Everything posted by dspillman

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Not really sure what the purpose was. But pretty sure it started with the 73 ? Model.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Fine crushed glass

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Reading through several stories, blogs and after texting with a respected z connoisseur earlier this month …. I heard my “51” called all sorts of names….basket case, train wreck, rusty, good car for parts…. Stoked my curiosity to the point I had to blast at her with the dustless system…… Last year a friend of mine peeled back some layers of paint and bondo, revealing a patchwork of welds and repairs that was somewhat disappointing. I didn’t notice the wide “hips” on that early car as well……I have a pretty good eye for wide hips….. on zs. Did the roof, and rear quarters to hopefully not find that same patchwork of repairs….. not perfect, but it was the first z roof I’ve seen without filler. I’m happy with what was …. Or wasn’t exposed today!

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

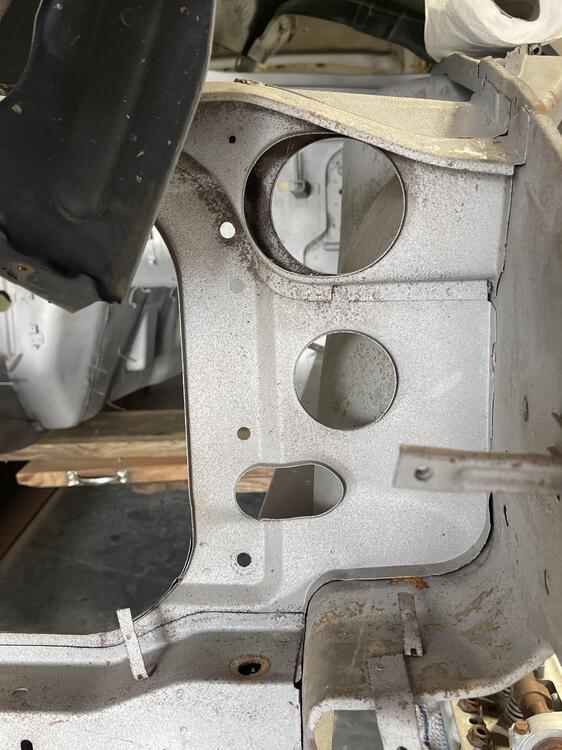

Surprise… Fenders off and removed engine block today, closer examination of radiator ore support area reveals a 73/74 z radiator core support. Lower support was reused. Quite a few differences from early to late supports. Most obvious being 3 large holes in early drivers side, versus 4 in later versions….. Honestly, I expected more surprises by now, The exploration continues….

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Well, I can say that 740 was pressed down. Change over possibly with no sound deadening tar on cargo floor?

-

Early 240 ”69” cars door wiring provisions

Not knowing the exact route of wiring as the factory intended for this rare or never installed light, I think it important to determine if in fact intentions were to have the wires run across the bottom of the door. Wondering if either of your early cars are accessible, and with door panel off to peak in and determine if this little tab is present? If you already know "which is likely" that this tab is present, it would be good to know either way. david

-

Early 240 ”69” cars door wiring provisions

-

Early 240 ”69” cars door wiring provisions

It takes a commitment to cut into a door panel for the Install

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

I learn something everyday …thanks Kats!!!

-

Early 240 ”69” cars door wiring provisions

Im hoping to get a couple of early car owners to peak inside their doors and see, and try to determine when this tab disappeared…. It disappeared earlier then vin 740. Kats was nice enough to share a wiring diagram showing the door lights path of “power” I’m tempted to use my set of door lights on a car one day….

-

Early 240 ”69” cars door wiring provisions

Recently, while disassembling a early 240z door, and noticed a tab welded on the bottom of the interior door, near the handle but inside the door, a Metal, plastic flexible tab that is used throughout our cars to maintain wiring. I”ve looked at vin 740, and 800 something, and tab is not present. Curious to those with one of the “first 550 cars in 69” who happen to have their door panel off to peak in and see if same tab is there…. Assuming it was for holding the aborted door light wiring? If this has previously been discussed in past 30 years please direct me to the conversation…. How far down the production line was this present? Picture attached

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

I need to study a bit on the hinges….. I’m thinking the early had smaller coil spring?

