Everything posted by Zed Head

-

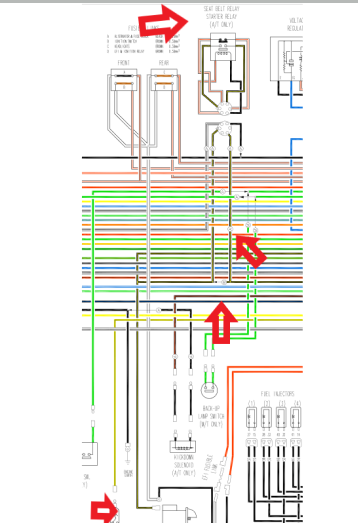

HELP: Rear red lights ON and no power to starter

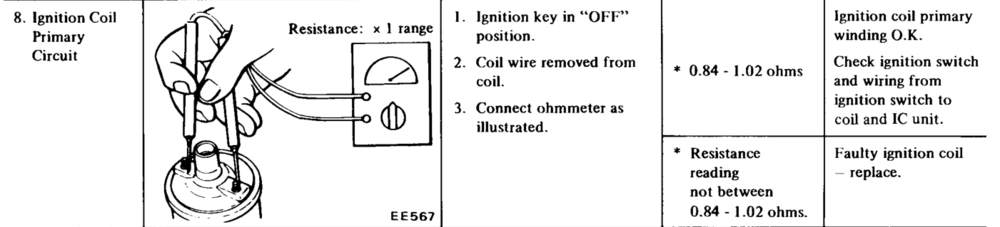

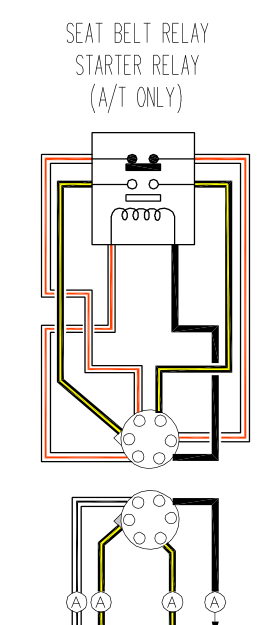

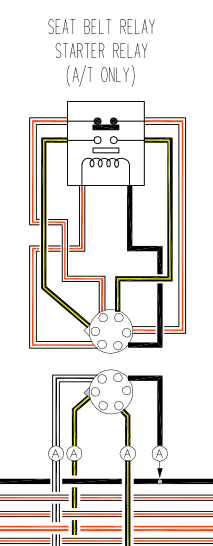

The inhibitor switch provides the current that actuates the starter/seat belt relay. It's shown in your diagram. Two devices, plus the switch and the ignition relay, that have to function properly before power makes it to the solenoid. It seems unnecessarily complex, but it is what it is. SteveJ has replied but I must hit Submit Reply anyway

-

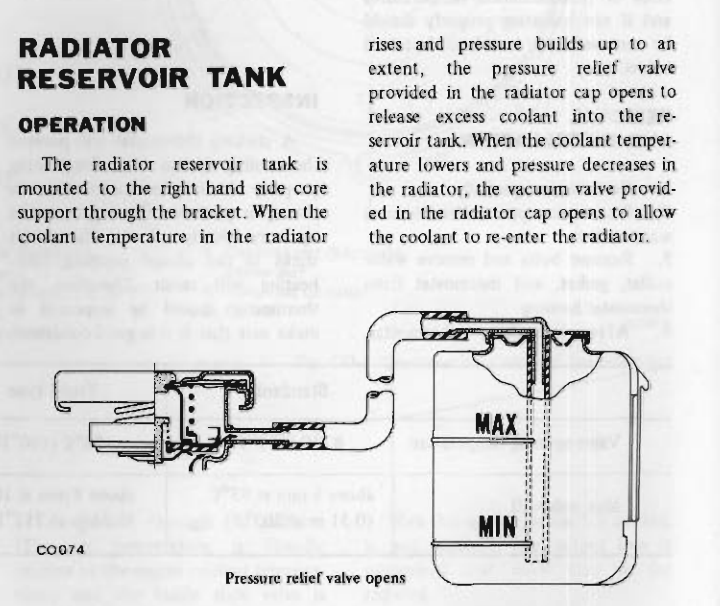

Not quite overheating

-

Not quite overheating

Seems like you might be avoiding the hard truth. Flushing the passages of a cooling system that used to work fine instead of verifying that your head gaskets are in good shape. If you have a blown head gasket flushing will not help. You can get a test kit for not a lot of money. Harbor Freight, OReilly, Amazon. https://www.lislecorp.com/specialty-tools/combustion-leak-detector Is your heater core connected? You don't have it bypassed? Bypassing the heater core can cause cooling problems.

