Everything posted by Zed Head

-

Fuel pump not working

You checked power at the pump itself? Back by the tank? Check the ground circuit also. If you used a convenient metal spot as your ground you might have overlooked the ground wire for the pump. And are you sure that the pump was not working? You could loosen a hose clamp at the filter and see if there's pressure. Looks like you just assumed there no pressure because you had spark.

-

Replacing a clutch

Yes, Nissan calls it a sleeve. We call it a collar. It must match the pressure plate finger height, nothing else. Even the parts makers get things wrong in their specs. Measurements are necessary unless you're a gambler.

-

Replacing a clutch

The only parts that need to have the transmission out to be replaced are the throwout bearing, the rear main seal of the engine, and the front cover seal of the transmission. And the clutch parts, of course. The clutch fork too, sometimes they're worn. The rest can be replaced piece-meal as necessary, or at better times, with the transmission installed. You might start your project by loosening nuts and bolts. Propeller shaft flange bolts at the diff, exhaust pipe bolts and nuts, exhaust system hanger bolts and nuts, fill and drain plugs on the transmission. It's that one nut or bolt that won't loosen or breaks that will stop a well-made plan. List all of the parts that you have and we'll tell you which ones to be careful with. The throwout bearing sleeve is the most common place that people go wrong. Some kits have it, some don't. You didn't mention it specifically.

-

Front Suspension not settling

Here's a thread from this year that kind of shows how things are still confusing. Some people like them, some people like them after they fix them, some people don't like them. Old Eibach doesn't seem like new Eibach. Nobody knows where they really come from. It's madness. But the name sounds good - Eibach. Like salsa.

-

Front Suspension not settling

I can't criticize writing if I can't do reading. But, "throughout" doesn't really tell the whole story. You're right though, if the front link bushings are polyurethane now, then that FSM passage doesn't matter. Back to Eibach springs. The're something weird about the Eibachs. Many people have problems, either too high or too low, but there doesn't seem to be much consistency. It's a dice roll as to what you'll get. Could be counterfeits, could be low QC on a low volume product. I'd never use Eibachs myself, too many people have problems. I'd post some links but there are so many stories. Some too high, some too low...general confusion. You can read the stories but none will have a solid answer.

-

Front Suspension not settling

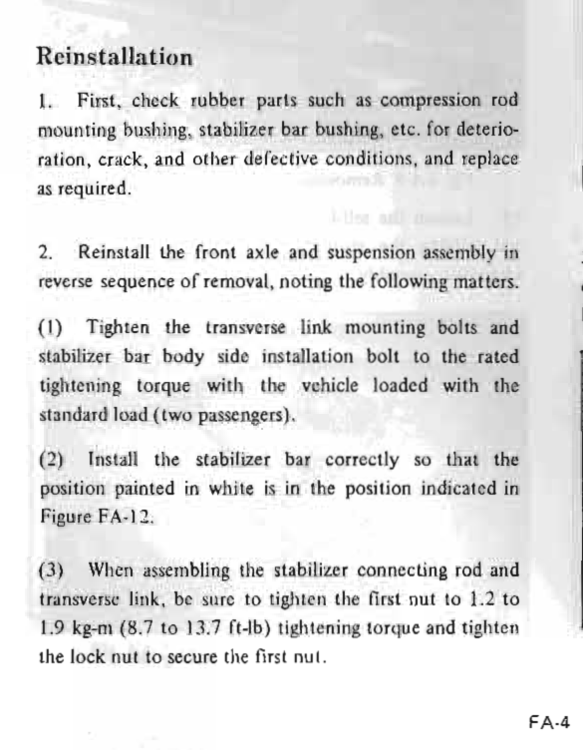

I completely overlooked the fact that the engine was not in. 400 lbs would make a difference, of course. CO has posted on this often - the bushing bolts need to be torqued when the suspension is loaded. Leave them loose until then. The factory bushing rubber is bonded to the metal sleeves and actually adds a small amount of elastic resistance to wheel or body movement, once the metal sleeves are locked in to place with final torque settings. It's described in the Service Manual. If that doesn't do it, it might be the springs. What kind are they? Progressive or straight rate? People have had problems with the progressive springs for many years.

