Everything posted by Zed Head

-

1971 HLS30-14938 "Lily" build

Also, I'm pretty pretty pretty sure that I've seen the flat ones on a very early 240Z or two. In the wrecking yards and maybe illustrated somewhere. We both misspelled crenulation. Not sure it's quite the right word anyway. Not irregular. https://www.merriam-webster.com/dictionary/crenulated

-

1971 HLS30-14938 "Lily" build

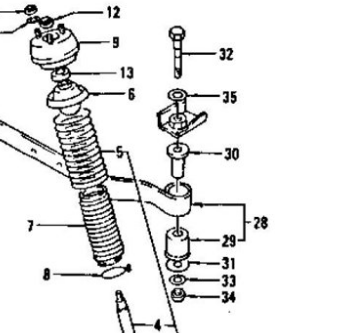

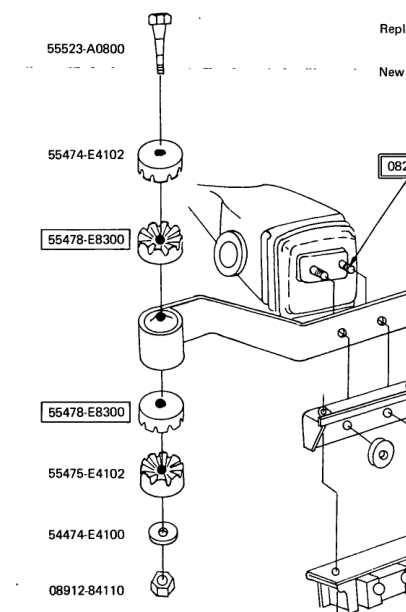

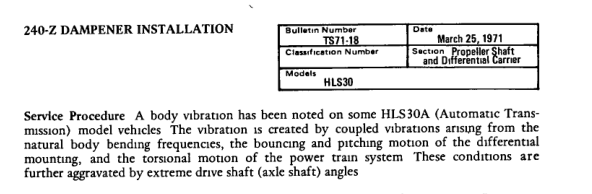

The 1969 - 1972 TSB book shows crennulations in a drawing for a March 25, 1971 TSB, "Dampener Installation". Carpartsmanual shows a few changes. Assuming that #30 and #31 is the part. The drawing looks screwed up, but the change dates match for the pair, and the label of "stopper" seems right. http://www.carpartsmanual.com/datsun/Z-1969-1978/axle/rear-suspension

-

zspecialties parts hoard for sale?

Thanks, I knew he had one. Weird that he doesn't frequent the site more. He'd sell some parts, I'm sure. Somebody needs a 280Z strut insulator right now. @zmanofwashingto I wonder if his name was too long for the various site changes. Washingto Maybe he can';t log on anymore.

-

New front end chassis frame 78 280

"front end" covers a lot of car. Maybe you just need a parts car.

-

zspecialties parts hoard for sale?

Maybe somebody can talk him in to making a trip. He'll have to load them up once anyway. Just noticed that he signed "Oliver" at the end of his CL ad. So it is zspecialties. Thought he was a member here but can't find a name. @

-

zspecialties parts hoard for sale?

I was thinking about selling a spare engine and came across this craigslist ad. Pretty pretty pretty sure it's zspecialties. Snohomish. Piles of parts. Still kind of spendy but nice to know that somebody is collecting them. https://seattle.craigslist.org/sno/pts/d/datsun-engines-trans-and-parts/6521512101.html

-

Invalid Certificate

-

Value question on a 100k all original 78 280z

Don't run the engine too much with the heater core bypassed. Better to block both ports. It's a topic of endless discussion, but seems pretty well decided.

-

Value question on a 100k all original 78 280z

People have posted about pushing the bumpers in on their shock absorber mounts, then locking them in place. FastWoman for one, and others. Still bulky but won't stick out so far.

-

72 240z distributor question

Probably not. Electronic ignition takes less maintenance and will spark a lean mixture better without missing, but won't really improve performance. You'll still have the timing problem too. My local old-timey locksmith shop had Datsun key blanks. Find an old shop, not a Home Depot.

-

How many threads on coilover to be safe?

