Everything posted by Dave WM

-

Front Suspension Issues

Its hard to see on those thread, but you should have a noticeable flat on the threads that engage the D shape of the strut mount insulator. What was the strut cart you used?

-

Front Suspension Issues

- Front Suspension Issues

looks upsidedown to me, going to have a heck of a time getting the strut on, it has to fit onto the steering knuckle. Don't you have a FSM to refer to?- Failed CO emissions - all controls removed - where to start?

it was a little oversized (I may have just cut it a bit larger when cutting the wood) had to sand it in spots, not a big deal.- Failed CO emissions - all controls removed - where to start?

- Failed CO emissions - all controls removed - where to start?

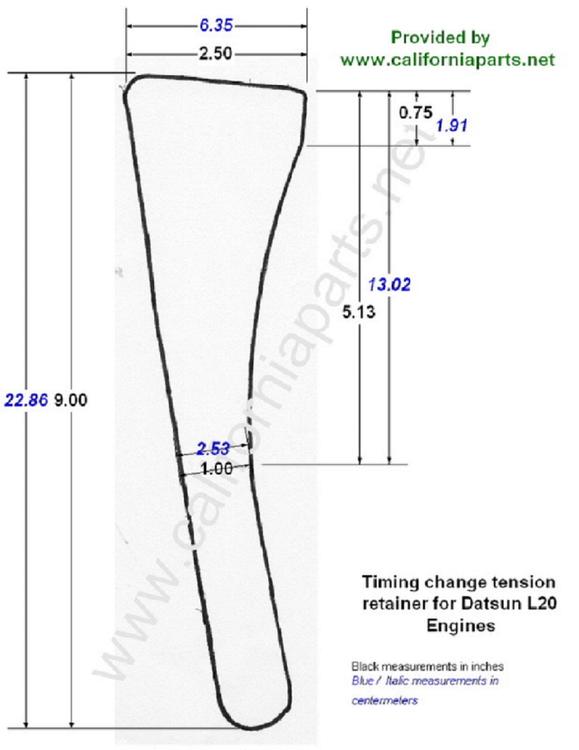

I made the one from the down load plans. That being said I would hesitate to go too deep into this. Back to orig problem failed HC, so I assume rich setting. easiest thing to try 1st is to confirm AT THE ECU the resistance values vs. Temps on the temp sensor. A little bit too much resistance there and you end up with a rich run. Next Start switch enrichment, again it should not be there AT THE ECU when key is not on "Start". Lastly AFM air temp sensor, again AT THE ECU. Since it has the stock ECU might as well make sure those parts are sending it good info. I just seems like its going to be hard to know what is working without a way to monitor the exhaust gases with any changes made.- Lost my brakes.

Did you try bleeding them? always a good start.- Failed CO emissions - all controls removed - where to start?

I am going to start all over. get some NEW plugs, run them at idle for 10 min, pull them and get some pictures. get some close ups of the injectors as ZH mentioned. Lets go from there. With out a way to read the exhaust gases while tweeking its going to be up to reading the plugs for now. the hope is you can salvage what you have without having to start all over (may need to at some point but for now lets see if you can get it going for passing emissions). Still need pics of the ECU (assume its OE). Check what you can (temp sensor) throttle position sensor (cant recall the correct name, the black box on the side of the TB). Just to see if at least those are in spec.- Failed CO emissions - all controls removed - where to start?

I orig thought that, but checked my test stand setup and noticed it was off kilter to and seemed ok.- Failed CO emissions - all controls removed - where to start?

Yes he does have a lot of major stuff going on. On the ECU, I would think its a stock unit, based the OE style AFM (I assume aftermarkets use something else but I don't know for sure), but checking under the panel would be a good start. I can see now there will be a need for a lot of pics of just about everything to try and unravel remotely. I am guessing the car drives well? starts ok? smooth idle? etc.. are we just talking failing the HC- Failed CO emissions - all controls removed - where to start?

good point about the ECU ZH, did not even think about that.- Failed CO emissions - all controls removed - where to start?

indeed, I did a lot of stupid stuff in HS.. Those pressures make no since at all, I would get that gauge out of there, get a reg temporary pressure gauge, check again see if you can get the pressure right before anything else. As mentioned start with a engine off pressure 36psi, once that is right you want to see the response to the vacuum, dropping to around 30 psi at idle. You may want to get a vacuum gauge hooked up (you certainly have enough extra ports) as well. It maybe as little as an adjustment to the AFM bypass to get the HC working, but I don't know how you can really do that with out a way to read it while adjusting. I played with that bypass while reading the vacuum. If you assume the vacuum is a good measure of engine efficiency then you can watch the vacuum and see how tweeking things effect it. The most vacuum at idle. once you have it at the highest vacuum reading a bit of tweeking on the bypass to lean out the mix will reduce the vacuum a bit, that should be about the best setting for low HC. IIRC I would get a vacuum of about 19 inHg, then lean the bypass a 1/2 turn or so and it would go to about 17 inHg. At that setting removing the oil cap would kill the engine. If I left it optimized for 19inHg, removing the cap would have no effect.- Failed CO emissions - all controls removed - where to start?

oh just noticed no AAR either (kinda slow today, recovering from hurricane prepitis), that sux. must be fun to start on a cold morning. Just don't get why folks have to remove stuff.- Failed CO emissions - all controls removed - where to start?

