Everything posted by Zed Head

-

No-Start: Fuel Injectors Not Firing 1978 280z

Is there supposed to be a "no" in front of power? No power to the dropping resistors, etc? Or are you saying that you have power there but it doesn't start? You know the timing is right because you used starting fluid? Sorry. All I see is "won't start, fuel injectors not firing".

-

I hate Chinese "Metal"

This is all I'm asking. Some simple evidence. It changes everything about a discussion. Funny thing though, the guy complimented the disc for lasting 211,000 miles.

-

I hate Chinese "Metal"

I was relating the two sets of non-facts. The unknown rusty rotors and the pads of unknown origin, supposed to be made of mystery metal, called "black steel". Connecting the two things that aren't really connected to anything else. They float alone. Together.

-

I hate Chinese "Metal"

That article fits the theme. It has some "stuff" in it that the author seems to have made up, and is irrelevant. Discs aren't painted or coated. I think that somebody just made up the term "black steel". It doesn't appear to be a real thing. Notice that the guy didn't supply any links to the study or any publications by the "Global Council". He showed the percentages when it was convenient but left them out to tell the "black steel" story. Fake news! Black steel is hot rolled steel that has not gone through the ‘pickling and oiling’ process to remove impurities, scale, and other contaminants. This will prevent paint or anti-corrosion treatment from sticking to the metal, leading to early death by rust. Still waiting for any proof that those rusty rotors were Made in China. Labels or it's fake! Salt water will make any non-stainless steel look like those pictures.

-

Beginner LF Help with 280Z Build

Bring A Trailer (BAT) has some nice cars go by. https://bringatrailer.com/datsun/280z/ Can penguins tea bag? Don't know...

- Hesitation during acceleration

-

Flywheel removal.

I hate that too. If the wires were longer I'd probably do more console removing to do more things that need doing. I've thought about making a set of a extension wires for it.

-

Hesitation during acceleration

The BCDD can affect throttle off/drop behavior. And the dashpot. The dashpot is easy to adjust and can have a big effect. Loosen the big nut and screw the dashpot body inward to delay the throttle drop. Too far and you'll get throttle-hang though. Your original reason for the new/reman distributor was the hesitation wasn't it? So you got a bad module (or a poorly grounded module) on a better distributor. Once you got the right parts together, problem solved, apparently. There are other electronics in the distributor than can have problems like the pickup coil magnet. It tends to break. Can't emphasize grounding enough on the ignition system. It's not about voltage, it's about current. Current needs ground. Don't throw that new/old module away.

-

mallory 4763901 distributor

Might be here. Summit is great about having instructions for the parts they sell. https://www.summitracing.com/parts/maa-3748201

-

Beginner LF Help with 280Z Build

Welcome. Browse the Downloads area for useful files. Menu on the right - http://www.classiczcars.com/files/

- Hesitation during acceleration

-

Flywheel removal.

Removing the bolts would turn the engine in the normal direction. Tightening will be backward. Posted a picture I stole from Hemmings, showing fan direction. Are you asking about two things, how loose the bolts were and, apparently, the fact that the engine doesn't turn? Once you break the bolts loose it won't take much to turn them. Pretty sure that my flywheel had never been removed, and it had what looked like threadlocker on the the bolts. I made a flywheel locker from a metal bracket I had lying around.

-

Rear spindle removal

Seemed like you're just implying that people are wasting their time trying to save a spindle pin. The post had some "troll" to it. The spindle pin is designed, I think, so that if the nuts come loose the suspension won't fall apart. The pin is locked in place. So a bolt might be cheap and easy but it makes the car less safe. There are lots of cheap and easy things we can do to our cars. Cheap and easy is a personal choice, of course.

-

Rear spindle removal

Wrong thread. This one is about removing the old ones.

