Everything posted by HusseinHolland

-

1977 280z Rear Carpet

Did you order new Carpet? I ordered mine (75 280Z) from NewarkAuto. The quality of the carpet is very good. Properly backed as well. They have a kit listed for the '77, which is definitely not the same layout as my 75. Can't tell from the image if they cut & seam the strap openings you would require. I would call them to check .

-

75 280Z - Water Ingress From Hatch / Hinge Area?

I was thinking I may have to squat inside & have my wife spray the roof (trying to simulate rain, so not a jet aimed directly into the hatch channel). I'll drop the interior trim for a better look see.

-

75 280Z -Front and rear hub sizing for rear rotors and aftermarket wheels

I chose them over some of the other rear brake conversions because they use a newer (more readily available for servicing) rear caliper & pads. They have been super responsive to email questions. I haven't fitted the brake conversion yet so I can't speak to the quality of fit. I'll post pics of course when I get there.

-

75 280Z - Water Ingress From Hatch / Hinge Area?

Thank you for the responses. The hinge area makes the most sense, in terms of water dropping directly from above, the car sits basically level, only a slight downhill angle of a few degrees. The undermatting in the hatch area was only damp where it touched the water in the rear pocket area, it's not wet below the hatch. I'll drop the trim panel & see if I can see what the hinge seals look like. I guess the next step would be figuring out who makes them anymore.

-

Heater Core Alternative - Escort Core into 260/280

I thought of you this weekend as I was down in Philly with some Art Honor students, visiting PAFA & Philly Museum of Art. 😬 There is also a cool Sculpture park about 1/2hour North

-

75 280Z - Water Ingress From Hatch / Hinge Area?

We had a deluge here last night. When I checked the car this afternoon, it was obvious water had got into the car, but I can't be sure where to look for the source. There are no stains on the inner roof trim that would indicate the passage of water, however most of the wet area was along the lip behind the seats, down into the pockets and from there out onto the floor pans. I had a box sitting on the ledge and it obviously absorbed an amount of water. This pic was after I mopped up the water by the ridge. Any specific places I should be looking? I have a new hatch seal I will be installing anyway, but I don't see how a hatch seal would cause water to drop so far forward

-

Designing A/C System Using Other Cars Parts?

Thanks for the link! Not sure if I would go that route, the goal is to rubber mount the compressor in the bracket, to reduce vibration when compressor is running. I have the one on my K-swap Fiat hard mounted, and I've had to be careful with the mount hardware working loose from the vibrations. That one is a top mount, which does seem more of an issue in terms of susceptibility to vibration. I went through several revisions to get it properly mounted. Having it isolated when possible just makes life easier mockup with spare compressor

-

75 280Z -Front and rear hub sizing for rear rotors and aftermarket wheels

You did this on yours? I was leery of hand drilling the rotors without a lathe or other proper centering equipment, however the machine cost around here to re drill would be around $60 or so per rotor. Hopefully I have them close enough to not cause an eccentric vibration.

