Everything posted by Zed Head

-

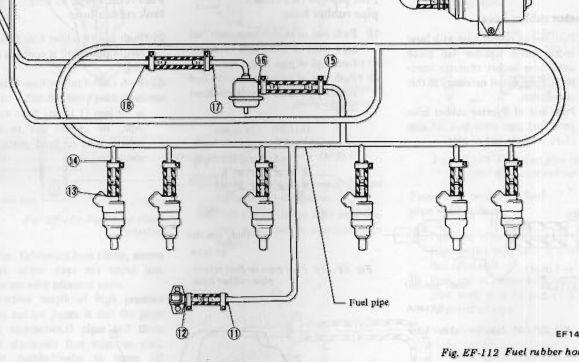

78 280z Severe Driving Problems

Hard to say why you're having such a problem with this. You are having waaaaaayyy more difficulty with getting fuel pressure down to about 37 psi than almost anybody in the history of the forum. Kind of exaggerating but need to be clear that you should not be experiencing this problem at all. Because it's so unusual it wouldn't be a surprise if you had similar problems with an adjustable FPR. Even though it's adjustable. Can't emphasize enough that the FPR is just a spring-controlled check valve, in essence, when the vacuum source is removed. It's super simple. It might be that somehow you're adding complexity somewhere, or somebody else did before you got the car. Have you examined the fuel system return lines all the way back the tank? I had considered adding a second FPR to my car for a short while because I had a pressure leak-down problem and didn't have the correct FPR to fix it right. I never did, it was just a thought, but maybe somebody has inserted a second regulator or even a spring-loaded check valve, to hold pressure. You might actually be fighting a PO's previous "fix". If so, you'll have the same problem with any regulator.

-

Fuel Pump Grounding

Does it smell like good clean gasoline, or turpentine? That's what I was wondering. If it squirted then fuel is in the intake manifold. Why isn't it lighting up, is the question. I don't think the "life delayed me" wordage is allowed unless it's over a few months.

-

Fuel Pump Grounding

That could be twenty years. I would see what's in the cold start valve line. Looks like the electrical checks out. The same fuel is probably in the injectors since they are branches off of the fuel rail loop. The new fuel will pass by those branches but there's no driving force to replace it besides the few squirts while trying to start.

-

Fuel Pump Grounding

But, of course, the history of the engine might be most important. If the cylinders are dry they might not generate enough compression to fire a gasoline mixture. Squirting oil in to the cylinders can help that. Maybe the car was parked because it quit running. You haven't given any history or much about how you prepared the engine to start. You might be about to suck a bunch of old crud and fuel in to the cylinders. The best is assumed, but maybe you should stop and rethink.

-

Fuel Pump Grounding

Many different ways to get the engine to run. Like many you've said that you "ran the tests" but didn't list them out with results. Here are a few things that you could do just to learn more. - Let the pump run for a while. this will flush old fule out and get new fuel close to the injectors. Of course, if you have water or old gas in your lines it will also contaminate your new fuel. - Remove the cold start valve and run the pump. Or just remove it and place the nozzle in to a container and give it power. See what comes out. It might be old dead gasoline. - Test the injectors using a "noid" light or one of the various test methods described in the forum. Make sure that the injectors are getting the proper circuit to open and close. - Use a screwdriver or stethoscope on the injector bodies to see if they click when the engine is turning over, like they are supposed to. - Connect a jumper wire to the coil's negative post and tap it to ground with the key at Run. Every third tap should cause all of the injectors to click. This might be the quickest, easiest way to confirm the injector operation. It's quiet and it's a one-man operation, in the engine bay. If the injectors aren't clicking they're not opening, if they're not opening there's no fuel. - Use starting fluid in the intake manifold to make sure the engine will actually run with fuel.

-

Alternator and Voltmeter question

The answer to the problem is probably here - http://www.atlanticz.ca/zclub/techtips/alternatorswap/index.html

