Everything posted by EuroDat

-

Making a one legged into limited slip

You might want to check the ratio. The 79 280ZX is a bit odd in the ZX line up. 280ZX 1979 2+2 4 speed R200 3.364:1 280ZX 1979 2+2 5 speed R200 3.7:1 ( also had wide ratio 5 speed like 280Z) 280ZX GL 1979 R200 3.7:1 The coupes used a R180 with 3.364:1 ratio. The 2+2 manuals went to the 3.9:1 in 1980 and all NA manuals (coupe and 2+2) were 3.9:1 from 1981 - 1983.

-

Crashworthiness of a 77 280z

Chris, I agree the 240Z is less reinforced in places, but I don't know if a 240Z or a 260Z would have been much worse. The reinforced door deflected some of the impact, but lets face it the improvements made to the 280Z are marginal compared to cars these days. And it was an S10, a bit like getting hit by a concrete block travelling at 60mph. You have luck on your side surviving such an impact in an S30. Ive weighed up the risks and try to reduce them by avoiding places were accidents occur often and drive outside peak hour when it is not so buzy. The rest is just luck I guess.

-

At The Salvage Yard

Bart is right. There is a lot of stuff that will be hard to find in the future. Things that don't seem important now could very we be worth their weight in gold, so to speak, in the future. Things like the steering rod uni's, rear brake drums, steering rack, even the bolts holding the fender along the bonnet edge are special for that area (thin heads) and often lost in careless restorations, like my PO did. It would be a bare carcass if I could get my grubby little hands on it, but then again Im a self confessed hoerder Over here that car would be considered a restorable project. It's a totally different market over here. It would never end up in a wrecking yard in such a "complete" state.

-

At The Salvage Yard

You need to go back. You forgot to get the the center valance panel. Seriously, it is getting hard to find good examples and that one, although not in clear view in the photo, looks in reasonably good nik. The horns look good. Grab the brake proportioning vavle and brake switch unit. They and both NLA and those maybe salvagable.

-

Fuel Injection Issues

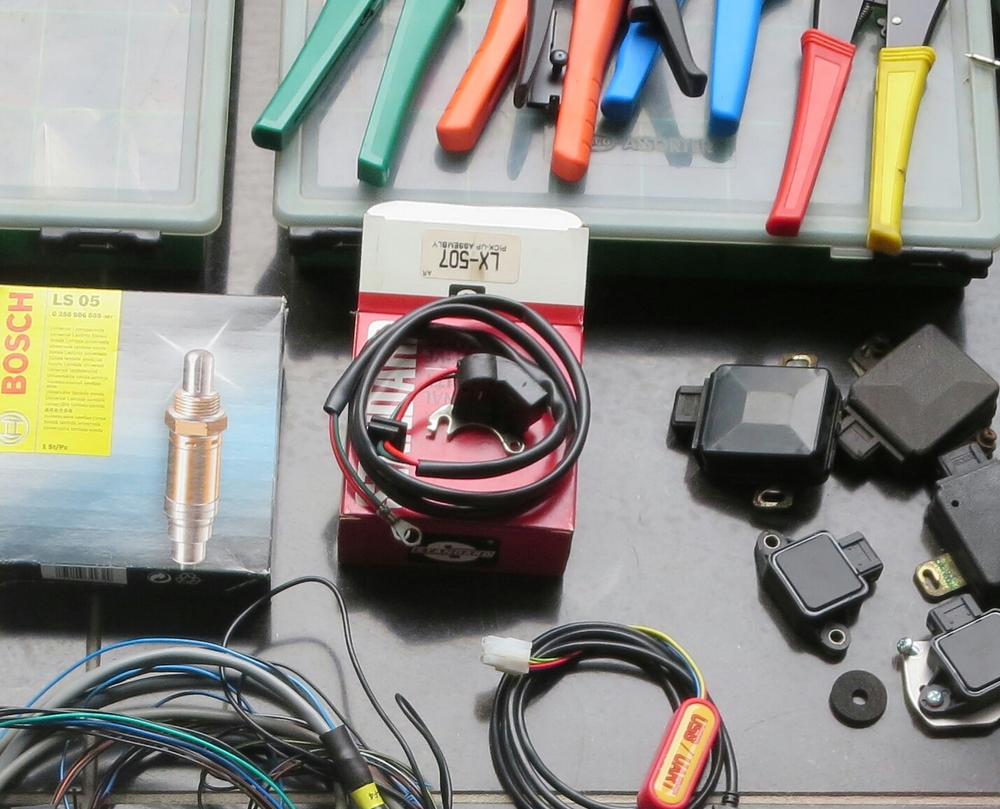

Your question: What is this thing and is it important? That is the EFI Main relay on the 78 model, (after Aug-77). Yes it is very important. It looks intact, but the contacts could need cleaning. If its not working properly that will be a source for the EFI not working for sure. The EFI fuel pump relay is rectangular in shape. See photo (Photo is not mine, but from another thread here under "1978 Z - Fuel pump control relay")

-

Time to sell my Z. What's she worth?

Hi Sarah, Sorry to hear you are selling the 280Z. I can understand your reasons, knowing a little bit about your partners situation and having gone/going though similar circumstances myself. Me being in Europe, Ill leave it up to other fellow members to advise you on pricing. Over here the prices are much higher because of transport and importing costs. One thing I want to say; who ever buys your car will be buying a car that has been looked after by a knowlegable Z enthusiast. I see that a little like buying a bisiness. Some businesses have little good will, some have a lot. Good luck selling. Chas

-

DIY Gland Nut Socket - With PICS!

