Private Ticket at Lane Aviation, Port Columbus International Air Port. Loved learning how to fly, and for the first few years it was affordable. By the late 60's early 70's I was in the Air Force - and making something like $350.00 per month - the cost of private planes was just too high and I have to admit that having been there and done that, I wasn't as motivated as I used to be. A few friends had planes and I'd fly with them every one-in-awhile. Funny thing was, by the mid 70's, 80's and 90's I was working on engineering programs for the F-14, F-16, AV8-B, F-18, F-22..(among other things). By the 90's I was getting old, eyes going South and problems with my heart... so I was grounded for good. Nonetheless, like you guys - I still love to see the war birds from WW-II. Personally I'd like to have an ME-109 or P-51... but it doesn't look like that's going happen. FWIW, Carl B.

-

Finding an old Friend - - or it's a small world..

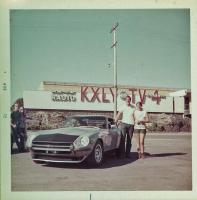

Oh.. I see... you have to go to your Personal Profile - then see the photo album. I wondered why it didn't show up in the "User Gallery"... One of these day's I'll have to learn how to use this forum software... The Z looks much better in front of your house than it did in mineROFL Looks like you washed it!! Anyway - here are a couple more for you... As I recall we were at an auto-cross in Spokane that day. FWIW, Carl

-

Need help getting right Blue Color

Did the dupont vendor use 14239 Poly Blue as a cross reference? It was used on the 1970/1971 Model Year cars. Too bad your in a rush - I'm sure some of the older Automotive Paint Suppliers have the older records. 903 was a shade darker blue and non metallic, than the 115 Metallic Blue in 72/73. FWIW, Carl B.

-

Datsun Parts vendor

BUMP - any updates to this thread? FWIW, Carl B.

-

Suspension Problems

Thanks for including the pages - Will read the data to me over the phone, so I must have recored the last one incorrectly. Nonetheless, the difference in OEM vs Euro rear springs - only accounts for 0.7in increase in rid height.. The original picture you Posted looks like the car was sitting 3 to 5 inches higher than it should. Could be - the shop had torqued the lower control arms down, with them suspended in the air. Could be something else was done wrong. Either of which they corrected when they swapped the OEM springs back in. Sorry - you did say Stage I. I may be calling them Stage II because the Stage I springs for the 240-Z's are 12% stiffer than OEM. The Stage II springs for the 240Z are closer to the 140 lbs/in... So when I see 140lbs/in I think Stage II. That may not be the case for the 260Z - If you can get an accurate measure of the wire diameter used in the Eupo Spec. Springs - we can get pretty close to what they would measure out to be. You have to find someone that has a coil spring measuring machine to get accurate measurements. The Coil Spring Measuring machine will be able to hold the spring in place, then compress it to 80% of its free length - then take load measurements as it is compressed an additional inch or two. Call Race Car Development shop's in your area - and you might find one with the necessary machine to measure the coil spring rates.. If you bought them in 84 they are the low pressure type - no one was building high pressure gas shocks as OEM replacements then. The newer high pressure gas shocks can have 100 to 200 lbs of lift - and they will set a very light weight 240-Z from 0.75 to 1.5 inches higher by off loading that much weight from the springs. But the FSM also says that if the bumper height isn't correct - you move the bumper up/down. We may never know exactly what caused the rear of your 260Z to be sticking up so high after the original installation of the Euro Spec. Springs FWIW, Carl B.

-

What's in YOUR garage?

Hi Jim... buddy.. old friend... exactly where in Florida do you liveROFL Carl B.

