Everything posted by Zed Head

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

Thank you. https://en.wikipedia.org/wiki/Walter_Winchell

-

Z's on BAT and other places collection

This is one of those examples of how your unstoppable urge to dominate leads you to make simple obvious errors. The car is in the "Masterpieces" section of the web site. Is it an error on the web designer's part? It's not supposed to be there?

-

Z's on BAT and other places collection

There is actually quite a bit on the S30.World web site. Fun to browse. There are stories. https://s30.world/collection/datsun-240z-hls30-00057-ca Can't wait to see which one comes up on BaT in three weeks. They should just disclose it now so people can look through the details on the web site. And how big is the "limited run"?

-

Z's on BAT and other places collection

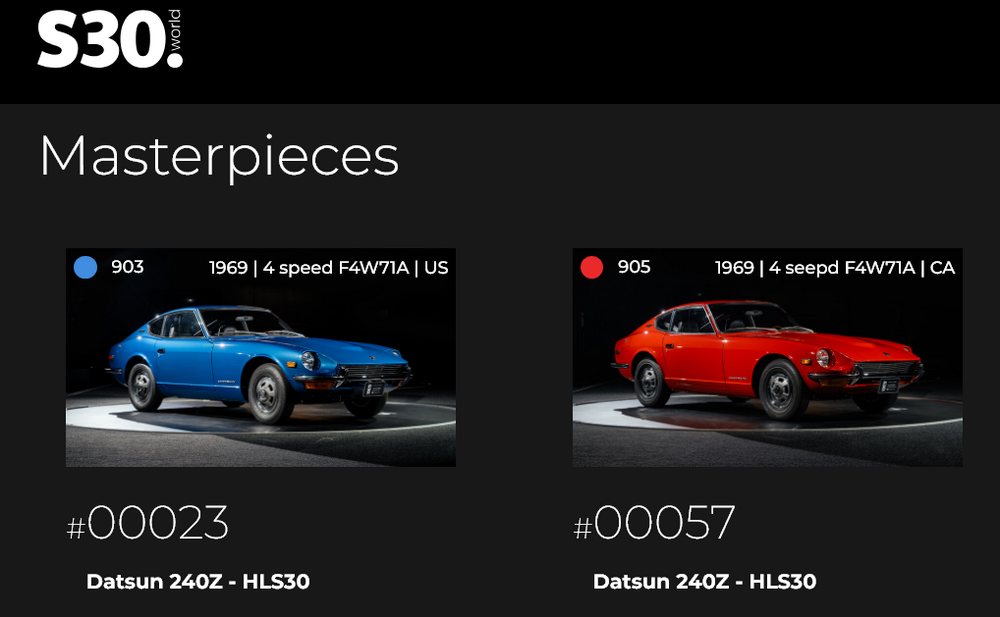

Just having fun here! I came in second place in my third grade Spelling Bee contest. These things catch my eye. Somebody missed a detail on one of the Masterpieces presentations...

-

Z's on BAT and other places collection

So, here's more of the story. Didn't realize that HS30-H was "consulting" for S30.World. Is it a paying position? On the board? Stock options? Maybe it's been disclosed, but I don't recall seeing it. S30.worldS30.world - The platformThe platform

-

Z's on BAT and other places collection

The current topic is - do these relative "newbie" restorers have the same concept of what "restoration" means as the "old-timers". Is it okay to remove the things were there "as the car left the factory" and call the car "as it left the factory". In literal terms the answer would be no. The statement is not true. The facts shown in the pictures seem to clearly illustrate this. They are "perfecting" the cars by removing the idiosyncracies of the high volume manufacturing process. The things that give each car originality, and make them interesting to people that want to understand how the cars were made back then. There's nothing wrong with doing that, removing the "defects", they just need to clean up their marketing prose to give an honest representation of what they're doing. Their whole web site is kind of grandiose. That's the whole thing, summarized. My posts and links are meant to help understand who these newcomers are.

-

Alternatives electronics wiring harness?

The switch on top of the steering column has the power supply contacts for both the running lights and the headlights. Have you opened it up? Search "headlight switch" and "headlight switch hot" on the site and you'll probably find some good threads. The contacts get pitted and stop working, or the heat causes the solder joints to break.

-

Z's on BAT and other places collection

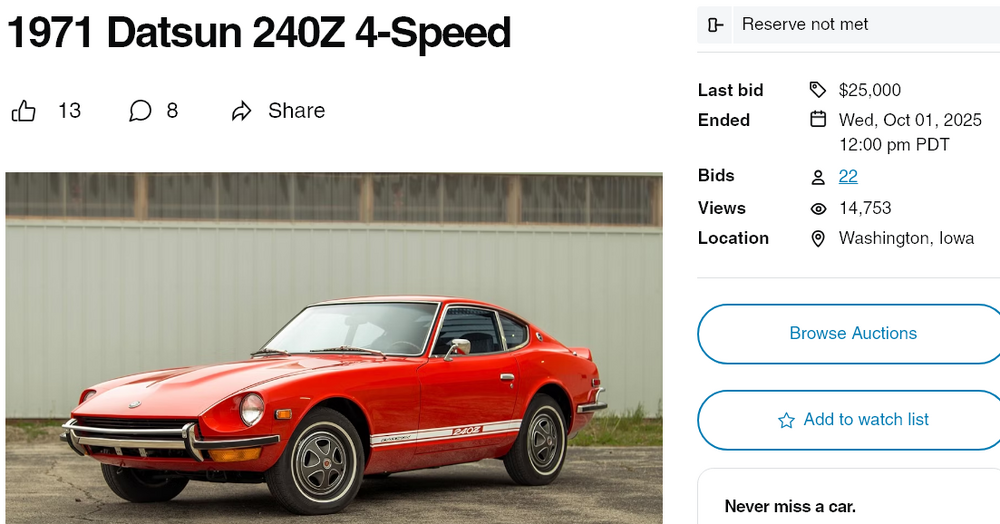

RNM at $25,000. Reserve too high or market too tight with their money? Scary times ahead here in the States.

-

Z's on BAT and other places collection

Naaa. I'm just trying to figure out who's running this new Z car parts store. And, as usual, you're ignoring what was written and projecting your own thoughts in order to create an argument. These guys clearly state that they intend to restore the cars to how they were as they as they left the factory. SpeedRoo pointed out some things that were not that, but you just ignored that reality and chose the argumentative path instead. Typical. They're just selling car parts, in the end. Nothing wrong with that, but nothing noble about it either. The Z car market just looked like a profitable one. Good luck to them. S30 World - The place for the S30 familyS30 World | Your online Datsun and Fairlady Z parts shopS30 World offers a selection of premium products designed to enhance your Datsun. Explore our quality parts to restore your Datsun or Fairlady Z.

