Everything posted by Zed Head

-

alternator swap

I've found that my old Nissan factory ZX alternator is better at low RPM than a "new" reman alternator. It's fun to modify but if you're just looking for an improvement that might be an option, if you see one on your wanderings.

-

alternator swap

I think that J30 alt is similar to the Maxima alternator. I think it uses a ribbed belt too, not a V-belt. I modified a 90 amp Maxima alt but it's still sitting in my garage waiting for my old ZX alt to die. The hardest part is getting the nut off of the pulley shaft, and getting a pulley that will fit and be centered after messing around with it. The Maxima alternator is a bolt-on as far as brackets go. I think. I should go out and refit mine to be sure.

-

Distinct clunk when accelerating in first gear

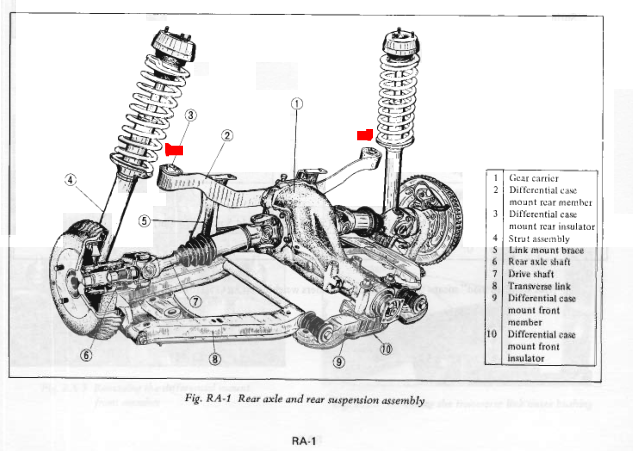

This is a nice looking undercarriage though. Very clean. No leaks. Wish mine looked like that. But, you should get some soft pads for your mechanic to use on the lift arms. He's denting things and lifting in the wrong spots. Each lift probably adds a little bit more damage.

-

Reverse backup light switch for 280z 5 speed tranny

You've been using the illicit side of the free market?

-

Reverse backup light switch for 280z 5 speed tranny

Free market economic principles.

-

'75 280z made it out of the garage.. briefly

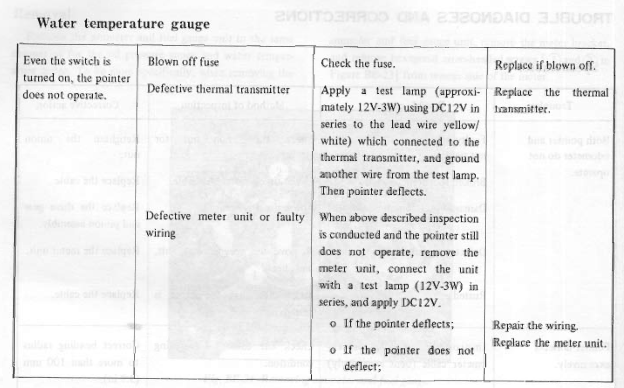

I think that you can test the gauge itself by grounding the harness wire at the sender to the block through a small resistance. You can also measure resistance through the sender prong to the block to see if it's good. The sender ground through its threads I think. Sometimes people use Teflon tape and don't get the ground. Found a procedure in the 1972 FSM -

-

Distinct clunk when accelerating in first gear

Good times man...good times. You can get thumping from the ends of the mustache bar also. The diff twists when you apply power, or torque from deceleration. If the mustache bar bushings are loose you'll be able to lift the end of the bar up by hand.

-

l24 blocked engine build - Few Questions

Here's something beyond quench... (For thought only. It's voodoo.). https://www.google.com/search?client=opera&q=Somender+Singh+Grooves&sourceid=opera&ie=UTF-8&oe=UTF-8 http://www.herningg.com/projects/groovyheads.html https://somender-singh.com/index.html

-

l24 blocked engine build - Few Questions

Sorry, I think I blended two threads together in my head, or assumed that the head they built was designed with "squish". Actually, I can't be sure, the details aren't in the thread. Here's the thread I was thinking of and another I found when I was looking. Sounds like he used an open chamber N42 head. http://forums.hybridz.org/topic/51825-scratchbuilt-l6-efi-intake-manifold/ Here's some squish stuff. I've found a lot of inconsistency in what people write abut quench/squish. For example, you'll find people taking about how the piston has to be within a certain distance to the head or you'll actually create a detonation hot spot. But then when you do the math on their engines you find that it doesn't fit, they have no quench. http://forums.hybridz.org/topic/63444-l6-squish-discussion-the-battle-against-detonation/ BRAAP has a post out there somewhere about getting the piston so close to the head's quench pad that the piston number transferred to the head, in the carbon residue. Sounds neat but not clear if an actual benefit was measured. That's the basic problem. Showing that it works.

