Everything posted by Zed Head

-

Series 1 mustache bar bushings and early washers

Might find something here - https://bringatrailer.com/search/?s=1970+240z

-

What is this??

Weird how complex the whole fuel filter market is. Few details and what looks like poor conversion skills. 10 mm = 3/8"...not. Here's a couple from the local store, one with paper media, one with bronze. One about 4" long, the other undefined. One special order, the other available. https://www.oreillyauto.com/detail/c/spectre-performance/spectre-performance-fuel-filter/spt0/5965?q=Spectre+Performance+Fuel+Filter+-+5965&pos=0 https://www.oreillyauto.com/detail/c/trans-dapt/performance/filtration/fuel-filters--universal-/383bc52af696/trans-dapt-3-8-inch-inlet-3-8-inch-outlet-fuel-filter/tdp0/9177?pos=3

-

What is this??

They're cheap too. Main problem is the 8 mm (5/16") nipples. https://www.rockauto.com/en/catalog/nissan,1978,280z,2.8l+l6,1209260,fuel+&+air,fuel+filter,6200

-

What is this??

Don't overlook that the pressure drop is affected by the area of the filter media. Not just the pore size. So, a larger diameter filter will be less noisy. It would be interesting to try one of the big 280Z EFI filters as a pre-filter. There's a reason there so big. Lots of surface area in the pleated media. Also, if you're filtering to save the pump don't over-filter. The clearance inside the vane-type roller pumps is pretty big. Certainly greater than 20 microns.

-

Car won’t crank

You need to add more detail. When, and exactly where? There are three "lugs". Actually two lugs and a spade. SteveJ is asking about the spade (black and yellow wire). With the key at Start. The 12 is a good sign though.

-

Speedometer pinion stuck

Slide hammer is not a bad idea, but good look finding that thread pitch. I have vague memories of using a rag and a pair of vise-grips, with a hammer tapping sideways on the pliers. Or maybe a big screwdrive levering on it. Anyway they do get stuck. Nothing special in there. I found a new Z store. TotalZPartsDatsun 240Z 260Z 280Z 280ZX 300ZX Speedometer Pinion Gear...NOS (new old stock) speedometer pinion gear full assembly, including the sleeve, seals, and the retaining pin. It has a 17-teeth gear & measures about 3 1/16" in total length. 18, 19, & 20 teeth ge...