-

1977, 280z with FS5W71B transmission

That rim looks a bit used. Aluminum wheels can bend also even though they often break. I'd lift each wheel, set up a runout indicator next to it and give it a spin. A runout indicator can be just a screwdriver sitting on a cinder block. The guy that balanced them should have noticed something but might have had old equipment.

-

280Z tachometer problems with a ZX (E12-80) ignition module

To be rigorous you'd try another 0.6 coil. Also, it looks like you're saying the 1.0 worked fine. Not clear why you went to 1.5.

-

Not quite overheating

Check your spark plugs. Use a borescope. How can you tell it's coolant smoke? I had a leak at the back of the head. Not obvious. Passenger side.

-

1977, 280z with FS5W71B transmission

Z car wheels are lug centric. In other words, the lugs and lug nuts are used to set the center of wheel's spinning motion. I would check the holes in the wheels and the lug nuts. Make sure that they fit tightly. Those wheels require a certain type of lug nut, that fits the hole precisely, not the tapered seat nuts that a steel wheel would use. Also, check the seating surface of the wheel on the hub. Might be some crud causing wheel runout.

-

Z's on BAT and other places collection

- 280Z tachometer problems with a ZX (E12-80) ignition module

Couldn't tell, I looked back but I don't think you mentioned which coil you were using. Maybe in your other thread. I had a vague memory of a similar thread (among many, tach problems are common) and found it. Post #29 is the one.- 280Z tachometer problems with a ZX (E12-80) ignition module

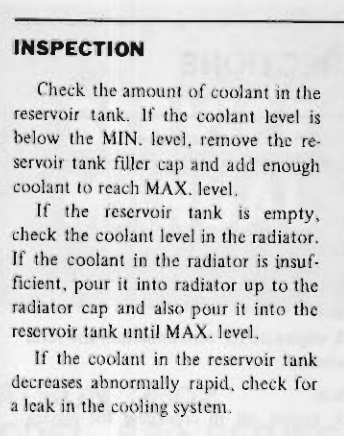

The CA Datsun thing is probably for using a ZX distributor in a 240Z. The 280ZX's use a resistor inline to the tach also, just like the 280Z's. The 1978 ignition system is very similar to the ZX system. Nissan just shrunk the electronics down. 1978 and 1982 both use a 0.84 - 1.02 coil primary circuit specification. Both ignition modules are designed for the lower resistance primary circuit, and the tachometer system is also. You could just copy the specs from the ZX system. 1982- HELP: Rear red lights ON and no power to starter

I'll go ahead and step aside here. Get a meter or test light and leave the key at Start. Start probing. Good luck.- HELP: Rear red lights ON and no power to starter

That is not an ignition module. It's an ignition switch. https://www.carparts.com/details/Nissan/280Z/Beck_Arnley/Ignition_Switch/1977/201-1174.html Find it, unplug it, test the proper wires for voltage with the key at Start.- Z's on BAT and other places collection

Somebody picked up a fun project today. Drivable with a spare engine and transmission. https://bringatrailer.com/listing/1974-datsun-260z-22-12/- HELP: Rear red lights ON and no power to starter

- HELP: Rear red lights ON and no power to starter

You have interchanged the words "ignition relay" and "ignition module" again. Relay and module are two separate things. Even so, cranking and running involve separate parts. If you don't have coil power at On then the engine should not have stayed running in your other test. So that doesn't really fit with what you described earlier. One possibility that might fit your problem is that the mechanical part of the ignition switch is not correct. I had a situation where I had to twist the rod between the mechanical part and the electrical part to get the electrical switch to turn far enough. That might explain why when you changed the switch it worked for a short while. The rod that fits in to the plastic slot has to turn the switch to the correct position. You can test it by disassembling the switch and turning it by screwdriver. You might find that everything works fine -- HELP: Rear red lights ON and no power to starter