-

l24 blocked engine build - Few Questions

It's one of those engine building concepts, to create the best combustion process, I believe. The "squish" is supposed to propel the gases in the squish area out across the combustion chamber for more complete combustion. There is also a cooling effect on the top of the piston that some people propose happens as it gets so close to the head. What's not really clear though is how the rest of the chamber design comes in to play. Valve and port orientation and the way the gases flow in to the cylinder, spark plug location, things like that, all come in to play, I think. The OP has put together a set of "perfect" concepts, but it's unknown how all of the perfection will work together. There's a good thread on Hybridz by BRAAP and Ron Tyler, where they took all of the "known" ideal concepts, including quench and porting and a new intake manifold design to build an engine. When they dyon'ed it, they couldn't get much power out of it without major detonation problems. They used Megasquirt and knew how to tune but the parts just wouldn't work together.

- 78 280z Severe Driving Problems

-

'75 280z made it out of the garage.. briefly

The radiator cap is just a pressure relief valve. If the pressure is exceeded the coolant is purged through that tube. Could be that you got the wrong cap or that you just didn't have it inserted right. Check that cap closely, make sure it's seated so that it can hold pressure. If it's not seated the coolant will just flow out as it expands. The heater cores are best if they are blocked, not connected. By connecting them you're creating a short circuit for the coolant and it doesn't pass through the head. It just circles around in that useless loop. It reduces the overall flow through the engine. Where'd you get that cool looking "FUSIBLE LINKS" cover? Is that what they used in 1975?

-

78 280z Severe Driving Problems

I forgot that you had the rail out when I suggested just starting the engine. In my test, I wired the injectors in series so total circuit resistance was 6 x 2.5 ohms...15 ohms. I was more concerned that they might not open. But the key is that it's not voltage that is the concern, it's current. Overheating. If you connect 12 volts to a dry injector I think that it might heat up enough to do some damage, over time. Maybe. But in your case with the dropping resistors in place, and fuel passing through, there shouldn't be any problem. The injectors see 12 volts as soon as you turn on the key. They're opened by grounding that voltage at the ECU.

-

78 280z Severe Driving Problems

Just realized that you might have run your vacuum port FPR test using residual pressure. Fuel pressure tests are generally done with the pump on. There are many ways to run the fuel pump without the engine running. A simple one for 1978 is to remove the oil pressure sender wire. Then turn the key to On. The pump should run continuously. It's a flaw in the system. The pump will be fine also, it's cooled by fuel too. It runs full time when the engine is running. You can also remove the starter solenoid wire and turn the key to Start. Or prop open the AFM vane and turn the key to On.

-

78 280z Severe Driving Problems

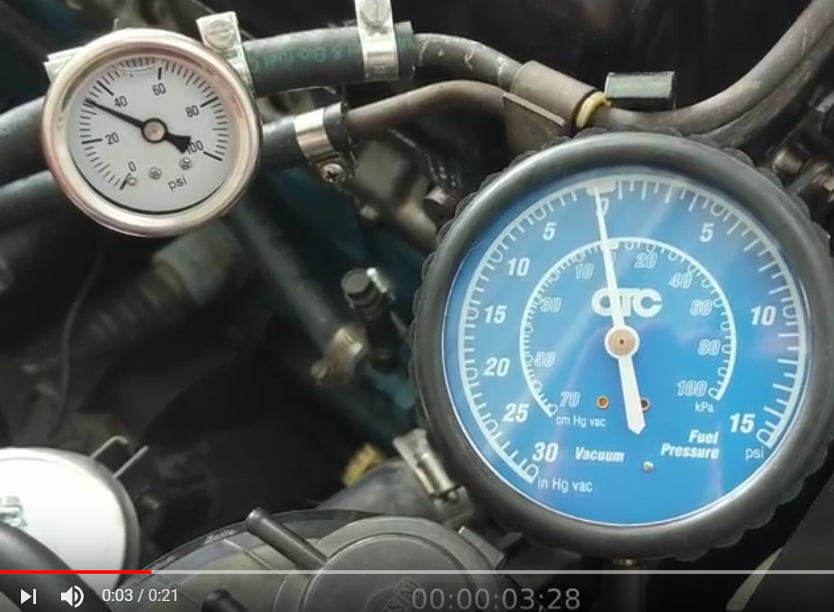

In the picture I grabbed from your video, copied again below, if you've ever seen 40 psi then you should have seen it at zero vacuum, as shown in the picture. Unless the extra 2 volts from alternator power pushed the Walbro up in to the excess volume zone. Who knows. Fire up the engine, remove the vacuum reference hose from the FPR, and see what the fuel pressure gauge says. Give the engine some RPM to be sure you're at maximum alternator output. The pump is just pushing against the FPR spring to get the seat open. Maybe you've got some particles holding the FPR seat open and that's why pressure is low and doesn't respond to vacuum. Ponder that FPR drawing that you posted earlier and you'll get some ideas. The vacuum just relieves atmospheric pressure from the spring cavity. You could probably blow on the reference port and get pressure to rise. These EFI systems are just a collection of really simple concepts. So, unless your helper was pulling vacuum in the picture below and it didn't show on the vacuum gauge I'd say your fuel pressure gauge is sticky. Pulsing the injectors adds extra information, but if your inlet screens are clogged it won't show that, directly. I filled those bottles at wide open injectors with my own tester. Injectors wired in series. The injector solenoids are cooled by the fuel passing over them and the current is low. They'll be fine. Pressure should be at maximum with no vacuum...

