Everything posted by Zed Head

-

78 280z Severe Driving Problems

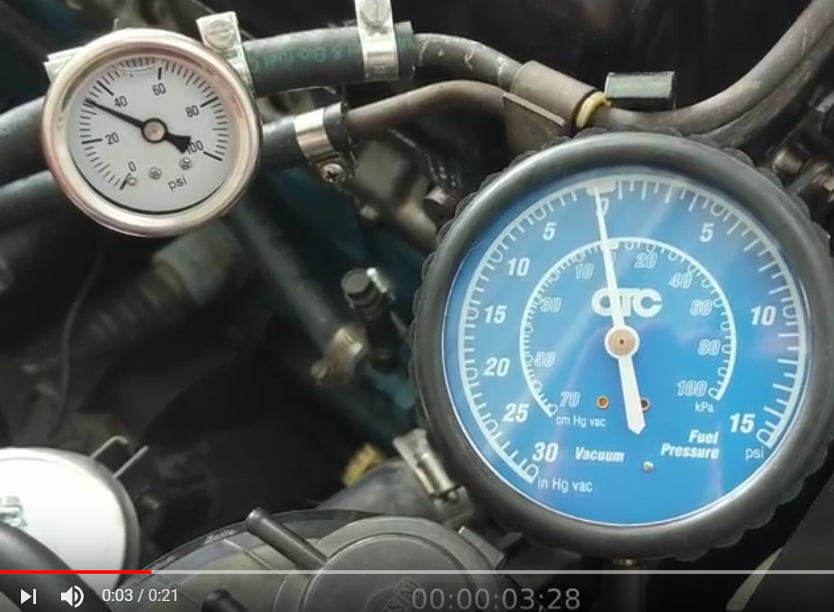

Just a followup. That's a good test. The fuel pressure should drop smoothly as vacuum is applied, just as shown in your chart. My pressure will sit at about 27-28 psi and jump up with RPM. Very smooth and very fast. You have a nice setup showing that something is wrong. Just not clear if it's your gauge or your FPR. Does the hose to the vacuum gauge have any fuel in it? That would be a cracked diaphragm.

- 78 280z Severe Driving Problems

- 78 280z Severe Driving Problems

-

78 280z Severe Driving Problems

You're right , the fact that it drops says that it's not the lines being overpowered by the Walbro. I missed that. But it's been proposed that it's too high, generally. That question is still open. The FPR could still be defective, giving generally high pressure over the vacuum corrected span. Beside that, the first, most basic fuel pressure test is with no vacuum reference. That number hasn't been seen yet. Edit - in short... I just want to see a 36-37 value somewhere. That's the FPR's starting point.

-

78 280z Severe Driving Problems

What is the highest value that you see on the gauge when you run the fuel pump without the engine running, or if you run the engine but disconnect the vacuum reference entirely? That should be the highest pressure reading. Best to do it with the engine running because alternator voltage will run the pump faster. One of the proposals is that the Walbro is overpowering the FPR or the return lines. You need to test at the highest possible pressure, which would be with no reference vacuum and maximum pump voltage. The engine will run rich but it's a short test. Consider also that you might have a bad gauge, with a 2-3 psi offset. Edit - zeeboost raises the point, below, that the Walbro can't be overpowering the fuel lines or FPR orifice if pressure is dropping. Still need the unreferenced number though.

- 78 280z Severe Driving Problems

-

78 280z Severe Driving Problems

Pulling the head seems drastic. Maybe you meant valve cover? You can fire/open the injectors while they're still on the rail. Just ground them at the ECU connector with the key on. Get six little cups, or small soda bottles and let them run for about 10-20 seconds, see how much comes out. You'll know if one or two is clogged. The screens in the inlets can get blocked easily. My comments about valve problems were assuming that something happened after you did your first round of tests. You never know.

-

240z 1972 Owners Manual

Here's the Service Manual, if it will help - https://www.classiczcars.com/files/file/19-1972-240z-factory-service-manual/

-

78 280z Severe Driving Problems

The vacuum hose mistake would have led to the timing being retarded by the total amount of vacuum advance possible. Probably about 14 degrees. So when you opened the throttle timing would have dropped to about -4. Of course as RPM increased centrifugal advance would bring it back up. Retarded timing will reduce power by quite a bit. The car might be drivable now, but still "poppy". You can check if the advance hose is correct by removing it when measuring timing at idle. Nothing should happen. Then with the hose connected timing should advance as soon as you crack the throttle. Weak cylinders won't show a big effect if you cut fuel by disabling the injectors. Low compression or burned valves for example. If you're sure the injectors are working that would be a good place to focus, assuming that you know you have spark. Here's another thought from other people's past problems. After these engines sit for a while the valves and guides get sticky and sometimes they spit a lash pad. Then the vlave doens't open any more. It usually happens at high RPM after people give the engine a little road tuneup. The way you were revving the engine in the first video it wouldn't be a surprise if that happened. These engines are so smooth that sometimes it's hard to tell when a cylinder is not firing. You might rerun your pressure check or recheck the valve lash. Could also be that you didn't get a lock nut tight and lash has changed.

