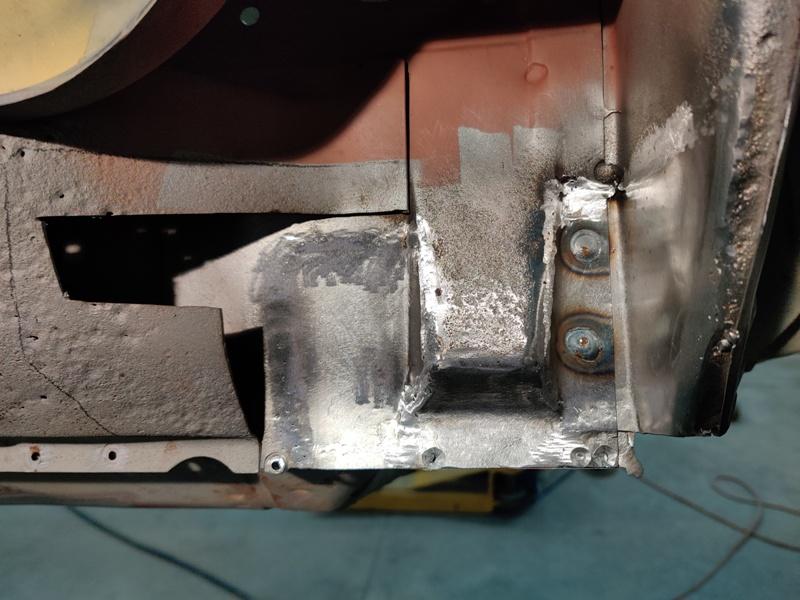

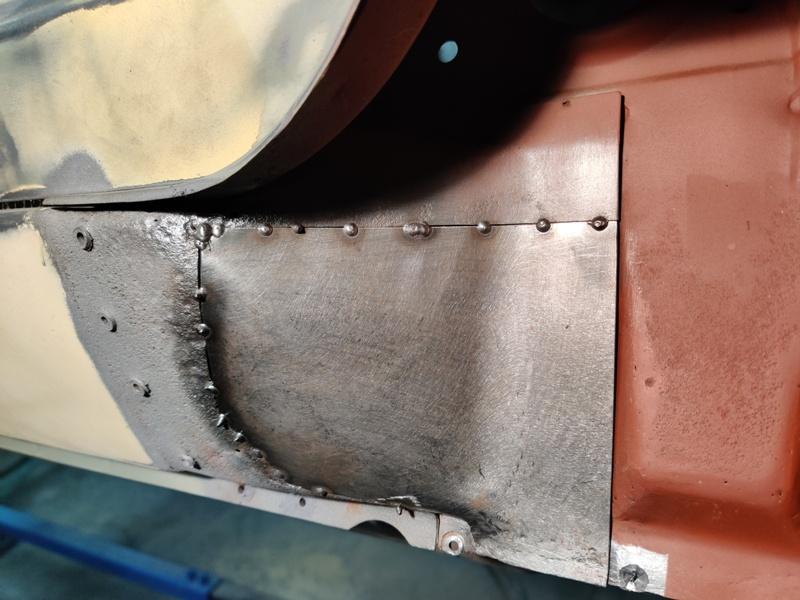

I made some good progress yesterday. As always, clicking on the image will give you a larger picture. Rosette welds on inner panel and finish grinding on wheel house repair area, marking out where to cut on the rocker curved surface:

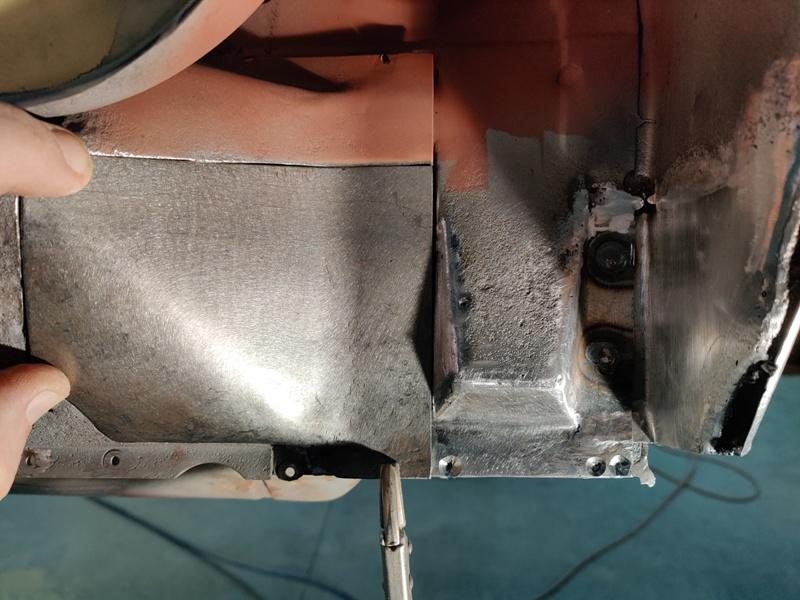

Trimming replacement rocker piece to fit (no overlapping joints):

