Everything posted by zKars

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

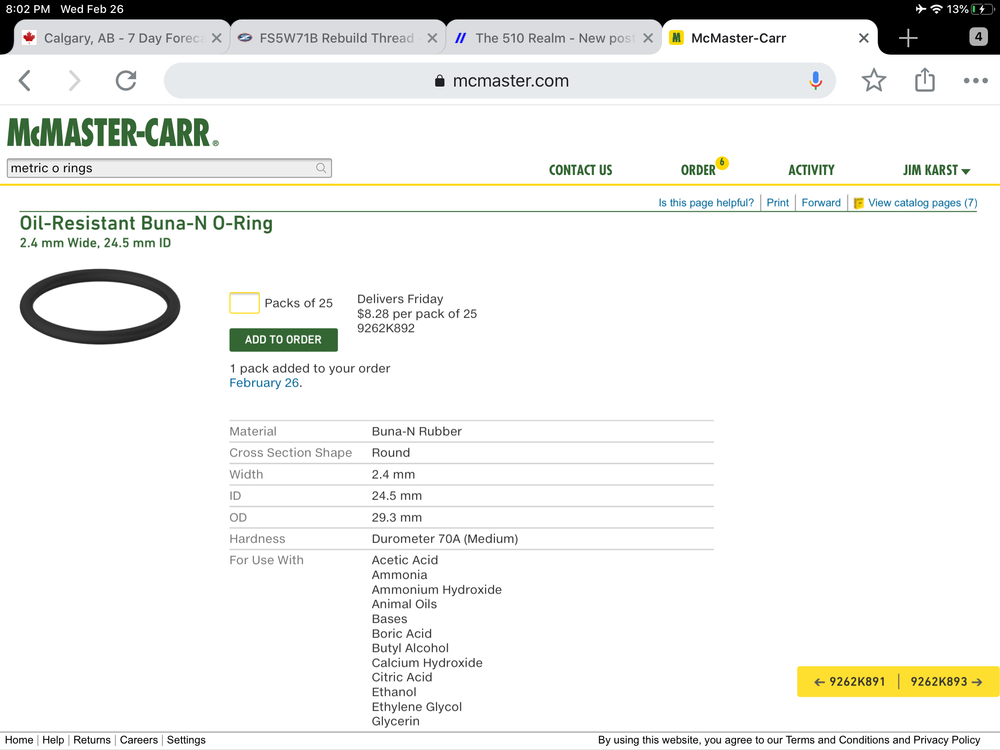

So this thread is titled "tips and tricks" so here is one tip and trick. This is related to using the bearing splitter and puller. I use the puller with long extensions to get the rear main shaft extension housing bearing off, then to pull the very snug bearing sleeve under the 5th gear needle bearing. It requires 16" extensions for one and 18" for the other. Being inherently lazy, and efficiency driven, the ordeal of spinning those 3/8 nuts back and forth on the long rods, or changing from 16 to 18 in rods and having two sets of nuts and washers, I find just too tedious and time consuming. What to do, what to do.... Let's see... Surely there is a nifty "something" out there that allows you release a threaded nut and slide up and down, then quickly re-connect it with the threads. Didn't take much googling to find the concept of a "slip on nut" to be a real thing. Here is the first thing I found. Two interlocked nuts that rotate to expose an opening, then rotate to lock back on the threads. Found it on Fastenal's website, and low and behold, they actually had some at the store near me. I zoom over, and yes, she pulls out four of them in a baggy, goes to the computer and says "That will $60 bucks please"! I let out the loudest laugh i have ever produced. She looked at me with very worried and surprised eyes, wondering what I'd say or do next. She managed to say with a straight face, "well, we do have minimum charges....". I apologized for possibly offensive behavior, thanked her for her time, declined the purchase and left.. Home I went to the internet. Found them on McMasterCarr for $5.75 each. BTW these are 3/8-16 thread. (PN 90125A031) Even better, I also found on McMasterCarr a much slicker sliding nut system, the "Push Button Slide Adjust Nut (PN 98150A360) for a mere $10.83 each. Of course I bought both items to compare. I had other important things to buy from them as well, so I justified it easily. Like a bag of 25 orings that fit the speedo cog body and striker rod for $8 bucks (9262k892)rather than the $8 each that Nissan charges you. Same for snap rings (97633A290), and various individual ball bearings that match the ones you always lose when you take the trans apart)..... They are surprisingly all perfect SAE sizes. 0.25 (shifter rod detents), 3/32, etc. (Yes, it all was more than $60 Canadian, I knew you'd ask....) Anyway, the push button slider nuts are the best thing out there. Push, slide, release, thread to lock. The nut OD is quite large (over an inch for a 3/8 nut), but for this usage its perfect, as the base is flanged and fit the fingers on the puller head without additional washers. The two piece slip on nuts work too, but are finicky. BTW the trick to getting McMaster Carr to sell to Canadians is to register your account with a business name. Don't have to provide proof, just have a name in the box when you fill out their on-line form. I use my zKars handle. Occasionally the courier driver will ask my name on delivery, I will blurt out my actual name and he will say "but the name on the waybill is ZKars". I show him a business card I had made up, he's happy.