-

Blinker won't stop even when car is off

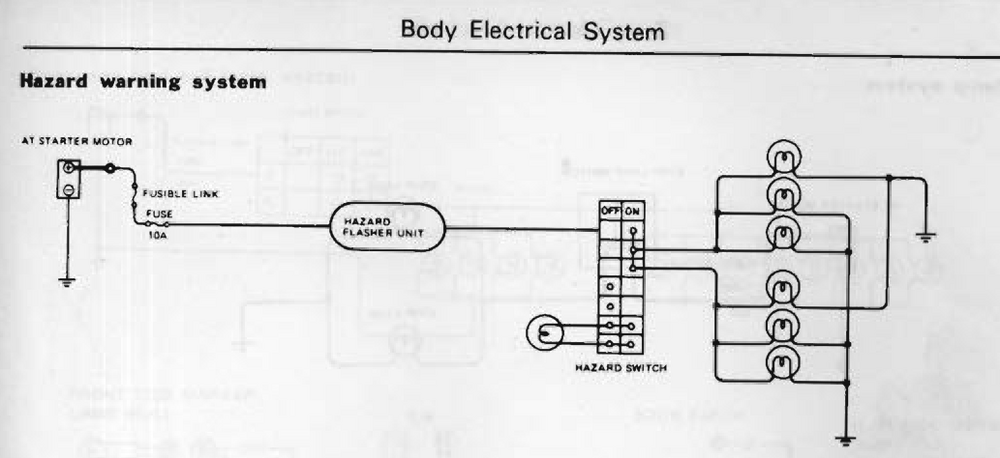

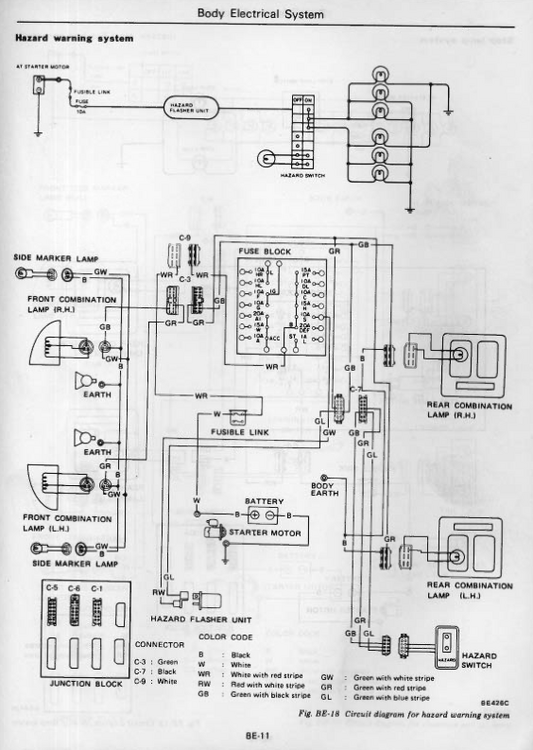

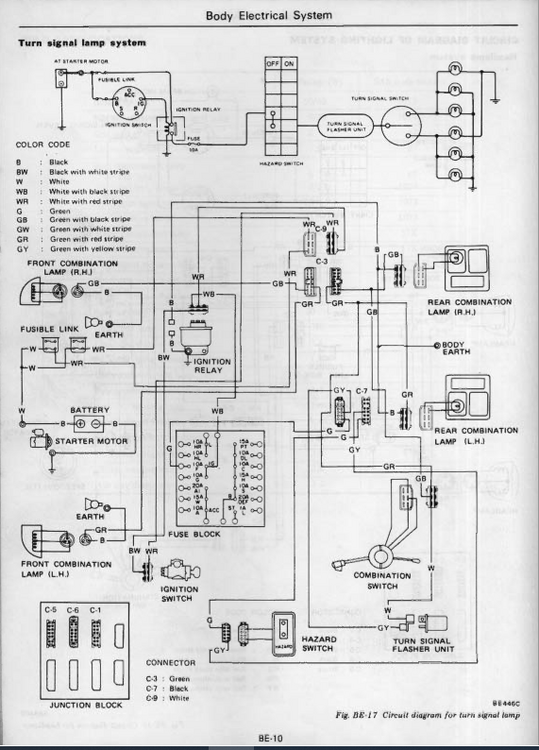

Are you sure? The diagram shows a left side and a right side, from the Hazard switch. It's a 78, I didn't look at any other diagrams. The Hazard switch is basically a gate between power and the flasher, and the lights. Since the flasher comes in to play the short to power has to include the flasher circuit. Basically it's just completing the circuit, like a short across contacts inside the switch. Interesting problem. For what it's worth, I erased about three different paragraphs about this problem. Writing about it does help the brain work...

-

Z's on BAT and other places collection

$137,000. Kind of amusing that the bulk of the discussion on BaT was about AC and undercoating. Bring a TrailerVintage Restoration Program 1972 Datsun 240Z 4-SpeedBid for the chance to own a Vintage Restoration Program 1972 Datsun 240Z 4-Speed at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #199,214.

-

Brake booster and cams

That cam doesn't look very aggressive. Not like a typical rumpety-rump muscle car V8 cam. Probably won't cause a problem. I've seen belt-driven vacuum pumps. You could probably add one after the fact if you find that you need it. Looks like you can get electric also. https://www.summitracing.com/search/part-type/vacuum-pumps-street

-

Blinker won't stop even when car is off

On second thought it might be the Hazard switch. Lots of mysteriousness in there. It has power when the key is off. @SteveJ seems to feel comfortable with it. "even when car is off"

-

Blinker won't stop even when car is off

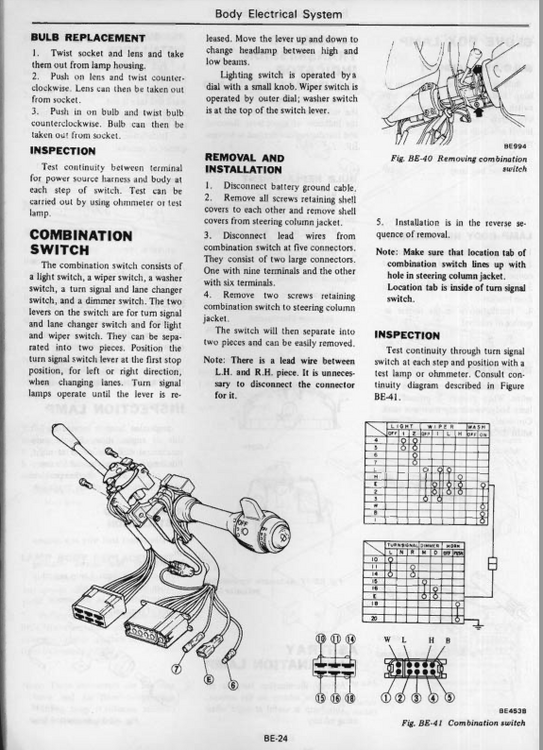

Pretty easy to remove. Something I learned - the ring around the ignition switch will pop out about 1/8" to allow you to remove the plastic shield around the column without breaking the corners off. Appears to be designed for that purpose.