-

75 280Z - Updating fuel feed & return lines in the engine bay

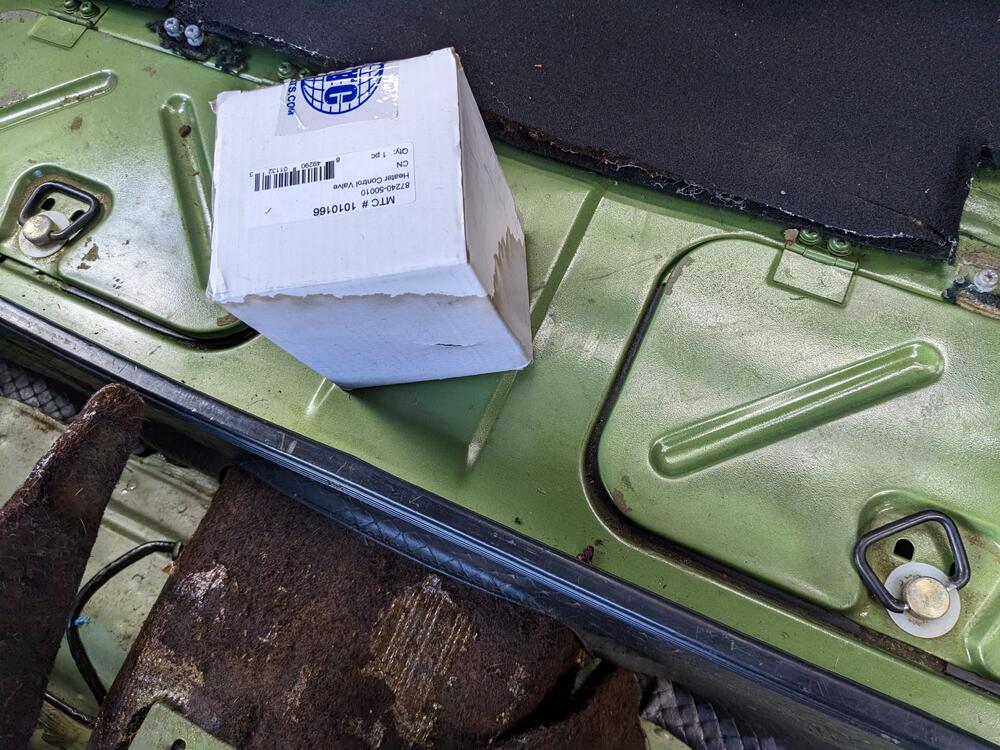

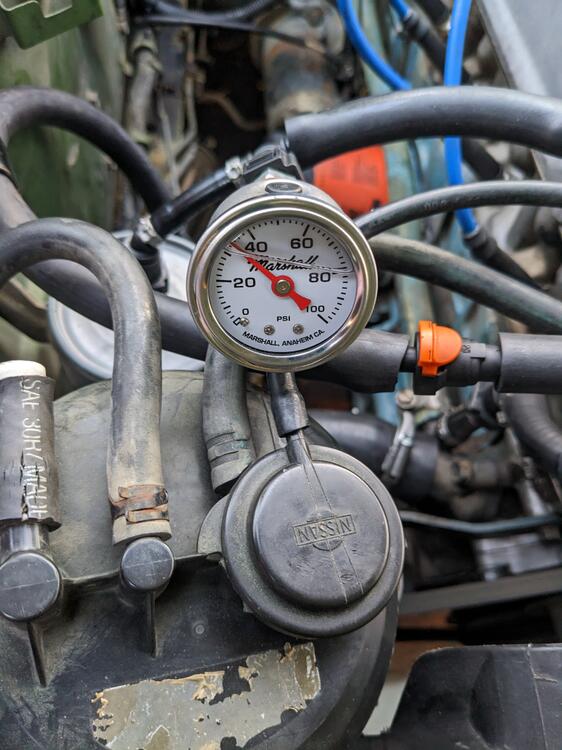

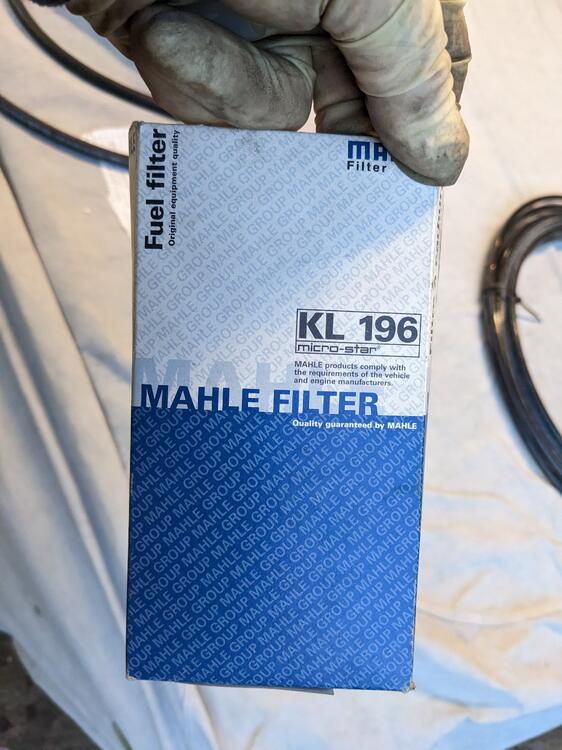

I made a start on redoing the fuel lines. I used sleeved 10mm nitrile line with quick-connect fittings. The ends are clamped to the hard lines, and are not intended to be removed moving forward. The quick connect fittings allow you to disconnect the rail from the feed & return. Did the return first. Rerouted behind the filter to get it away from the motor. Support bracket previously attached to the filter clamp is now secured it at the inner fender QC fittings for the (Volvo application, Mahle KL 196) filter needed a longer M5 bolt while I was there I added a branch to allow me to add the fuel pressure gauge (M10x1 w/QC, 1/8" NPT) Used a left over silicone elbow from my C30 turbo upgrade, perfect fit for the torn filter-AFM elbow