-

78 280z Severe Driving Problems

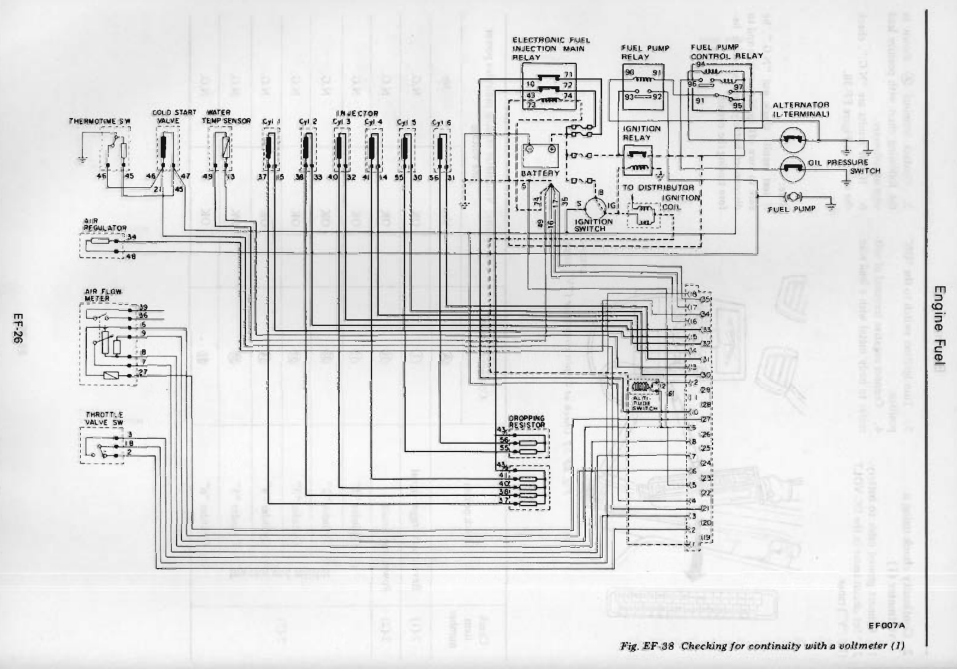

One area that has caught some people is the EGR system. Since your engine sounds good at idle you might try disabling it to see if anything changes. I think it actuates by ported vacuum so blocking that hose might have an effect. And like jr says above, make sure that the AFM vane is moving freely. When I was watching your video I thought I saw it hang, its movement trailing the engine sound, but I couldn't be positive when i rewatched it. A slight delay in vane reaction will lean things out and cause intake popping. And as CO suggested, if the AFM has been messed with maybe the atlanticz calibration procedure is the way to go. I'd get a magnifying glass and see if I could find the original glue blob traces myself. Or crank that potentiometer up and try to drive it. Something will show up. You're doing all of the right things.

-

78 280z Severe Driving Problems

That's a good point about the Walbro. Beside that it is way overkill for a stock 280Z engine. I've read about noise but not many overpressure problems though, with the 280Z lines. The 240Zs have problems for sure. Easy to check. The one major problem for a daily driver with the Aeromotive FPRs is that they leak down immediately on pump shut down. This can make hot start problems worse, and next day cold starts also. Even the factory FPRs are a pain when they leak down.

- 78 280z Severe Driving Problems

-

78 280z Severe Driving Problems

Another way to say it is it should be running much better and differently than the problems you have suggest. I've had the lean problem and it wasn't like yours. It popped back and bucked when you tried to give it gas. Yours is running like it's on 4 or 5 cylinder. It could be fouled plugs but these engines can run really rich, enough to make your eyes burn, and still not foul plugs.

-

78 280z Severe Driving Problems

Just watched your last video. Very informative. I don't think it's firing on all cylinders. Could be several reasons. I would confirm that firing order AND rotation direction are correct. Check all of the injector connections. While it's idling pull one injector connector at a time. Each one should cause a change in idle speed. Pull the connector, confirm idle speed change, put it back on. If you find one that seems dead, switch it with the one next to it. They all fire at the same time, there's no order. If the problem follows the injector connector it's that, if not it's the injector. We got way ahead of your actual problem I think, although everything you've done so far will probably help with the fine tuning. But you need to get each cylinder firing first. Another reason for cylinder misfire is bad cam lobes. Could also be improper lash setting. You might check your lash again and/or do another cylinder pressure check.

-

280ZX Stalls and Restarts an Hour Later

The ZX distributors and ignition modules are known to be flaky. The distributor has a magnetic ring inside with six spikes that ride very close to the six spokes of the reluctor. The bushings are weak and tend to let the points contact, breaking the magnet. You can usually see that by eye, wiggle the rotor and see if things move. The ignition module on the side is electronic and overheats when it goes bad. One test for that is to spray the module with some sort of cooling spray, or apply an icebag to it. If it responds to cooling that's a sign. It has many of the signs of bad electronic ignition. The coils are durable though, the other parts, not so much.