-

Blinker won't stop even when car is off

It's probably the mechanism in the combination switch. Not likely to be the flasher. There is no separate turn signal relay.

-

Z's on BAT and other places collection

A 71 is up on BaT. Oddly, it ended up in Florida with an Illinois title, after having "spent time in Texas, Arkansas, and Oklahoma before it was acquired by the seller", Bring a Trailer1971 Datsun 240ZBid for the chance to own a 1971 Datsun 240Z at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #200,055.

-

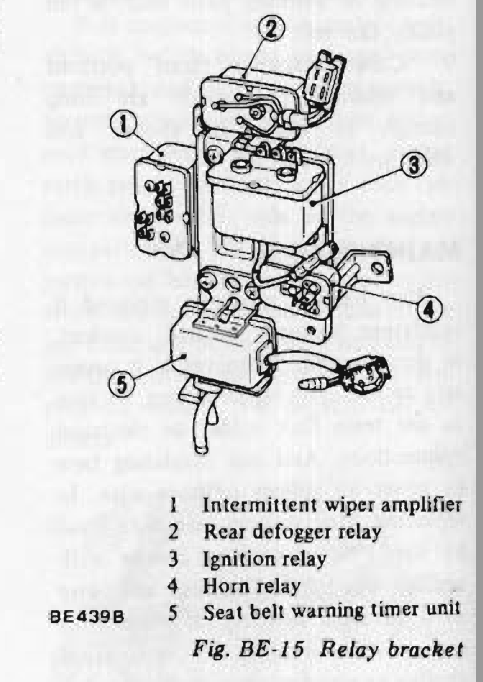

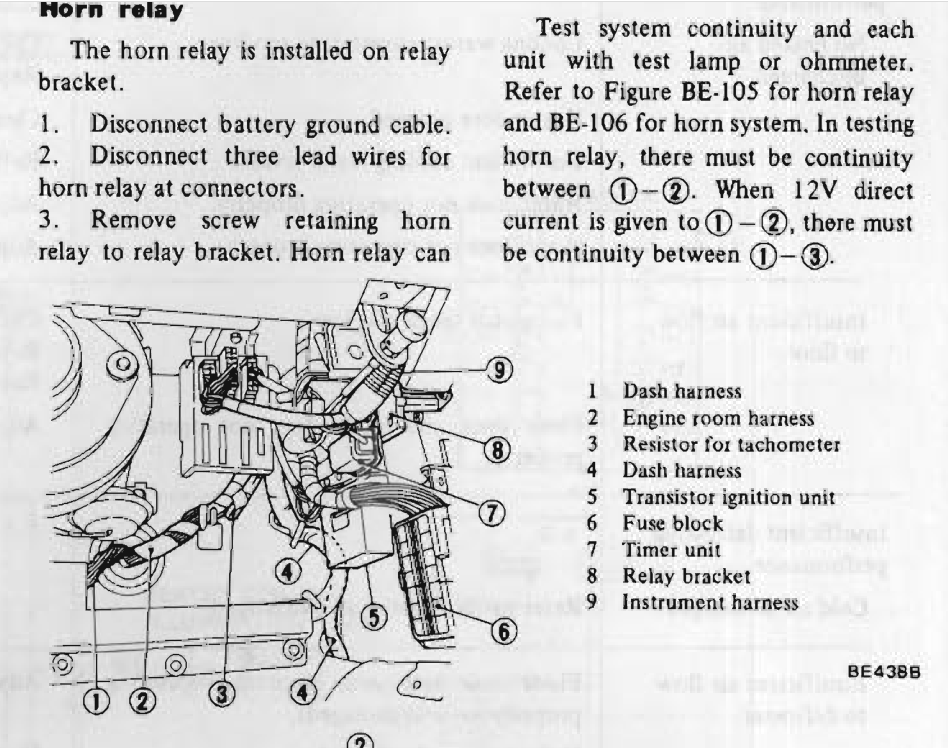

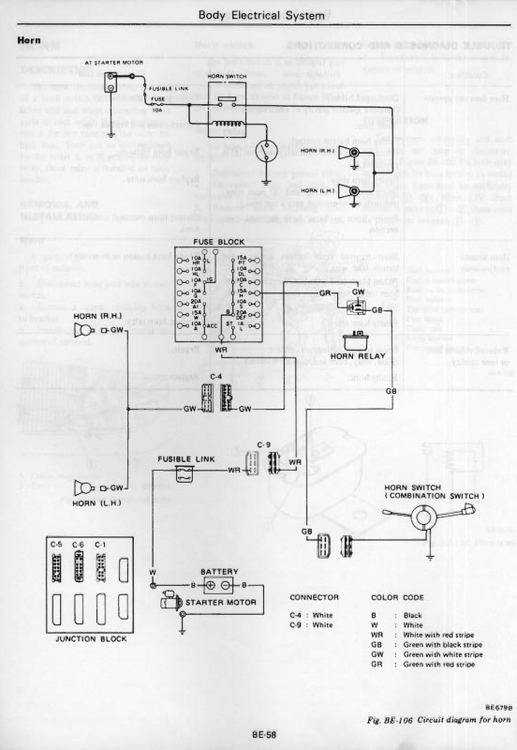

Horn Relay Location on a 1978

Are you sure the horn switch isn't stuck? The control side needs to be grounded to actuate the relay. Seems like that would have to happen before it could get "stuck". It's on the relay bracket.

-

Helpful tip for getting directly to the last post when not signed in

So, on the All Activity page, you can click on anything and it will take you to the end. So, this would be the page to start from when not signed in. But...the page lists all posts instead of all Topics. so there's really no need to click through since they're all right there in the list. Oh well. https://www.classiczcars.com/discover/

-

Helpful tip for getting directly to the last post when not signed in

I think that Mike just changed things. Now, everything takes you to the last post, signed in or not. And the comments show on the Activity pages, although I have not tried all of them. So my thread is irrelevant now. Try it out and see what happens. 1/2 Thanks Mike. Actually, only the comments part has changed.

-

Z's on BAT and other places collection

The comments are focused on the AC system for some odd reason...

-

Z's on BAT and other places collection

A person could ask why any of the old 240Z's sell for high price. Or why people pay high prices for Bob Sharp cars. Or why first edition comic books sell for high prices. Collectors have their own values. Here's an article about the program. https://www.hemmings.com/stories/nissans-z-store-restored-240zs-might-not-have-made-the-company-any-profits-but-they-did-help-save-the-z/ Old pieces of colored paper sell for six million dollars! https://www.cnn.com/2024/04/05/style/superman-comic-record-6-million-intl-scli#:

