Everything posted by zKars

-

Brake Drum Removal - Astro puller endorsement

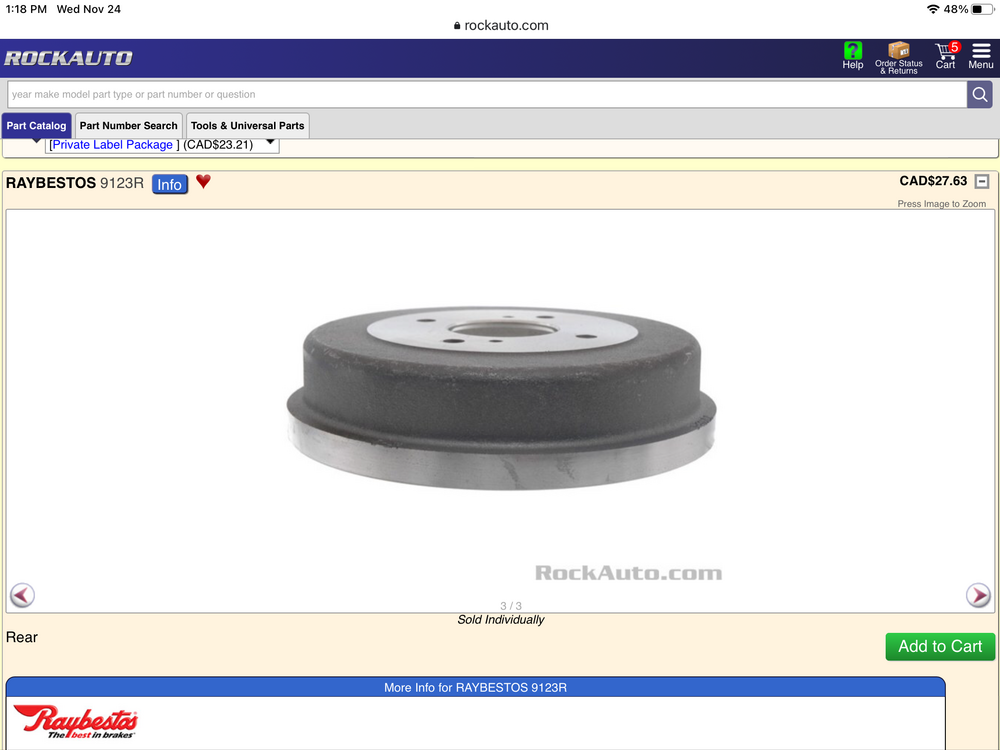

I’ve struggled with enough of these nasty corroded on drums to take the plunge with this puller. Thanks for the part number. Just finished another session of MAP gas heat and 2lb sledge blows that always ends up with drum damage to some extent. While I’m here, I’ll also share a related issue we all need to check each time we get one of these nasty super-stuck drums off. On the second last 71 I worked on, someone had gotten the drums off for me, (thank you thank you thank you) but for the life of me I could not get them to go back on and sit flush. Once I studied them a bit, it was obvious. The first 1/8 inch of the inner circle of the edge of the aluminum drum had actually come off (more like fallen apart) and was stuck to the face of the stub axle around the raised center section! Because that material was un-even, the drum only when back on flush if you got the clocking right so the bits (on the hub) and gaps (on the drum) lined up again! I had to chip that hard aluminum oxide residue off of stub axle face all around the hub center with a chisel. So if your struggling with rear wheel vibration, maybe your drums are sitting tight to the stub axles. Oh! And another hint, this one gleaned from the 510 world. Their drums have two or four M8x1.25 threaded holes in the drum face between the studs. You just thread in some bolts and these press on the stub axle face and pop the drum right off! Technically you could drill and carefully tap some holes in a stuck Z drum (with a bottoming tap) and use the bolt trick, but maybe do this to new drums before you put them on to prevent any and all future grief. Here is a picture of a new aftermarket 510 brake drum from Rock Auto. Note the extra pair of holes.

-

Lots of new repair panels introduced by KF Vintage JDM

There stuff is amazing and accurately done. Got a shed full of it. Almost makes me want to take on one more major rust repair challenge. There is this somewhat rusty 71 in storage that I should.... no, yes, not, yes. ah dang it... And more exciting, is that they are starting to do 510 stuff as well! Be still my beating heart

-

Parts for Sale: Air Flow Meter Clear out. AFM 75-83 Z and ZX

View Advert Air Flow Meter Clear out. AFM 75-83 Z and ZX I have WAY too many AFM's in stock for 75-83 Z's . I'm talking 15+ See the list of part numbers in the first picture. $50 each. Buy in bulk for amazing deals! Give one to every member of your family for Christmas Shipping costs on the buyer, paypal for US buyers, e-transfer for Canucks. PM me discussion. Advertiser zKars Date 11/22/2021 Price $50 Category Parts for Sale

