All Activity

- Past hour

-

getting 1977 280z started

1980 EFI Bible.pdf

-

Yarb started following getting 1977 280z started

-

getting 1977 280z started

@Toiletduck34 Where did you find this reference material?

-

getting 1977 280z started

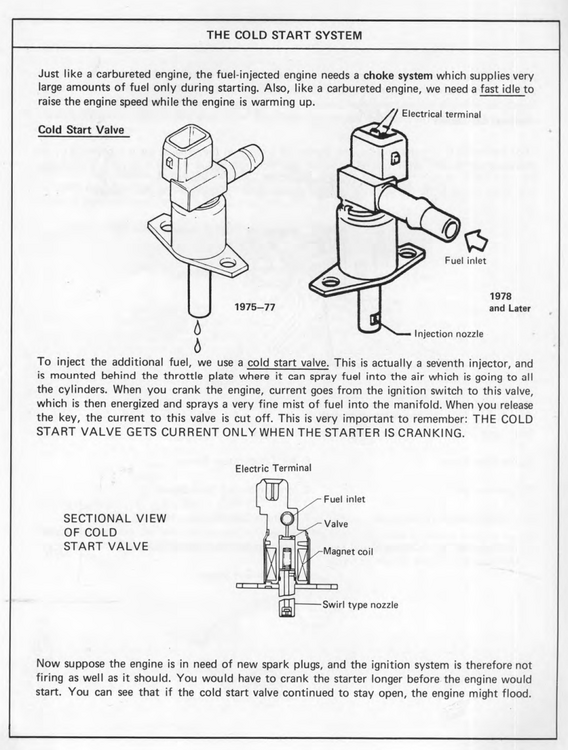

sorry im refeering to the cold start valve. I thought i wasnt getting enough fuel after the initial start and checked the fuel pump and its sending fuel, the filter is staying full. there has to be something that stops sending a signal of some sort after the start procedure because I ran a test. Test: started the car and let it run for 8-9 seconds. the moment i hear it start to fail i click over the egnition for just a moment. the starter grinds for a milisecond... BUT the engine continues to run. I did this 4-5 times to let it run for ~1 minute and it idle perfectly. ****maybe im only getting gasoline from the cold start valve... when it stops im not getting anything from the 6 injectors.****

-

getting 1977 280z started

-

Z Story Contact

Sean, you need to improve your reading and comprehension skills. My messages are clearly meant to help the guy find you. And my second message implies that it was his fault you didn't want to reply to him. Both messages are in your favor. Why DM a guy who doesn't respond to a customer's messages? And why try to help a guy run his own business? Not my responsibility. You're way off base and not making sense. Good luck with your business.

-

w3wilkes started following Z Story Contact

- Z Story Contact

-

getting 1977 280z started

i added a new fuel filter a few days ago. I ran the old fuel out with the pump and added about 5 new gallons, ran that through until it cleared out. it should be good enough to keep it running. Im leaning towards now the cold start sensor and the thermal switches. still trying to understand all these system. these sensors are ~50 years old, im sure they arent working perfectly. I think im to the point i know the engine is good. i want to tear this entire engine bay apart, clean, replace and start from fresh.

-

Z Story Contact

The op had the wrong contact info and posted that. I apologized. Stfu? Okay I'll remember to do that in future post. Kindest regards Pip. Cliff

-

saturday night music thread

I've been stuck on this album for a couple of weeks now. I'll put on something else and after that finishes I'll say to myself... Let's give John Hiatt - Walk On another play.

