Everything posted by Zed Head

-

1976 280z engine runs rough then dies, will not idle.

That's for the 78 280Z and 280ZX's. One inlet.

-

1976 280z engine runs rough then dies, will not idle.

If there's a wrecking yard nearby you might check for a 1978 280Z or 280ZX fuel rail and regulator. They will transplant over and it looks like you can get Bosch parts. Edit - the picture they show on Rockauto is wrong but it shows right on Amazon. Cheaper too. https://www.amazon.com/Bosch-64018-Fuel-Pressure-Regulator/dp/B000BZGAOO https://www.rockauto.com/en/catalog/nissan,1980,280zx,2.8l+l6,1209316,fuel+&+air,fuel+injection+pressure+regulator,6124

-

Tranny swap problem

The collar matches the pressure plate, not the transmission. That's the message we're trying to send. The clutch fork pivot ball is in the exact same position on both transmissions, relative to the engine, flywheel, and pressure pate. You might just make sure that slave cylinder bleed screw is angled upward when bleeding. Give it another bleed. Sometimes people don't get the fork spring clips properly attached to the pivot ball and things get jammed up. Maybe make sure that the fork is right. Just offering suggestions. There are no parts to suggest swapping to if you used all of the same parts from the 4 speed and did not change the pressure plate.

-

Tranny swap problem

You suggested two different things in your post. Said you used the 4 speed parts, but then said the 5 speed parts worked fine. Not clear. If you used all of the same parts that you had for the 4 speed it should work. Could be something simple like the seal in the slave cylinder got damaged as the piston extended in the bore as it hung free. Pretty common for seals to get damaged when they travel over unused cylinder bore corrosion. Pop the rubber dust seal off of the slave cylinder and see if it has fluid inside.

-

Tranny swap problem

@Mojos 72z

-

Emissions saga and a home test for idle setting/tuning tip

It's the DEQ fee plus the registration renewal fee, good for two years. It all happens at the DEQ facility and you get as many trips through as you need to get it to pass. Very convenient. They even have a camera so you can get an idea of how busy they are. Closed today. https://www.oregon.gov/deq/Vehicle-Inspection/Pages/Sunset-Hillsboro-Station.aspx

-

Emissions saga and a home test for idle setting/tuning tip

Thanks, good for everyone to know. Maybe I'll send Fuel Injection Corp. an email if I get time. I've never liked that AFM for passing emissions, it's never worked, except for when I had the original set of clogged injectors on my car. It worked great otherwise but might also explain my typical 18-19 mpg.

-

Engine test stand

Just watched your video. Pretty cool! Also a good example of a strong spark. Noise and color. I saw the 9 volt battery there and thought that you were going to use it to trigger the module. Probably could have if you didn't have a spare distributor.

-

Emissions saga and a home test for idle setting/tuning tip

But does it run rich?

-

Duffy's 1/71 Series 1 240z build

But the vapor doesn't do the work. There is no "blasting" by vapor. Vapor is a byproduct. It's appropriate for getting attention I guess. Good luck with it. Dustless media blasting is the most appropriate term, I think, for people who know how things work. No offense. Maybe I've learned too much about science and technology to let it slide. Understanding is important, especially in today's world. .

-

Duffy's 1/71 Series 1 240z build

I think it's just dustless media blasting. They're all based on the same concept. Propel the media at the object being cleaned. Water, walnut shells, dry ice, glass beads. "Vapor" is just branding. They all have their pluses and minuses. It kind of looks like somebody just took their waterjet cutting nozzle and cleaned some parts with it. Detuned so the parts don't get damaged but I'll bet you can still wear away some material if you're not careful. https://www.bigbluesaw.com/faqs/parts/how-does-waterjet-cutting-work.html Only posting 'cause I think it's important to understand what's being done. And "vapor" is a misnomer, used to sell the process. Kind of offensive.

-

Valve stem replacement w/ head in car

Seems like asking for problems. One mistake and your small project turns in to a big one. Plus time spent on the valve seals is time that could be spent on the engine you really want. Nothing wrong with using higher weight oil on a worn engine.

-

Duffy's 1/71 Series 1 240z build

I think that the word "vapor" is a marketing word. It's just pressure-washing with an abrasive slurry. Certainly not vapor. These guys can't even figure out what they really want to call it. https://www.vaporblastingequipment.com/wet-blasting/what-wetblasting-guide-vapor-blasting-process

-

Leaking Drum Brake Line, Can't Stop Leak

Take the old one to the store and match it up. They'll have precut, flared, and nutted lengths on the shelf. You'll have to bend it yourself. I used wood screws in a board to get the curves right and avoid kinking the line. It's not hard if you have the old one right there for comparison.