-

Checking correct fuel level at Round Top 3 screw SU CARBS Float bowls

I can't find Randalla's Floatsync product on ebay. Searched a ton of different ways. AK260's experience with his website being down is telling. I can't decide if it's fair to point people to a commercial source for the right size banjo fittings, I feel like I'd be doing Randalla a disservice, even though he is MIA at the moment. I found them with simple google searches. Once you know the thread dimensions of the float bowl plug, you will find them too. My initial design (not the one above that Site shows BTW) was to drill a hole in the drain plug, insert a brass tube in the hole so it sticks out 1/4", solder that in, then stick a piece of clear tubing on the end of tube and bend it upward. put a piece of stiff wire in the tube to keep it vertical. Then you have to plug the tube when you're not using it. I had spare plugs..... You all have to find the thread size yourself. I will not divulge my sources of the parts. Happy hunting.

-

Anyone ever tried a 195*F thermostat?

Does it have an aluminum rad by any chance?

-

Parts for Sale: Datsun FS5W71B Close Ratio 5 Speed Transmission

Ebay says the winning bid was $1100 Canadian. Excellent price! Did it sell locally or do you have to ship it? Good to have a local bench mark for 5 speed prices. Look forward to seeing more of your project. We have a Facebook group for Alberta Datsun owners. Calgary Classic Datsun Owners Group. Feel free to join up. Let me know if you need anything, we have a great bunch of Datsun nuts in your area.

-

Absorbent Pads for the Garage Floor. Keep it dry with Puppy Pads!

A buddy of mine with pets and a similar love of cars put me onto a great shop convenience and floor maintenance idea. Puppy Pads. Let's face it. If you have a Datsun, you have dribbles under your Datsun. If you take the engine out for example, you forget to cap the heater coolant pipes on the engine, and even though you drained the rad, when you tip the engine as it comes out, antifreeze hits the floor in great quantities. (I myself have never done this... I just imagine it's an issue). Puppy pad absorbent sheets are utterly fantastic. Big (30x23inch), cheap, super absorbent, did I mention cheap? 100 pads are $25 CAD at Costco. I used to use newspapers, but I no longer get a paper newspaper, so I've been scrounging for newsprint in dumpsters or begging from strangers at bus stops "Hey buddy, you done with that paper?" I did learn a few new words for "No!" however. Big enough to put under a transmission you happen to be rebuilding, under the engine when you're changing oil or draining the rad. Under me when I sitting on a dirty floor. Whatever! I even stuffed one under my big 60 gal air compressor when I open the drain valve to release condensed water. One pad holds a couple of quarts of water I swear. There. That's my "Hint's from Heloise" for today. Keep that floor clean!