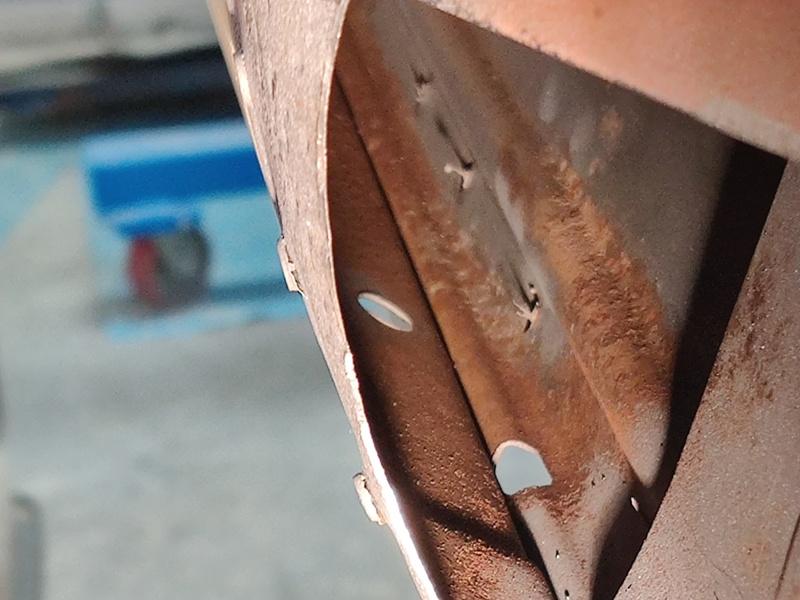

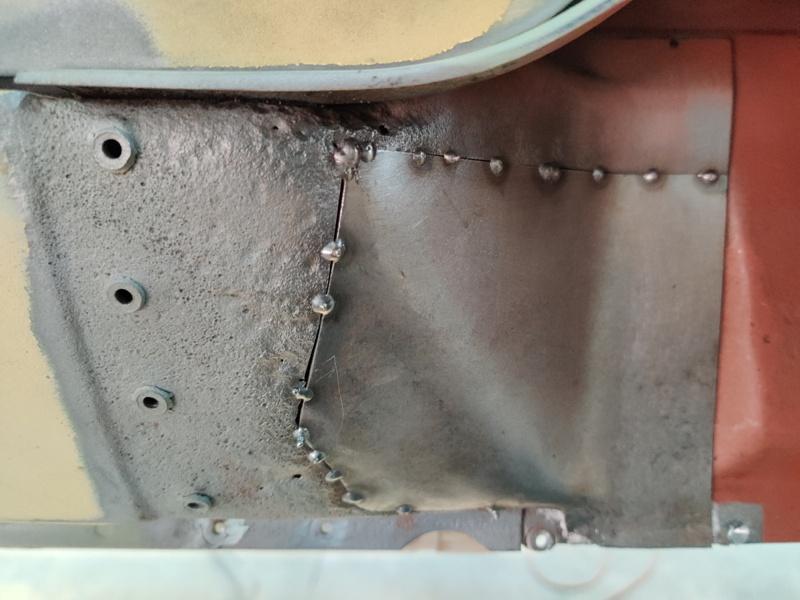

Fit is decent. After removal of the area being replaced, I took some pics showing the inside of the rocker:

Inside the rocker looks very good. Starting to tack the new panel in:

Several angles:

Continuing to weld all the way around:

