Everything posted by zKars

-

How I want it to be handled when it's my time

If that turns out to be difficult, I’ll settle for a high resolution picture of the bottom of a filthy rusty thick undercoating covered Z applied to the underside of the coffin lid. Leave me a wire brush, scraper and propane torch so I have something to do for all eternity.

-

How I want it to be handled when it's my time

- FS5W71B Rebuild Thread - Tips tricks and discoveries!

Ok, got a part today that is good news and confirms shift fork compatibility AND availability. One more Fs5W71B saved from the scrap heap. 32811-58S10 is the 3/4 shift fork from a Fs5W71C transmission. It is a usable replacement for both the 1-2 and 3-4 shift fork in FS5W71B with aluminum forks, and would also replace the 4 sp version metal forks. One tiny snag. The roll pin hole in the C and B type 5sp forks are larger than the 4 sp forks. If you break a 4 sp fork, you will need to drill the rod roll pine hole out to 0.195 or 15/64. A number 8 drill bit is good enough. Let me also repeat that the C type 1-2 shift fork will NOT WORK in the B types, it fits a larger diameter selector ring.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

It is foolish to assume the balls have no play, very good point. I shall measure a fresh and old one and see what deflection I find.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

The Nissan bearing is actually a light press fit. You can't push it through with your hand, but a very light rubber hammer can tap it through, if you keep it square to the bore. Remember when you put the case back on over the bearings they have to fit "just so", to allow them to be both properly and snugly located, and loose enough to allow you to push the case over them without a big hammer. I'll have to practice to see if the bearing will press through easily with the push from the mill quill or if it hangs up. Being a bearing, the middle will rotate with the cutter head, the OD will just be a stationary guide that gets pressed through. All has to be pretty smooth to feed the cutter down with good control and slow smooth action. Might have to sand just a tiny bit off the bearing OD to get a slightly looser fit. Capt'n is saying "just center the dang cutter over the hole with the Co-ax like we talked about and stop getting fancy!" but I have fear I haven't tested yet. With working down inside the bell housing, both seeing the dial gauge and swapping from the center finder to the cutter head may prove to be a challenge given the constraints of quill plunge depth (5"), different mandrels lengths on the two things, and clearance/vision. One thing I haven't said is my mill is more of a very heavy duty drill press. The one thing I can't do with it is move the entire head up or down in perfect straight line. The head, once you back off the lock down to allow it be moved up or down, can rotate on the column very easily, so there is no simple way of keeping the exact X/Y location. I have to work within the 5" quill plunge to get everything done. Should be playing this game today. Will take some pics and let you know how it goes.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

I too was concerned about that amount of cut, but it will be hard to adjust my welded cutter head. That is partly why I chose the index bit style cutter. It cuts aluminum like proverbial butter. I’ll cut very slowly. Thinking back to Philip's early idea of a dual concentric hole cutter, the inner one guiding the outer cutter by riding in the existing hole, I’m now thinking about making my own cutter head with a 22mm dowel on the bottom that mounts the stock ‘B’ 56mm bearing. Let the bearing ride in the existing hole to guide the cutter set out at 62mm. Maybe I’m getting carried away. Yeah, that’s new...- FS5W71B Rebuild Thread - Tips tricks and discoveries!

And some good news tonight about the issue that started this thread, the trans that wouldn’t shift into 5th. It was in fact the ‘wrong’ shifter. What worked was a shifter from a zx, the one that has the spring loaded center and flat face bushings. The one on the left. What is interesting, is the wrong shifter has a slightly longer hole to bushing tip length than the zx one that works. well a day to learn something new is a good day.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

- FS5W71B Rebuild Thread - Tips tricks and discoveries!

Been busy today proving I can drill, no actually enlarge a hole. I drilled a 2.25” hole in some 1/2” aluminum plate using my Forstner sawtooth bits, about 57mm, then adjusted my boring head until I got 62mm hole. Well, slightly smaller, actually trying to match exactly the hole in the C type bell housing I have. I’d rather be over so slightly small then enlarge with a bit of sanding to make perfect. The insert style bit can easily cut the 57 to 62mm in one pass. Once I get it perfect, I’ll spot weld the boring head and bar into the head for repeated use.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

