Everything posted by Zed Head

-

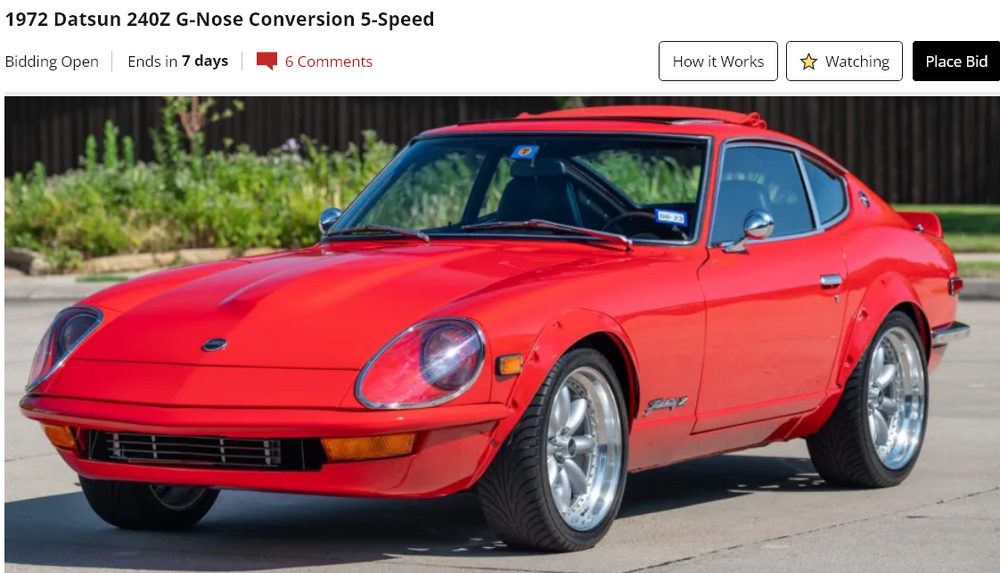

Z's on BAT and other places collection

I got curious after reading about The 240Z Guild, and the police car thing, and other stuff on the internet, so started looking at the pictures. Could somebody else describe what they see in the three screen grabs below? I'd like to verify. BaT should know, if I am correct. Picture #150 is the firewall stamping. Reminds of when I was a kid in the sketchy wrecking yard looking at a 10 bolt chevy rear end. The yard guy said "yep there is is, a 12 bolt rear end". I didn't even count the bolts until I had it home. Used it anyway but felt like a dummy. That story only makes sense if you're an old GM muscle car person.

-

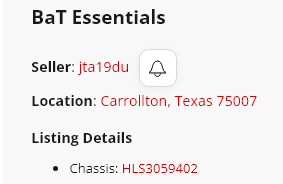

Brake booster push rod adjustment

That's a good point. I had a similar problem when the front calipers were on the wrong sides. The pedal went halfway down before any brake action. My problem was air in the system though, that could not get out. Easy mistake to make. Bleed valve on top.

-

Brake booster push rod adjustment

What does the brake pedal do? The play in all of the mechanical parts gets taken up when you press the pedal. There's a tool for adjusting the master vac. But getting it properly adjusted probably won't make the brakes work differently with no vacuum. https://www.google.com/search?q=vacuum+booster+adjustment+tool If it's the rear wheels that won't lock up it might just be poor quality shoes. I found when I replaced mine that the shoes seemed to be designed for oversize drums. They only contacted on the ends. I couldn't lock up my rear wheels at all and the parking brake was definitely not an emergency brake.

-

Z's on BAT and other places collection

This has to be noisy inside at speed, right? And why the wipers? Looks like it has potential though. Seems more "rag top" than a convertible. https://bringatrailer.com/listing/1972-datsun-240z-287/

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Thinking back it might be that I had found that I could not get to the two small screws of the electrical contact portion without removing the whole switch. Maybe I just didn't have the right tools. Meaning I had to grind one of the anti-theft screws. Whatever it was, it wasn't a simple process. Good luck to NightSpark. Edit - actually, it might be that I did what SteveJ suggested instead of grinding the screw. Who knows, can't remember. I do remember having a switch from a parts car that had a loose pin on the back though. That's the one that I restaked to fix.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Are you sure? I guess we'll find out. That would defeat the purpose of the break-away screws. Once you get the electrical part off all you need is a dime or a screwdriver to start the car. Actually, not sure, my memory is unclear, but there might also be those one-way screws on the electrical switch. I have a memory of one one-way screw and one regular screw. Whatever it is, on a factory stock car you had to do some grinding or filing to get the switch off.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Found a good video. "Break-away" screws. You don't need the whole assembly. You might actually be able to fix what you have with a small drift.

