Everything posted by Zed Head

-

Too much gasket sealer on head gasket?

There are only two oil passages and they have their own copper seal. The copper probably contacted the surfaces before the sealant started squeezing too much since they have some crush to them. The sealant won't cause any deterioration once it sets up. The non-hardening ones use ethanol as a thinning agent and that's gone almost before you assemble. Probably not a concern, although "it couldn't hurt" is concerning all by itself. That's where many problems start...

-

Too much gasket sealer on head gasket?

What brand? Most have instructions on the old internet.

-

78 280z idle problem

A couple of threads about the green stuff. http://www.fidanza.com/wp-content/uploads/2015/03/NEW-GREEN-COATING-ADDS-STYLE-PROTECTION-.pdf Not sure where this guy ended up -

-

Complete Misfire on Three Cylinders

I'll bet he did it so that he could replace the intake/exhaust gasket without removing the exhaust manifold, or just to make it easier to install. Or he got those from the hardware store and that's all they had, and he didn't have a hacksaw handy. If you decide to replace them beware the odd nut sizes from some of the kits out there. Some use a 12mm and some use a 13.

-

78 280z idle problem

You might have more than one problem. The Fidanza flywheels are known to stick the disc to the flywheel, that green coating doesn't always wear off like it's supposed.to. So it might be that one problem is the sleeve height and the other is the flywheel coating. If you take it apart again, we can show you what to measure and what to check, like Eurodat suggests. Here's a few threads about the 92 mm meausrement - https://www.google.com/search?source=hp&ei=oswsXdywKfGCk-4Pnuid8As&q=site"classiczcars.com+92+mm&oq=site"classiczcars.com+92+mm&gs_l=psy-ab.3...1010.9742..10494...0.0..0.83.1539.27....3..0....1..gws-wiz.....0..0i131j0j0i22i30j0i13j0i13i30j0i13i5i30j0i8i13i30j0i8i13i10i30j33i160j33i299.qjmk9MsnnnM

-

78 280z idle problem

Sleeve/collar, not bearing. The sleeves are different. Sometimes called collars. Look at Post #9 here - https://www.classiczcars.com/forums/topic/58235-trans-id-help/ Don't pay any attention to the years and models of the cars described, it's the pressure plate and sleeve that matter.

-

Complete Misfire on Three Cylinders

You do know that you can daisy chain zip ties, right?

-

78 280z idle problem

We've produced several threads describing the measurements you should take to be sure your parts will work correctly, before installing them. 92 mm. Not clear what you mean by the fork is "hitting" the bell housing. Also not clear which throwout bearing sleeve/collar you're using. You put the old pressure plate in but did you use the old sleeve? There are a bunch of bad combinations of sleeve and pressure plate out there. Clutch problems are common with the Z's. You're doing a lot of stuff but not providing much info to work with. Numbers. Good luck.

-

My weekly rant. Premature Parts Death Plague

So it's the US government then... You're saying that the US government should control the behavior of US companies. Like in China.

-

Clutch Slave or Clutch master failure

Have you popped the slave cylinder dust cover to check for fluid?

-

Clutch Slave or Clutch master failure

This is a big clue. More bleeding probably won't help. Something is getting hot. Could be fluid, could be seals, Not likely mechanical, there's not much to the pressure plate and disc.

-

My weekly rant. Premature Parts Death Plague

Home Depot and Amazon are the biggest drug dealers in the world by that theory. Two giant American companies.

-

Clutch Slave or Clutch master failure

Sounds like you might have one of your hydraulic lines next to a heat source. The exhaust manifold or headers.

-

L28+(maxima)47 build

That's a new one. How about chimping? Which is worse...