Guy, I would try a piece of 1" pipe or maybe 1-1/4" pipe, weld a socket on one end for a socket wrench and tack weld it to the glad nut. 1" should be small enough to give you room to tack weld it in a V weld fashion and still slide over the shock. 6 to 8 good tack welds should be enough and maybe a little heat to the strut. Good luck with it. Its a pita when something like that happens.

- Nothing coming from ignition coil

-

1976 280Z Restoration Project

Mark, Is the lip completly rolled back. I mean touching the inner panel? The reason Im asking is it might be hard to coat and prevent rust form developing. It could also trap dirt and keep moisture a lot longer. I remember that from a friend who owned an old Holden LC Torana years ago. He rolled the lips and the cavity behind filled with dirt. That held the moisture and it rusted out in no time. Would be a pity if that would happen. You are still making good progress. That is good to see.

-

Looking for Cable ties for 280Z engine bay harness

Hi, I forgot all about this thread and didn't post what I ended up doing. I did try to order some from Nissan with yhe old p/n, but they substituted something from the modern cars. Ebnded up throwing yhem in the garbage can. Then I tried the ones that SteveJ posted from Panduit. They work well and look similar to the originals, but are single use. They are designed for a hole around 6.5mm in diameter and the holes in the 280Z are 7.0mm. That means they fit ok, and maybe a little looser then yhe originals were when new. I purchased a pack of 100 for about €25. The price has increased a little since then. http://www.panduit.com/en/products-and-services/products/cable-and-wire-bundling/plastic-cable-ties/cable-ties-with-metal-barb/push-mount-ties/BP2S-D0 Hope that helps. BT_0286.pdf BP2S-D0 Product Page.pdf

-

I was thinking about freshening up the suspension!

Are your four legged friends helping you with your built or just mental suport? Looks really neat all nice and shine with a fresh coat balck paint.

- Nothing coming from ignition coil

- Nothing coming from ignition coil

- 1976 280Z Restoration Project

- Nothing coming from ignition coil

-

Nothing coming from ignition coil

Since he showed us a photo of the E12-27 TIU, I thought it was a 280ZX engine in a 1978 280Z with the original distributor. The EFI harness doesn't include the ignition system, so that is quite feasible. The terminal block in front of the coil is still intact which would also indicate the 280Z distributor. The top view of the distributor doesn't give any view of the module. Based on the photo's posted above my conclusion was the engine has a 280Z distributor with E12-27 TIU and a 280ZX EFI system. I think The Wondous made a error quoting 260Z. It looks like a 280Z to me. Unless someone has done a lot of frame modifications for brackets like AFM mount.

-

Thinking about installing an BMW M6 engine in my Z

I don't mind stolen ideas. Prevents a lot of R&D & redo work. I never get it right first time If you can fit the brace, I think I would do it. With the other braces you made, you should not need to brace the towers back to the centre of the firewall. That would help keep it clean. I can imagine dipping would be addictive. It really looks clean.

-

Thinking about installing an BMW M6 engine in my Z

Looking good Chris. The bracing looks very neat and tidy. Did you get that idea from someone or your own inventiveness? Are you doing this because you can't use the tower brace over the bmw engine? Must be a pleasure to work on now all the metal is so clean.

-

280zx gauges in a z?

Why do you want the change clocks. If you are doing it because you happen to have a ZX clock handy, it might be easier to try and repair the original. Do you still have the original? Here is a write-up by @monkeyman in australia. It seems an easy procedure to follow and would probably be a lot easier than converting a ZX. I think zclocks does an exchange service. How to fix your 260Z or 280Z clock - rev 1.pdf

-

Nothing coming from ignition coil

I agree Zed. First identify the problem, then fix it. It could be a number of things causing his problem and changing stuuf will eventually solve it, but that can cost $$$$. It could be as simple as a loose pick-up coil and the gap is now too wide. Just saying.... The tests I listed in section 9 of the instruction are out of self evaluation and from the manual. It should be enough to identify where the problem is or eliminate sections until one item is left. Testing the TIU is very difficult for the home hobbyist, but using the process of elimination you can identify it ss the cause. A quick test would be: Disconnect the TIU plug and use a wire with spade terminal to make a connection to ground. Turn ignition on and tap the wire rappidly to ground while someone checks for spark using the timing light on the HT wire going from coil to the distributor cap. That would eliminate everything on the coil side of the system. Then it's down to testing the reluctor, reluctor wiring, TIU and power/ground to the TIU.

- Nothing coming from ignition coil

- Nothing coming from ignition coil

- MUSTACHE BAR QUANDRY/HELP!!!

-

Expectations versus reality

I agree Zed. You se it a lot with PU rubbers. The mustache bar rubbers are a good example. If you look at the originals, they have a certain amount of flex before contacting the "star like" rubbers on the top and bottom. The original could isolate much better. I might have a look at mine and try your idea on the extra spacers. One of the things I've regretted doing to mine.

-

Expectations versus reality

Drivetrain noise is normal for the 280Z especially when you compare it with the 350Z. What can make it worse or more noticable is PU bushings in the mustache bar, PU bushings in the transmission crossmember and/or a solid diff mount. The type of oil your using can make the diff a little quieter or noisier. An RT diff bracket with the rubber stop touching the diff can transfer noise too. Back in the eighties a common complaint about the 280ZX was it lost a lot of the sports car feel when they introduced all the creature comforts like power steering, electric windows etc. The car was much "softer". My 280Z is heavy, but I axcept it. My wife doen't like driving it because the steering is so heavy