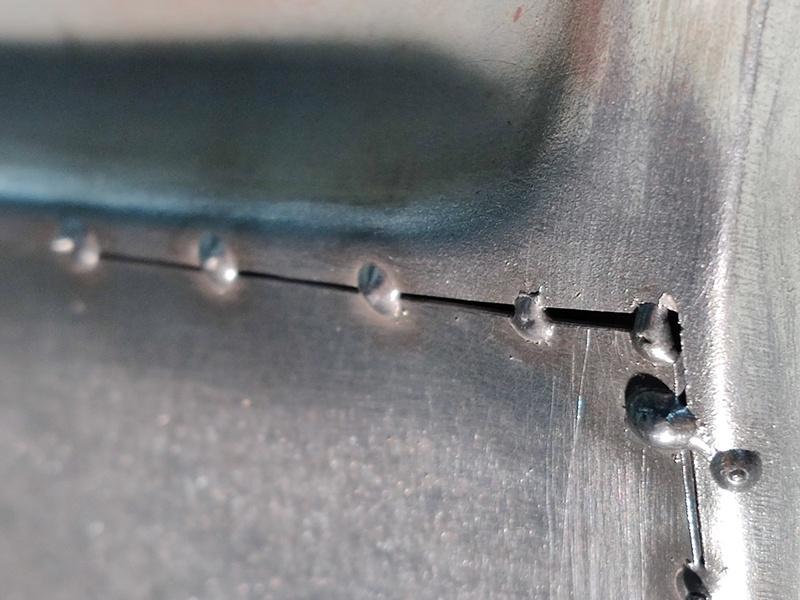

Just a small spot that needed to be closed:

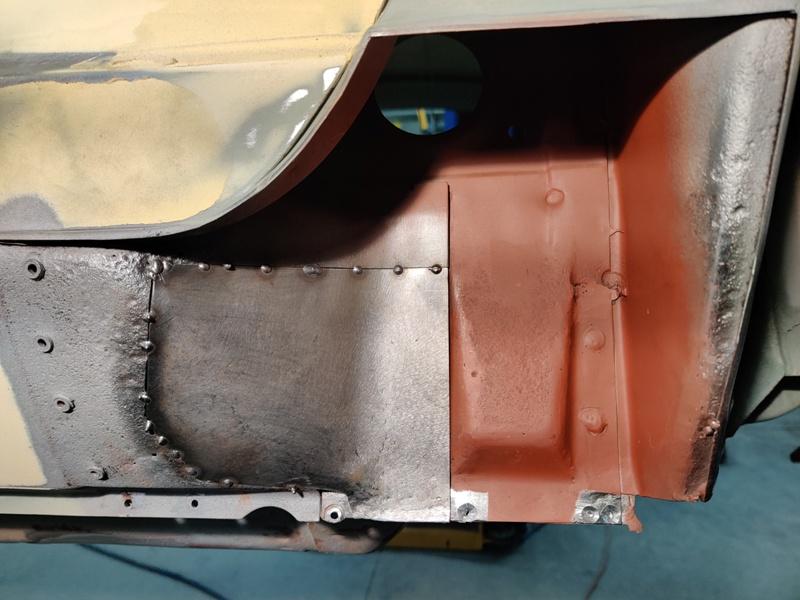

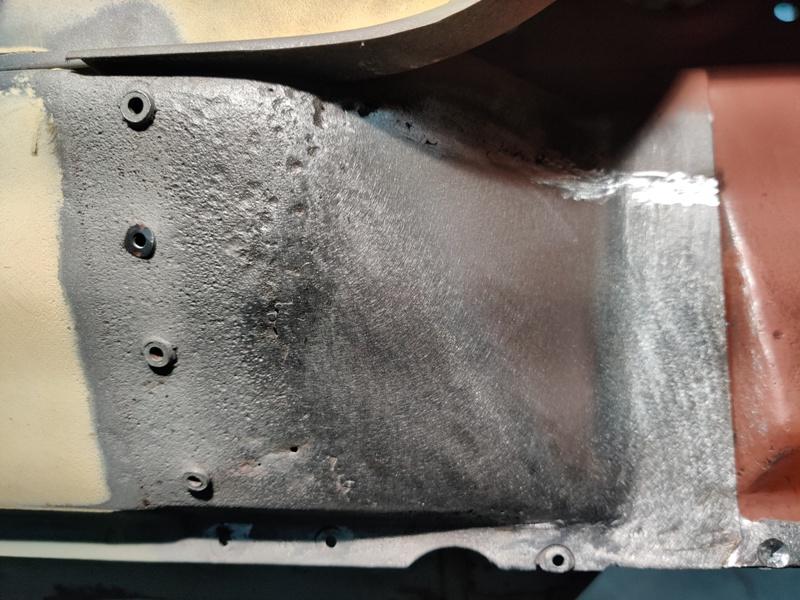

Grind down welds - finish work:

More rosette welds where needed. Additionally, I used a small amount of fiberglass body filler in a few strategic areas. Fiberglass body filler is 100% waterproof. And I learned recently that it is a good idea to use it on certain weld seams like these to fill tiny holes that are present after welding and grinding down. Additionally, I wanted to fill the pitting and couple of holes in the rocker panel in the area that I did not replace.