-

78 280z Severe Driving Problems

Just a followup. That's a good test. The fuel pressure should drop smoothly as vacuum is applied, just as shown in your chart. My pressure will sit at about 27-28 psi and jump up with RPM. Very smooth and very fast. You have a nice setup showing that something is wrong. Just not clear if it's your gauge or your FPR. Does the hose to the vacuum gauge have any fuel in it? That would be a cracked diaphragm.

- 78 280z Severe Driving Problems

- 78 280z Severe Driving Problems

-

78 280z Severe Driving Problems

You're right , the fact that it drops says that it's not the lines being overpowered by the Walbro. I missed that. But it's been proposed that it's too high, generally. That question is still open. The FPR could still be defective, giving generally high pressure over the vacuum corrected span. Beside that, the first, most basic fuel pressure test is with no vacuum reference. That number hasn't been seen yet. Edit - in short... I just want to see a 36-37 value somewhere. That's the FPR's starting point.

-

78 280z Severe Driving Problems

What is the highest value that you see on the gauge when you run the fuel pump without the engine running, or if you run the engine but disconnect the vacuum reference entirely? That should be the highest pressure reading. Best to do it with the engine running because alternator voltage will run the pump faster. One of the proposals is that the Walbro is overpowering the FPR or the return lines. You need to test at the highest possible pressure, which would be with no reference vacuum and maximum pump voltage. The engine will run rich but it's a short test. Consider also that you might have a bad gauge, with a 2-3 psi offset. Edit - zeeboost raises the point, below, that the Walbro can't be overpowering the fuel lines or FPR orifice if pressure is dropping. Still need the unreferenced number though.

- 78 280z Severe Driving Problems

-

78 280z Severe Driving Problems

Pulling the head seems drastic. Maybe you meant valve cover? You can fire/open the injectors while they're still on the rail. Just ground them at the ECU connector with the key on. Get six little cups, or small soda bottles and let them run for about 10-20 seconds, see how much comes out. You'll know if one or two is clogged. The screens in the inlets can get blocked easily. My comments about valve problems were assuming that something happened after you did your first round of tests. You never know.

-

240z 1972 Owners Manual

Here's the Service Manual, if it will help - https://www.classiczcars.com/files/file/19-1972-240z-factory-service-manual/

-

78 280z Severe Driving Problems

The vacuum hose mistake would have led to the timing being retarded by the total amount of vacuum advance possible. Probably about 14 degrees. So when you opened the throttle timing would have dropped to about -4. Of course as RPM increased centrifugal advance would bring it back up. Retarded timing will reduce power by quite a bit. The car might be drivable now, but still "poppy". You can check if the advance hose is correct by removing it when measuring timing at idle. Nothing should happen. Then with the hose connected timing should advance as soon as you crack the throttle. Weak cylinders won't show a big effect if you cut fuel by disabling the injectors. Low compression or burned valves for example. If you're sure the injectors are working that would be a good place to focus, assuming that you know you have spark. Here's another thought from other people's past problems. After these engines sit for a while the valves and guides get sticky and sometimes they spit a lash pad. Then the vlave doens't open any more. It usually happens at high RPM after people give the engine a little road tuneup. The way you were revving the engine in the first video it wouldn't be a surprise if that happened. These engines are so smooth that sometimes it's hard to tell when a cylinder is not firing. You might rerun your pressure check or recheck the valve lash. Could also be that you didn't get a lock nut tight and lash has changed.

-

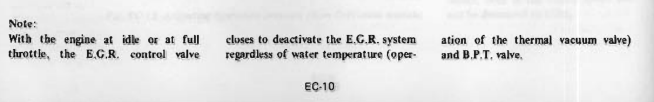

78 280z Severe Driving Problems

One area that has caught some people is the EGR system. Since your engine sounds good at idle you might try disabling it to see if anything changes. I think it actuates by ported vacuum so blocking that hose might have an effect. And like jr says above, make sure that the AFM vane is moving freely. When I was watching your video I thought I saw it hang, its movement trailing the engine sound, but I couldn't be positive when i rewatched it. A slight delay in vane reaction will lean things out and cause intake popping. And as CO suggested, if the AFM has been messed with maybe the atlanticz calibration procedure is the way to go. I'd get a magnifying glass and see if I could find the original glue blob traces myself. Or crank that potentiometer up and try to drive it. Something will show up. You're doing all of the right things.