-

75 280Z -Front and rear hub sizing for rear rotors and aftermarket wheels

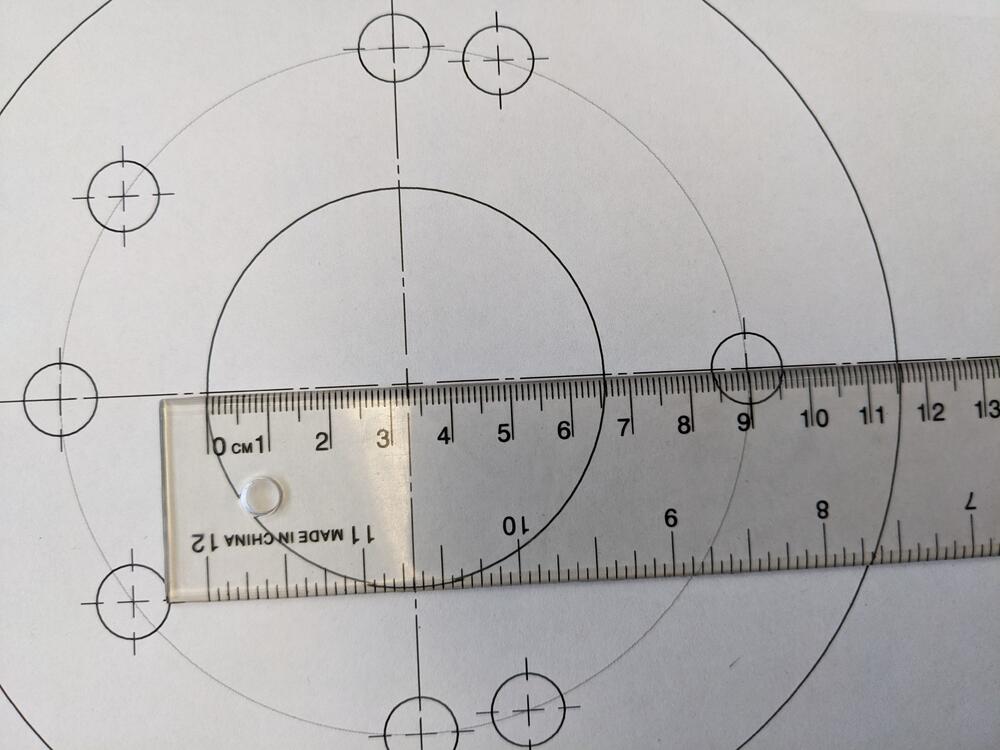

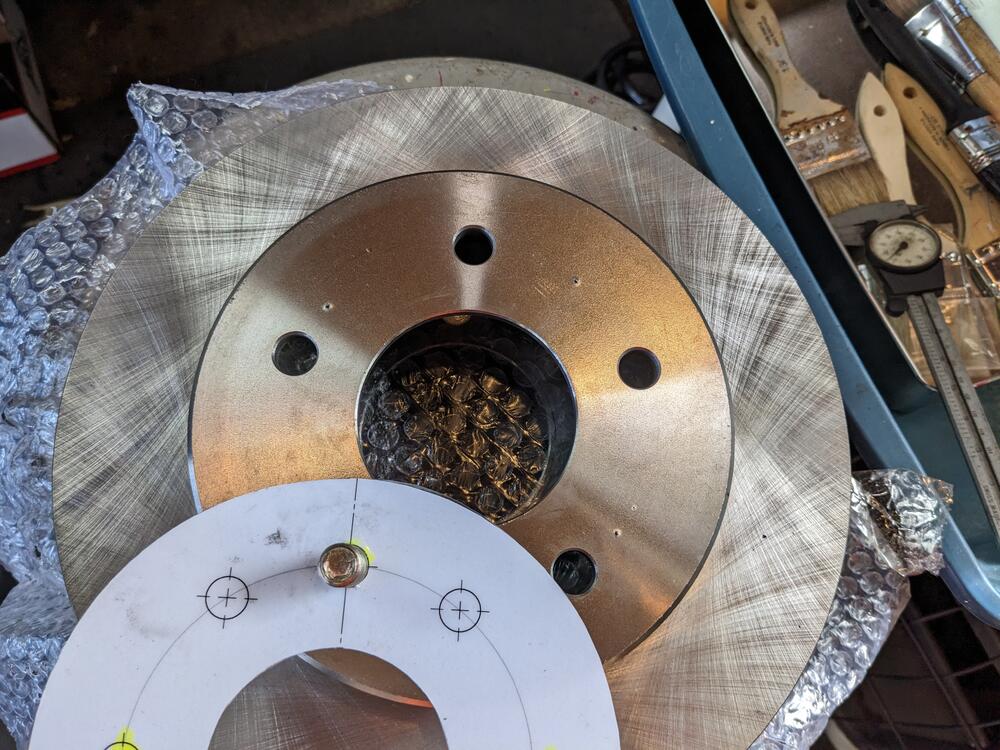

I'll get a better sense of what I'm facing with the wheel/hub concern once I pull all the suspension apart. In the meantime, I did get the 300ZX T rear rotors redrilled to 4x114.3 using the Milkfab template. I had to redraw the center to 67mm, as the printed version they send was only 66mm ID. I used an xacto to carefully cut out one locating hole so that it is a snug fit on a stud, then center-punched the other 3. I also used the steel wheel center I cut off the spare wheel to test fit the rotor. as provided: laminated the template to make it rigid enough to be useful Checked the spacing & offset on each relative to each other and the inner & outer hub lips before drilling All done

-

75 280Z -Front and rear hub sizing for rear rotors and aftermarket wheels

I guess I'm just used to cars (such as Volvo) that utilize wheels that are (obviously) lug-centric with cone-seated nuts or lugs to ensure proper seating, that also combine hub-centricity in their design. All the hubs on the cars have a wheel centering lip. I may just be assuming that wheels I've bought are lug & hub centric. The only aftermarket wheels I ever bought that were only lug centric were those American Standard wheels of the 70-80's that were in many cases slotted to allow fitment to a couple of close bolt patterns. Those do not use a cone seat. I had definite balance issues with that style - one had to torque the lugs with the wheel unloaded to avoid vibration. I'll take a read of the article.

-

75 280Z -Front and rear hub sizing for rear rotors and aftermarket wheels

There is a significant difference between lug-centricity & hub centricity, I'm sure you understand. Relying solely on lug centricity brings in greater likelihood of wobble or out-of-round. I guess I'll have to figure it out. I'm just surprised that no one has either encountered this or commented on it using aftermarket wheels.

