Everything posted by Zed Head

-

Ah come on! Another one? Enough Already. Oh Fine.

Looks like you made it past the two red battery cables. Good luck with it. The projects that don't cost you much if they get screwed up are the most fun sometimes.

-

32K mile 1976 280Z Original - Survivor

Bumping, just because $12,280 is pretty good for a 76 280Z. Hagerty numbers make somewhere in the 20's seem reachable. Polish those treads... Six days. https://www.hagerty.com/apps/valuationtools/1976-datsun-280z

-

FS5W71B 280zx transmisson rebuild

I just looked at my 4th gear (the one on the input shaft) and 5th gear and the "engagement ring" (been Googling, proper name) on those two is pressed tight against the gear. 3rd has the .014" gap. I wonder if it's coming apart. If you get yours to work I might give mine a little tapping with a hammer to see what's what. Did the gap close up tight on yours or just even up?

-

FS5W71B 280zx transmisson rebuild

I'm tempted to try and pry the synchro cone off of a gear just to see if I can.

-

FS5W71B 280zx transmisson rebuild

The owl or an identical one comes back every year. Then they raise a family in another box in the yard. After they kick the squirrel out (and maybe, eat its babies).

-

FS5W71B 280zx transmisson rebuild

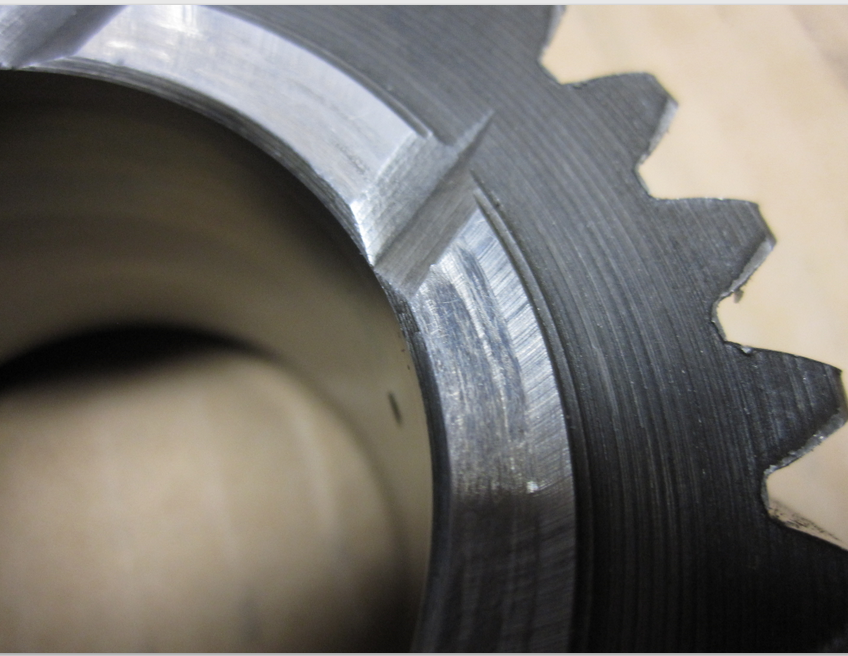

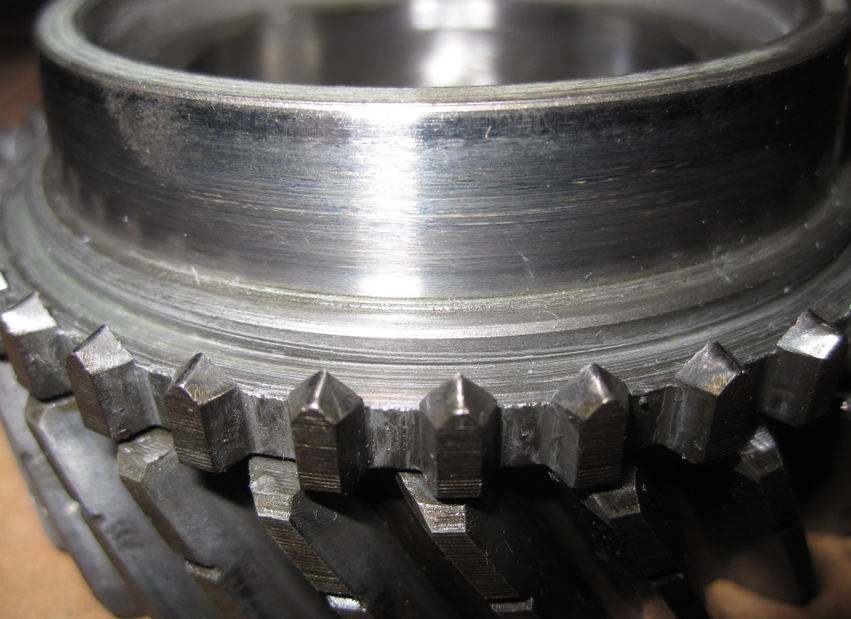

So the gear is the right one, but, as you might recall, this transmission was severely abused. I got it for cheap and used the front case for a 71C conversion. Here are a few pictures of the worn bearing surface and the blunted dog teeth. USPS will be cheap, I'll just send it under out under our last transaction, but it might not be usable for you. I did come up with another way to look at the wobble though. A feeler gauge in the gap between dog teeth and gear. I found that mine would take a .015" gauge all the way around but got tight for about 6-7 teeth on one side. Let me know if you still want it. The synchro surface looked worn too.

-

Can't get timing to less than 25 degrees?

I highlighted what I think is a critical statement. It was at 15 but something changed. I went with the easy one of a misplaced hose. Another thing that can change, on its own, is for the breaker plate to get stuck in the advanced position. Broken Z and ZX breaker plate bearing assemblies are very common. One way to check is to reconnect everything then watch what timing does when you apply vacuum to the vacuum advance canister. If it doesn't move it's probably already advanced and stuck there. Or you can take the distributor out and examine it, and move it by hand.

-

FS5W71B 280zx transmisson rebuild