-

Advice for inertia kill switch

If any of the wire on the negative side of the pump before the switch gets pinched and grounded the switch won't help. Unless you mount it close to the pump. So, at least be careful with how you run the ground wire.

-

Weather stripping for 280z

You might be able to still find the Kia Sportage stuff. It seems to work best. https://www.classiczcars.com/search/?q=kia sportage&quick=1 https://www.google.com/search?q=site%3Aclassiczcars.com+kia+sportage

-

What Would You Do? Long lost HLS30-07631

You'll do better with more pictures. The door jamb tag and the fenderwell tag and the firewall VIN stamp and more of underneath. Also some side-on views from a lower angle. Those rockers look rusty. Floor pans too. And interior. Anyone looking to restore a low number car will want to know how bad the rust is. I'd guess that Indiana uses salt on the roads and that that car saw some salt. Good luck. Post the listing when it's up.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Jump the appropriate pins in the relay connector. If the various lights are still dim then it's likely that the relay is fine. That way you don't have to contort yourself to remove it. There are a lot of connections on the brake warning lamp circuit.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

It might help to restate the state of affairs. One change seems to be that "won't start when hot" has morphed in to "runs funny after it starts".

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

?

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

-

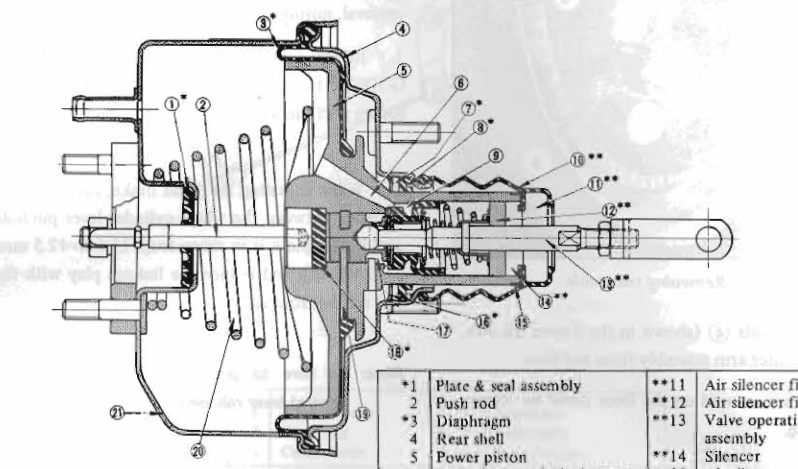

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

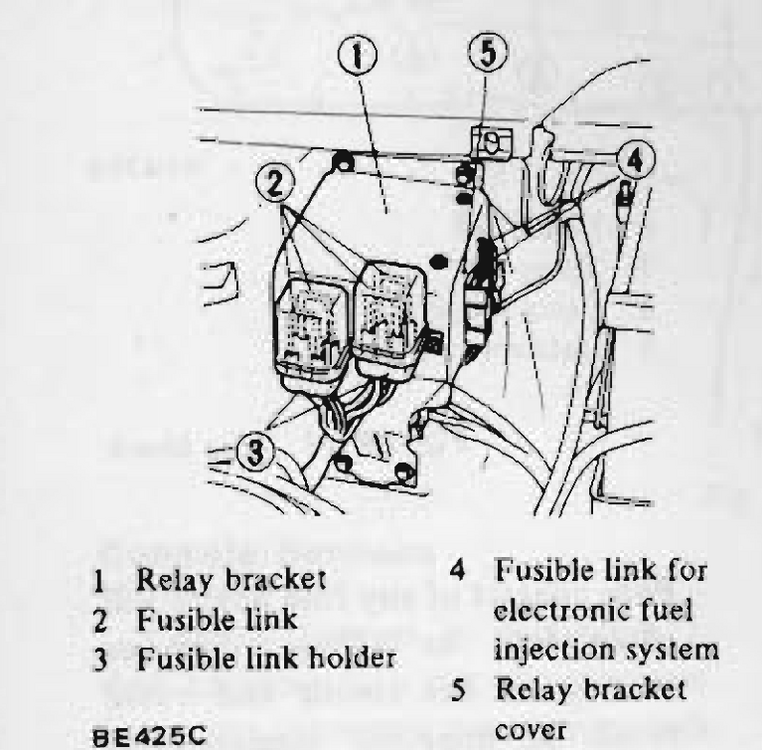

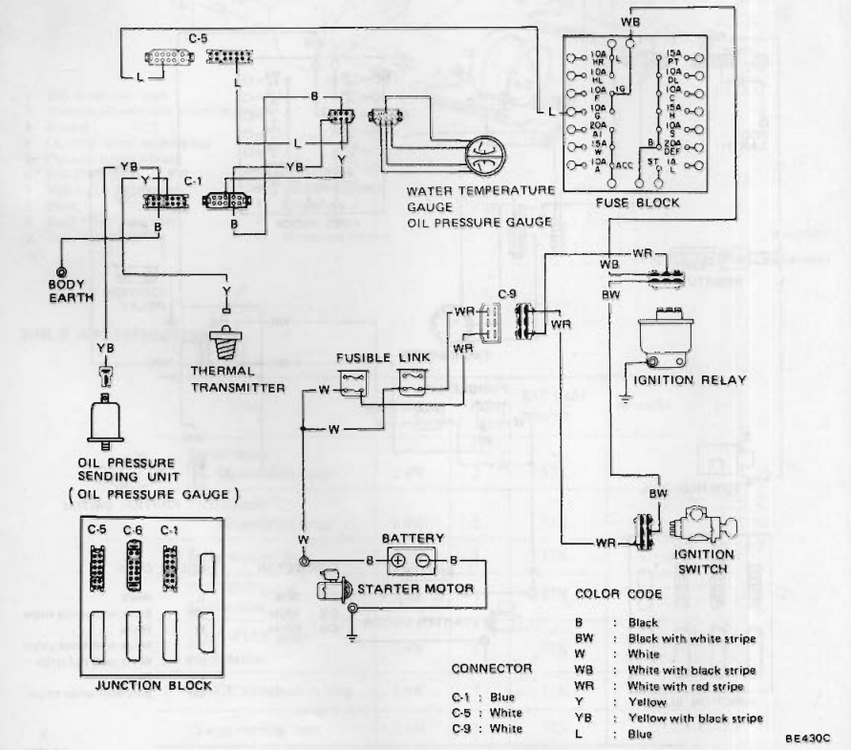

Somewhere between the terminal on the battery and the other end of the battery cable at the starter, there should be a another wire with a white plastic connector that has two green wires heading off to the EFI system. Open the cowl cover and take a look. Take a picture and post it.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

You didn't say if you cleaned and tightened the loose fusible link terminal. If it responds to a wiggle it's loose. (All of this wiggling and squeezing is making me feel funny. Says Garth). You can just just squeeze them tighter with a pair of pliers. Don't forget to check the two green EFI links from the battery positive post. And, of course, check your grounds.

-

Thermostat Housing replacement

Heat. The bolts typically rust in the bores and rust expands when it is formed. Heat the aluminum to get it to grow and it will help break the bond. If a bolt breaks it will probably be just the head and upper shaft. The housing will still be stuck on the rusty part. Once you get the housing off the remainder of the bolt will probably come by hand.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

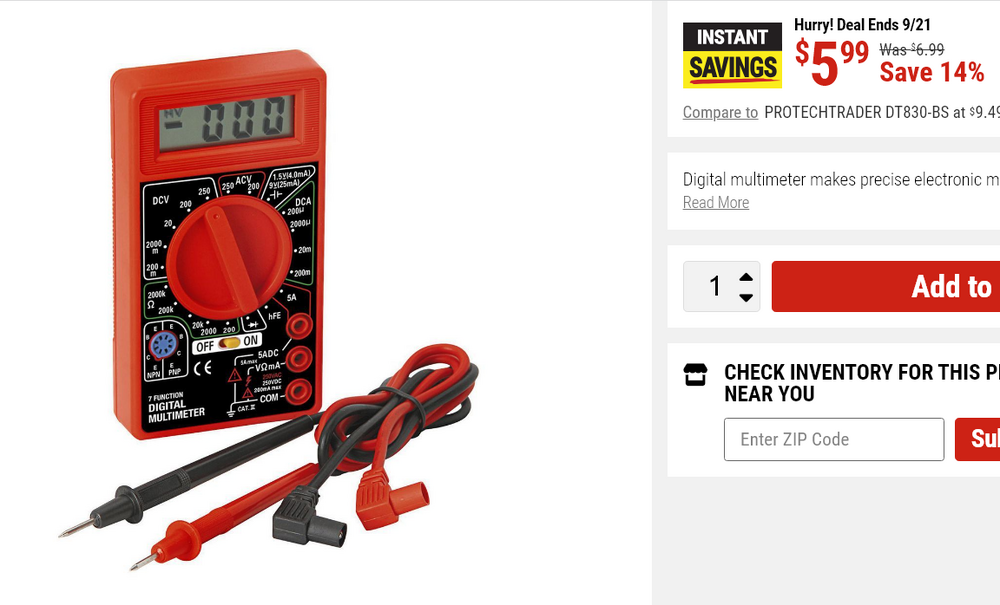

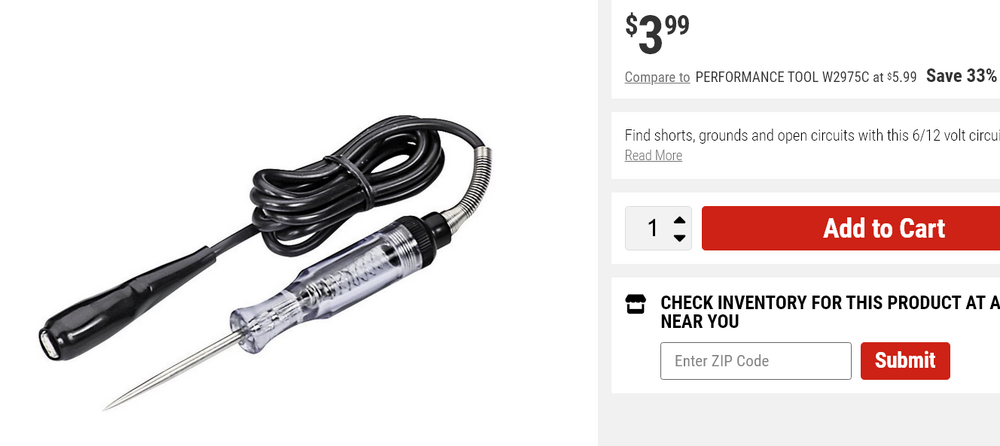

You can't do SteveJ's test with wire wiggling. Multimeters look complex but most of us only use two of the functions. Voltage and resistance. You can ignore all of the rest. https://www.harborfreight.com/7-function-digital-multimeter-63759.html https://www.harborfreight.com/612v-circuit-tester-with-5-ft-lead-63603.html

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

You'll need a meter or test light to continue. Wiggling wires might get you there but it will be a lot faster with some simple testing equipment.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

I'd diagnose the two issues separately. There's a crank/no-start issue and the gauge power issue. You can test the no-start issue by testing for coil power and injector power with the key On and at Start. It's not clear that the ignition relay is the problem but it could be. You can test for power with the key on at several points on the path through the gauges and on to the sensors themselves. I'd start at the fuse box. If there's power on that fuse with the key On then the ignition relay is fine, for that circuit. A loose fusible link connection seems like a possibility. Many ways to break the system down in to parts.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

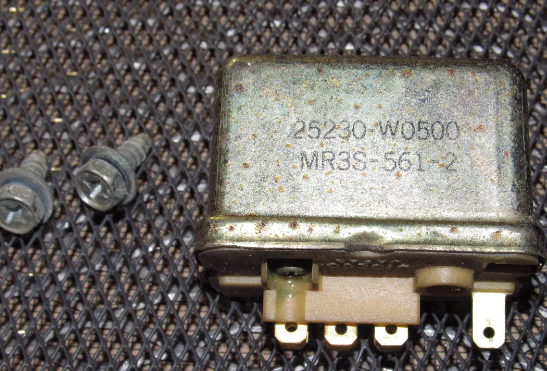

Here's a ZX relay just to fill the thread out. Maybe it's just two years. https://www.autopartone.com/products/79-80-datsun-280zx-oem-relay-25230-w0500

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

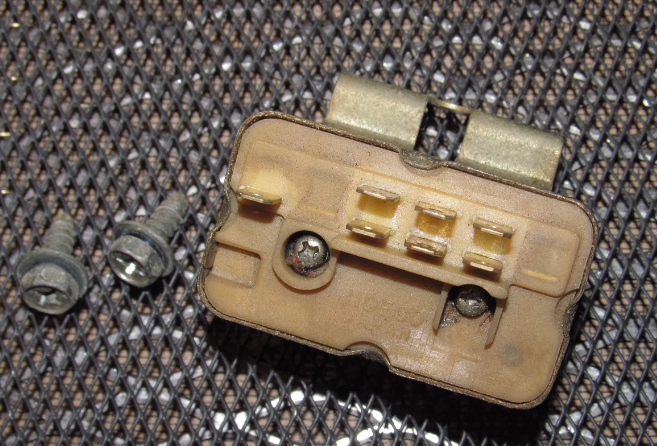

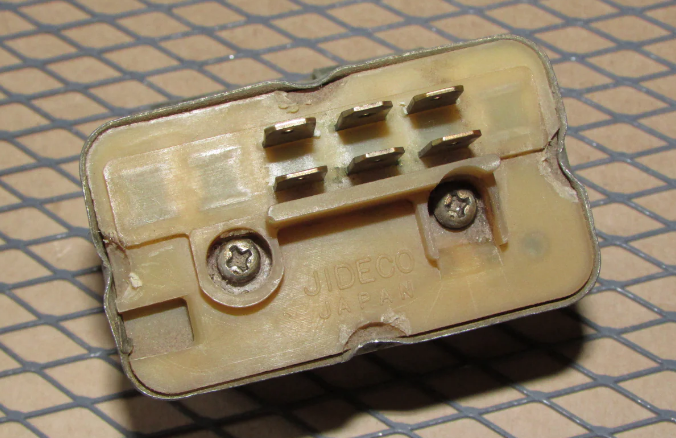

Yes, I looked at the 76 diagram and it shows the same thing. What's funny is that the ZX's did have a terminal and a dedicated ground wire so the drawing does match a ZX. Weird. It was a spade terminal though, not a threaded stud. I picked up a spare from a ZX just in case. In the ZX's they're behind the glove box. Here's a listing and a picture of 78 relay. You can see the four places to bend to get the cover off. I called them tbas but they're really more like crimps. A pair of straight jaw pliers and four squeezes and it will pop right off. Might be a ground wire connected inside though so be careful, if you get that far. https://www.autopartone.com/products/75-76-77-78-datsun-280z-oem-ignition-relay-25230-89958

-

Fuel rail upgrade?

Looks like the SARD might be like others. https://www.google.com/search?q=sard+fuel+pressure+regulators+leak+down https://www.rx7club.com/new-member-rx-7-technical-256/sard-fuel-regulator-leak-injector-line-816953/ But then this guy below says his does hold pressure. I'm seeing that many people aren't real clear on things like the check valve inthe fuel pump. The guy in the link above could have a check valve problem. https://aus300zx.com/index.php?threads/holding-fuel-pressure.337928/page-2

-

Fuel rail upgrade?

Weird that that link is dead now. It should have opened to a page with a couple of SARD FPRs. Google shows them on eBay too. I'd search around first and see if you can find any internet comments about leak-down. Just because one didn't doesn't mean that they all don't. https://www.google.com/search?q=sard+fuel+pressure+regulators