-

getting 1977 280z started

How long since a new fuel filter up front on the passenger's side? Sounds awful familiar of a clogged up tank. You can run a hose before the pump to a gas can to bypass the tank as an easy test

-

getting 1977 280z started

I can still learn! Yay? https://en.wikipedia.org/wiki/Toilet_Duck Toilet Duck is an American brand name of toilet cleaner noted for the duck-shape of its bottle shaped to assist in dispensing the cleaner under the rim. The design was patented in 1980 by Düring AG from Dällikon, Switzerland.[2][3] It is now produced by S. C. Johnson & Son. The Toilet Duck brand can be found in the United States, United Kingdom and other countries around the world. In Germany, it is known as WC-Ente, previously produced by Henkel,[4] and now by S. C. Johnson (Germany).[5] In the Netherlands and Flanders it is called "Wc-eend", in France it is sold as "Canard-WC" and in Italy as "Anitra WC". In Hungary it used to have the name "Toalett Kacsa". Meanwhile, in Spain, it is sold as "Pato WC", in Portugal as "WC Pato", and in Mexico, Brazil, Colombia, Argentina and Chile as "Pato Purific" or simply "Pato". In Indonesia, it is one of the "Bebek" (duck) line of products, such as Bebek Kloset, Bebek Semerbak, Bebek Semerbak Flush, Bebek In Tank, and Bebek Kamar Mandi.

-

getting 1977 280z started

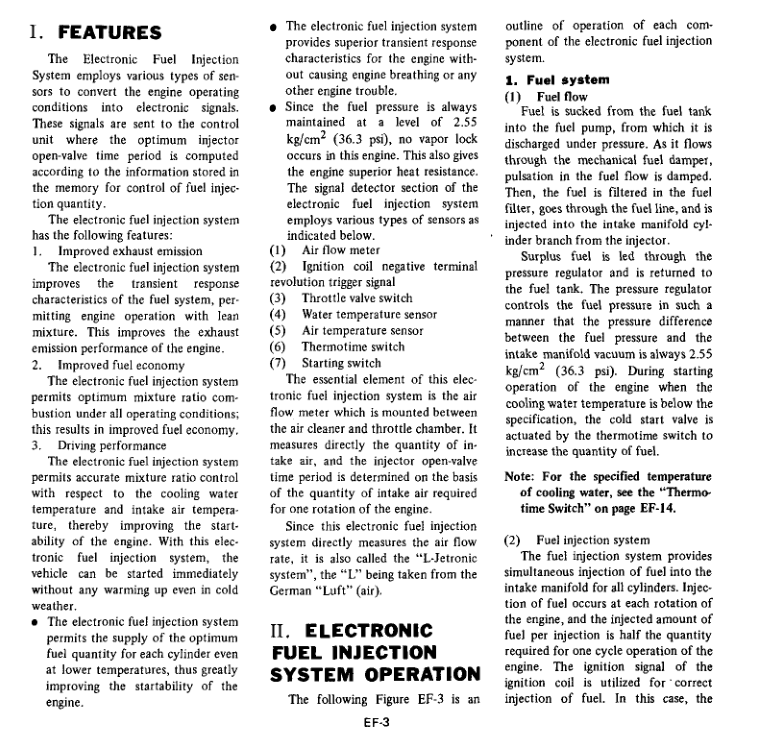

Close up any vacuum leaks to the intake system. All air has to pass through the AFM so the computer knows how much fuel to add. And the big screw with the wide washer head on the throttle body is the idle speed screw. It lets air past the throttle blade. You can adjust it by hand to raise idle speed while you troubleshoot.

- Today

-

saturday night music thread

Well you don't know me as a music snob, just a greasy guy from Alabama, but you need to listen to that album. I'm going out on limb without google.com but that's the last one? P.s When I was young you could flip the needle over for a new one.

-

getting 1977 280z started

its not near close enough to get into the intake. I did test the injectors and they are coming up with 12V now. When i tested them i was testing while cranking thinking both sides would be (+, -) but both sides are showing 12v. i can make it leak anywhere on the fuel rail and it seems to work. its really odd. i dont know how the fuel pressure regulator works but maybe i have too much pressure? Ill check the RPMs. EDIT: RPMs shows, i can keep revs around 800-1000+ and it runs for 10 seconds then stops every time. I engine has warmed up and I tighened the all the hope clamps so gas isnt leaking out and it still runs. Maybe whatever cobwebs were cleaned out since its been sitting for 10+ years. will continue to read and troublshoot.

