Everything posted by Zed Head

- 1976 280Z Restoration Project

-

1976 280Z Restoration Project

Some of the COP coils have their own dwell control, I believe. I think it makes the head bigger. There's a bunch of COP options out there. Some smaller motorcycle COP coils might be less bulky. Just getting vicarious. https://www.ebay.com/itm/09-12-KAWASAKI-NINJA-ZX6R-ZX600R-OEM-IGNITION-COILS-COIL-SPARK-PLUG-CAPS/153137994597?epid=18017017407&hash=item23a7bc5b65:g:-6sAAOSwZthbZzSc

- 1976 280Z Restoration Project

-

1976 280Z Restoration Project

But with the bracket you can't see the full COP. Why not just use the coolant line bolt holes for the full mount? You could build a rigid mount, thin so that the COPs are visible and use the coolant line bracket holes to lock it in solid to the block. More stuff is visible. With a big bracket you're covering up a lot of good stuff. Just ideas. My engine bay is a pilot plant.

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

-

Setting Distributor Air Gap

Yes. I would. Many reman parts are poorly assembled. The parts might be new but the people putting them together are probably in a hurry. I would check and adjust the new one as if you had a problem and are running through a check list. Measure pickup coil resistance, make sure the vacuum diaphragm isn't blown, rotate the breaker plate, etc.

-

280z dies randomly while driving..

I've never adjusted a tach. I do remember trying to turn some of the screws in the back of a tach and they wouldn't budge. I would try putting the stock coil back on. That 0.6 ohm coil might be affecting the tach. I don't really know what the tach "sees", if it's a flyback thing or a low-high voltage thing. But I do know that ignition system modifications can affect the tach operation. Plus the 0.6 ohm coil is letting more current through your 40 year old ignition module. Not going to add to its probably short life remaining.

-

280z dies randomly while driving..

Don't worry about the 2-3 psi change. That is actually good, the engine is running better now and pulling more vacuum. The higher intake vacuum drops the fuel pressure in the rail because the intake manifold is pulling fuel out. It's working like it should.

-

Relay Testing and Fuel pump help

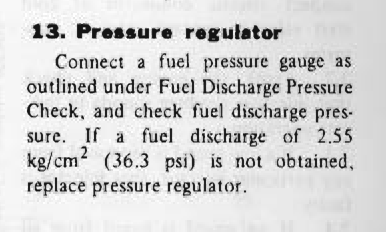

You have to isolate the problem first I think. Can't say what you need. With the 280Z EFI cars everything needs to be right. Fuel pressure is one of the most important things to have correct with EFI.

-

Relay Testing and Fuel pump help

Not injectors. They are not in the fuel path, they are on separate branches. The fuel passes by them. It would have to be in the FPR or one of the hoses in the fuel path.

-

Relay Testing and Fuel pump help

Yes, move it down to the return line. You should not get much pressure at all after the FPR but if you do that means you have a restriction back toward the tank on the return line. When you have it off just eyeball the size of the hole in the T. If it's comparable to the hose it's not going to be the problem. You should be able to see right through the T fitting.

-

Relay Testing and Fuel pump help

Also, is there any chance that your gauge is causing a restriction? Where is located? If the adapter "T" is small diameter is might cause a problem.