-

75 280Z -Front and rear hub sizing for rear rotors and aftermarket wheels

Not the same OD F & R

-

75 280Z -Front and rear hub sizing for rear rotors and aftermarket wheels

Andrew from Milkfab got back to me with some info: "The factory hub diameter on the rear is ~67mm. Most aftermarket rotors and factory drums have a center bore ID between 67mm and 68mm to center the rotor to the hub. The wheel itself centers on the studs in the rear so the 73mm inside diameter is for clearing the front hub only." Having wheels not hubcentric seems like such a bad idea, especially when increasing the rotating mass with larger wheels / tires. I'm going to get hubcentric spacers for the rear - 67.1 - 73.1. Anyone have experience with this?

-

Valve Cover Ventilation Hose Flame Arrester

I would use a Volvo part on my Datsun, however I would NEVER use a part designed for any British car. I used to have MGB's back in the late 70's early 80's. The quality of the factory parts was always less than stellar 😂 I'm sure you've heard the joke about why Brits drink warm beer?

-

75 280Z -Front and rear hub sizing for rear rotors and aftermarket wheels

Searching has not brought me any definitive answers. It appears the front and rear hubs are not uniform size? I'm asking for two reasons - 1) because I'm converting the rear brakes to disc, and the Milkfab kit uses 300ZX Turbo rotors which have a 67mm bore. 2) I bought Konig Rewind 15x7 4x114.3, 73.1 bore 0 offset - So now I'm assuming I will need hub centric spacers for the rear wheels, but not for the fronts? Can anyone advise?

-

Valve Cover Ventilation Hose Flame Arrester

I didn't realize I was missing this until I was scanning through the FSM looking for the PCV. On old SOHC Volvos they use a "Flame Trap", between the air inlet and valve cover with a small vacuum draw that serves the same purpose, but that's it, they don't have a PCV in addition. Don't think I can make one of those work, so I guess I'm looking for the 20ga shotgun cleaning brush to mod 😄

-

280z Master Cylinder Heat Shield Picture Request

Thank you. The top mount bracket? It has a raised ridge & folded rear edge, I think it will be OK. I know what you mean though. I tried to locate a spare bracket with similar form without success. I can always remake it DTR if need be. Yeah, I wanted to drop the height & move the booster vacuum rearward. Vacuum draw out the end of the plenum will be much the same as the top rear. I'll be revising the AC lines coming out the firewall & wanted as much space in that area as possible until I have that all figured out.