Aren't you going to count them? I think I have the right one. Here's a little bit better picture showing what I think must be the splines used to lock the synchro cone on to the gear. I've noticed the pattern before but never really thought it through. Metal can stretch so maybe a good beating can actually break those two pieces apart. The back of the input shaft shows a really clear line. And a bonus picture of my neighbor, since he was out. Edit - some good micrometer or caliper measurements might pick up a wobble.

-

Can't get timing to less than 25 degrees?

Did you mess with the vacuum advance hose? Maybe it's attached to the wrong port, getting full time vacuum. Try disconnecting it and see what happens.

-

FS5W71B 280zx transmisson rebuild

I can't remember what 3rd gear looks like but I'm sure it's in the bucket. Let me know. Post a picture. Looking at the structure of the gear it wouldn't be surprising if it was a press-fit two-piece assembly. People say the whole gear needs replacing if the synchro is damaged, but maybe not. Maybe you can press it back together. If not, take it apart just to see what the innards look like.

-

32K mile 1976 280Z Original - Survivor

I clicked the links and it just re-opened the thread. Not sure why. Here's an attempt at a fix. Edit - took out my links to shrink the page since cygnus fixed his.

-

FS5W71B 280zx transmisson rebuild

I think I might have a new clue for you. It's one of those things we don't really think about, like getting the wrong collar for the throwout bearing. The engine is actually involved in locating the input shaft, through the pilot bushing in the crankshaft. Without that locating and support function the input shaft can **** and wobble inside its bearing. There's really nothing keeping its axis parallel to the other shafts without it. I remember thinking about that when I took a transmission apart years ago. The shaft is short and the power is transmitted through the coupling sleeve to the output shaft. But there's not a whole lot supporting it. It really looks all loose and disjointed when you ponder it. In short, your drill drive test procedure, while brilliant, may be flawed.

-

FS5W71B 280zx transmisson rebuild

You should have made mention of the video. Would have looked sooner. Sounds terrible! I would use input, output, and counter- as the shaft designations. One possibility that might be possible is some sort of problem at the interface between the input shaft and the output shaft. The "direct drive" fourth gear path. Also, could it be possible that one of your coupling sleeves is partially engaged? Maybe a problem with a shift fork. Or maybe one of the inserts inside a coupling sleeve is out of place, maybe missing a spring or something. Spitballing...

-

FS5W71B 280zx transmisson rebuild

Could you have cocked a bearing when installing? Maybe try the test with the front cover removed. Then you'll only really be using the adapter plate bearings, assuming that the front bearings aren't rubbing on something. Which you'll be able to see. Could also be a problem in the front cover. The nose can get bent or damaged.