-

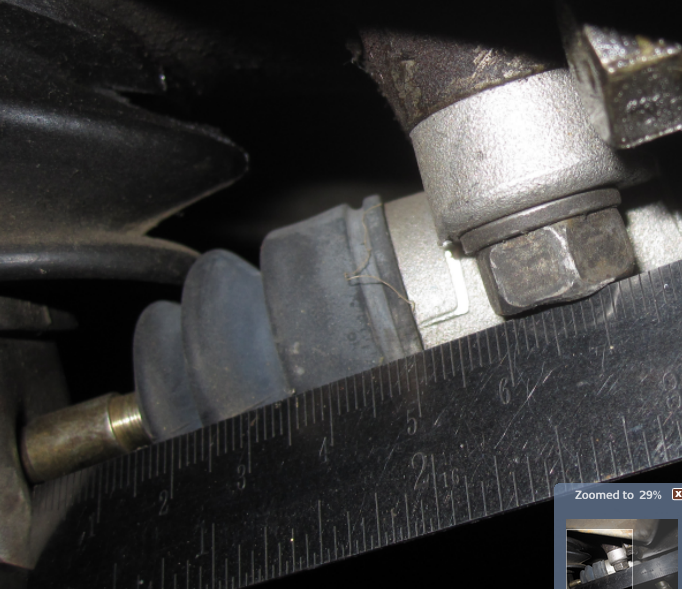

78 280z idle problem

Edit - actually I can't tell what you're measuring. I measure to the bolt head. Edit 2 - it looks though, like your fork is bottomed out on the hole it sits in. Can't go any farther. This is at rest, no foot on pedal.

-

78 280z idle problem

It's kinda looking like you might have a ZX or Maxima engine, or head, in your 78 280Z. They use a cylinder head temperature sensor in place of the water temperature sensor. It does the same thing and has the same temperature profile. Those engines also had several extra temperature switches on the T-stat housing. Take a picture of your engine's serial number area, and the head ID area. You'll know more about what you're working with.

-

My weekly rant. Premature Parts Death Plague

There are several threads out there about Pertronix quality diminishing over the years. New modules dying, while thirty and forty year old modules spark on.

-

Complete Misfire on Three Cylinders

Don't confuse from with function. If it doesn't leak then, technically, it's fixed. If you can get the hole properly aligned and threaded so a valve cover bolt works correctly, then, technically, the problems are solved. You could be heading down a worm hole trying to fix something that is only aesthetic.

-

78' 280z EFI troubles

I think that you might be measuring power at the injectors incorrectly. Looks like you're probing across the pins in each connector instead of from a single pin to a ground point. The fact that your tach doesn't move and it starts with fluid implies that the Pin 1 circuit from the coil to the ECU is broken. Check Pin 1 continuity to the coil Or you have a funky ignition system like a an MSD or Crane. They don't work well with the 280Z EFI.

-

Complete Misfire on Three Cylinders

Measure each end and you'll also get an idea of the tolerances for an individual head. If they're not tight within a head, they won't be tight across many heads.

-

Complete Misfire on Three Cylinders

What's the backstory on the car? I wonder how deep the PO got in to the engine.

-

Complete Misfire on Three Cylinders

I didn't say it was uncontrolled. I said the spec. was set wide. It' not economical to set a tight tolerance where it's not necessary.

-

Tension rod mounts worn out - please help!

I was just offering another way to look at the problem. You'd have to grind some welds and then reweld. It's not a high precision area, squishy rubber bushings fit in the pockets and there is not adjustability. Polyurethane bushings are probably stiff enough that you don't really need a pocket for them to ride in. Their purpose is to locate the wheel, fore and aft, and prevent it from moving under braking. Compression when stopping from forward motion, tension when stopping from backward motion. Opposite on the ZX's.

-

Complete Misfire on Three Cylinders

Everything I've seen suggests 108 mm as the number. Metric, of course. From a manufacturing perspective I don't think t's a high accuracy, precise dimension. Valve lash adjustment can take up quite a bit of error/range. Might be that a half mm either way was acceptable during manufacturing.,

-

Tension rod mounts worn out - please help!

The bracket itself might be dissassemblable. #15... http://www.carpartsmanual.com/datsuns30/Datsun-Z-Index/Body-260Z-280Z/2-2/Floor-Panel-Spare-Tire-Cover