I assume the PCV has been deactivated (based on the air filter on the top of the valve cover, Just curious, I assume the PCV tube on the engine block has been capped as well, If not it should to prevent junk from getting in there. A better fix would be to return it to function. Also when you say the engine number did not match the VIN, did you compare it to the ID plate in the engine compartment? the I prefer to say serial numbers since that is really what they are, and the SN of the engine never match the SN of the car (top of dash). The plate in the engine compartment has both vehicle SN and engine SN. I suppose it does not matter but the AFM is turned 90 degrees out, the plug should be on the bottom. A typical test for air fuel mix would be to remove the oil fill cap, if the starts to slow and die, then its right, if it speeds up its rich, But that only works when the PCV system is installed and working.- Assessing Manual Transmission Condition

did you do the 10 turns?- Assessing Manual Transmission Condition

that bronze bush on EuroDat list is the one I used, very nicely made. Omega Tools.- First Engine Start After One Year Of Restoration

I cranked mine with the plugs out as well, figured less stress on the crank and main bearings until the oil pumped up.- Assessing Manual Transmission Condition

I am not sure but I think the 81-83 also used a reverse nut on the main shaft, CW to loosen, Just some thing to consider when trying to disassemble.- Assessing Manual Transmission Condition

you could mark the output shaft and input shaft with a grease pencil, turn them say 10 times (input shaft) and compare (output shaft). IIRC the later ones had a taller gear ratio, but you should know better if you have been looking at it recently.- Assessing Manual Transmission Condition

the only thing I did not like was the input shaft needle was branded "made in china" I think the other larger ball bearings were made in japan, but I can not swear to that. You can buy the ball bearings only as well, they are standard size, I suppose if you did some research you could perhaps by "premium" stuff. I know I talked about the to the guy at Datsun Spirt, IIRC he only wanted to use OE Nissan parts, both bearing and balk rings, that would up the cost a lot. His point of view was it a lot of labor cost to install sub standard parts.- Assessing Manual Transmission Condition

90-150 depending on if you get just the bearings and gaskets or the whole set (balk rings). lots of places sell them, they don't include the needle bearings for the gear clusters, I guess those are not a typical failure point. you get the main ball bearings, gaskets and seals, brass balk rings and the one needle bearing that fits on the input shaft. I would say that unless there is a known issue OR you just want the experience (I fully understand that as well), rebuilding may not be needed. You could just install it, try it, then if not happy pull and rebuild. It takes me about 5 hrs to pull a transmission so its not like a huge investment in time to try it out. A lot of the time for me was just getting the car up high enough and safe enough to crawl around and have room enough to drag it out from under the car.- Assessing Manual Transmission Condition

I don't know how critical it is, but there is a brass bush on the tail shaft. considering how long that shaft is, I would consider that a replacement item as well. this is what the front of the driveshaft turns in. You can replace it by separating the tail shaft housing only from the center plate. that would be a good time to do both it and the rear seal. If the bush is ok then the seal can be done without taking anything apart. there is a long bushing and a short one, you want the long bushing. On mine the oil catcher that feeds oil back to it was broken off. I knew this cause it was stuck to the magnet. Not sure how else you would know without separating the transmission front half from the bearing plate.- Assessing Manual Transmission Condition

there is a guy on you tube "villageland" that has a nice video, no audio but you will get the idea of what is involved, and he manages to rebuild it without a press.- Assessing Manual Transmission Condition

having a press helps a lot with that and a bearing puller set and an assortment of steel pipe connectors (the kind used in plumbing to make fixtures) its really pretty easy. On a Torx driver is needed as well, and a SOLID snap ring remover tool is a must. I used a wood dowel to store the gears and hubs to keep everything in order. One last thing there are a couple steel balls used to lock in some parts, you just have to keep up with them. The actual workings are not that intimidating once you get into it. You have to use some creativity to substitute for the jigs mentioned in the FSM, but that is what the steel pipes are for. The only part that gets tricky is the small parts inside the sychro hubs. If you are careful they can come out with out disturbing those bits. No real need to break them down. I think the main wear items besides the baulk rings is the teeth on the sychro hubs. That's what you hear grinding if the trans is abused. The front counter shaft ball bearing is another part to look at, its a bit smaller than the later transmissions. The reverse idler is often chewed up a bit but that is not a huge deal. I would think the worst case would be a bent output shaft. That would be worth putting on some v blocks and checking for excessive runout.- Assessing Manual Transmission Condition

Other than do they go into all gears, not much. Could try to spin them in gear and listen for weird noises. I hooked up a high speed drill to a rubber hose that fit tightly over the input shaft, then a bolt into the other end, chucked into the drill. the hose acted as a flex coupling. You could remove the drain plug and look at the metal particles that will be stuck to the magnet (if not already cleaned off). Look for chucks (bad) fine particles not a big deal. You are looking for bearing cage bits etc.. The only real way would be to open the case up and examine the gears for broken teeth or other obvious damage. You could prob check the end play and baulk rings wear with some feeler gages. As a minimum plan to at least replace the seals on the input and output shaft. that can be done without separating the cases. - Front Suspension Issues

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.