-

Fuel Pump Grounding

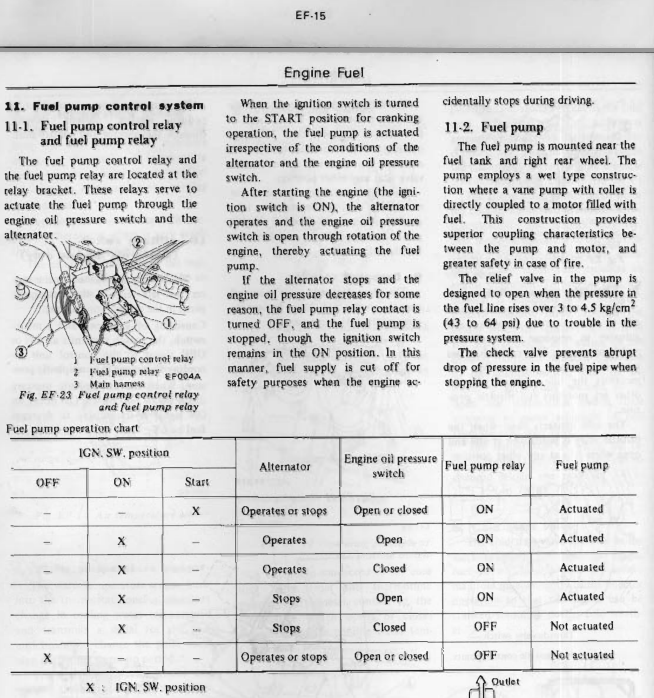

You should download the FSM from the Downloads section of the forum. Read the Engine Fuel chapter. The fuel pump does not prime on the 280Z, or turn on with the key. It only gets power during Start or engine running. Thinking that the pump should get power when the key is on is a common 280Z error. The Engine Fuel chapter has an extensive list of tests that you can run. Many things have to be right for the engine to start and run. It might be that you have fuel pressure but no injection. Or that you have fuel pressure but the fuel lines are full of water. Or bad gas. Lots of ways to test these things. Welcome and good luck. https://www.classiczcars.com/files/category/13-280z/

-

1970 Series1 240z "barnfind"

I'm just playing around jakay. I love a good logic debate. Words and what they mean. I Google a lot. Good luck. Too bad you couldn't have made it down to the ZCON in Atlanta. The car probably would have been a hit down there.

-

1970 Series1 240z "barnfind"

Is your Z really the "26th" Z? I used the serial number to designate the lineage of somebody's Z, like you're doing with your screen name, and HS30 tried to correct me. Should we go down the rabbit hole? Should you change your screen name to be correct?

-

Fuel Pump Grounding

The operation of the pump and its relays is described in great detail in the FSM. There's a flaw in the design that lets you test the pump and relays, by pulling the oil pressure sender plug off and turning the key to Run. The pump should run then. Why do you think that you have a problem, besides the 3.4 volt measurement? Not sure that your understanding of the wiring is 100% correct.

-

1970 Series1 240z "barnfind"

No need to pick any side really. Just wanted to give you a heads up. Conversations can take a turn for the worse when these early cars come up. Some people like the full restore, others like some original history. And, there are others who would love that car for a V8 conversion, because it's so clean and rust-free.

-

1970 Series1 240z "barnfind"

HS30 loves to split hairs and other things. Serious. Don't get caught up. He has an early Z and is incredibly protective of the brand and model. There are a few other guys that might join in also. A tiny club of early Z owners. You might have to pick a side. What are your plans for the car?

-

Alternator and Voltmeter question

I had an internally regulated alternator/regulator fail once and the dash light came on dimly and got brighter with RPM. But the voltage looked correct on the meter. The internally regulated alternators use solid state regulators though and they can fail indifferent ways. Here's the FSM description for the external, mechanical, regulator. There are test procedures in the FSM. There's even an adjustment procedure. Kind of a shame that we all swap to the later models when it's all there in the FSM's.

-

Alternator and Voltmeter question

The light tells you when it's not charging, too little. The needle tells you when it's too much. It's kind of primitive compared to today's electronic monitoring systems. Are you sure that it failed? Could be that the voltage sensing circuit lost contact. It's not clear what you mean about the VR. You said the old one is there, then said it's bypassed. Not sure what you mean. Did you convert to an internally regulated system?

-

1970 Series1 240z "barnfind"

Pretty cool. I feel like I just bought a brand new 240Z.

-

280z L28 setting engine timing

In the end it boils down to comfort level. I made a tiny paper protactor once to measure an angle on small small part. Just took a short time with paper, pen and a big protractor. If that was my engine I'd probably do that. I trust the angles and would be comfortable putting everything back together that way. Some of the forum people could probably design and build a chain tool that allows the chain to slide by so the tensioner pop-out problem doesn't exist. I saw on another forum that some guys built a little jig to hold the sprocket where it would be on the head and mounted the sprocket on it on top of the block to hold the chain tight. Probably doable with some wood. If the common wood or plastic tensioner is tight the chain will ball up underneath it when you turn the crankshaft. And as we all know, the more bolts you remove on these high mile engines the more bolts you'll break. Anyway, good luck to him whatever he decides to do. Here's another one - remove all of the rocker arms so that the valves are all closed. Put it together, turn it to wherever it needs to be to see the marks. Adjust, then reinstall rocker arms.