-

Leaking Drum Brake Line, Can't Stop Leak

Sounds like you might have split the line. If it "shoots" out. There are actually two surfaces, one between the nut and the back of the flare and the other between the inside of the flare and the cone inside the hole. The inner surface is where the sealing happens, the nut presses the flare on to the cone. Take it off and look closely. The nut will slide back allowing you to see the flare on the end of the line. Here's an example. Click through the pictures and you'll see the cone also. http://www.fedhillusa.com/?page=flare

-

Front suspension renew and adjustment

Left and right should be the same length. carpartsmanual only shows one part number so no changes there. Looks like you got a bushing jammed up or something. The second one is correct, I have mine double-nutted. There's room. So you can focus on the other one. http://www.carpartsmanual.com/datsun/Z-1969-1978/axle/front-suspension With stock bushings what you're seeing is correct. That's why final tightening is done with the car's weight on the suspension. It's in the FSM.

-

Home Built Z 'Full video build'

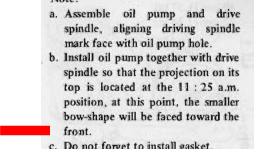

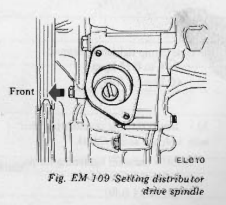

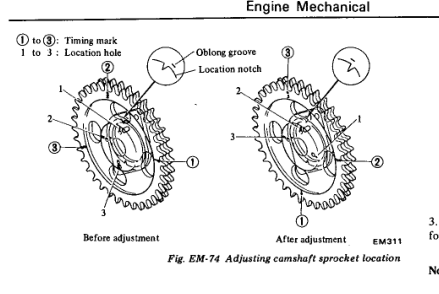

Have you had the timing mark on the cam sprocket, and the timing mark on the damper both at "zero" at the same time? The distributor also has two timing marks on it that are often overlooked, two lines that will line up when timing is close to zero. I stole a picture from a thread that stole it from atlanticz, below. Also, the ZX distributor base is offset from the 240Z and 280Z base. You might have a ZX base under your 123 designed for a Z. I think the set screw is off about 30 degrees. Stole another picture from zcarsource, but he owes me since he stole a picture of mine, of a rusty relay.

-

Home Built Z 'Full video build'

It might be that the timing marks on the damper are off. Could be the wrong damper, or the wrong tab on the timing cover. The early 240Z's used a different setup than the later 240Z's and 280Z's. I browsed through the video but didn't see a timing light anywhere. How do you know timing is at 30 degrees? The actual timing won't be affected by where the distributor is on its drive gear. Ability to set timing will be affected, but not the timing itself.

-

Rebuilt engine won't "first" start

It would mean more with a video of the engine running... Or at least tell us what happened. You never said. Saga incomplete.

-

Rebuilt engine won't "first" start

The gauge used can have a big impact. I have a gauge with a long tube to use as an extension. That extension drops it down to the 130's from 180's. Adds to "effective combustion chamber" volume. I wonder if he had the throttle wide open.

-

Rebuilt engine won't "first" start

I think he ended up in the right place so that's what matters. My rambling probably caused confusion. He's probably tooling around the countryside right now...

-

Rebuilt engine won't "first" start

Alright, I knew it was in there somewhere. They used words!!! Who knew. @CaptainMajestic You should be good to go.

-

Rebuilt engine won't "first" start

Just reread all of my stuff and the only good advice is the notch and groove. I don't even use the half moon, I use the rotor and #1 plug wire. Lots of redundancy in the FSM. Not really sure which way the half moon goes, There's variation all over the internet and the FSM pictures are bad. Good luck.

-

Rebuilt engine won't "first" start

EDIT! - THIS IS WRONG. It's just a tooth off. I posted mine before I realized you might have it backward. See my edit way above, about the half moon. Can't emphasize enough, using all of the marks. You should have the valve cover off so that you can see the cam lobes.

-

Rebuilt engine won't "first" start

You haven't shown the notch and groove either. Match up all of the marks and you can't go wrong. Most people run in to problems when they guess about where things are. It's why Nissan had somebody draw all of these pictures, even if they are bad.