Everything posted by madkaw

-

Saving- 04858

The next thing to attack is the firewalls . I can’t finish the passenger upper frame because I need access to spot weld the firewall panel . The firewall is sandwiched between the inner fender wall and outer . I also have an issue with the passenger side firewall panel from KF . The drivers side worked out pretty sweet and I should be able to do a decent job welding it in . The biggest obstacle is that I wanted to preserve the vin# that’s stamped on the wall so I had to cut around it . The passenger side doesn’t line up right as you can see but the pics . They said they will send me a new one . I think the panel wasn’t square on their stamping machine . KF has been really good supporting their products . I’ll also add that their drivers firewall panel does not include the doubler for the inside

-

Saving- 04858

I didn’t make the larger pieces of upper frame rail. Same car I bought my roof from I also bought all his straight scrap pieces . It was enough of a challenge to make that 1” filler strip between the pieces he sent me - ha . I don’t have the tools to do that complex of bends and curves. The tool is just a right angle air grinder with a Roloc sanding discs . I use that tool more than most . I have cut- off wheel mandrel and scotch bright disc options . I actually have 3 of them with different mandrels on each .

-

Saving- 04858

The passenger side was exceptionally bad in this car relative to other sections . The car sat outside on a rotisserie for years on its side with the passenger side down . Probably gathered water from rain . When I finally dug into this I was grateful I had scrap pieces to do some of these repairs . Somehow I was missing a hunk that I had to make - but it’s was a small hunk . Removing the firewall and all its spot welds really tears up the kick panel . That and rust required some patching work to make the kick panel strong again . I probably will end up ordering the panel for under the battery tray from KF Vintage . I don’t think my skills are up to fabbing that panel .

-

1970 drivers side A pillar section

About rust free section from a series 1 . Not using this so up for sale. Hard to find a clean section like this . I’ll ship anywhere 200$ Email Sfinnerty1018@gmail.com

-

Rocker arm noise when accelerating in 3rd gear! Timing too advance?

Need a lot more info to help with this . Ignition set up ? Timing at WOT ? Still running vacuum advance ? What year head ? Was the camshaft degree’ed? Camshaft specs ? Engine compression ratio ?

-

Told him to scrap it !

And now he says - I’m out ! I had a hard time reading this guy but don’t think he was ever a serious Z owner/buyer . Good luck - I said Moving on

-

Told him to scrap it !

Now the gentleman has requested I find him a Z ! He says his budget is 35-45k . I should be able to find something nice enough in that range I believe .

-

Told him to scrap it !

He sold it yesterday for 1500$ He did good !

-

Told him to scrap it !

It didn’t even roll and I didn’t see enough to warrant the hassle . I told another z guy that it had a white interior and he should grab it . I don’t have room

-

Told him to scrap it !

I was contacted by a former client that a guy wanted me to look at his 72 that he’s owned since 73! I was glad to go look at it - especially being owned that long by the same guy . I was told he was ready to restore it . When I pulled up to his house I was like - holy $^!# that’s bad . The guy had it sitting in storage and needed to proceed with fixing it up since he was moving . He said a shop quoted him over the phone that it would take 1 year and 60k . I proceeded to let him down . He seemed indignant at first . I told him that sentimental value would be the only reason to even start on this car - and I didn’t think there could be any plausible reason to spend 60k . I also told him the reality that the car would sit at a body shop for 5 years . At the age of 72- he said he might be dead by then . I told him I couldn’t - in good conscience- tell him to invest any money in that car . I said with 60k budget you could buy two Z cars that were nice drivers . In the end he thanked me . He really had no clue about restoration and the reality of that adventure . It did have a crack free dash as best I could tell .

-

L28+(maxima)47 build

I plan on making a driving video just for the sound ! I installed these 75mm stacks from TTT. Their ad seemed humorous about scaring the guy in front of you at the track -BUT-these things sound glorious! Never driven a Datsun race car , but the only thing missing is an open header -lol. OMG they sound good. I hope a video will capture the sound correctly. About everyone I've taken a ride have been blown away.

-

240 Cyl heads

You meant N47 =MN47

-

5 speed from a 720

A 720 unit would be a 71B series which is not great . I would recommend finding a 71C from a 240sx .