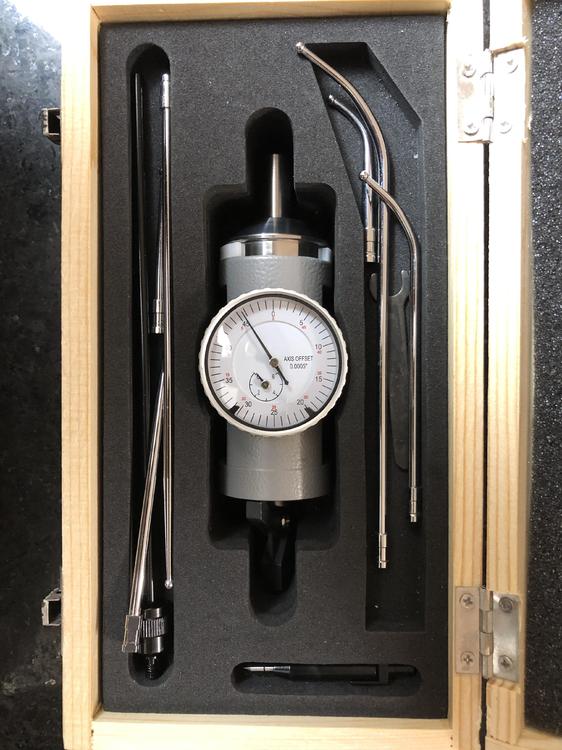

So today I go to play with my new co-ax center finding thingy after drilling a nice 2-7/16 hole in a 1/2" thick piece of aluminum plate.. Get the co-ax, chuck it in my arbor, attach an indicator arm, move the table around a bit, start to move the indicator arm a bit to see what the dial gauge is saying, and..... It doesn't work. The needle never so much as budges when you move the center shaft in and out..... There is a pin I'd have to punch out to disassemble, but figure that will end my ability to return it. Back in box to Amazon with a return slip. Got what I paid for again..... sigh..... Order a better one and wait for tomorrow to see if the quality gods are on side or not- FS5W71B Rebuild Thread - Tips tricks and discoveries!

- FS5W71B Rebuild Thread - Tips tricks and discoveries!

- FS5W71B Rebuild Thread - Tips tricks and discoveries!

Ok I have five transmissions apart in the shop. A 4 speed, Three 71B’S and a 71C. This is getting out of hand. But I’m learnin’ lots. Best of all is that the 3-4 shift fork from the C is perfect match to replace my bad 1-2 shift fork in the B!!!!! Only the 3-4 C shaft is 16mm in the C, the others are 14, so don’t even need a bushing. The only thing you have to do is make roll pin hole in the B’s shift rod bigger to match the larger hole in the C fork. Now regarding the new fork mentioned above from transdistparts above, it likely will not work. The 1-2 shift selector C type is slightly larger than the 3-4, so the fork is too big. They aren’t listing a 3-4 fork replacement.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

Looking for trans parts? These guys have a decent selection. Even claim to have my shift fork. https://www.transmissionpartsdistributors.com/fs5w71-fs5w71a-fs5w71c-fs5w71e-fs5w71g-fs5w71h/ Thanks to Aaron Heath on FB for pointing this out. I put out a plea for parts last night.- FS5W71B Rebuild Thread - Tips tricks and discoveries!

I knew I could count on you guys. Of course! The boring head. And a coax? Looks complicated, but you need what you need, right? off to the tooling store! Yahoo! all this requires that my mill head fits down into the transmission case. Haven’t tried that yet....- Steering wheel parts

- FS5W71B Rebuild Thread - Tips tricks and discoveries!

So all you machinist's tool makers, inventors or dreamers out there. If you were going to "create" a 62mm cutter of some sort to put in your mill to enlarge a 56 mm hole, what would it look like? PS. 62 mm is just a teeny bit bigger than 2-7/16" (61.92mm) and just a tad smaller than 2.5"... (63.2mm) I've drilled a LOT of holes in Aluminum with one of these. They make a lovely hole with lube and a gentle hand. Buy a 2-1/2" one (63.2mm) and machine it down to 62mm, or a 2-7/16" one and weld on / add a cutter ?? That nice round shaft on there is exactly 0.500" to fit in a nice collet chuck. Centering is simple. I'll lathe up a 56mm puck with a 0.500 hole in the middle that fits oh so nice and tight in the bearing hole, then use a 0.500 rod in my 0.500 collet chuck to get the mill head in the right spot. Then put the bit you-all are designing for me in collet and cut away! Simple right?- FS5W71B Rebuild Thread - Tips tricks and discoveries!