-

280z Master Cylinder Heat Shield Picture Request

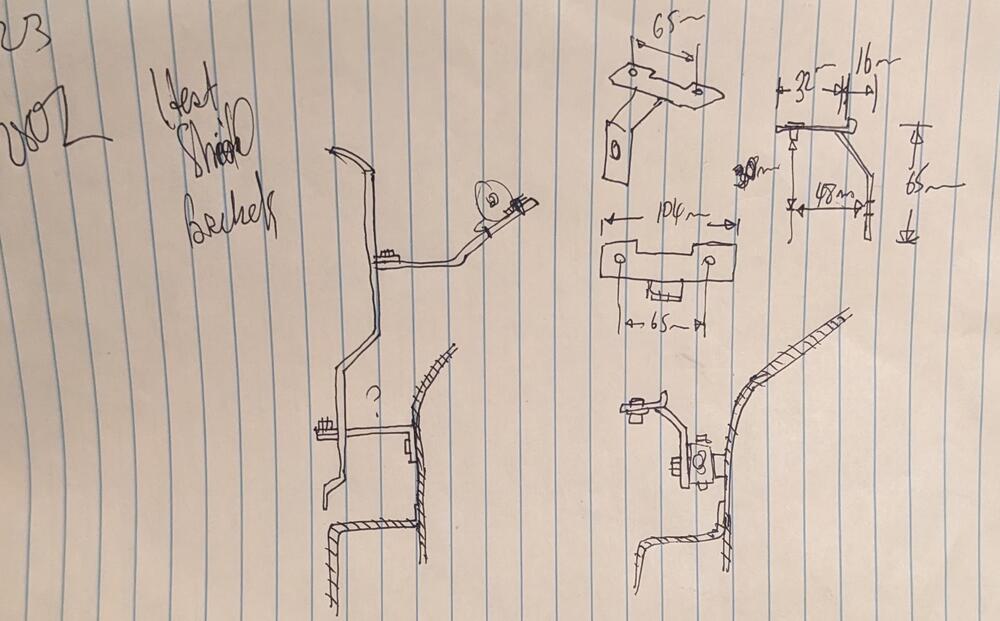

I made a bracket when I got home - I saw that the brake valve was in the location that made sense to mount to - confirmed by Gwri8's pics. I wish I had checked back here first & seen his & your pics above, that would have simplified things a little 😬 In any event, this is what I made tack welded a few pieces of cut up bracketry to test I only have a finger width between the back lower edge & the steering shaft, so I didn't want to move it any further rearward . Made the upper support bracket to have 2 mounts at the shield, and holes to allow the stock bay light bracket to stay where it belongs. Engine harness lays nicely over the bracket. I curved the left side to both make it more rigid, and to make sure there is no harsh edge for the harness to chafe on.

-

Designing A/C System Using Other Cars Parts?

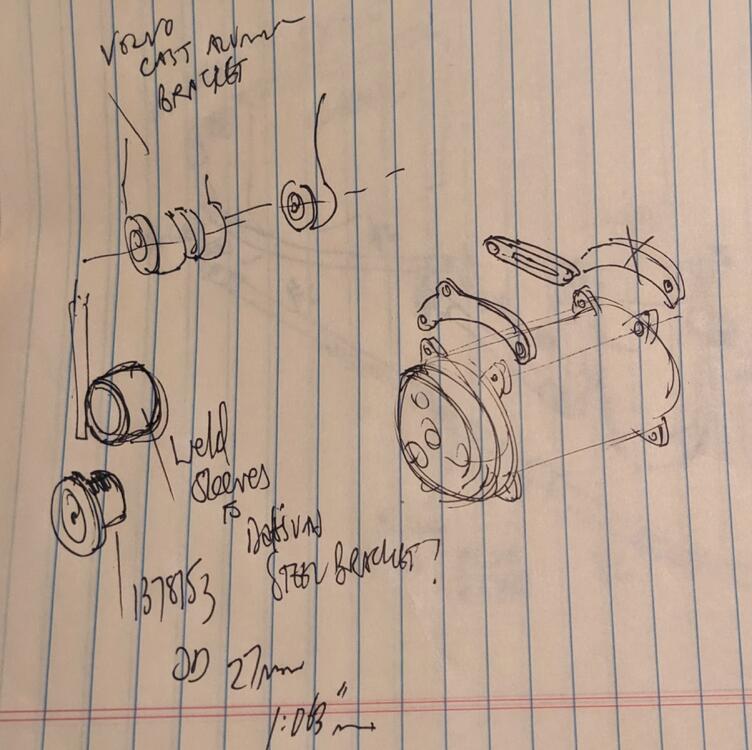

I've owned Volvos since I was a teenager. I have quite a stash of parts 🙂 I'm thinking of revising the compressor mount. Volvo setups all have rubber isolators on the pivot and adjusters to reduce vibrations. They use aluminum mount brackets, which I'm not prepared to modify to fit (pic of my old Volvo 740) What I can do is weld these steel sleeves to my existing mount bracket, to match the mount design

-

280z Bosch Relay Correlation? Stock Relay vs Porsche Relay

Looking at this as my 75 has the original relay with 250K miles on it... The 120 relay is no longer 'cheap' at anywhere from $170 on up in searches. I have the original 127 from my 87 Fiat/Bertone X1/9, but I'd hardly consider that a safe spare. I'm wondering if anyone documented the resistor value for the AFM circuit. That would be the only 'special' component required. Diodes are just diodes. The VW site linked is very informative, but does not give that info.