-

Clutch slave reservoir

Isn't the brand name stamped on the pressure plate? I see a Japan there. I think see Unisia maybe. I have a clutch disc with Atsugi on it. They're suppliers to Nissan. http://www.carparts.com/atsugi-unisia-paraut

-

Help with headlights

The help would be to get a meter or test light and figure out what has power and what doesn't. Sounds like you don't have a ton of electrical experience so you'll have to do some learning or get some help. I'd start with the 12 gauge wire to fused battery voltage. Make sure it has power and the fuse is intact. Then check the wires from the harness that are supposed to actuate the relays. You'll want the wiring diagram for your year of 240Z. You didn't mention that. The fact that you don't have parking lights either, suggests that maybe a fusible link is blown.

-

Help with headlights

Year of car would help. The wiring changed a little. You said "the headlight relay up grade" so it's probably a 240Z? Do you have a bigger picture? That one clicks open to the same small picture.

-

axle shaft u-joint replacement fail

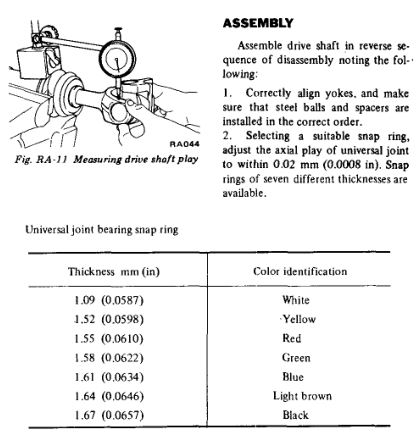

I rebuilt two half-shafts with $90 worth of Precision u-joints, four, from OReilly auto. Then saw that they were looser than the old ones I had replaced. So I removed them and took them all back for a refund. I felt half-bad, but the parts really did seem of lower quality than the used ones I took out. The Nissan joints have seven different thicknesses of retaining clip. Probably why they cost ~$80 each An old used Nissan joint is better than a new aftermarket joint, I think. That's why I've stocked up on used half-shafts.

-

Rear spindle removal

When I was removing mine I found that spinning the pin, and moving it back and forth in the bore, helped. I think that the rust and grit and metal shavings get jammed and the movement lets those particles find a new place and release the bind. Also distributes the lubricant up and down the bore. I used an old mag wheel lug nut on the end for spinning and also hammering. Same thread size. I also tore the end off of a pin but I think my fixture got misaligned. And heat cannot be neglected. Gotta have heat.

-

Steering Rack Disassembly and Refurb

We need another sacrifice. Melt the plastic out and see what's left.

-

What frame rails?!

Could also be a good reason to buy a MIG welder.

-

Steering Rack Disassembly and Refurb

I didn't really grasp what the pictures showed. Just to summarize, it sounds like we/us/the Z world is saying that the two metal parts are assembled, maybe fixtured, a pin is driven in to lock them together, then a molten plastic is injected in to the two grooves (which are apparently aligned). I could see the plastic as a longitudinal lock, and the pin as a radial/rotational/locational lock. Without the pin the tube can spin. One probably came before the other. A proper design might have the two functions combined. "Dang it, this tube keeps spinning"...translated from Japanese.

-

What frame rails?!

If you think of them as "boxed reinforcing members" instead of frame rails it generates some extra possibilities. You could cut the bottoms off and have a flat piece welded on without even removing floor pan parts or even carpet. Just an alternative view. Edit - I didn't read all of the posts. I like madkaw's. Edit 2 - I like grannyknot's post. Edit 3 - they're all good. I have bad forum etiquette.

-

Steering Rack Disassembly and Refurb

I overlooked hot melt, or glue gun material. That would be an injectable thermoplastic. Fits all of the necessary criteria. It would even set up faster than a two part material. Once the heat is gone it's set.

-

1973 Rebuild

Edit - The self-lockers seem like the convenient way to do things. BUT...if a person wanted to pick, they could point out that the locking portion of the nut might sit on the flat portion of the shaft, the flats created for the staked nuts to stake on to. So, functionally, the crimped nut end has less area to lock on to. But I think the self lockers might be short enough so it might not matter. Probably have to put them and decide if they look like they'll do the job. Looks like you have the stakers on and haven't decided yet to stake them or not.