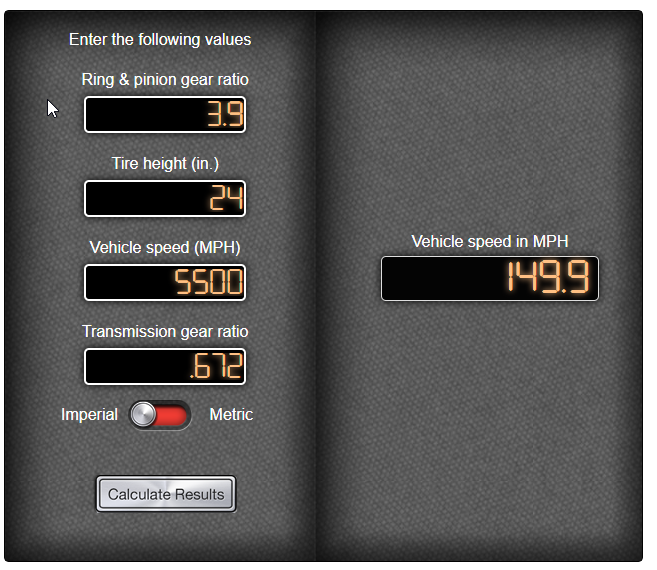

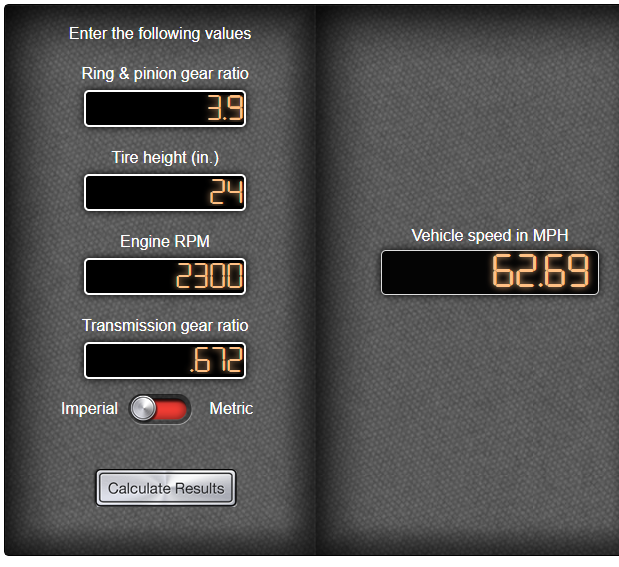

I have closer to 24 in tires Would be fun to get my little yellow brick to go 150! My WAG about 2300 at 62 mph/100 kph is pretty close!- Alternative Brake Vacuum Hose Source?

https://www.jbugs.com/category/vw-hoses.html- FS5W71B Rebuild Thread - Tips tricks and discoveries!

Feel is such a personal thing, and torque curves and rpm ranges are different in every car. As are driving styles and how I drive 90% of the time. I will have to put it in and try it out to see if I really like it. Swapping trannies is a just nice way to spend an afternoon. I plan on several long trips in the next couple of years so I hope to make good use of that .65 OD. Got the torque to lope along happy at 2300 at 65 MPH. I’ll be running 3.9 subie CLSD currently working on an idea for a jig to make the 62mm bearing opening enlargement easy and relatively fool proof.- Can anyone identify these RIMS??

- FS5W71B Rebuild Thread - Tips tricks and discoveries!

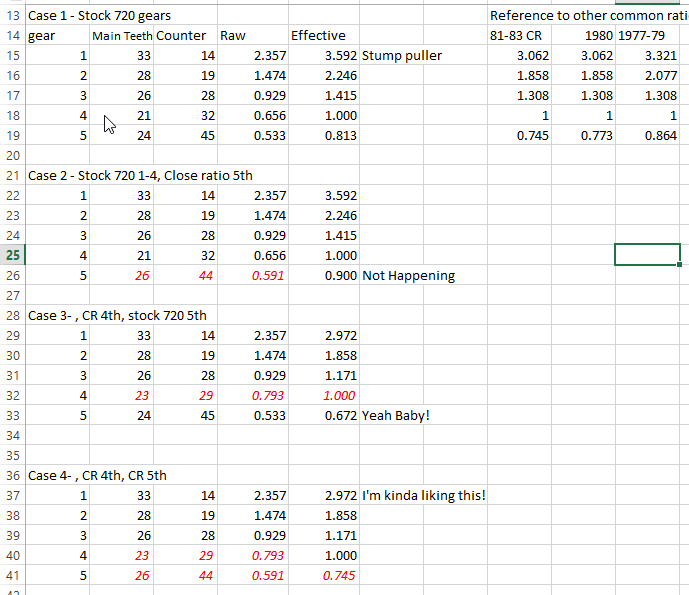

The more I stare at these ratio's the more I want to try case 3! Case 4 is also a winner if you like the .745 OD and gives you much more reasonable 1st over the stump puller truck ratio- FS5W71B Rebuild Thread - Tips tricks and discoveries!

