Everything posted by Zed Head

-

Clapsing a coil?

When I cut my springs I heated a point halfway around the coil on the cut end to red hot and bent it to give a flat perch for the spring. Otherwise the bottom coil sits on the point of the cut portion and puts bow in the spring. Maybe they did the same. If you can see the spring perch you might be able to see signs of heating on the last coil.

-

Car statred running bad suddenly

Where there's rust there was/is water. Could be that you just have a puddle of separated water at the bottom of the tank and some sloshed over to the tank outlet. If you haven't looked at your plugs in ten years, I'm going to guess that this not a daily driver. Does it sit for quite a while between drives? Today's ethanol-containing gas will suck up water pretty quickly if it can. Are your charcoal canister and gas cap intact, to keep the tank sealed from the atmosphere?

-

Car statred running bad suddenly

How big is the park and what was the drive like? Were you showing the neighbor what the car would, with some high RPM stuff or was it just a mellow three or four block trip? Were it me I might drain the tank contents, change the filter, and refill with new gas, just to take that variable out of the picture. You can use the fuel pump to drain the tank by running a hose from the filter to your portable tanks, removing the solenoid wire and turning the key to Start. As far as other sources, what was the tachometer needle doing while the bucking was happening? If it was moving faster than the crankshaft could possibly move, jumping and/or reading abnormally high, you might have an ignition system problem, maybe the module.

-

Removing Tie Rod Ends

Harbor Freight has a ball-joint splitters that are fairly cheap but look sturdy. The mechanical type, not the pickle fork. Looks like it might work. They had a 20% off coupon going for the summer too. Found a picture of it on the Google. 3/4" Forged Ball Joint Separator Put the tension on and wack the side with the hammer.

-

Optimum thermostat for 1969-1971 Z?

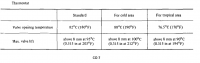

Don't forget to factor in boiling temperature depression due to intake vacuum on the PCV system! Nissan got more specific on thermostat temperature choice after 1972. Here's the 1976 chart. You still have to figure out Tropical and Cold. There's probably some general world-based definitions out there somewhere.

-

I need some dimensions or pic moustache bar area

Here's a picture of something I did just to see if it would have an effect. Big steel washer, and big rubber washer that fit the outer diameter of the bar but with a big hole in the middle, for up and down, and also smaller washers that fit just inside the inner diameter to reduce side to side. The rubber was just to avoid any buzzing or rattling. The picture is with the jack under the diff but you can see that the bottom scalloped washer still is compressed. I had more installed than shown at one time, enough to transmit diff noise to the cabin. Ace Hardware washers, nothing fancy. It was a good experiment for my purpose. Edit - might as well show my next experiment, to try and avoid the diff noise from the urethane bushings. I cut a boat trailer roller in half for the top bushing, and used the urethane on the bottom. Urethane kept the diff located side to side and the looser bushing on the top damped the up and down. Worked well, but looked ugly and started showing signs of age. Eventually went to all urethane but with an air gap to avoid noise transmission.

-

The Z that almost killed me

A blown head gasket will cause overheating. Check your radiator also, it may be plugged. How did the old water pump look? Were all of the blades intact? Does your fan clutch work? Maybe the overheating happened after you got off the freeway and did a lot of stop and go driving. There are a variety of methods for checking if you have a blown head gasket. A cylinder pressure test might show you something, along with the appearance of the spark plugs and piston tops. The missing thermostat is a sign that the engine had been overheating for a while. It's one of the thing people do when they don't understand the root cause of the overheating problem. One scenario is that overheating started from a bad water pump or radiator, leading to a blown head gasket, leading to more overheating after the common fixes were applied. You might have a warped head also, they don't like overheating.