-

Suspension Problems

Fixitman: Coil springs provide a fairly constant rate of compression, once they are compressed to about 80% of their Free Length. If you look at the Spring Spec's for a stock US Spec. 260Z produced between 8/73 and 8/74.. you will see that the Free Length is 15.4 inches, the Installed length 8.7 inches. The load on the installed spring is 706 lbs. The stock spring constant (rate) is 106 lbs/in. So if you divide the load 706 by the spring constant 106 you get 6.66 inches of initial spring compression when the car is sitting on it's struts. If you subtract the listed Installed Length of 8.7 inch, from the listed Free Length of 15.4 you get 6.7 inches. (rounding errors etc) - so close enough. Now change the rear springs - to one's with a spring constant of 140 lbs/in. (the spring rate you provided) Looking strictly at the picture of the springs you Posted above - I'd guess that the Euro Spec. Spring is the clean one on the far left - and it looks like it might be 1 inch shorter than the others.. So call it 14.4 in. Free Length. Divide the load of 706 by the spring constant of 140 lbs/in and you get 5 inches of initial compression. 14.4 Free length minus 5 inches of initial compression = should be close to 9.4 inches installed length. 9.4 minus the stock 8.7 inch is only 0.7 inch increase in ride height. I'd have to have the exact length of that "Euro Stage II" spring.... to be sure, I would also have to know for sure what the spring constant is (to be sure you have the springs that you think you do) However it strikes me that it was NOT only the Euro Springs that could account for the huge difference in ride height, as pictured on the rear of your 260Z in your first Post. Where did you get your Shocks? Now old are they? Billstein hasn't sold OEM replacement shocks for the 240/260Z's since the mid 80's. Back then they were low pressure gas shocks. With the Euro Spec. springs removed, and stock springs back in the car - it still looks like it is sitting a couple inches higher - but that just may be the angle of the pictures... We'll know more when you measure the usually places... THE STOCK SPRINGS - according to the Field Service Manual: -The two rear and the Left Front are the same - the Right Front is the shorter one. -The two rear and Left Front have a free length of 15.4 inches -The Right Front has a Free Length of 14.9 FWIW, Carl B. BTW - thanks to Will (HLS30.com) for the info on the 260Z springs from the 260Z FSM.

-

How do I get this off...

Reset - - - I should have said, it is BEST to have a set of metric swivel sockets. In the case of the intake/exhaust manifold - I can't remember if the nuts are 12mm or 14mm... If you go to Sears for Craftsman - buy the individual swivel 6 point sockets - don't buy the 6 piece set - the set is missing the 14mm socket - one of the dumber things I've seen Craftsman do.. individually they run $8.50 for the 10 though 14mm sizes.. That will cover 95% of the things you need a swivel for on a 240-Z. The way Sears has them priced, you really don't save anything buying the 6 piece set anyway.. If you can afford Snap-On you'll always hate the price, but you'll never reqret the quality. FWIW Carl B.

-

How do I get this off...

You need a universal swivel, a 10" extension and the socket... as I recall. FWIW, Carl B.

-

How do I get this off...

Sorry mally002 - I thought you had the air injection tubes circled in Red in that picture. If your not staying stock - then I'd take the air injection tubes out as well. They stick down into the exhaust ports and restrict exhaust flow, plus you can eliminate the air pump - which most likely isn't working anyway. As for headers - to each his own. I don't like the additional heat and noise under the hood. You don't gain any measureable HP with them alone. Opening up the stock "y" pipe into a 2.5" or larger dia. exhaust system will yeild measureable HP however. I remember seeing the new Carbs/Air cleaners - but can't remember if they retain the air horns on the SU's. Do they? Removing the OEM Air Horns, without replacement will cause a loss of power. FWIW, Carl B.

-

How do I get this off...

Take the intake manifold and old carb's off first to get them out of the way. Soak the flair nuts on the air injection tubes, where they bolt into the exhaust manifold - down with Kroil Penetrating Oil (Aero Kroil). Spray them and let them set for a day.. spray them again and let them set for an hour or so, then spray them one final time before putting a wrench on the flair nuts. See: http://kanolabs.com/ I cut the tubes off about an inch above the flair nuts, so I can get a good box end wrench on the nuts to avoid rounding them off. The I put the box end wrench on the nut - and give the other end of the wrench a swift blow with a good brass hammer. A good brass hammer is a must have - if your working on 30+ year old cars. You can get them at Harbor Freight for around $25.00. Using the above method - I've removed about 15 air injection tube assemblies - without having to drill any of them out. If you aren't using "Kroil Oil" (Aero Kroil is the spray car version) - then all bets are off. You then get some brass pipe plugs (Allan head type), put a little pipe dope on the threads and screw them in the holes. FWIW, Carl B. BTW - if you have a gas tourch set - you can heat the flair nuts to break them loose. You just have to be careful not to melt them. This is best down with the exhaust manifold off the car.