-

Parts for Sale: ECM ECU EFI Control Module ECCS for sale

View Advert ECM ECU EFI Control Module ECCS for sale I have WAY too many Bosch EFI ECM's in stock for 75-84 Z's . I'm talking 20+ See the list of part numbers in the first picture. $50 each. Buy in bulk for amazing deals! Give one to every member of your family for Christmas Shipping costs on the buyer, paypal for US buyers, e-transfer for Canucks. PM me discussion. Advertiser zKars Date 11/22/2021 Price $50 Category Parts for Sale

-

MIRROR FINISH ON PISTON WALLS

Not sure this is helpful. Under just the right conditions of light and angles, I can see remnants of home marks, but overall they are remarkably smooth. First four are all cylinder 1. Last two are the notches cut in #1, and 3td last is cylinder 6

-

MIRROR FINISH ON PISTON WALLS

Yes pictures are definitely in order here. Will comply shortly, I hope they convey the smoothness. Long block is block/pistons + head, short block is block/pistons only.

-

MIRROR FINISH ON PISTON WALLS

Back to the original topic (harumph….). I’ve a L24/N42 combo in a 72 with crap for compression. 100-20-20-20-50-90. Oh oh…. This was an engine free spinning but not run for 10 or 20 years, cold with 10cc of oil added through plug holes, cranked until engine got oil pressure, which was almost immediately. Not number matching block, so something someone stuffed in. Block number is 90xxx, chassis has 160xxx mi. What’s left of it… So why the poor or absent compression? Did someone not notch the L24 block for the N42 exhaust valves? Bent valves? Not likely, #1,5,6 has SOME compression. Pulled the N42 head, its been rebuilt at some point, clean, all new exhaust valves some new intake valves, AND!!! the SHINIEST smoothest almost 99% no more hatching on the cylinder walls that I have ever seen. Stock 83.00 bore. This thing must have 500,000 miles on the short block. No matter what block I’ve seen (not rebuilt) the stock hatching is plain for all to see., Not this thing. Good new might be, fresh hone, fresh rings, and it might just drive away happy. Oh, and bores had been notched. Someone new enough to do that when this N42 head was put on, but didn’t bother to check the state of the bottom end. I suppose that’s why I’m parting out a rusty 72 now…..

-

The Pinnacle of Ignition Technology!

It’s all yours for the price of shipping. Including the main box if you want it.

-

The Pinnacle of Ignition Technology!

-

The Pinnacle of Ignition Technology!

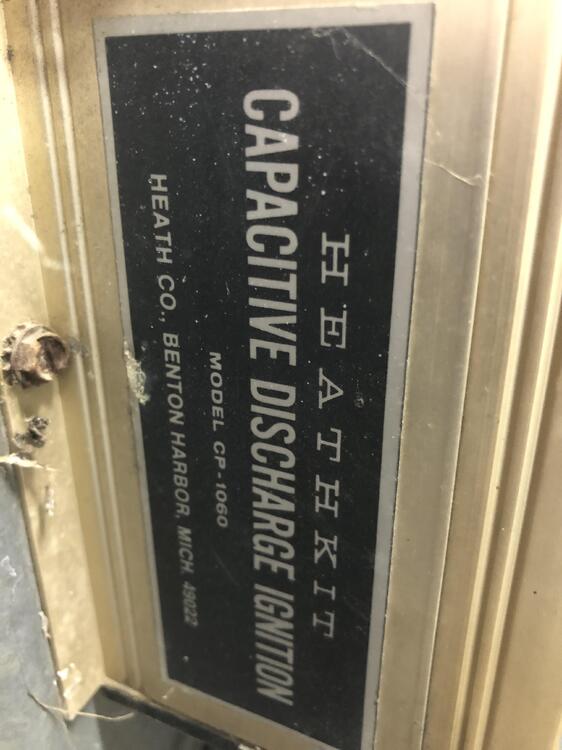

That looks nearly identical to the Heath unit. Even that little red terminal board on the end of the leads looks the same as what I saw on mine before I un-ceremoniously chopped all the connections off the coil. The distributor was still using points, I was kind of expecting to see some old optical coupler stuffed in there, but no, still depends on the points to trigger spark. Definitely first generation stuff.

-

The Pinnacle of Ignition Technology!

Here you can see the Model Number and serial number. Just barely. CP-1060 is the model number. https://www.radiomuseum.org/r/heath_capacitive_discharge_ignition_cp_1060.html https://www.physicsforums.com/threads/heathkit-model-cp-1060-capacitive-discharge-ignition.929262/ This tag is about as sun baked and faded as the rest of this 72…. Best I don’t look at the google links, I don’t have time to be soldering a Heathkit oscilloscope or something silly…

-

The Pinnacle of Ignition Technology!

Heathkit has a place in my life for sure. My Dad and I built a number of kits in the late 60’s including, if you can believe it, our first color TV. Then shortly after we added the remote control option. It was an low ultra sonic transmitter. I could hear the beep tones when you push the buttons. The volume and channel knobs were powered and turned by a little teenie weenie fan belt and motor. You could see the knobs spinning from across the room! It definitely drove me to being the hands on tinkerer and eventually EE that I am proud now to be.

-

The Pinnacle of Ignition Technology!