-

Relay Testing and Fuel pump help

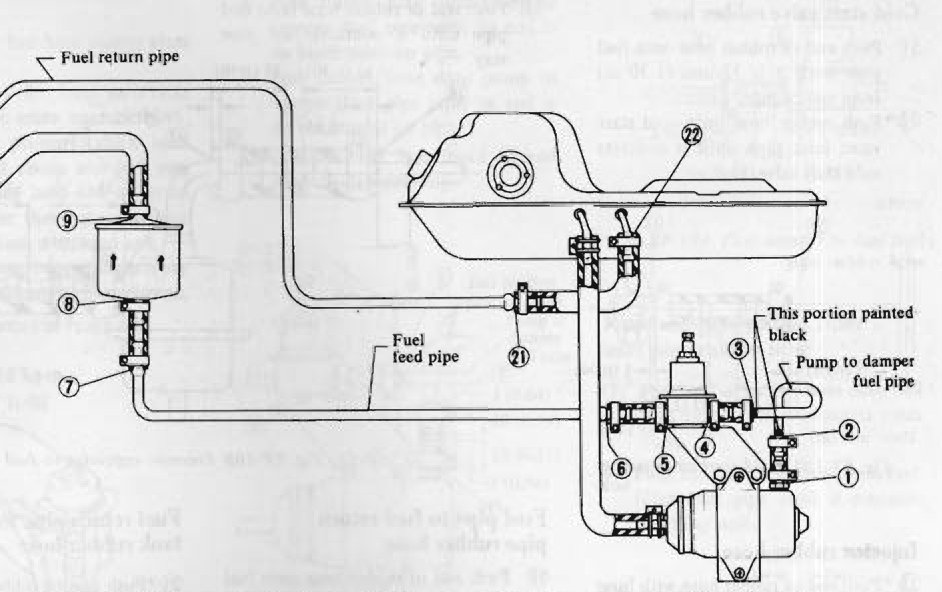

The damper should be on the inlet side so would not cause higher pressure. Maybe somebody plumbed it in to the return line? It looks like you have a restriction in the lines somewhere after the gauge. Try moving the gauge to the return line, in the engine bay. If the pressure stays high that means the restriction is between the engine bay and the tank. If the pressure drops that means the restriction is between where you had the gauge before and where it is in the second location. You need to find the restriction to get the pressure corrected. Pump > damper > filter.

-

Relay Testing and Fuel pump help

-

1976 280Z Restoration Project

You might be able to get a generic replacement. Those types of seal are sized by inner diameter, outer diameter and thickness. I took an old seal to a bearing house and they had no problem finding a generic part. Here's an example of the huge number out there. https://www.powerindustries.com/catalogs/US_Seal_Mfg_Catalog_2012.pdf

-

Oil bar gasket

Cut your own is probably your best option, or use a light coat of RTV. Some people say that their bars don't have any gasket. We've rambled on about them in the past...

-

Relay Testing and Fuel pump help

A little compressed air shouldn't hurt anything. You can probably knock some of that dent out with a broomstick too. I would do as much testing as possible before dropping the tank. You don't know what the root cause is. You could put it all back together and be in the same spot.

-

Relay Testing and Fuel pump help

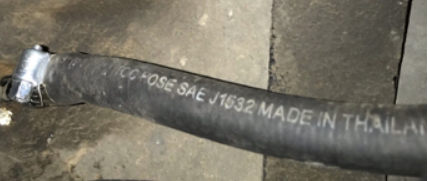

My mistake, they don't need to be high pressure. They should be fuel rated though. I don't know if automatic transmission fluid hose will swell in the presence of gasoline. The one on the other side of the fuel pump needs to be high pressure EFI hose though. I've found that when people start using the wrong hose in one place they tend to do it in many places.

-

Relay Testing and Fuel pump help

SAEJ1532 is transmission fluid hose. I would do that flow test in the engine bay, get your numbers written down so you can study them, then maybe tear your system down and get the right hoses on it. https://www.sae.org/standards/content/j1532_200503/

-

Relay Testing and Fuel pump help

I would disconnect it in the engine bay by the filter. It's easier to access and get a container in there. A clear two liter bottle would work well. Plus you can watch the gauge. You'll have flow and pressure right in front of you. Are those hoses high pressure EFI rated? You should check. They might be splitting internally. Even the return line could be failing. You can still run the pump and report pressure before you do anything. Ideally you get all of your measurements at the same point in time. You have your pump voltage and weird fuel flow above, but no pressure readings.

-

Relay Testing and Fuel pump help

You should get a constant flow. Pretty strong too. If you want to be sure, remove the return hose and put it in a container, then run the pump again. You have odd things happening with your fuel supply. Maybe your fuel pressure regulator (FPR) has foreign material in it. Your pressure fluctuates from too high to too low. You might have crud in it blocking the outlet, raising pressure, then holding it open lowering pressure. Who knows. Let the pump run like you just did and report the fuel pressure. Sorry for the weird quotes. Turns out you can only "multi-quote" from one page at a time. Not the whole thread.

-

Hard to find Redline MT90

The description you copied is for a diff fluid. Maybe you were on a multiple item page. Forgot to say the "10-4014" part number got me here. Here's a few links. That Scoggins Dickey price looks good, I might buy some. Watch out for shipping costs. https://sdparts.com//i-24093516-acdelco-friction-modified-synchromesh-transmission-fluid-1-qt-10-4014.html?gclid=EAIaIQobChMIyMf-nYfb4AIVkxx9Ch2ZJA0HEAQYASABEgKnX_D_BwE https://www.summitracing.com/parts/ado-10-4014 https://www.amazon.com/ACDelco-10-4014-Friction-Synchromesh-Transmission/dp/B0026JK8FK

-

What are the facts about 280z ECU compatibility and differences

Different for automatic transmissions, same for manual. The chart is manual, M/T, on the left, auto, A/T, right. I think any differences are tiny and probably tied to emissions. I've tried 75, 76, and 78 in my car and they all worked the same.

-

Hard to find Redline MT90

I'm using Synchromesh in a Ford transmission and it's good stuff. I've been thinking about using the Friction-modified for a little more. It's a notoriously notchy transmission. The Ford spec. Mercon V was terrible compared to the Synchromesh.