I started the car from dead cold a couple of days ago - this was after using the Uni-Syn to measure flow through each carb while the choke was in operation. I am very happy with how car starts now with the choke. I have also eliminated my sticking nozzles by bending the "Connecting Plate A". This is the flat bar part of the linkage that attaches to the bottom of the nozzle. Slight bends to it removed sideways force being applied to the nozzles. I had to do this for both carburetors.

And, by setting the throttle plates firstly, to open to the gap specified in the factory workshop manual, and secondly, to achieve the same flow rate in each carburetor as indicated by the Uni-Syn flow measurement tool, I believe I have set the "starter interlock opening" on both carburetors very accurately, and I have achieved a well functioning "starting mechanism".

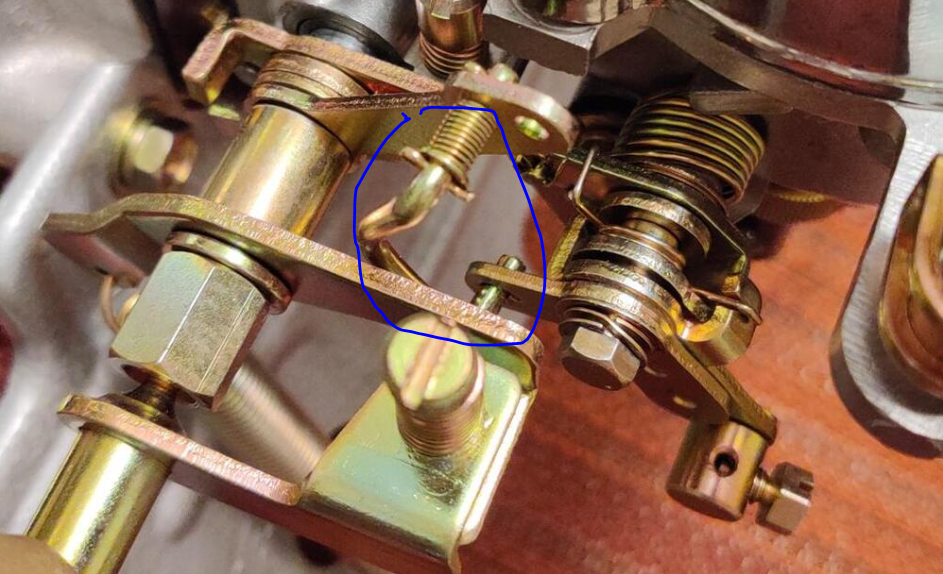

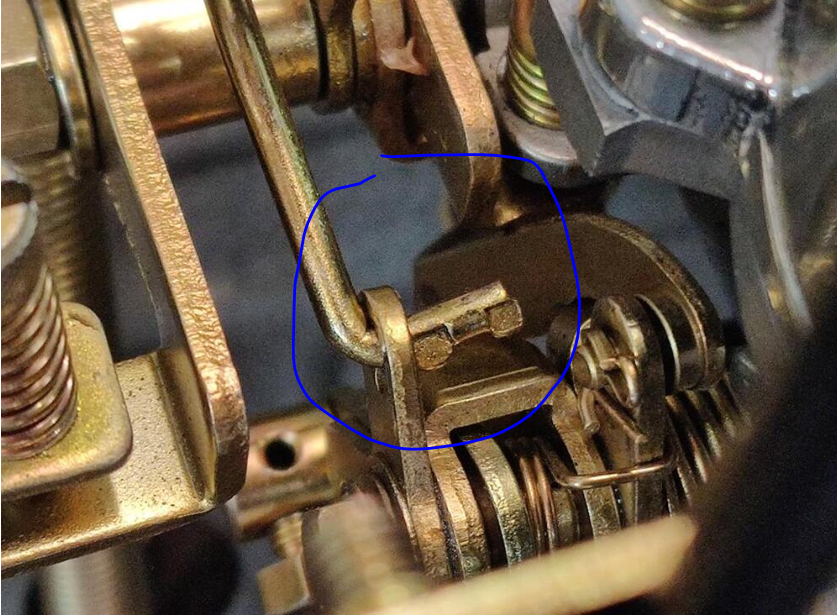

The first step is to get the gap between the bottom edge of the throttle plate and the carburetor bore (as measured by a piece of ductile wire which I hammered to the right thickness and then used as a feeler gauge) to the .0232" to .0271" which is specified in the factory workshop manual. The second step is to start the car and set the "choke" lever to a spot where the engine is running at a fast idle speed (with the starter interlock acting on the throttle plates in the carburetors), and adjusting the "bent" connecting rod. This rod is circled in blue here:

By bending it either more or less at the kink, you adjust its length, which changes the amount that this starter interlock linkage opens the throttle plates via the operating arm to which it is attached.

When I was working on resolving my sticking nozzles a week or so ago, I managed to break the connecting rod on the front carburetor. I have since figured out what happened. When the screw holding Connecting Plate A to the bottom of the nozzle is removed, the starter interlock linkage (which is spring loaded) will forcibly move itself to a position where the bottom of this connector rod (blue circle in this pic) can shift laterally. In this picture, the rod on the rear carburetor has indeed shifted. It needs to be shifted to the left, so that the arm is located on the rod between the two pinched spots.

The two pinched parts of the rod can align with the "key hole slot" in the linkage arm. When they do that, then the rod can shift out of its correct position as seen above. I did not notice this the other day, and when I couldn't bring the linkage back down to attach Connecting Rod A back to the nozzle, I just applied more force. The bottom of the rod had one of the pinched parts in the "key hole" on the attached linkage arm, preventing rotation at this joint. When I applied more force, this end of the rod twisted and broke.

So, that is something to watch out for if you decide to work on your sticking nozzles!

Subscriber

Subscriber 4Points1,282Posts

4Points1,282Posts Subscriber

Subscriber 4Points2,228Posts

4Points2,228Posts