-

280z L28 setting engine timing

The tensioner popping out. "Need" is subjective. He probably hasn't been back yet because he realized the tensioner popped out three weeks ago.

-

280z L28 setting engine timing

That's what the marks on the engine parts are for. Notches, grooves, pointers, to verify correct cam timing. If you go slow you can turn the engine by hand once it's together. If you're really strong you could probably bend a valve by hand, but you'd have to have hands of stone to not feel the initial contact. Odds are he'll get it right the first time. I think I did some math once and found that one chain link is like 7 degrees or something like that. If he takes the front cover off he could end up on a whole trail of "while there" fixes and replacements. Front seal, water pump, timing chain is probably worn, probably break some thermostat housing bolts so better have the drill and Helicoil ready. Don't damage the damper rubber while pulling the damper... Many possibilities. Kind of comes down to risk/reward.

-

1970 Series1 240z "barnfind"

The car looks great. If you have pictures of any paperwork that you have, and the car's ID tags, that would be fun to see. Some people get really caught up in the numbers, and as you can see, there are still open questions about how the cars were built and how they got distributed around the US. Even with the paperwork there will probably still be arguments about whether it's real or not, what "model year" it is, what "series" to call it, whether Bob Sharp touched it or not. Good stuff. See if you can find a Bob Sharp fingerprint somewhere on it. Remember also that anything original to when the car was built might add more value than being shiny and clean. Patina, provenance, history, whatever. I wasn't kidding about the fingerprint.

-

280z L28 setting engine timing

He could also turn the camshaft the few degrees to match the damper pulley. The key to not damaging a valve is that the cam timing matches the crankshaft timing. If he's 30 degrees advanced on the crank the cam should be 15 degrees advanced. Then install the sprocket and chain. The chain is what actually controls the cam and crank relation. There's basically two steps involved here. 1. Get the head on with the valves in the proper position to not hit piston tops. 2. Get the sprocket and chain on so that the crankshaft can be rotated without valves hitting piston tops. Keep those two things in mind and come up with a solution. People have used a pipe or lever to hold up the sprocket and chain while they moved the crankshaft. The big risk now is having the tensioner pop out. Then he's in a whole new world. The tensioner really really wants to pop out of its hole. Many possibilities.

-

280z L28 setting engine timing

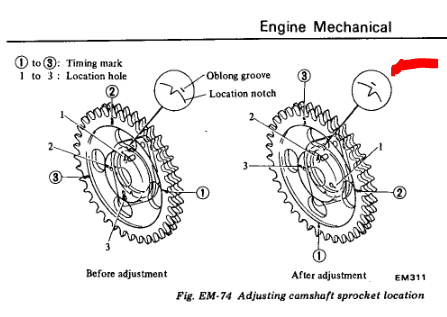

Just thought also that you can put the sprocket on to the head temporarily to line up the notch and groove. A little more precision than just having the cams pointed up. If you're worried.

-

280z L28 setting engine timing

I forgot about that. I'll bet your timing mark is within a few degrees of zero right now. I'd go ahead and put the sprocket on, remove the chain holder, then rotate the engine slightly by hand to get timing mark to exact zero and to get the chain tight, to see how your marks line up. I can tell by your piston positions that the timing mark is close. Your valves will have plenty of room. Just go slow.

-

280z L28 setting engine timing

Yes. Once the sprocket is on it's not needed. But if you need to adjust the sprocket put it back in. It can be difficult to get the sprocket on even if everything is right. Good luck.

-

71 240Z for $2850 in CA Seems like a decent deal

From zcar. https://www.zcar.com/forum/15-cars-sale-1970-83-240z-260z-280z-280zx/418412-1970series1-gmail-com.html

-

280z L28 setting engine timing

Set the damper pulley ignition timing mark on zero, it's almost there now. Install the head with the cam lobes up on #1 as you described. Then install the cam sprocket so that the notch and groove are aligned as shown in the FSM. You'll probably have to turn the camshaft slightly to get the sprocket on. Since your timing chain is worn you might have to use the #2 hole on the sprocket. Make sure that the driver's side of the chain, the straight side, is tight, and the damper pulley mark is on zero, when you compare the notch and groove positions. Once you get those three marks lined up you can spin the engine with no fear. That's the basics. That's why the marks are there.