Alas, I am but a dreaming fool. My plan above to use my .754 gear set will actually make the 5th ratio a stupid 0.900. You have to account for the 4th gear main/counter gear ratio to correct the actual 1, 2, 3 and 5th gear tooth count ratio's to get the total drive ratio. With the close ratio, the 4th gear teeth are 23 vs 29 or 0.793 ratio, then apply that to that actual 5 gear tooth ratio, which are 26 and 44 = 0.593, / 0.793 = 0.745 actual 5th drive ratio. But do that with the truck 5 speed gears, 4th main and counter are 26 and 44, or 0.591. so with my 5 gear stuff. is 0.593 / .591 and you get a utterly heart breaking 0.90 5th ratio. Not doing that! But!!!!! As I'm typing I'm thinking more (haven't learned my lesson yet...), I could ALSO use the 4 main and counter gears from the close ratio in the truck trans (the only gear you can remove and replace on the counter shaft hahahah), which would give me the 0.745 5th, but wait, oh crap, it will also screw up all the other 1st and 2nd and 3rd ratio's as they are corrected by the 4 main/counter ratio. Let's see how bad is that.... So I have two sets of 5th gear gears, and two sets of 4th gear gears, so could build 4 different ratio sets. Let's be scientific and get Excel going. One of these combo's "might" be worth trying. 720_trans_ratio.xlsx- FS5W71B Rebuild Thread - Tips tricks and discoveries!

Back on topic Way in the back of the tranny garden (forest?) I remembered I have a 720 truck five speed! I've been ignoring it because it has a bell housing I can't use on a Z or 510, anything with a tilted L series. Outwardly it looks identical to any long eared one-muffler hanger FS5W71B except for a couple of key details. The wrong bell housing for one, and the fill plug is on the other side of the case. Look here to review the differences if you're not on top of that. https://ratsun.net/topic/74205-620-transmission-identification/ BUT this sad little truck trans IS a donor for my worn out 1/2 shift fork! They are identickle! Took it apart today, and it's in perfect shape. Gear ratio's are interesting. Being a truck, first is a bit of a stump puller. 1 3.592 2 2.246 3 1.415 4 1 5 0.813 Let me say here that I am actually not a fan of the much coveted "close ratio" 5 speeds. Gotta say I've had just about enough of the fawning and slobbering over their supposed greatness. The 2-3-4 ratios are nice and close, wonderful for road racing I suppose, but first is about 2.5 miles away from 2nd. I've always been a bit ticked about the huge gap between 1 and 2 in both my Z and now my 510. Not ideal at all for tight auto cross circuits. SO!!!! I going to hypothesize that I like the above truck ratios for 1-4. Now the Z close ratio 5 has that nice .745 overdrive, while the truck has a so-so .813, but I have a solution. I'm going to put the lovely .745 5th gear gear bits from my Z trans into the back side of this nice truck cluster. It's all separate gears behind the intermediate plate, just gotta take ALL the parts from one and stuff them in the other. BWAHAHAHAHAHA!!! THEN when I break it next I'll stuff the C type in there and live with it's ratio's. You know, a guy could get the bell housing machined for the 62 mm front counter shaft bearing, and strengthen up a B type pretty nice. It's the bearings that give out, never busted a fork or gear set. Who needs those fancy C types with their longer length, wider gears and skinny syncro's anyway? ( read that with a sneer pls).- tail shaft leaking

If its failing that quickly it is likely a defect in the driveshaft surface that rides on the seal. You have four options 1 replace the seal again, but don’t put in in as far as last time. Ie put the seal lip at a different point on the driveshaft surface. 2. use a speedi-sleeve. Google it. 3. replace the driveshaft yoke so you get a fresh seal surface 4 polish the driveshaft sleeve to remove the defect. - FS5W71B Rebuild Thread - Tips tricks and discoveries!

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber