Everything posted by jfa.series1

-

Quiz Of The Day

-

COVID-19

Information coming out today in the New England Journal of Medicine on how long this bug lives in different environments: "In a study published in The New England Journal of Medicine, scientists found SARS-CoV-2, which causes the Covid-19 disease, was detectable in aerosols for up to three hours, up to four hours on copper, no longer than 24 hours on cardboard and up to three days on plastic and stainless steel. The research, led by the National Institute of Allergy and Infectious Diseases (NIAID), sought to mimic the virus being deposited from an infected person onto everyday surfaces in a household or hospital setting, such as through coughing or handling objects. The findings highlight the main risk of contracting the virus after touching contaminated objects, but also the small danger of airborne transmission."

-

COVID-19

I think the main difference here is the level of contagion. The flu is only moderately contagious, the virus has a very short life on surfaces, and we have a vaccine and proven anti-virals. Most of us can go about our daily lives with little concern. The folks that tend to get the flu are those who do not get vaccinated and older folks with underlying health issues - for that group the flu is potentially deadly. Our hospital system has the capacity to handle the regular flu incidence. This new bug is highly contagious and seems to have a longer life on surfaces (not yet conclusively proven). While not as deadly on a case-by-case basis, it has the potential to hit all of the population that might be exposed and if it does so, the death toll will be much higher. We have zero built-in resistance and no proven anti-viral meds or vaccine to fight this new virus, and our hospital system does NOT have the capacity to handle all of the potential cases. People will die due to lack of care! So... right now, avoiding exposure is the ONLY WAY to slow down the spread and the only way to avoid exposure is to halt personal interaction. The flu virus is known to die out as soon as the weather warms but there is no track record on CV.

-

Datsun Club Hungary #7.jpg

These guys in Hungary insist on distracting us from their amaZing work on the cars with pics of their amaZing ladies. I don't get it.

-

Parts Refurb

I have a couple of complete switches with a broken toggle, not likely to have the missing handle segment but will check. As a fallback, I could take some measurements of the NOS handle segment for you. If you want to mess with a busted switch sans handle I can send it - still have your address.

-

Parts Refurb

Captain - You are on target with the point of breakage. In going thru these units, I determined that the deciding factor has been the amount of weather exposure that resulted in deterioration of the exposed handle portion of the entire toggle. It is similar to the breakdown of the nylon insulators found on the fuel rails. My car has always been garaged, not a bit of breakdown on any of these bits. I suspect it would be every bit as difficult to turn out a replacement handle as it would be to turn a complete unit and as you point out, a tricky process to drill a receiving hole in the ball. As I mentioned a couple of posts ago, the metal bat is a bit larger in diameter but properly finished it might be difficult to spot by show judges. Heck, it would only count in the ZCCA Stock class anyway. I hope to have a prototype ready soon.

-

Parts Refurb

Today's mind-numbing exercise: servicing 18 switches with disassembly, cleaning, burnishing the contacts, dielectric grease, assembly. About 3 hours for 18 units. Two others in the batch have broken toggles and will get the new metal toggle replacement switches.

-

Early vs. Late Series I 240Z's

You are on target. Per Carl Beck's site, there were approximately 20,500 cars produced into late January 1971 with the flow-thru ventilation exiting via the hatch vents. Beginning in February with VIN 21,000 the flow-thru vent outlet was moved to the C-pillar / sail panel. That was a hard change and as HS30-H stated, everything else was a matter of what parts were available to the assembly line.

-

Kanji found when removing a dash

-

Anyone Running Cut OE 240Z Springs?

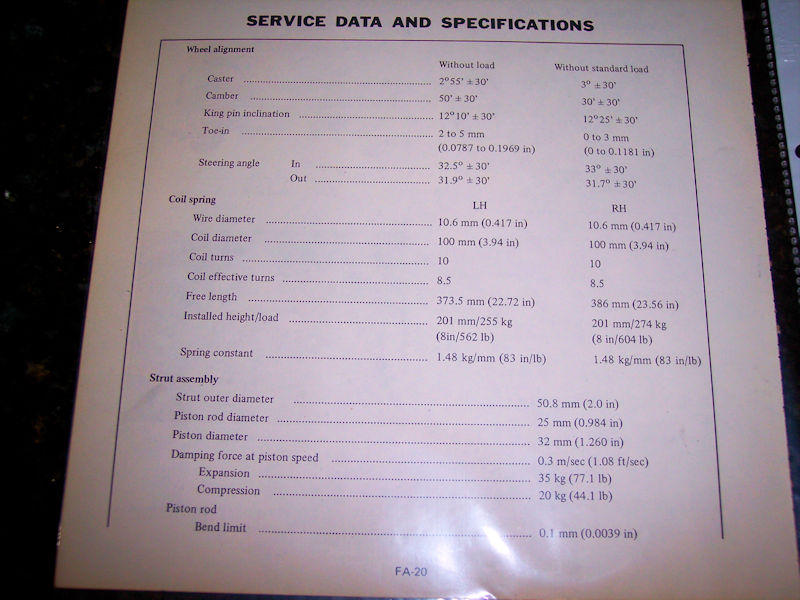

Thanks. Perhaps you could count the number of coils on a front spring for me, OE is 10 turns from the tip of the wire to the other tip. No rush on this.

-

Anyone Running Cut OE 240Z Springs?

I'm not particularly satisfied with my car's ride quality with Tokico HP shocks and Eibach Progressive springs. I have the new KONI's in hand and a set of OE spirngs and DO want to get the car lowered a bit more than it's current setting. I'm thinking that with stock springs and the KONI's I can more easily tune the the ride quality. Any comments on cutting the OE springs would be welcomed.

-

78 280Z rear strut removal

Unless you just want to own a set of spring compressors, check with your local auto supply such as Auto Zone or O'Reilly's that have tools to loan at no cost. If the last set of shocks was installed into the strut without some oil, you may find they have become rust welded to the inside of the tube.

-

Parts Refurb

I think we have a winner! Here is the new switch installed in a light body, pictured with a NOS unit for comparison. No interference inside when installing the switch. The bat (toggle) is larger and the bushing extends further out of the body. The exposed bushing length can be adjusted as there is a hex nut inside the body for that purpose and one outside to lock it in place. I plan to have the hex nuts yellow zinc plated and will paint one of the switches to more closely resemble OE. Stay tuned to this station for continuing updates.

-

Any tips on getting the quarterlight seals to relax?

I went thru this frustrating exercise years ago. With no one around to assist I found it impossible to both get the assembly pushed back into the body and get the screws in place to lock it down. My solution was to create "extra hands" with a ratcheting tie-down strap. I installed a large hook in the base plate of the garage wall and positioned the car with the rear towards the hook. A length of stout rope was attached to the hook. One end of the strap was attached to the rope, the strap passed into the car via the open hatch, around the front of the quarter window and back to the rope for a second attachment. The rope allowed for a shallow angle for the strap. Gentle ratcheting pulled the window into position and held it in place to get the screws installed. Loosen the strap, re-position the car, and repeat for the second window. Thankfully, no pictures exist of this particular McGyver moment. ?

-

Parts Refurb

Inspection Light 2.0 - go for it! ? Sign me: Anxiously awaiting your prototype.

-

Parts Refurb

Thanks again to @SteveJ for the link to DigiKey. Going thru their catalog I located this switch that has dimensions very close to OE. I've got 5 on order, will update this thread with fitment results when they arrive. https://www.digikey.com/product-detail/en/electroswitch/7105B/451-1156-ND/2679539

-

Parts Refurb

Thanks Steve. The threaded bushing needs to be 12mm to correctly fit the hole. Many of the smaller body switches are sub-mini's with a 1/4" (8.9mm) bushing. In a quick review I spotted a pre-wired switch that looks good, would eliminate soldering wires to a new switch - just use a small butt connector. Will get back to it later for more investigation.

-

Parts Refurb

The switches arrived today and are not a good fit for the housing. The 29.5mm dimension is too big to fit flush against the end of the tube. The OE switch is 23mm (0.9"). Now its off to the site recommended by @SteveJ to shop for a better fit.

-

Parts Refurb

That's on my list of to-do's.

-

Parts Refurb

Thanks for the link. Need a few replacements, I just ordered a group of five.

-

Parts Refurb

From grunge to glitter! Next up - Dremel wire brush to clean out all the insides, then wet sand final prep for handoff to the plater. I was pretty lucky with this group, only one body had a couple of dings and only one had any serious patina issues.

-

Parts Refurb

I have a grommet assortment box from Harbor Frieght, found a size that works well. I do open the center hole with a drill bit to handle the connectors. You probably don't have HF in Canada but likely a similar outlet.

-

Parts Refurb

@S30Driver - any recommendations?

-

Parts Refurb

Not to my knowledge. Our good friend @S30Driver has substituted modern switches with a metal toggle with success.

-

Parts Refurb

I pulled this nest of inspection lights out of the garage attic stash yesterday. By moving quickly, I was able to get them de-fanged before any harm was done! ?

Subscriber

Subscriber