-

Z's on BAT and other places collection

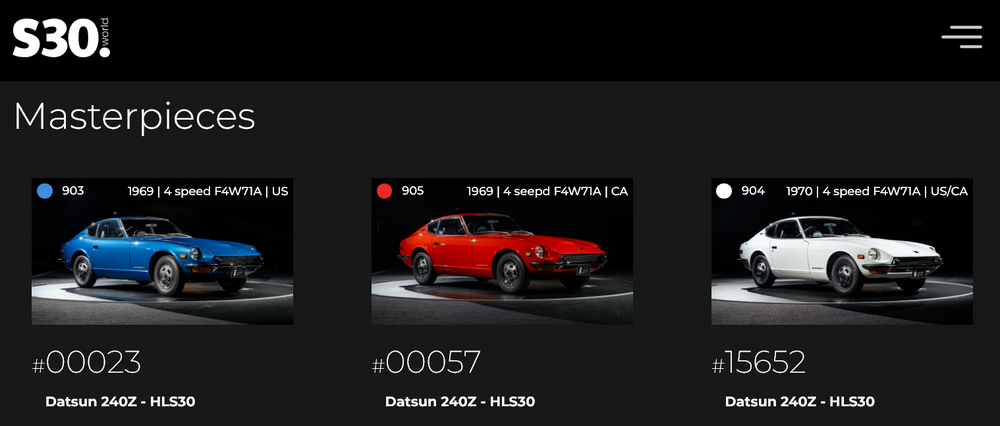

I wonder who the "restorers" are. They seem very proud of their skills, but they really haven't been around that long. Since 2019. Apparently their marketing manager was born in the back of a Datsun. https://s30.world/masterpieces "S30.world launches “The Masterpieces program” A celebration of Nissans S30 platformA limited-run of factory-correct restorations of the iconic Datsun 240Z will become available, with the first one to be sold at auction in the United States on October 23rd 2025. This unique program is focused on the full, factory-accurate restoration of Datsun 240Zs, also known by the S30 chassis code, to a level of detail that makes them identical to how they left the production line over 50 years ago. Each vehicle in the Masterpieces program keeps its original exterior and interior color and undergoes a complete, ground-up restoration. The process is guided by an obsessive commitment to authenticity, where every component is either restored or remanufactured to original specifications. From the expertly built drivetrain with its matching numbers engine to the flawlessly restored original interior, right down to the smallest original equipment fasteners, nothing is overlooked. “No expense or effort will be spared to achieve this peak level of quality,” says Chris Visscher, founder of S30.world. What truly sets these examples apart is the craftsmanship applied to the bodywork. Every shell is meticulously returned to its original condition with such precision that no trace of welding or repair is visible, even under close inspection by the most trained eye. All spot welds are recreated exactly as they were applied by the factory, matching both the original pattern and technique." https://s30.world/our-company "In 2019 Gustav Oplasnik and Chris Visscher decided to join forces. The desire to do the best possible restoration with an S30 was and still is our passion. The foundations of S30.world are passion, knowledge, craftsmanship, determination and cooperation. Today we are able to do the best possible restorations on S30s and the time has come to make this available to others worldwide as well. Our next goal is creating an international platform to promote the love for S30s, our restorations and the parts we sell. To make that happen, Florian Steinl became our marketing and content manager. Florian shares the same passion for S30s as we do, since he was born in the back of a Datsun."

-

Z's on BAT and other places collection

Recreating the various oddities/imperfections that happen during the factory assembly of the car would be a restoration. Removing those inconsistencies, like the overspray, would be "perfecting", in my opinion. Removing the stuff that they think doesn't belong. It will be interesting to see what types of finish they used on the hardware. Will they use what appears correct, or what would be "correct" for the time of manufacture? How does one tell? Apparently this is the first appearance on the market of one of their "restorations". Kind of surprising how many they have. And why are they are selling?

-

Fuel Pump Hammer Smack

@Ellison Brooks Another one brought here to espouse the benefits of Seafaom. Powerful stuff! Great for training and verification. Good luck! What brand of car do you specialize in? The four-wheeled kind or three?

-

Z's on BAT and other places collection

Should be plenty of pictures. Close to 400 on their last Z listing. https://bringatrailer.com/listing/1973-datsun-240z-290/

-

Z's on BAT and other places collection

Maybe these should be called "PerfectoMods". "The authenticity of the Masterpieces was affirmed in October 2024, when Takeo Miyazaki, a member of the original S30 development team at Nissan, tested three completed cars. After experiencing them firsthand, Miyazaki San remarked that the cars “truly brought him back in time and that he was amazed with the perfection in details” ..." Interesting that S30.World is based in The Netherlands but the BaT auction is being coordinated by Garage44 in Pennsylvania. I'd guess that the target buyers are here in the States. Many moving parts. I wonder if they'll bring the car(s) over, or if they're already here for viewing. https://bringatrailer.com/member/garage44/ https://garage-44.com/contact/ ""The commitment to quality and accuracy exhibited in these restorations is unsurpassed. I am excited to partner with S30.world and bring these special 240Z's to market" says Adam Eisenhauer, from Garage 44, the US firm coordinating the sale of the cars in the United States."

-

Z's on BAT and other places collection

Looks like they're only selling one, to start. Wonder which. BaT has been having a run of RNM's lately. https://s30.world/collection https://s30.world/masterpieces "... A limited-run of factory-correct restorations of the iconic Datsun 240Z will become available, with the first one to be sold at auction in the United States on October 23rd 2025. ... The auction will take place on the renowned Bring-a-trailer site, and it represents a rare opportunity for collectors and enthusiasts to own a piece of automotive history. The auction date of October 23rd, 2025 ..."