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

CO, yes, I see my jaws don't quite close perfectly, well one of them anyway. Grrrr... . I'm saying the run out is the lathe's fault. Still that one shaft with the pitting is trash or last resort use anyway. I took the trans apart (again) that has the missing 4th gear set and "borrowed" it's shaft while I wait for a donor to show up. Also found one of the sleeves that the needle bearings run on was pretty marked up, under 3rd gear. Switched that out for a better one from the above donor. Now maybe that tranny will make less noise. Got that seal switched around and buttoned up that trans, again..... I can do this with my eyes closed now. Wish I could post pictures.

-

New Source for Wiper Linkage. Speed up those wipers!

i took some pictures of a real S30 linkage and there are significant differences I think. I can’t seem to add pictures today for some reason, but I have doubts the Suzuki linkage is a bolt in. The most problematic issue is the angle of the wiper pivots at they pass through the triangular mounting plate. Hard to tell from the Dorman images, but their wiper pivots seems to be more or less 90 deg to the mounting plate, where both S30 pivots are definitely not 90, and they are each different. The little crank arm on the end that connects the free mounting plate is straight on the S30, but is clearly a Z bar shape on the Suzuki part. My hopes are sinking the more I look. Maybe there are useable components to use, but as a total bolt in replacement, I’m doubtful. I’m not tossing my selection of stock linkages just yet.

-

New Source for Wiper Linkage. Speed up those wipers!

Maybe he just spotted it and thought it looked way to similar not to work. He didn’t say anything else, just posted this link. https://shop.advanceautoparts.com/p/dorman-oe-solutions-windshield-wiper-transmission-602-885/10719361-p?product_channel=local&store=5412&adtype=pla&product_channel=local&store_code=5412&gclid=Cj0KCQiAtOjyBRC0ARIsAIpJyGNoSrTfthsi3VtZRBBZHq_Z2n6nFrwLhfcAjRg7g_llcr99PgGV0GwaApYtEALw_wcB&gclsrc=aw.ds

-

New Source for Wiper Linkage. Speed up those wipers!

https://www.rockauto.com/en/parts/dorman,602885,wiper+linkage+/+transmission,8856 Harold Burroughs posted on FB yesterday about the availability of new aftermarket S30 wiper linkage from Dorman, PN 602-885. Just thought I’d spread the word. He reported the find from Advance Auto’s website, but Rock Auto has access to it also. Anyone with access to Dorman can get it. The price is impressive, $69 CAD. That’s about a $1.98 in USD, so who can resist? Yes as we know you can rebuild and re-lube the stock stuff, but if your shafts are all rusty (as all us old guys know), no amount of lubrication will make things go smoothly or last that much longer.

-

2.4 with 5 speed and round top SUs. $350

Could it be any further away.....

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Naw, flog it. I stuck 3 different shafts in the lathe and they all say 5-7 thou run out. Should have spent more on the lathe....

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Nobody caught my booboo on the little seal. I installed it backwards. The fluid your trying to keep out should be on the open U shaped side of the seal, you would then see the flat closed side looking down into the shifter housing. I had just done the front cover plate seal, which you install with the open end of the seal outward, and my head for what ever reason said “ this seal too”. Not....

-

Missing Parts

I scratched my head and finally at least have a clue why I can’t figure out what this. That fender badge says 280zx, so most here (including me) aren’t up on all the little hidden plastic body and fender bits and pieces. Does remind me of a mud flap like thingy

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

And finally The o-ring on the outside end of the shifter rod body. Somewhere it was noted that it’s the same as the one on the outside of the speedo cog. That is in fact true. The groove ID is 24mm, and it’s 2mm deep, and just over 3 mm wide. The o-rings I pulled off were 24mm ID by 2.4mm cross section. And magically a 15/16 or 7/8 x 3/32 o-ring fits just fine. The cross section is nearly identical and tiny stretch from 7/8 to 24mm does not deform the ring. I tested the fit into the speedo cog hole and they all felt identical in drag and insertion ease. McMaster Carr has a 24.3 x 2.4mm oring too if you can’t get a Nissan one and you want a really close equivalent.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