-

Front Suspension not settling

You have to roll it back and forth. The wheels and tires move inward as the suspension drops. They hit the ground inward to the position they should be in, and will move out as they roll.

-

Hesitation during acceleration

Everyone has their own way of problem-solving. Getting things back to factory settings is always a good way to start. I suggested the fuel tweak as an "in the mean-time" test. It's completely reversible, and/or you can just set the potentiometer to zero resistance. Besides that, we need something to discuss while he's waiting for the canister.

-

Hesitation during acceleration

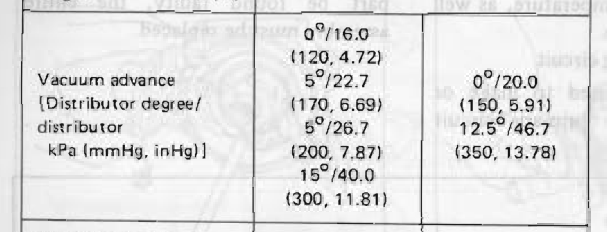

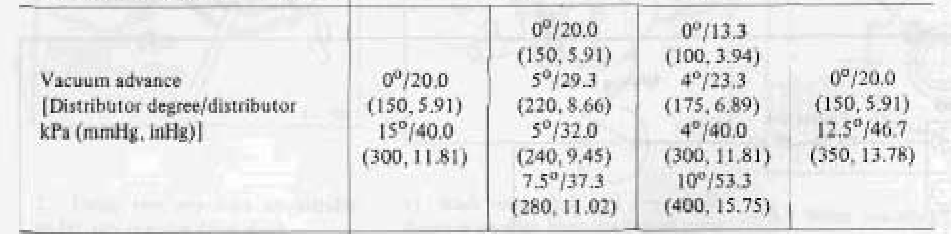

The vacuum advance goes away at any sizable throttle opening. As soon as the the blade opens and intake vacuum drops the advance won't come back until engine RPM increase. So part-throttle acceleration would see a difference but it goes away as you press the pedal farther. All I'm saying is that my math doesn't add up to the lack of timing advance itself as the problem. Maybe the mechanical advance is stuck also. I don't see any timing light info. I just went back through the whole thread and see the things I missed. But, basically, it's an engine with a hesitation at some unknown level of acceleration, and a hole in the vacuum advance canister. That's really all that we're working with. A little work with a timing light would be illuminating. I found the old ZX canister. It's from an 81 2+2 so should have up to 15 degrees. Looks like some sort of two-stage system. Could also be an 80 unit (it had 1980 transmission). Which has even more possibilities. The 80's was the emissions era.

-

Hesitation during acceleration

Thanks. His site is down now so I can't check it out. The "tweak" is well-established. It's not really a tweak anymore, more actually a "fix". Not really feeling a bad vacuum advance as a hesitation problem, that's why I suggested the fix. DC8 didn't say if he plugged the vacuum leak. It would be a small one but still might have an effect, especially with the an engine on the edge of leanness. The first thing that I would do is to plug the vacuum leak.

-

Hesitation during acceleration

I took a leaking one apart in the past and the diaphragm material was cracked and brittle. Made me wonder if they lost performance before they actually cracked and leaked. zcardepot has a fuel tweaker? Can you post a link? I looked but didn't find it. Might be a day or two before I refind my distributor parts.

-

Hesitation during acceleration

I might have a ZX vacuum can that's still intact. I'll dig around. You'll still need a new canister, but I wonder if the hesitation was from the vacuum leak. You might get by in the mean-time by just plugging that hose. Might be a bit "doggy" at part throttle with no advance, but better than hesitation.

-

Hesitation during acceleration

Is it the vacuum can or the breaker plate? They can both go bad. How did you determine that "it" was bad, whatever it is? The diaphragm in the can can spring a leak or the bearings in the breaker plate can fall out. Both will stop the advance from working. Beside that, your symptoms sound more like a running lean problem. You could try the coolant sensor tweak while you're looking for distributor parts. The problem is pretty common and I think that several 10 ohm resistors have been found in the wiring harnesses of various 280ZX's, if my internet memory serves me right. Today's gas is not the same as 1980's gas.