-

Helpful tip for getting directly to the last post when not signed in

I have found that there are two basic starting points to use when looking at the CZCC forum to see what's new, when not signed in. The first one shows the text of the last comment in a thread. But if you click on any of the options to open the thread all of them take you to the first post in the thread. This is no good if you want to see the latest comments, more than just the last one. So you have to click, click, scroll to get to the end of the thread. https://www.classiczcars.com/discover/112/ The second will take you to the last post directly if you click on any of the options, but does not show the text of the last comment. It just shows that somebody commented. https://www.classiczcars.com/discover/ Just an observation. Not all of the Activity pages are the same.

-

Ads attacking!?

Never mind. I erased my internet history and the problem went away. Didn't know that "cookies" could do that. I think I had clicked on something by accident. Back to original programming...

-

Ads attacking!?

Is anybody else suffering a barrage of ads on the forum? Just started. I'm signed in and even getting pop-ups even though I use Adblock. Never had this problem on the CZCC forum.

-

Z's on BAT and other places collection

Yikes! Also see some nastiness in the comments, (468!), from 2020. Didn't read through them but Lstepp4re seems involved. I don't keep track of all of the players on BaT so not really sure who he is. It's up to $70,000.

-

Z's on BAT and other places collection

Just noticed that car was on baT in 2020. The new owner did some work on it. Wonder if the new work diminished or enhanced the original Restoration work. Original > Restored > Enhanced? It's definitely shinier now than then. 105,240 + 9,000 = 114,240 to break even. "...A paint correction service was performed, and the paint was ceramic-coated in September 2021. ..." https://bringatrailer.com/listing/1972-datsun-240z-127/

-

Large Language Model, Machine Learning, Artificial Intelligence

This is AI playing a game... https://apnews.com/video/beijing-hosts-chinas-first-fully-autonomous-3-on-3-ai-robot-soccer-match-e304c40f16684667a9c35a73ab8e5b31

-

rear clunking noise '76 280z

Were they noticeably loose?