Everything posted by 240260280z

-

[2015] What Did You Do To/with Your Z Today?

Snow-blowed beside ol' Blue shheeesh will it ever stop snowing?

-

Enlarging Rod Small End From 21Mm To 22Mm?

Anyone know of this mod and its success/risk? It is needed to do the 88mm VW piston upgrade.

-

High Oil Pressure

The 77 FSM states oil pressure 50-60psi @ 2000 rpm (warm).

-

Triple Oer Carburetor Troubleshooting - Help

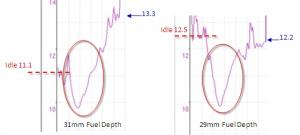

I had a closer look at the data. Here are some observations: The time you are driving from 1000 to 3000 is only ~4 to 5 seconds. It looks like the accelerator pump is coming in and driving the A/F ratio towards 10. (This same "V" shaped dip signature [circled] is evident in all plots after all gear changes...It seems to last ~2 seconds). To remove this extra circuit when collecting data, try idling for 5sec then driving for 5sec at 1000, 5 sec at 1500, 5 seconds at 2000, 5 seconds at 2500, then 5 seconds at 3000 (you will need a nice straight). So no big pushes on the accelerator and slow smooth acceleration. You can also replace the spill jets with bolts to eliminate the acceleration circuit altogether. This will make the data less cloudy and help focus on the right idle jet and fuel level. FYI The 2 second blast low A/F ratio after a shift may be causing your transition bog problem (i.e. a false lean) so it is good to note. The extra fuel squirting on the intake wall (thx to Bryan Little!) from the accelerator pump may cause intake popping if it ignites. Going from 31mm to 29mm seemed go give you a point lower of A/F ratio at cruise (from 13.3 to 12.2). However the idle seems to be richer at 31mm (11.1 vs 12.5)? Were the idle enrichment screws the same for both of these runs or was the throttle pumped at idle? This is a bit confusing? With respect to your timing, keep it at 15 degrees at idle while tuning. triples like lots of initial advance at idle. Your Emulsion tube and main jet will also affect cruise but focus on the tuning with these tubes removed first as you are doing. Also try to disable the accelerator circuit by replacing the spill jets with bolts at the bottom of each fuel bowl. Bottom line: It looks like 31mm fuel level and the 57.5 idle jet can give you a nice fuel average distribution ~ 13.5. Just get rid of the rich-dip to evaluate better. If you want to tune to 12.5 A/F, the 29mm fuel level and 57.5 idle jet will be the ticket.

-

Triple Oer Carburetor Troubleshooting - Help

Try raising the fuel to 27mm then make a run with idle enrichment at 2 turns. Then turn the idle enrichment screws in until the idle air fuel is 13.5. Here is a graph of how enrichment screw affects idle and cruise.

-

[2015] What Did You Do To/with Your Z Today?

Ordered main bearings, rod bearings, front and rear seals, freeze caps for a new motor build... finally some work on old blue after 8 years!

-

Reminder F1 2015 Starts Today.

Australia Grand Prix 05:00 UT/GMT 01:00 EDT NYC

-

Triple Oer Carburetor Troubleshooting - Help

How does the A/F Ratio track as you gently go from 1200 rpm to 4000 rpm while gently accelerating in 2nd and 3rd gear? How does A/F Ratio track going from 1200 to 4000 rpm while hammering it with WOT. For your mid rpm problem, if it occurs when gently accelerating, you can raise your fuel levels 2mm at a time from their current 31mm level and the leaner mid will go away but you may have to use a leaner idle jets or turn in the idle enrichment screws as the higher fuel level will also affect the idle A/F ratio. For your mid rpm problem, if it occurs when aggressively accelerating, you will have to address the pump jet size. Play with fuel level and report back the data and we can help more.

-

Correct Rpm At Idle And Choke Adjustment On 240Z

Sure, don't worry about the choke. Just make sure that when the lever is pushed to off that the jets are all the way up. A friend of mine is building a BRE tribute car so I just told him about your cam. He may be interested. I'll send an offer when I hear back from him. If you could email me pictures that would be great: philip@atlanticz.ca Thanks!

-

Got Bored So....

Here is a quick reference for your AFM position at 4000rpm with the car not moving (thus not a lot of air flowing into the motor as it has no load). If you hold the motor at 4000rpm the afm wiper should be close to this location:

-

Got Bored So....

The spring tension adjusts how much fuel is added as the rpms (air flow) goes up. If the spring is too tight, the wiper will not go far enough and the engine will run leaner. If the spring has less tension, the wiper will go too far and too much fuel will be added. There is no need to turn the wiper unless it goes too far CW and overshoots the end of the carbon trace when the engine is off. Set the air bypass to it's middle position when adjusting the spring. The bypass changes can only be read with a gas analyser or A/F meter so don't bother with them until you have an A/F meter.

-

Correct Rpm At Idle And Choke Adjustment On 240Z

btw did you want to sell your cam?

-

Correct Rpm At Idle And Choke Adjustment On 240Z

800 rpm is purrrrfect for a nice idle The choke is used primarily to add more fuel to a cold motor because so much of the fuel vapour condenses in a cold engine and can not burn. The way Nissan designed the choke linkage, it does increase the idle ~ 200rpm. Since you are in Panama, you do not need to ever use your choke as the engine is always warm. I would not worry about it.

-

Got Bored So....

Robert, this may help with emissions Adjust AFM spring for the higher rpm a/f Once it is set, adjust the bypass screw in the afm to set the a/f ratio at idle.

-

Got Bored So....

maybe get a cat from a calif scrapped S2000

-

Got Bored So....

Just speculation

-

Got Bored So....

I am wondering if a reverse turbo set up would be the way to go..... a bypass that keeps the mild turbo out during low rpms but closes at high rpms. This way you can have a torquey high compression motor that goes crazy with the mild boost of extra air when you get on the gas pedal. Keep the nice low end torque but lots of power when you need it.

-

Which Way For Manifold Gasket?

concur

- 77 Z Drives For About 10 To 15 Minutes,then Dies.

-

Got Bored So....

1. turbo 2. overbore 3. stroke 4. head and cam

-

240z alternator upgrade (instructions w/ pictures)

I have to refresh and install the electrical system for a friend's 73 so I'll have photos of the harness in a month.

- 77 Z Drives For About 10 To 15 Minutes,then Dies.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

The early 77 used the switch in the AFM to shut the fuel pump off. The logic was that if the car crashed, the engine would stop and not draw air. These caused the AFM door to shut and open the contacts in the switch that send +12V to the fuel pump. Later 77's used a pressure switch on the oil pressure sensor (next to oil filter). The logic was that if the car crashed, the engine would stop and not pump oil. This caused the pressure to drop and open the contacts in the switch that send +12V to the fuel pump.

-

Timing Chain Rotation To Hole #3

Sorry. If you are on 3 now, stay there and do the full 4 stroke rotation (2 turns at the crank). be sure to stop exactly at the TDC mark on the damper then check the cam mark.

-

Timing Chain Rotation To Hole #3

With the cam on #2 and the chain back on the cam, just torque the cam nut and related (washers eccentric, etc) then you are safe to pull the screw driver/wedge. Next rotate the crank around CW twice until you are seeing 0 on the TDC damper mark then look at the marks on the CAM to see cam timing.