-

Suspension Problems

Hi Fixitman: Where did you get "factory spec's" for the height of the top of the front and rear bumpers for a 260Z? So far - almost all of us have been using measurements taken at: 1. The center of the headlight - that is the headlight adjusting screw on the outside of the headlight nacelle. 2 The height of the front wheel arch - from the ground, measured though the center of the wheel. 3. The height of the rocker panel in front - measured from the bottom of the rocker (not the lip that sticks down), to the ground - at the cutouts that show where to place the jack. 4. The height of the rocker panel in the rear - measured from the bottom of the rocker (not the lip that sticks down), to the ground - at the cutouts that show where to place the jack. 5. The height of the rear wheel arch - from the ground, measured though the center of the wheel. The only measurement that I have found - given by the factory - is the distance from the bottom of the front frame rail to the ground - taken below the front frame rail where it meets the firewall. That is given as 6" in the FSM. So with the "bumper height" spec's you list - we have really no idea how that compares to all the previous measurements gathered. If you get a chance, can you take the 5 measurements above and report them? <img src=http://ZHome.com/FixitZMeasure.jpg> FWIW, Carl B.

-

F.I.A. Brake System-Stock Rotor

I had a source in Japan, but now the Web Page seems to have either moved or is gone. The Calipers were Sumitomo MK 63's that Nissan sold though the old Datsun Competition Dept. and were for either ventilated or non-ventilated rotors. They are four piston calipers and Datsun Comp. also had different rear wheel cylinders that were used with them. FWIW, Carl

-

Undercoating my 73 240z

Are you stripping the entire undercarriage down to bare metal? With everything taken off the car? (suspension, fuel/brake lines, etc) Under what conditions, what road types, etc. do you plan to drive the car? Will you have the car on a rotisserie - in a place that you could spray anything you wish? Do you have a compressor and spray gun - or will you be forced to use spray cans? Without knowing all the above - it's hard to make a recommendation FWIW, Carl B.

-

Iridium Spark Plugs

The longer change interval is mostly if not entirely due to the HEI ignition and significantly wider plug gap's in modern cars. Also due to the use of computer controls metering out all but exact air/fuel ratio's for every combustion stroke using lead free fuels. Spark plugs rarely "wear out" or "burn up" in an L6 - normally they become carbon fouled. In which case all you need to do is clean them. Most people, not having a high quality spark plug cleaning machine - wind up simply replacing them. The el cheapo spark plug cleaners (aka Harbor Freight) are worthless. The A/C and Champion Spark Plug Cleaners from decades ago will make dirty/fouled plugs look and perform like new. Clean them up and run a file across the tip of the electrodes... and put them back in... FWIW, Carl B.

-

Differential Damper

I'm not positive... I know that when you install an R200 in the 240Z body(which is all but the same as the early 260Z), you turn the differential mount around... The pictures that were posted in the other thread are of a 280Z with the R200 and it is turned the other way (from yours now). I'd say that the differential mount is correct in your car with the R180. Anyone have a stock 260Z to go check??? FWIW, Carl B.

-

Differential Damper

Stephen: A 74 260Z FSM is one that I don't have. Looking at the Parts Catalog, it shows a Bar-Torsion Rear Stablizer from 08/73 to 08/74 55611-E8100 and 09/74 forward as 55611-N4701.

-

Accelerator linkage fix questions?

I'll just add this - but I think Joel's solution is better for most people. In the original article, or in follow on questions - I don't remember which - the person that did the fix to begin with - cut a couple of slots in the top bushings lip - one on each side of the mount. Then drilled a very small hole though the mount, in the grove where the "C" clip was - and slipped a safety wire though - I suppose you could use a very thin cotter pin as well. FWIW, Carl B.

-

Differential Damper

OK - if we are talking about the Dealer manufactured part - added to dampen vibration into the body - then based on the pictures provided by twsutt in the other thread - Yes that damper is mounted backwards. I don't see a rubber part of the Dealer manufactured part, so I could be missing something here. I do see a rubber part on differential mount/insulator - in the pictures supplied by twsutt - But that is on a 75 280Z with the R200 rear end. The mount in question - if there is indeed a question about the differental mount - is on a 260 Z - that is based on the 240Z body with the R180. In that case, I'm not sure about the differential mount being reversed. Just want to make sure we are all on the same page at this point. I think I misunderstood the original question... Do you mean the stock bar is straight on a 280Z - or did you really mean it is straight on the 74 260Z? FWIW, Carl B.