-

Saving- 04858

Technics or tactics . They can be a MFers . I use the spot weld cutters you can buy cheaply anywhere . Predrill small hole for center pin and saw away . I did buy a pneumatic drill just for spot weld but it’s limited where it can be used . Finding the center of the spot weld helps to get all of the weld

-

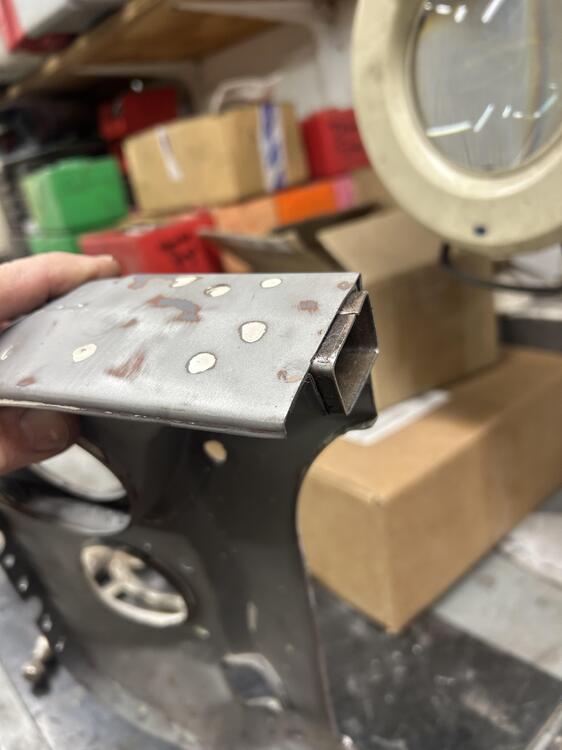

Saving- 04858

I couldn’t close the gap but I could fill it . The reason I made the sleeves was to give me adjustment . Ideally it would have been the perfect gap for a bead of weld . Since the sleeves are close to 3” long I was able to weld it strongly and then cosmetically fill the gaps . I had left over A pillar material which I used to fill that .250” gap .

- Saving- 04858

-

Saving- 04858

First project after getting the roof attached was the passenger front fender support . I had cut up two 240z’s years ago and had a whole front clip left. No easy way to do this either .I was tempted to buy the sections from KF so I wouldn’t have to disassemble the front clip . In the end it worked out .

-

Saving- 04858

-

Screws for the instrument console finisher (ICF)

I like the white face gauges . Where did you get the faces ?

-

Series 1 body parts

Pretty much rust free pieces from a 70 . Drivers side A pillar section and B pillar section . I won’t need these for my project . 250$ shipped for both

-

L28+(maxima)47 build

Is it Charles ? My memory is short . I’d refer you to my thread on Hybridz . I managed to document a lot on there . I also have a thread on the Megasquirt install there . Ask away about anything you read HybridZ3.2 Build EFI N42 / MN47

-

L28+(maxima)47 build

Damn- 5 year update ?!!! I’ve been thru several induction systems including Protunerz . Now running these FAJS . I’d say this package runs better than anything I’ve had on this engine . The Protunerz ran good but I think the runners were too short and fat . I did manage 35 mpg driving to the Woodward cruise last year with that manifold - that’s at 80 mph -windows down! I’ve been blown away that I’ve been able to get these ITBS tuned in so well . First start it idled at 750rpm . I run the cable linkage which like any linkage has to be dialed in correctly . I was always told that when the engine gets hot the idle rpm will climb , but I’ve got these to idle better than my single plenum . These are 45’s . The stacks are 75mm long . I have not dyno’d this package . Looking back at this thread I can say I was running too much ignition timing . Also blew up #6 piston . I run 28 degrees WOT . Finally got smart and made det cans to wear while tuning . I had some pinging at peak torque . I still run a lot of timing at light cruise - thus able to get lean cruise . I think I got high 20’s MPG going to ZCON . I was still tuning on the fly . Though I ran triple Mikunis before - I didn’t think I would do ITBS because I thought they would be to challenging . They are a challenge but glad I did it

-

Electric cooling fan control

I’ll have to recheck my setting for my stroker but I think my fan comes on at 185 and goes off at 180 ? I have an ECU so it turns on my fans at a lower setting at 185 and full speed at 195 .

-

brake proportioning valve

Won’t find this info on FB- lol. I worked on a 72 thru Covid . The guy texts me yesterday that he has no rear brakes . I put all new SS lines in his car and had to clean/ rebuild his brake switch valve . I’ve had the weirdest stuff with his brakes . The O rings failed on the brake switch and fluid was forced from one side to the other back up into the MC . Now his rear brakes don’t work - so after reading this I assume it’s that proportioning valve . I haven’t laid hands on it yet . Looks like I have good reference material here . Wish me luck

-

Saving- 04858

RUST!!! Random pics of rust before I started chopping and treating rust . I’ll put a link to a YouTube video I made regarding Rust911 . The rust seemed bad but my buddy said “ nah- it’s too bad” . He got me started on rust911 . Being a scientist he did controlled testing on various products on the market for treating or getting rid of rust . He’s currently doing a 72 Volvo 1800es. He had treated his car with amazing results . I followed his methods and I’m still using them to this day .