-

72 240Z Disassembled Project, ~95% Complete, Parts Boxed

The link works. Not obvious how to get in to the pictures though. Clcik on the Google Drive link, a new page will open > double click on a folder name > double click on the first picture > then you can scroll through all of the pictures in the folder using the arrows on the sides. It's pretty well deconstructed. A box truck would probably be best for transport, or a trailer with room for parts.

-

Hole help

Might help to identify where it is on the body. Probably recognizable to the guys that have torn their cars down but most have only seen carpet and interior fabrics.

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

I was just passing on a comment from the listing. Don't know who LookCloser is, but apparently he did. I think the rubber was just old and aged though, and the backward washers had little to do with the cracking. Many commenters were expecting over $100k, but those small details are often signs of bigger problems. Surprised it wasn't caught by the seller or the owner.

-

Z's on BAT and other places collection

This seems to be one of those cars with its own fan club. Interesting. A Players Club car. Dilettantes need not apply! "This isn’t a car for dilettantes or dabblers… it’s for connoisseurs and real players…"

-

Z's on BAT and other places collection

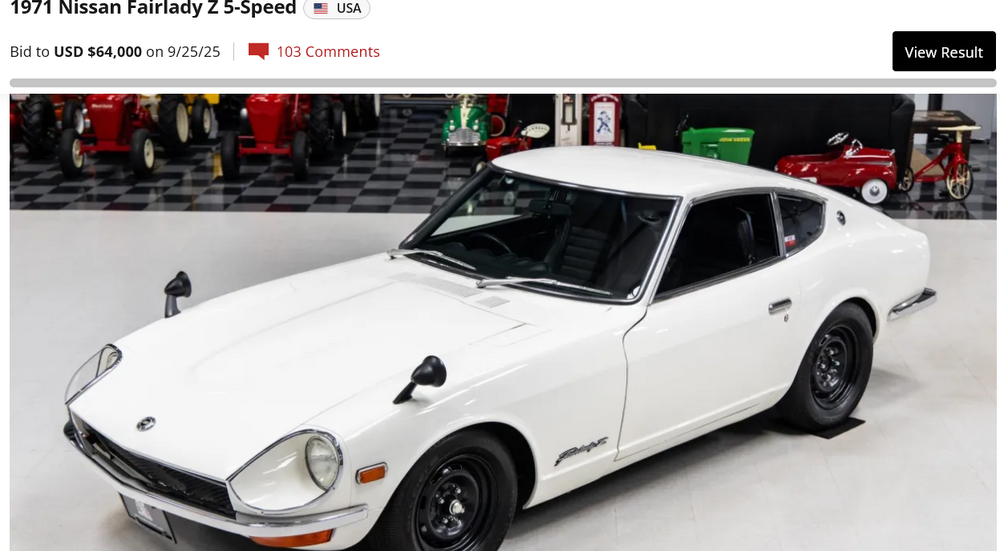

It didn't bring anything. Not moving. Isn't this guy a CZCC member? "JDM Car Parts and Restoration founder Tsuguya “Jay” Ataka". There were some small things that might have hurt it, like below, with the TC rod bushing. Small part, its degraded quality impossible to miss. He owns a car parts company. But, the money doesn't seem to be flowing anyway.

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

Who is Paul and where is it being sold? That "rarest of the Fairladies" is finishing today. I've noticed many "Bid to"'s though. People are getting tight with their funds, I think. Edit, aside - always funny how the sellers tell people how to use their computers so they don't screw up in the final two minutes. Smart enough to make an extra $100k or more to blow on a collector car, too dumb to know how to get the money spent. "As the listing approaches the end over the next few hours I’d recommend refreshing your screen and having the auction on two devices so it’s in live time." Bring a Trailer1971 Nissan Fairlady Z 5-SpeedBid for the chance to own a 1971 Nissan Fairlady Z 5-Speed at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #211,860.

-

Floor vent rebuild

You guys probably know this but if you're trying to restick an original headliner often the foam backing is so degraded that it fails internally, not at the surface. Just posting for anybody who ends up like I did. I used 3M contact adhesive in a spray can. But the foam was "toasted" (literally) and it sagged again. I never did scrape off the old foam and try again. What I should have done.