This transmission also has a leaking shifter shaft. The area where the shifter plugs in was always full of GL4 and causing a dribble on the floor. So I had a chance to try both my latest discoveries about removing that wedge pin to take the shifter rod out to change that little seal, AND how to remove and replace that little buried seal. Success on both cases. The air hammer gun popped the wedge pin out in 30 milliseconds again, and this time without any heat. I bought a set of really long seal picks, and that’s all it took to get that little seal out. You just need to put the tip of the 90 deg pick under the seal and YANK. And then to put it back in, I had no choice but to spend time on the lathe making a seal pusher-in-ner thingy. What other option would there be? Guess you could whack it with a 3/4” punch tip, but what fun is that. The specs are 13.9 OD on the seal ID part, 13mm long, then a section of 19.8 mm again 13 long. The nose guides into the hole, and the OD is just a tad smaller then the seal to push it home. The place it sits is about 1.5 times deeper than the width of the seal, so make sure it goes all the way to the bottom. I have no clue why the old seal leaked other than it was pretty hard and fit pretty loosely on the shaft. It was not damaged. Oh yeah, remember to put the dang thing in the right way. Oil is in FRONT of it, so when you insert it, with the open side to the back, against the insert tool.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Well now other than the need for a set of input shaft 4th gear set, I now need a main shaft too. I took apart the last of my good close ratio 5 speeds, in fact the one I’ve had rebuilt back 2008-9 and have had in my old 73 Z until its sale, and more lately in my 510. It was noisy in several gears, most noticeably in 3rd and 5th, and when you’re at a stop, foot off the clutch, you get a good rattly bearing noise. Other than that it worked perfectly. Upon disassembly, I noticed really only one problem. The forward end of the main shaft where the little needle bearing seats inside the back end of input shaft, is all scored up. And not evenly. When I put the shaft in the lathe, it seems to have about 5 thou run out. The needle bearing is quite loose on the shaft over the damaged area. These videos show the problem. Dang stroker torque bent the dang thing.... The 6 bearings look just fine, and spin silently. 84EDA2A5-E3BF-4942-B3D7-07C976AA7EB5.MOV EC2D0D51-2FEE-4A0C-A96B-F68E05F9A443.MOV

-

'71 temp sensor thread size

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Common misconception I believe. All the trans I've looked at have a 4th gear pair, just like any other gear. The only thing that is 'special' about the 4th gear set is that its ratio acts as a modifier to all the other gear set raw tooth pair ratios, since the drive power goes through the 4th gear set first, for all gears, all the time. It's only a matter of which of the lock up hubs (on each gear set) is engaged to the main shaft that determines the power path. The counter shaft is engaged and spinning all the time, and since all if its gears are engaged to the gears on the main shaft, THEY are spinning all the time too (except 5th), though they may all be free from the main shaft (if in neutral) or any one of them is engaged (and only one!), which then drives the main shaft at that gears ratio. The confusion comes because for 4th, it's special because when its main shaft gear is locked to the mainshaft, power goes straight through the main shaft WITHOUT first going down to the counter shaft (at the 4th gear ratio) then back up to the main shaft (through that gear's ratio) through the selected gear set. That's why its ratio is automatically 1:1 no matter what the 4th gear tooth ratio is. Hope that's clear as 25 year old GL-4 fluid.....

