Everything posted by Patcon

-

Servicing Cooling System Questions

Only because you haven't assembled your at home hardening line...yet 😉

-

Taillight Gasket Exhaust Leak?

Maybe try without the tape first. Otherwise you wont know if the seal and peel actually worked

-

Total internal reupholstery

I believe the chrome strip molded to the vinyl on the panel. I don't believe it will come loose with the rivets Maybe Cantech can verify.

-

Air chucks

I have bought Milton HiFlo hose air chucks for years. I've been really disappointed in them in recent years. Them seem to start leaking pretty quickly as of late. What is everybody else using? Anyone else's experience?

-

1971 HLS30-14938 "Lily" build

@Namerow What is the best way to use those templates? I would print them but that seems like it would use a lot of ink. Is there a better way to do it?

-

1971 HLS30-14938 "Lily" build

Worked on the heater box some more today. Blasted the cases. Primed and painted. Blasted the hardware and strung it. Ready for plating. Need to test the heater core somehow

-

L20b Cody's Goon

Worked on the dizzy some more. Got the advance shaft disassembled and polished the shafts. It would appear the mechanical advance is going to be 13d? Disassembled this part too I took lots of pictures! There are several little details that would be easy to miss on reassembly Might work on this part some more tomorrow, we'll see...

-

Caswell Plating

I plated the vacuum advance the other weekend I wired it and then put the hose on it to keep the liquid out. I plugged the advance port It turned out pretty nice for as crusty as it was. What was interesting was when it was in the tank one side would get really shiny but the other got dark. Rotate the piece and the discolorations would move. So at the very end I just wired the negative directly to the wire coming off the part and held it in the tank by hand. I rotated the part slowly and all the plate brightened up. It was really cool to watch. So this would tend to support barrel plating as giving the best finish results...

-

Replacing All Large Opening Seals & Hatch Small Seals

How do you do this heat and oil black thing?

- A/C trinary switch

-

Engine rebuild smoking

That's too funny! Well at least he's confidant in his work! That's what you want.

-

1971 HLS30-14938 "Lily" build

Here it is...

-

1971 HLS30-14938 "Lily" build

Thanks John

-

280z Steering Wheel Vibration

It's always good to find an expert!

-

1971 HLS30-14938 "Lily" build

I had a wire going through that area and used it to fish the harness in, but there are brackets and bolts welded up in that area of the car. The harnesses snag on those making it hard to get them back in

-

1971 HLS30-14938 "Lily" build

Installed the gas flap and ring today Also I was stripping down the heater box for freshening up Do anyone know if I can get this flap out? I don't see anything retaining it but it seemed like it didn't want to come out. I would also like to two floor heat flaps out too but I don't know how to de-assemble those either. I finally got the rear harness pulled in. It was a huge pain. Took maybe ten tries to get the defrost and dome light harness pulled up from the quarter panel. I would suggest not pulling those out when you strip the car if possible. Wrap them up and leave them in place...

-

Caswell Plating

I have been doing some plating while working on other things. These distributor clamps were plated yesterday. I plated them and then baked them for 4 hours to reduce any embrittlement. But after plating they blistered. So they will have to be redone. I suspect this is from too much brightener.

-

Engine rebuild smoking

https://store.totalseal.com/collections/ring-sets Nice chart here https://www.rpmrons.com/Total Seal Rings.html#79 https://www.racetep.com/totalsealframe.html

-

Engine rebuild smoking

@Diseazd Guy do you know of a place for us to shop for Total seal rings? I haven't found a source for them yet.

-

Fuel recommendation for a '73 240z with rebuilt engine and SU carbs?

How many turns down are the mixture nuts? Are you sure its rich? Is the float fuel level correct?

-

Engine rebuild smoking

The fact that it didn't smoke at first but smokes more and more as it runs, makes me think they have self destructed

-

1971 HLS30-14938 "Lily" build

I was going to use a spring for the 180d bend in the tank vent line but I can't figure out the right search terms. Does anyone have a link to a proper spring for this purpose?

-

Engine rebuild smoking

Of course!! I wanted to be sure you had documentation for reassembly

-

Engine rebuild smoking

So I don't want to get ahead of Ernest but I'll post up some info from today. I went and helped him get the engine out. We tore it down to the long block The intake valve stems were really clean looking. The exhaust ports looked really wet! It's a little hard to see in this picture. That is actually a puddle of oil in the exhaust port! This is actually liquid like oil that was seeping down under the gasket. Pretty much all of the ports had the same situation. The PCV hose was nice and clean. I would say all of this is coming from the bottom end and it's not isolated to one cylinder. To me that rules out a broken ring or bad ring indexing or something isolated like that. This is an issue across all the cylinders. I also don't believe the engine builder is going to be the issue. He's apparently been building races engines for probably 40+ years. If I had to guess, I would suspect the oil rings destroyed themselves. Possibly poor quality rings... Will be interesting to see what he finds when he tears it down

-

L20b Cody's Goon

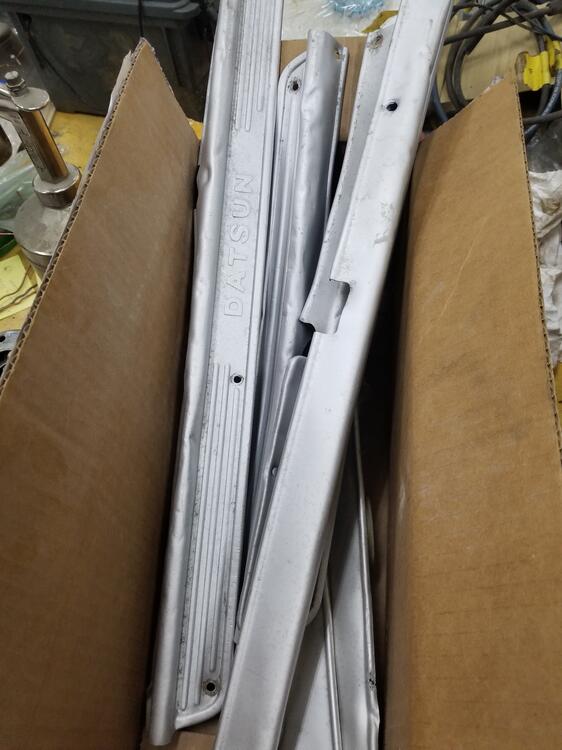

I also took his spare tire mount apart last weekend and replated and painted everything. The chain was tough to plate! I really should have done it in the barrel plater and I don't have enough amperage for a part that big. So I had to do it in sections and that made it sort of inconsistent. But like Cody said it will be up under the car I also started on the door sill tin at Ernest's

Subscriber

Subscriber