-

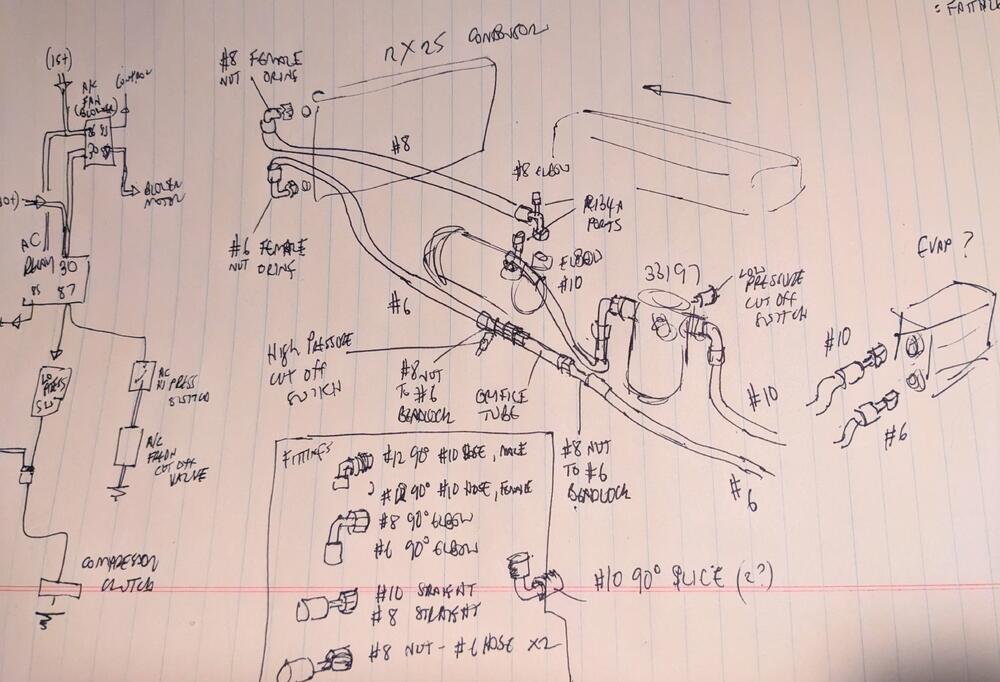

Designing A/C System Using Other Cars Parts?

Had to sketch out the overall layout. This is following the hose routing of my dealer-installed universal/generic AC kit. This is also assuming I don't use any stock factory AC lines, which is still an option I'm considering. Once I have the dash & HVAC box apart & can see what the evaporator looks like, I can make a more informed decision on that. Seltech compressor, this one was specifically sold for Volvo 240 & 740 series cars. I'm going to modify the steel mount bracket on mine to move the compressor back. Mine uses the rear groove on the pulley. The compressor was one of the reasons I could fit the eFan/shroud, so I'm hoping I can revisit that once I have the compressor repostioned Definitely room to move the compressor back at least the inch or so needed I did forget to measure the ear spacing on the new one to compare (3.25" on the installed unit), however that is a pretty standard measurement, so hopefully it's the same or I will have more work involved in modding the mount bracket

-

280z Master Cylinder Heat Shield Picture Request

Thank you - that makes the positioning & upper bracket clear. I will just have to make a mock up bracket that positions the shield at that place relative to the frame rail. As an aside, I see that the booster check valve is placed with the grey side facing the intake. On my 75, the (original) valve was also placed that way, however the arrow markings and blow-through indicate that is should be facing the opposite way. Is yours original?

-

Servicing Cooling System Questions

Hopefully I will be OK with the seal depth change. That is SOP on Volvos, which can easily see way past 250K miles in service.

-

Differences between 240z and 260z dashboards

They don't provide any guide for install? It would seem to make sense to start from the speedo & tach openings to makes sure those are properly located, then stretch the leather out from there?