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

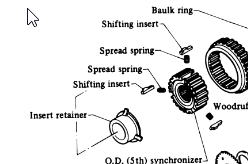

So I've been back in the transmission business again last couple of days. Mostly trying to assemble all the carcasses I have laying around here with new bearings and syncro's to get at least the clusters together. The first I one I completed today is the one that had the very very failed counter shaft intermediate bearing. About the only thing I found that was also "Wrong" with it was the needle shell bearing under the 1st gear on the main shaft that was very very loose. I went to put it back on, and it was rattly loose. Couldn't see any damage, just worn I guess, so grabbed one of the old ones from another trans and it slipped on nice and tight. Didn't buy many new spares. There was also a strange bit of damage I can't explain. You know that "Insert Retainer" on the main shaft on the back of the intermediate plate? The thing with the three fingers? Always makes me think it's home made the way it looks and fits. Three little tabs of metal welded onto a tube. Locks the 5th gear syncro gear to the shaft. Anyway. Yeah, well one on fingers was bent. Toward the back. Couldn't make the shifting insert fit back in at that spot. Must have been an errant bearing cage piece got caught in there somewhere when the bearing just below it went KABLOOOWEEEE. It's quite buried, not sticking out or anything. Glad I caught it. Then moved on tranny #2. This was the one with worn out 1/2 shift fork. Now old bright boy here stole its 4th gear set to build up that truck 5 sp I have with the custom ratio's I detailed earlier, that give me the .68 OD. Wonderful. Unfortunately, if I put the the truck 4th gear set in this tranny, I get stupid ratios, like a 0.9 OD. So now I'm kinda stuck. So now the interesting part. Anyone have a busted 5 speed they kept around for parts, that they are willing to maybe give up their counter gear cluster and the matching main input shaft nose part with the 4th gear on it? Otherwise I have a really nice Close ratio 5 speed without 4 gear..... or any gear actually.... Along these lines, anyone ever see a listing that gives the tooth count of the counter cluster and main shaft gears for the common FS5*71 trans? There are a million places that list the final drive ratios, but not the internal tooth counts. I know the tooth count for the late ZX ones, (got lots of those open), but not the 79-80 and the earlier 77-78 280z. Need to know what their 4th gear tooth counts are to see what the final ratio's compute out to, should I procure some parts from those types...

-

Transmission rebuild NLA parts recommendations?

I really think if your nut threads on just fine, there is no reason to not reuse it. To ensure the staked section ends up in a new spot, make a thin spacer from some brass or thin steel stock. I’ve got a method of releasing the original stake without harming the metal or breaking it. The nut metal is surprisingly soft. In fact I have been successful twice now by simply undoing the nut WITHOUT doing ANYTHING to remove or push up the staked part of the nut! It just gets pushed up as it engages the threads. That 2 ft long 1-1/2 wrench makes it easy to twist that sucker right off. Of course you’re all cringing, “how dare you risk buggering up the precious threads on the shaft, you monster!” But in every case so far, there has been 0 effect on the threads. The shaft/thread metal is about 15 times (professional estimate...) harder than the nut. Then when I put the nut back on and torque it down, I just re-stake in the same spot. Yes after a couple of these I’m sure the staked area will fatigue and break out. Then do the spacer thing to move the stake location. Regarding the reverse switch, Every one I’ve ever taken out hasn’t had an oring or copper crush ring, and new ones I’ve purchased don’t come with them, including Nissan ones. Just clean it and the case where it seats and snug it down. If it leaks, use a thin crush aluminum or copper washer crush washer or a dab of gasket maker goo. Don’t add too much thickness or you may cause the switch tip to not contact the shift rod and render it intermittent or inoperable.

-

'71 temp sensor thread size

The temp sensor is a straight thread, not a tapered pipe thread. The temp sensor is a two part deal like a brake fitting. Finding an adapter will be a trick. I feel quite bad not knowing the thread spec off by heart....

- Parts for Sale: Datsun FS5W71B Close Ratio 5 Speed Transmission

- Parts for Sale: Datsun FS5W71B Close Ratio 5 Speed Transmission

-

1978 5-speed transmission Tail-Housing Removal?

Well I tried my fancy azz press tool on a “fresh” tail housing pin. Not quite perfected. It was not pushing dead straight and the threaded portion began to bend. Quite happy it didn’t snap. resorted to more heat and a punch with the fancy azz new support tube/angle iron. Still no joy. Still too much bounce in the system. Decided to try the air hammer. Machined one of the tips with a flat and 1/4 hole to catch the end of the bolt. Well I have to tell you, it popped free in about 2 milliseconds of pounding. I suppose I had loosened it up a bit with previous attempts. Let’s just say that’s true... For me, the right thing to do is to just use the dang air hammer, making that hole in the side of the case first if you have to, and plugging later. Having decent backup, even a chunk of wood wedged in there, would be plenty.

-

Tim's 1978 280z

Aha! PM=Personal message. Click on my screen name, zKars, then when the new window opens, find the message button. Click it and type your message. That way we can discuss details without polluting the thread.

Subscriber

Subscriber