-

'72 or '73 wire harness to coil, need photo

I notice from the schematic that when the wires are disconnected from the ballast, the Run and Start BW wires are disconnected, circuit-wise, electrically. So you could disconnect the ballast of all wires, then check for voltage at the BW wires. One will have power at Run, and one will have power at Start. Then you can use the schematic to connect them properly.

-

FYI - 240Z Dashboards

Those are good points. Don't leave out volatiles, which can dirty up windows pretty quickly. Hate to be negative but there are many ways to go wrong. Finding a material to make the shape isn't too hard, finding one that meets the demands of use is more work. An installed dash after a test run in Las Vegas summer would answer some questions. Pretty sure that there's a setting in Facebook that opens viewing to the public. Then we could all see it without logging in .

-

Good neighbors, I think?

It comes in an eight-pack? Scary.

-

3/72 Datsun 240 Z

I think that the P90 is like the P79 but with square, unlined exhaust ports. Bigger combustion chambers than the N42 or N47. So you're right, it is like the N42, with the square unlined exhaust ports. The P90 is designed for the turbo engine I think, I don't know if the combustion chamber shape is the same as the P79 or not. The turbo engines used dish pistons so there is no quench to speak of. The liners tend to fall out under the heat of a turbo, people have found that put turbos on their N47 or P79 head engines. Nissan probably learned that early and changed the P79 casting molds to square ports, and called it a P90. Nothing wrong with going back to original, or period-correct. Especially if you're going to the car shows. If I had a good-running 240Z with an L24 I'd just leave it and drive it.

-

3/72 Datsun 240 Z

Actually, a P90 with flat top pistons would be at 8.8 CR. The F54 NA blocks came with flat tops. It's essentially a late 1980 to 1983 280ZX engine. With carbs. 17% more displacement. If I had a 240Z I'd do that swap, if my old L24 was worn out.

-

3/72 Datsun 240 Z

The bolts around the side flange, and the lack of a rectangular slug on the cover, along with the shape are pretty good R180 signs. Plus, no fingerprints in the grease from a recent swap. That grease might hold dirt from 1972.

-

3/72 Datsun 240 Z

Post up the engine serial number from the tag in the engine bay. Maybe somebody out here has it. That greasy diff in your picture is an R180. You can use the same propeller shaft (Nissan called the half-shafts driveshafts and the driveshaft a propeller shaft) if you change transmissons. The throwout bearing collar must match the pressure plate. Not the transmission, or car. (sorry site) Best to take some measurements before installing. There's a bunch about it on this forum.

-

Cannot get injector pulse - passes EFI bible tests!

Only MrChefur knows for sure. Meter, meter, pumpkin eater.

-

Cannot get injector pulse - passes EFI bible tests!

There's one at the battery too.

-

Cannot get injector pulse - passes EFI bible tests!

Found a picture on zcar, from Echutton. I think he's a member here. http://www.zcar.com/forum/10-70-83-tech-discussion-forum/398985-78-datsun-power-line-circuit.html @echutton

-

Cannot get injector pulse - passes EFI bible tests!

I don't see the other ground wire for the EFI system. It could be attached somewhere else but it came from the factory with a plastic connector, to a pigtail at the battery negative post. Somebody has monkeyed with yours, that battery cable to the firewall is way overkill.

-

77 280z with N47 head, stock engine, should I remove exhaust port inserts? Does it help?

If you measure the area of the port without the liners you'll probably find that you'd have to do a lot of extra work to get the header opening to match the head. If the header opening is smaller than the head opening you'll get turbulence that will ruin flow. Beside that, without a lot of other head work, enlarging the exhaust port is probably pointless. Somebody over on Hybridz showed that there's very little gain in flow from removing the liners. They're cast in. Some grinding on certain areas will get them to fall out, sometimes they fall out on their own. Once they're out you'll have a rough casting that needs smoothing.