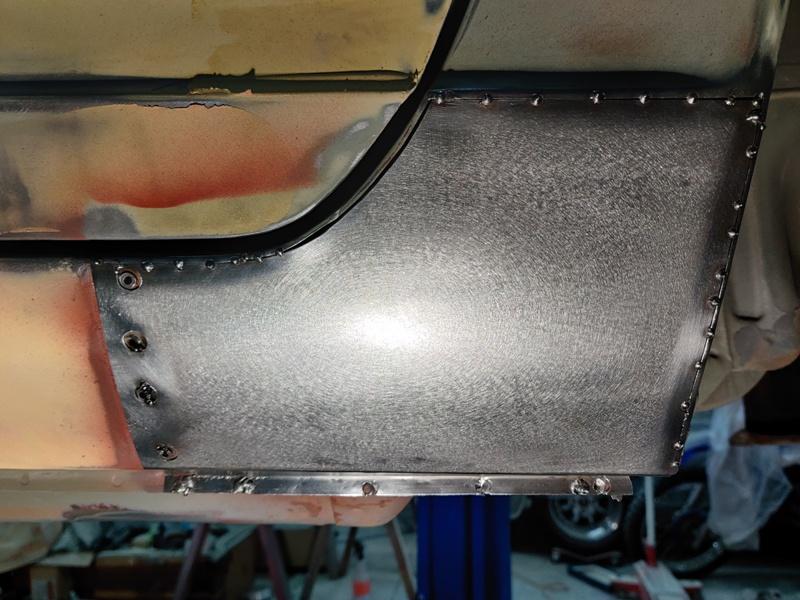

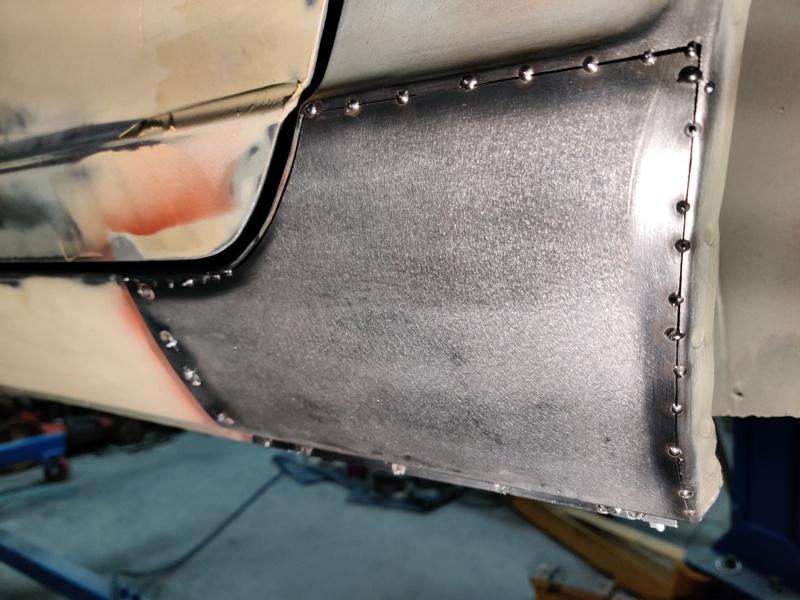

Finish repair of inner panels in red oxide primer. Final fitting of outer replacement panel. Taking time here to get the fit dead on is really important. The finished result after grinding down the welds will come out much better if old to new panel alignment is 100% level and weld gaps are present but don't exceed 1 mm.

New to old panel fit is good. The gap got wider than optimum in a couple of areas (middle photo):

Front edge fit. Door gap in corner corrected for better gap consistency:

There isn't much more welding and finish grinding to do here to complete this part of the project. Body work elsewhere on the panels is probably about 75% at a guess. I am going to be spraying the whole thing and all loose panels in epoxy primer one more time, then the high build primer, and started guide coat sanding.

Subscriber

Subscriber 2Points1,286Posts

2Points1,286Posts Subscriber

Subscriber 1Points381Posts

1Points381Posts

.thumb.jpg.5773de9e8b4fb1e6e8ae94ad9ca5638e.jpg)

.thumb.jpg.0e15ff6d68903030860de7e52c077255.jpg)

.thumb.jpg.d2bd9602f29cc4bd2e07e82ca8b5005c.jpg)

.thumb.jpg.c9c2b6eeca68b6a00fd82c717d6ddc83.jpg)

.thumb.jpg.2266c5e8920524521450406020fb6aa6.jpg)

.thumb.jpg.b054fec78b2be911938a6cf18f7c7c10.jpg)