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Pulled doors/hinges today from the body, doors are quite nice, original door passenger side will need some repair, but shouldn’t be that difficult to repair…… Hinge attachment point at body is in great shape on both sides. Have plenty of help from 3 of the grandkids!!!

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

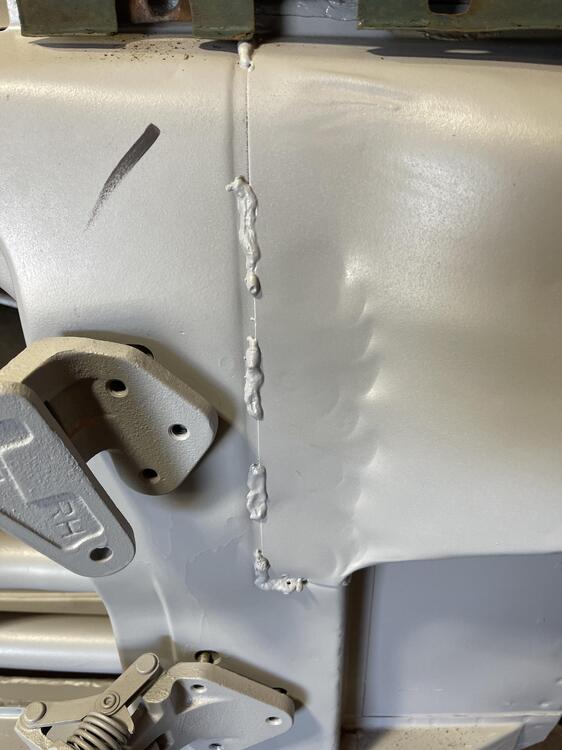

No “booger beads” up the drip rail…… spot welds from the lead filler and foward. Couple of quick pictures with naked drip rails….. One car has obviously been aggressively sand blasted to the point of removing the lead in the process. “ it was purchased this way”. Gray car with lead still in place, and visible where the joint is and the feathering of the lead smooth each direction. Orange car can also just make out where the lead sits, and where spot welds in the drip rail IMG_7461.MOV IMG_7462.MOV begin foward of the lead cosmetic patch.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Attached via stitch weld for sure, then “hidden” with the lead filler spread over and smoothed. Properly shaped wooden paddles for the front and rear, and the self leveling tendencies of molten lead, smooth and flexible. Pulled apart the interior side of panel junction at corner of rear roof area…. 6 panels held in place/reinforced by a “t-plate” of sorts…. All spot welds in this area.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Captured nut in picture is shoulder belt attachment. 2nd picture back towards the taillights…3rd accross the top of hatch.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Multiple joints, and spot welds needed to be smoothed out of sight, lead would be a single application “brushed smoothed/grinded” smooth versus multiple filler applications and sanding. Lead continues out around the base of the window.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

While we’re making crude videos, here’s a quickie of lead at base of front window frame as well. Clearly applied to blend and smooth for appearance. IMG_7403.MOV

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Alrighty, this is a interesting video just taken of the weld joint and just how much lead is in the c-pillar “cosmetic application” I just don’t see any strength in this lead being applied in this area. This is a rusted out 73 Fairlady I purchased for parts car. I ground off paint and bondo down to “metal”. IMG_7401.MOV IMG_7402.MOV

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Couple quick pictures with rear valance and slam panel removed. I’ve got decent material here, mainly surface rust. Repairs/replacement will need to be made to left side bumper mount.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

It’s all good, I am reading through and trying to learn as well, soak in what I can, I’m hoping to not have to pull apart the flexiflier joint, but will if needed. The conversation is directly related to this build and others.

-

Finally found a 69 240z, #51 Time to finish a 30 year multiple owner restoration.

Having to shout squirrel every 30 minutes or so, when distracted by items not noticed before, or perceived body and fender support changes in production methods like this welded joint between ….some changes through the years…. Hls30-00051 first pair welding exhibits “Green car” Hls30-00740….”blue car” Hls30-03496…. “Primer” Hs30- 10324…..”red” quite a difference in weld patterns.

Subscriber

Subscriber