-

The Z that almost killed me

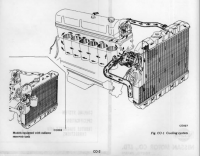

The port at the back right of the head is only for the heater core supply. It actually affects flow in a negative way when coolant flows out at that point. It's a necessary evil to keep the people in the cabin warm. Some other car models used what's called the block drain plug port, under the manifolds, as the source for heater core supply. Here's a diagram of the coolant flow. Notice that the heater core supply is not even shown. Coolant flows through the block, up in to the head and forward to the thermostat housing, then out to the top of the radiator.

-

Steam Powered Z???

You grind it, you bought it. I'm sure that will void the 30 day warranty. By wipe pattern, I meant the area of the rocker arms that the cam lobes ride on. Checked by blueing the pad, then rotating the camshaft and seeing where it rubs. It's described in the Monroe Rebuild book, page 109. A good book for you to have, if you don't already. At least check wipe pattern before doing anything, if it's off you can spend a lot more money trying to make it right. Plus it's a good indicator of the quality of the rest of the work. I hope that it's a good buy for you, but I would not buy anything from DatsunParts myself. Besides his past reputation, his eBay ads, which you must have looked at, look shady. Good luck.

-

Several problems with my 1972 240z

So the main question is how to keep the fuse from blowing. Fuses blow when they get too hot, usually from too much current but sometimes from corroded connections in their vicinity. Clean up the connections to the fuse and around it to make sure it stays as cool as possible. Look for short circuits on the fuel pump power circuit.

-

Several problems with my 1972 240z

I don't think that you can generalize all mechanics in Panama from the work on one modified old 240Z. You didn't really define a problem in your post. Does the fuel pump fuse keep blowing? Does the car start now? What is the current state of the car, you've only described something that happened in the past. Have you looked in the FSM at the basic adjustments for the SU carbs? Pretty sure that there are some simple things you can check.

-

The Z that almost killed me

Overheating from bypassing the heater core was demonstrated by Tony D on zcar.com a couple of years ago (data seems to be deleted now). Apparently, with no restriction between the head outlet and the water pump inlet, the water pump ends up re-circulating too much coolant from the back of the block, instead of running it through the head and the thermostat. Basically reduces the total flow through the head. If you don't get a heater core soon, just block both holes and the coolant will flow through the head like it's supposed to.

-

Steam Powered Z???

Not to put a damper on the project, but you should check that head carefully, or have it checked professionally. DatsunParts LLC is not known for their expertise, they(he) are(is) just very persistent in a market that has few options. A few years ago he sold some pretty poor work. Word is things might be better now, but early on it was obvious that he just collected parts, then re-assembled them in to packages. You could have a mis-matched set of rocker arms and cam, for example. Check the wipe pattern, check the lash, re-torque everything. Check the head thickness too, to see if the cam towers should have shims or not, calculate what your new compression ratio is since the head has been shaved. Check the spark plug threads before installing the head. If it was a Rebello head I'm sure you could not worry, but still would be worthwhile checking. This guy - you have to verify what you have.

-

What Engine Harness is this?

The fine people here can get you close but you won't really know unless you dig in yourself. The EFI harness is almost completely separate from the body harness. It has its own power wires and ground wires. There are connections to the fuel pump relay, which you may or may not need for carbs, and a few other indirect connections which aren't needed to power the car and can be disconnected, like the wires to Pin 1 from the coil (although the wire does need to stay connected to the tach). But, you said you pulled an "engine harness". It's not really clear what that is, the EFI harness is a separate harness and doesn't have a voltage regulator connection. Your best option is to study the wiring diagram and see what you can figure out. A few member of this forum have worked up some nice color diagrams. Here's 1978, and 1976 which is close to 77. 77 might be out there somewhere too. http://www.classiczcars.com/forums/misc-s30/44992-somewhat-color-wiring-diagram-1978-280zs-enjoy.html http://www.classiczcars.com/forums/open-s30-z-discussions/36494-free-full-color-wiring-diagram-1976-280z.html

-

What Engine Harness is this?

The wrecking yards in my area get the year wrong all the time. If they went by the build date, it might be a 78. 78 had the internal regulator.

-

Engine differences about Series 1 S30 Zs?