-

My two swiss S30Z Fairlady Restoration build thread

Doesn't look terrible. Looks like maybe it had a collar of rust catching the edge of the piston, holding it in. I had a thought, that doesn't help you now but might someone else. I think that you could have blocked the brake line and the bleeder holes then filled the cavity with a low compressibility fluid, like water, oil or grease, and then pressed the other piston in with the C-clamp to generate pressure. Or popped it with a hammer. Just a thought about another way. If you pop it with a hammer you'd get a much faster pressure increase so leakage wouldn't be so significant. And the stuck piston would fly a lot farther when it came out.

-

FS5W71B 280zx transmisson rebuild

The gear in the drawing could certainly go on backward. I have a vague memory of somebody mentioning that in a different thread. Might have been duragg over on Hybridz. He got so deep in to building his transmissions for 7000 RPM shifts that he was hand filing the synchro gears to perfection. Here's a EuroDat at, he probably has a thought. @EuroDat

-

High Tone Horn Not Working

Don't overlook the often overlooked ground circuit. Bad ground, bad sound.

-

Can some please take pictures of their stock horn locations 75/76 280Z

That piece on the left in your picture is made of hard plastic. Is that what you're looking for?

-

1997 280z rev fluctuating between 2000-3000 rpms

This is not the site for you then, by a long shot. Try www.zcar.com you'll get more response.

-

1997 280z rev fluctuating between 2000-3000 rpms

Edit - this post is blunt, but true I think. No offense. You really do need to learn the details. You're in way over your head. You made it work, boost happens and it probably goes faster, but fine tuning requires detailed understanding. How about your boost controller? Maybe it's on the fritz. Without all of the details of your "turbo" system people can just throw out ideas. But you're not really processing the help you're getting. You just repeated my words back to me on my smog question, but didn't add any details. "FSM smog"? You're going to have to study up on how turbo engine management works, and keep cobbling away on your NA system. We'll throw ideas at you as you give more details though. Nothing good happens after 2 am.

-

1997 280z rev fluctuating between 2000-3000 rpms

Did you do the work, or buy it that way? There are people here who can add some ideas, but this is "classic" Zcars. com, not what you're running. I don't think that "aftermarket" heads exist for the L6 block, except for Derek's. If you bought one of those you should probably be on hybridz.org. But, back to the the basics - describe the engine details, and how it got that way. Are you running a ZX engine management, or a cobbled 77 EFI system? The stock Nissan turbo, or "aftermarket"? "Smog" means what? Hoses not understood or actual systems described in the Emissions chapter of the FSM? We know a lot about the Nissan made stuff, but once somebody gets in and starts tweaking, it can get weird.

-

1997 280z rev fluctuating between 2000-3000 rpms

Is your BCDD still attached? They are known for causing idle speed problems. You should put your car and engine details in the first post or your sig. Not clear what you're working with. It might be a 1977 (right?, not 1997) car, but the engine could be a transplant. Plus you have an AFR gauge, which implies that you've done some modifications.

-

1997 280z rev fluctuating between 2000-3000 rpms

Is it an automatic transmission? With a manual you can just push the clutch pedal. Engine RPM is controlled mainly by air allowed in to the intake manifold. You might have some kind of intake system leak. Automatics have some vacuum actuated mechanisms, that can cause problems.

-

Overheating after modifications, what am I overlooking?

My 76 has done the same thing in the past. It's either the fluid heating up and expanding or the water pump collapsing the lower hose, reducing overall system volume. The coolant reservoir level will only drop as the engine cools off and a vacuum is created in the coolant system, pulling coolant through the tube attached to the radiator neck. The radiator cap needs to be one designed to work with the reservoir, not an old 1950's cap. And it needs to be working correctly. If the radiator is full now you know there are no air pockets in it. Put the cap on and leave it. Make sure that the hose from the radiator fill neck to the reservoir is tightly sealed at both ends and has no pinholes, otherwise the system will suck in air instead of coolant from the reservoir as it cools down.

-

Plugging open port on underside of exhaust manifold

Looks good. Worst case, the brass fails (unlikely) and you have to find a steel replacement.