-

getting 1977 280z started

Which clamp? And where is the fuel leak ending up? Maybe it's getting pulled in to the intake system. At least you know that you have spark. Does the tachometer show engine RPM when it is running?

-

Operator-chan joined the community

-

getting 1977 280z started

UPDATE: Thank you for that information. I have unplugged everything I could from the Neutronics device, though I'm not sure if it's affecting anything. However, I've made a big step forward: I can now get the engine running for a short period of time! I don't understand why, but hopefully it makes sense to someone here. Here's what happened: I decided to clean the cold start sensor. While I was putting it back on, a neighbor came over to talk, and I forgot to tighten the hose clamp that connects to the fuel rail. I started the car, and it ran—but with a fuel leak. If I tighten the clamp back down, it won't start at all. I checked the fuel return line to ensure it's flowing, and it's fine. When the engine does run, the RPM is very low. If I increase the throttle to approximately 1500-2000 RPM, it runs perfectly for about 9-10 seconds and then instantly dies. This happens every time without fail.

-

getting 1977 280z started

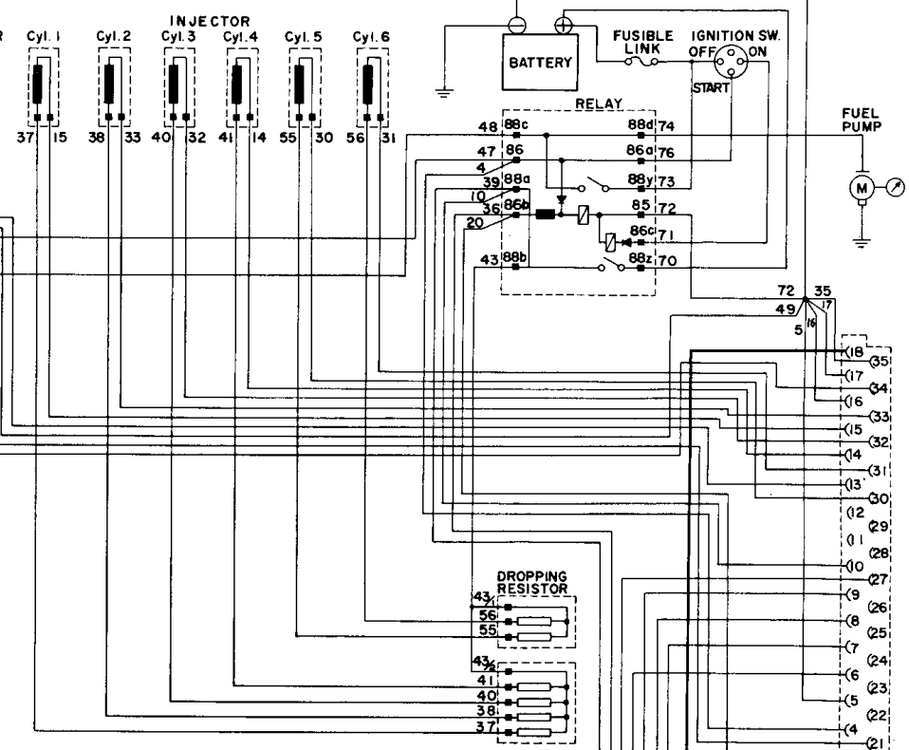

Actually (I think) this only true if all of the injectors are disconnected. It's a parallel circuit for the 280Z EFI. Batch fire injectors. CO pointed that out way back when I mentioned getting voltage on both sides. Or it might be if the injectors on the same transistor are all disconnected (there's two, either 3 + 3 or 4 + 2). The later sequential systems wouldn't do this. Anyway, I have seen 12 on both sides, which was confusing. But can't remember the conditions under which I was measuring. There are other tricks to test the injectors and the injector circuits. Like tapping coil negative to ground three times. But, it's best to do the simple stuff first, probably.