In the most recent Z that’s in getting parted, I found what must be the absolute pinnacle of ignition technology. Ok, maybe I’m thinking of 1978 , but anyway…. Anyone remember the brand name “HeathKit”?

-

Front Brakes Don't Work - Need Help!

If you hear air sounds from the booster, but the booster is just rebuilt, right? then not likely the diaphragm is leaking, then maybe the check valve in the line to the booster is leaking.

-

Front Brakes Don't Work - Need Help!

Assuming you mean a few hundredths…. 0.0625 is a 1/16. The reaction disks just keep biting people in the a z z as when you pull the rod forward or out to adjust the tip length, the disk often follows and drops down into the body of the booster, then you put the rod back in and don’t notice the extra 1/4”. Other than that, make sure you bleed the master as well

-

Front Brakes Don't Work - Need Help!

Did you check the clearance between the end of the brake rod sticking out of the booster and the inside of the master where it will touch? I’m guessing there is way too big of a gap. Should be 1/32 or 1/16 max. Also check and make sure the reaction disk is in place.

-

Parts Wanted: 280z stock right front lower valance

I should have a couple. Let me look and see what’s there. I actually need a 240 lower valance three piece set for 11292 if anyone has one…..

-

Fuel Line Blockage - New Cleaning method

Small addendum to complete the thread. After hooking up the stock mechanical fuel pump, and getting the car started last night (another victory to discuss elsewhere) the dang thing would run for about 5 minutes then run out of gas. Change pump, same thing. It took several rounds of back purging with compressed air into the tank, then circulating the 20 litres of fresh gas I bought from back to front using a nice big external 12v fuel pump to finally get the line to flow freely. There is likely still some spooge in the tank that was getting sucked up and partially blocking it, but its fine now. Hopefully it will dissolve in the fresh gas. Point here is, it might take several days and persistence, but you too can save a gas tank. Now if it’s rusty, that’s a whole ‘nother ball of wax. Or flakes.

-

Fuel Line Blockage - New Cleaning method

No one has asked how I shook the tank when it was full of thinner. Tank is in the car, right? Take rear wheels off, stash under car. Place floor jack under diff. Jack the back end way up, let the back end down as far as I dare. Jack the back end up, let the back end down. Etc etc etc. Got a great arm workout! If you jiggle the jack handle side to side, the whole car wiggles a little too. Front end was on jack stands too.

-

Fuel Line Blockage - New Cleaning method

Just let it run out. It is highly evaporative and won’t stick around long. Blow compressed air through to get it all I suppose. I’m hoping whatever is left in the gas tank will add a little octane boost!

-

Fuel Line Blockage - New Cleaning method

The fuel pump and carbs were simply dry. No Goo. Just needed to cleaned and lubed and set up again. Hope to hear VROOOM today. Next challange might be the coolant system. Found this. Might now be a good sign….. Having spare parts like a speedo cable I could adapt is the key to this, but if you don’t have one, any speedo cable from a junk yard car could work just the same.

-

Fuel Line Blockage - New Cleaning method

Pretty soon a stream of lacquer thinner started to flow. I ran a litre or so of the stuff through a couple of times and called it good. Clearing the tank line was the same deal. I put a section of hose on the tank outlet, about 12 inches, just so that it would curve back out toward the wheel well so it was easier to feed the line in, and just drilled without the funnel and filler for a bit since that is just a short section of hard line in the tank. That too work lickety split and the line was freed up. Air pressure blew out the rest of what was left. Yahoo! Now the goo in the tank was taken care of by 2 gallons of lacquer thinner poured in and sloshed around for a couple of hours and drained out, then put back in, drained out, repeat a few times.

-

Fuel Line Blockage - New Cleaning method

After about 15 minutes of drilling, and pushing it in and pulling it out, I saw some magic at the other end of the line. A slow and steady drip of goo coming out of the other end! C9116DD0-8DCC-46B1-BB93-33EA809B0F06.MOV

-

Fuel Line Blockage - New Cleaning method

Now the pretty pictures cause you’re getting bored of my lengthy explanations….. Now I have to explain something. While I could drill the line, it didn’t clear it. I had to then move to stage two, which was to hook up my lacquer thinner soak funnel and line, then drill down through that, which got the thinner down into and distributed through the fuel line. 11D0252B-B714-45B5-8269-D969D272A91C.MOV

-

Fuel Line Blockage - New Cleaning method

Last week I was parting out a rotten old ZX and one of the things I pulled out and tossed was the speedo cable. Got one of those in stock already and they don’t work on S30’s. Then I start thinking about the rotating core wire. You don’t suppose…….. I go grab it, and have a look. Its pretty long, like about 7 feet long, and has a diameter of about 1/8” or so. real flexible, but the end has stiff part about 1” long that ground down square, like they welded that section to lock the spiral outer core to the center so it would grind down without fraying. It’s too long to make any decent turn in the fuel pipe. Dang it. But if I cut it down to about 1/4” of hard square end it might! Chopped it off, and I chuck the other end of the thing in a drill, and start stuffing the chopped off end down my fuel line. Well I’ll be horn swaggled! That thing digs in and heads on down the line making all the bends along the way.

Subscriber

Subscriber