-

What are the facts about 280z ECU compatibility and differences

Don't forget that we're talking about 1978. The cover pops right off of the ECU. Two little screws on the back and it slides off. You can open it up and see where the pin leads are. A good idea to examine anyway, they do get fried occasionally from backward battery hookups and corrosion.

-

78 280z Severe Driving Problems

You talk about the idle at different potentiometer settings but don't say anything about what you did while driving. You want to increase resistance until it's drivable. A little bit at a time. Watching your video makes me think that you do things in very large steps. The resistance changes will be fine steps, not big cranks of the knob. Your fuel pressure seems high for the vacuum reading. 18 inches of vacuum = 8.8 psi. 34 + 8.8 = 42.8 psi. It might be that the hose to your FPR has a leak or a split. Make sure that the FPR is getting a godd vacuum source. That should drop your fuel pressure, which will clean up the idle smell. When you open the throttle the FPR doesn't see much vacuum. That's how you can have a rich idle and a lean driving problem. The EFI system needs the fine details to be right.

-

ZG only went for $53K

Are the fender flares stock to the homologation class? Do they call them "over-fenders" in Japan? Never heard of the ZG. That's the thing about scarcity and popularity. Best to be scarce and popular. Scarce and not popular...not so good. "The over-fenders riveted to its body begged for wider wheels, just like the Group 4 cars."

-

What are the facts about 280z ECU compatibility and differences

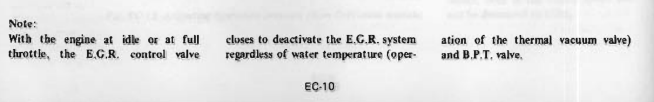

I'm pretty sure that I've tried the whole range of ECU's in my 76 MT and not found any difference. I would guess that differences over the years might just be in refinement and durability. There doesn't seem to be any change in circuitry and the descriptions in the Engine Fuel chapter don't indicate what might be different. Fuel cut, for example, is still at 3200 and restart at 2800 in 1978, just as it was in 1975. There are some errors in things like the cold start valve wiring schematic, that have been discussed before. Much has been discussed but nothing has been demonstrated. Always good to have spares though. I got stranded once, a short way from home, when I was testing my spare to make sure it was good. Forgot to bring the known good one with me. Now I keep a spare ECU behind the seat. You can test them just by letting them dangle by your foot on the connection. They have their own ground. Give them a good workout. p.s. idle is its own little world, entered through the throttle valve switch. Might be a change between years, and CA v Fed. EFI started as an emissions control effort, not performance, so changes for emissions purposes are likely.

-

Is my coilover spring rate too high?

Take some pictures and report how it goes. Maybe I'll learn something. Should be fun. Good luck.

-

Is my coilover spring rate too high?

You do know there's a shock absorber inside that tube... If it's a gas shock it will extend so even if you could get the hub to drop far enough to split the strut it would be a nightmare to handle. The spring is supposed to come off from the top. Detach the top of the strut, lower it and swing it out to where you can work from the top. Lowering the bottom spring perch will allow you to make the strut much shorter so it will swing out easier.

-

71Technotoy rear lower control arms question

Here's a set for just $300 each - https://www.classiczcars.com/forums/topic/60663-its-up-for-sale-again/?tab=comments#comment-556415

-

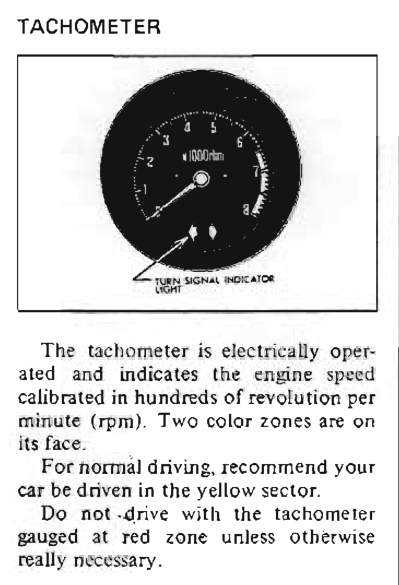

she falls on her face at 3500-4000 rpm

These engines are tough but I don't think that they're bullet-proof. The overheating isn't a good sign. Over-revving can blow head gaskets. You're way up in the "unless otherwise really necessary" zone. Danger.

-

she falls on her face at 3500-4000 rpm

Did it take 15 minutes to get fully warmed up or was it 15 minutes of driving fully warmed up then it went bad? Was 15 minutes really 15 minutes? No offense, but it seems like you're jumping the gun, then shotgunning solutions. Let things cool down and see if it is heat related and reproducible. You didn't answer the question about the tach needle either. Could be a carb problem. Good luck. Make sure you can go back after you make your changes, you might end up making new problems.

-

It's up for sale again!

Nobody's going to complain about putting a V8 in that car... Can you desecrate the desecrated? Sorry, feeling poetic.