I think that Kerrigan's quest may be to find out what's true and not true. How do you know? Lots of conjecture out on the internet. For example, all of my comments in this thread about no need for L20A until there was L20B are wrong, if the information in the links in Post #21 are right. Apparently there was an L20, then an L20A, then an L20B. Apparently, according to the internet.

-

Engine differences about Series 1 S30 Zs?

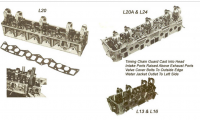

By "cooling setup illustration", do you mean the water jacket outlet on the side of the head? You don't have that?

-

Rear axle peened nut alternative

Many people reuse them. You can tell when you get in to the locking part of the thread, it gets much harder to turn. Other nuts on the car are self-locking also, like the ones on the two long transmission cross-member bolts. But, the FSM recommends a new nut. On the axle, probably best to go new. You can still get them at your dealer, I believe. They even show up on the Nissan data base. $4.98 each. Rear Axle :: 280ZX Parts (S130) 1979-1983 :: Nissan Parts, NISMO and Nissan Accessories - Courtesyparts.com

-

77 280Z Dropping Fuel Pressure once Warm

True, at some time in the 1978 model year they changed the type and location of the relays. But the FSM's shows the same picture and location for 76 and 77. 1977 still used the AFM switch, so would have had the dual relay. And, oddly, for some reason, a 1978 parts car that I bought and dismembered a few years ago (with title and proper build dates for a 78) had the 76/77 style dual relay in the same location. It's actually sitting in front of me right now (I keep various odd parts laying around, for inspiration). If I knew then what I know now I would have messed around with the AFM switch and the oil temperature sender on the 78 car to see which controlled the fuel pump.

-

Engine differences about Series 1 S30 Zs?

Here's another Fairlady topic. More stuff. Fairlady Z ID help - S30 Series - 240z, 260z, 280z - HybridZ

-

Engine differences about Series 1 S30 Zs?

Here's a 72, but the engine's been swapped - 1 tuff z: 1972 Fairlady Z-L project! - S30 Series - 240z, 260z, 280z - HybridZ

-

Engine differences about Series 1 S30 Zs?

Another - Post #6 (looonnggg thread). Again, no engine picture, just the body tag. By the way, could you link to your pictures for comparison? Might as well tie all of the Fairlady's together in one thread. Build your own case. http://www.classiczcars.com/forums/misc-s30/16660-gotta-sell-my-69-fairlady.html

-

Engine differences about Series 1 S30 Zs?

Here's one from this site that would be good to compare to (maybe you've already referenced it). With an A on the body tag. And some comments from your friend Alan T. Post #20 has the picture of the body tag. None of the engine though. Note that the OP does not say it's an L20A engine, he says it's an L20. Implying (to me) that there was no A stamped on the engine. http://www.classiczcars.com/forums/misc-s30/14433-information-about-very-rare-s30.html

-

Engine differences about Series 1 S30 Zs?

Post #4 - Orange, and only a little rust: `76 710 - Project Datto - Ratsun Forums Implies that the format is L20X XXXXXXXXX, not L20 X XXXXXX I would assume that the format would be the same and would only be used when the potential for confusion was realized.

-

Engine differences about Series 1 S30 Zs?

You're good at writing on the margins. I can't tell if you're serious or not. Anyway, an interesting thread for you might be titled "Who has an L20 engine and what is the serial number, and year of car?" You might get a sampling of information that tells something. The picture from the past that you remember would be a start. I take it this is an argument about originality, and maybe value, of your 1971 car? Those arguments are served well by comparison with like articles. There must be others out there. There would be no good reason to mark your engine before the L20B 4 cylinder was planned for production. And, logically, you know it's not an L20B, and it is an L20, therefore it can only be an L20"A". Unless you're trying to find out when Nissan started marking A's and B' on their L20's, if they did. That would be a question that could be answered. Maybe go could out and find out what the 4 cylinder L20B's have stamped on the block.