-

1972 240z tachometer not reading nor working with MSD blast 2 coil. Any solutions?

Stock wire? How green (or brown, I mean oxidized) is the copper? That's a long run between the ignition switch and coil. Oxidation = increased resistance. If you take the ballast out of the circuit is it better?

-

getting 1977 280z started

First thing - the AFM does indeed have a wiring connector, it's of Bosch design (as is the entire EFI system in your Z) and it's, like most Bosch connectors of that era, a PITA to remove. If your AFM is in place it will be difficult to see as it's underneath all that. Second thing - you really need to make sure the injectors are opening. It's sort of easy if you have the right stuff, and can be done in place IF you know how to release and remove the BOSCH injector connectors... If for instance you HAD a spare Bosch injector connector with a pigtail, you could put it on each injector in sequence and use a 9-volt battery to quickly apply and remove voltage to the pigtail wires. Yes, a 9-volt battery will open an injector. If you hear the distinct CLICK of the injector opening you can immediately rule out the "crapolla, the injector is stuck closed". (here I have to say: one side of the battery needs to be permanently connected, the other (doesn't actually matter which) needs to be loose so you can just tap the exposed wire end to the bare pole quickly. You DO NOT want to hold voltage to the injector except for a very brief period of time - that's how they work, milliseconds... IF STUCK they in truth need to be pulled and cleaned (and flow balanced) by a professional shop OR replaced - BUT most of the time I can get a stuck injector opening again by rapidly tapping the wire for awhile (several seconds or more) until I hear it clicking. That may help you in your effort to get it running even if things are not all perfect. The injector is a coil (an electromagnet) so both of those spade connectors are actually tied together by the coil. You should see that when testing with an Ohm Meter - leads placed on the two should show a steady Ohm value. If that circuit is OPEN, the injector is bad and you can't fix it. Now, you can also test that the injectors are getting voltage - they should ALWAYS show battery voltage if the Ignition switch is in the ON (or Start) position. And, because it's a coil, you WILL see voltage on BOTH sides IF the harness wiring is connected to the injector. If the injector connector has been removed you will see battery voltage ON ONE SIDE of the connector an not the other. The ECU asserts a ground to the other side of the connector to open the injector and, like I said, this happens FAST. You will never see this activity with a meter (oscilloscope yes). Because they are basically a coil IT DOES NOT MATTER which side gets power and which gets a ground signal. Most people wire the "hot" side consistently to one side of the connectors, BUT they don't have to! There is NO "+" side or "-" side. If there was, the injector would tell you.

-

-

1973 Exhaust Downpipes?

I would like to know the casting code, please, on the 1973 OEM exhaust manifold ? Are you selling a '73 downpipe ?

-

Z Story Contact

Hi all and with my profound apologies for not having replied sooner - somehow windows was blocking my logon ! siteunseen and zed head, thanks for your negative assomptions - great attitude between Z owners in the community ; seriously, if you having nothing constructive to say - stfu please or at best - DM the guy with your unfounded fears. :-) Kind regards, Sean

-

saturday night music thread

That's a late one. Never heard it. I was listening to them on vinyl on a cheap record player with a penny taped on the stylus.

-

getting 1977 280z started

p.s. did you measure voltage across the injector connector pins or from one injector connector pin to ground. The second way is the correct way. p.s. 2 you're falling in to the "it measured good" trap. We need the numbers.

-

getting 1977 280z started

Did you disconnect the Neutronics thing? The EFI computer is sensitive to the tachometer/coil - signal on Pin 1. I see a "Power/Tach" label on the box, implying that it's also connected to Pin 1 or the coil. If the Neutronics box is shorted it could cause a no-start. Plus, there's no guarantee that it ever worked. Does the tachometer needle move when cranking? I also see some open vacuum lines in your picture. https://www.classiczcars.com/forums/topic/69545-1977-280z-ignitionfuel-system-neutronics/#comment-679115

-

getting 1977 280z started

I tested the voltage going to the injectors and I'm getting right around one volt or less.