Just for fun and because the wrong words were used early on. Here are the three parts with "ignition" in their name - ignition switch, ignition relay, and ignition module. From ZCD - Autopartone - From Vintage z parts -- HELP: Rear red lights ON and no power to starter

Just realized that this is not very clear. "Connected" what between the two big posts? Why did you have to touch 12V to the solenoid pin if you had a remote starter, with a button? A typical remote starter does all of that for you. Does "removed everything" mean everything, all of the wires to the remote starter and the wire to the solenoid pin? If so the ignition relay is fine. The simple way to test the ignition relay is to measure voltage at coil positive after you turn the key on. And, you should have only needed to touch 12V to the solenoid wire with the key on to get the engine to crank, and start. Cliff/site - if the engine cranked and started then the positive cable and the ground have to be okay. The solenoid grounds through the starter motor mounting bolt just like the motor does.- HELP: Rear red lights ON and no power to starter

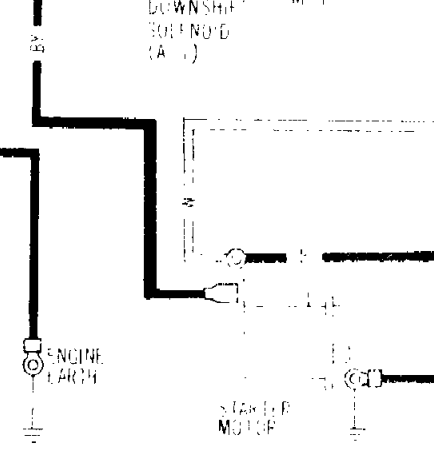

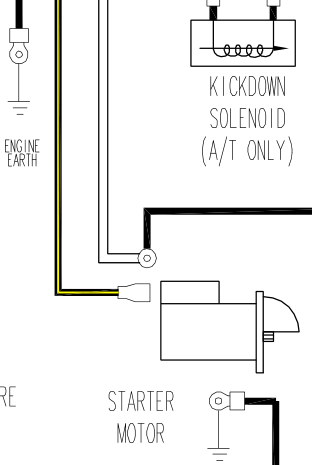

The starter solenoid power wire does not pass through the ignition relay. You bypassed the ignition switch and the inhibitor relay. The cranking circuit is completely separate from the ignition circuit. You have a cranking problem, not an ignition problem.- Parts Wanted: Looking for a interior light lens for a 1975 Datsun 280Z ?

The one in my car crumbled when I pressed on the wrong area. Unless a used one came from a garaged car I don't see why it would be any more durable, they all get baked from the roof heat. That $25 replica seems like a good bet. It's an odd color though.- HELP: Rear red lights ON and no power to starter

- HELP: Rear red lights ON and no power to starter

I just looked at the 1977 FSM wiring diagram, the one in the back of the book, and realized that what I thought was yellow with a black stripe is actually supposed to be black with a yellow stripe. Also realized that Revision N from the Download area shows a "seat belt relay starter relay" but the FSM shows an inhibitor relay. And the connections are of a different shape. I think that this has been discussed before and that's why there are there is a Revision N. Anyway, the fact that it started and ran, above, indicates that the ignition relay is working properly. It also shows that starter and solenoid are working properly. I would guess that the wire at the connector from the ignition switch would be the same color as the wire at the starter solenoid. Good luck.- HELP: Rear red lights ON and no power to starter

Click this link, type details in the box, then click Save. I know it doesn't makes sense that Profile data is in the Account Settings area but that's where it is. https://www.classiczcars.com/settings/signature/- HELP: Rear red lights ON and no power to starter

I would check power to the seat belt relay on the yellow/black wire. That's the power that comes from the ignition switch. If you have power there then you can assume the ignition switch is good. Separate in your thinking the starter solenoid wire and the ignition relay. You've already saved yourself the effort of removing the starter. Forgot the picture. Haven't you bypassed this already? -- HELP: Rear red lights ON and no power to starter

Edit - replying to SteveJ's comment... Not clear what you mean. This is about power on the yellow/black wire to the starter solenoid. He says his starter does not turn. If he has an automatic, then focusing on the seat belt relay would make sense.- HELP: Rear red lights ON and no power to starter

The ignition relay is not involved in the starter motor operation. The starter motor solenoid circuit varies depending on vehicle. You don't have any signature details so it's not clear what you're working with. - 280Z tachometer problems with a ZX (E12-80) ignition module

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.