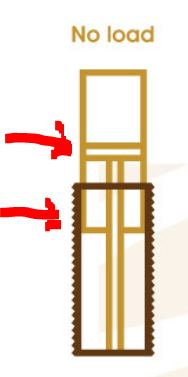

Did you just finish a game of Quidditch when you took that picture? I mentioned an extension earlier. I meant for the spring. Same as getting a longer spring. I saw cgsheen's comments over on Hybridz and he contradicts the Stance instructions about preload. So, apparently, you could add a spring spacer, or use a longer spring, if you needed it, since Sakura didn't design their setup for preload. Just moving the spring perch should do it since the spring is just "perched" there, not loaded. But, before you get too far along in fixing things I'd still assemble everything without the springs and run the wheel through it's expected stroke. You might find other potential problems. Adjust the sleeve so the shock piston is where you want it at desired ride height and the top and bottom of the stroke don't damage anything. Then adjust the spring, via the perch or a spacer or a longer spring. If you can't make it work that way then you'll know you need to get more drastic.

-

Value question on a 100k all original 78 280z

All original! >>> was original.

-

How many threads on coilover to be safe?

Edit - if you need to keep preload on the springs, you could add a spacer between the spring and the perch. That would allow you to lower the sleeve. If you find that the parts are not right. Well, turns out I wrote a bunch of stuff while I was learning. And most of what i wrote is wrong. Except the first post about nomenclature, words, labels, etc. It's looking like your struts might just be too short. Not sure what you do about that. Maybe you can add an extension. Good luck. They say to do what you're doing. https://stance-usa.com/about/faq/#toggle-id-9

- How many threads on coilover to be safe?

-

How many threads on coilover to be safe?

Sorry, I was confused myself. Yes, the Stance system is weird. You want to adjust the strut length so that the piston can travel up also. Basically you trade some down-travel for some up-travel. Not sure what the general rule of thumb is but I'm sure it's out there somewhere. 2:1 or 3:1 or something like that, compression to extension. Then adjust the spring perch to the calculated ride height. You have to do two separate adjustments, not just start with the shock fully extended. Many struts don't use preload. The typical Tokico lowering spring has no preload. So, yes it's an odd system, and I'll bet that may people don't have theirs adjusted for best performance. I would assemble thew struts without the springs and put them on the car and run them through their travel at the height you want. Set the sleeve so that the piston travels in the range that you want. Insert a bottoming cushion/bumper for the shock body so that you don't damage anything if you hit a big bump. Put the springs on and set the perch to ride height. Hope that you chose the right spring rate for a good ride. That's how I'd do it.

-

Tackling 2 leaks, rad and front main

I think it's a matter of scale. If you're transmitting small loads then a key, a small tab of metal pushing on a small area of the shaft's outer perimeter, is probably fine. The damper pulley transmits a lot of torque though. And the are of the damper with the slot in it is thin and fragile, hence the breakage. Seems to be more for location. I over-generalized to all keys. I do remember plastic extrusion applications where the key was used as the failure mechanism, to save the shaft and other parts from over-torquing. So it was the power transmitter in that case. I searched the internet and have supplied only the words that kind of support my argument, below. https://ipfs.io/ipfs/QmXoypizjW3WknFiJnKLwHCnL72vedxjQkDDP1mXWo6uco/wiki/Key_(engineering).html

-

How many threads on coilover to be safe?

Just realized my understanding of the Stance setup was wrong. I think that there shouldn't even be a question of "5 threads". The sleeve is supposed to be screwed all the way in. The threads for ride height adjustment are under the collar, which has plenty of thread left, in the picture. No offense Alby Cage but I think that you might be adjusting the wrong part. Screw the sleeve in and the spring perch up. I might still be wrong. I'd like to see it in action, with no spring, to be sure of full stroke, no binding, etc. The moving part in that strut is the piston inside the shock tube, and the outer portion of the shock tube inside the sleeve. Edit- actually, the best way to adjust it might be so that the shock body bottoms out in the bottom of the strut tube before the internal piston (moving upward in their drawing). Seems like a damper/bumper in the bottom of the tube would be a good idea also. Otherwise it's metal on metal if you hit a big bump.

-

Lowering springs and new struts 280z

The gland nut (strut cap?) is supposed to clamp the shock body tightly in to the strut tube. So it's not so much the nut itself but whether it was working properly. Can't see any of your .HEIC files, whatever they are. Where'd you get the Tokicos? Craigslist, eBay?

-

Tackling 2 leaks, rad and front main

Just feeling a chime in urge. These keys are generally meant for location purposes only, or mainly. The clamping force of the bolt is what stops the movement. 105 foot-lbs, etc. If a person really wanted to be detail-oriented, they'd clean the surfaces that clamp together to ensure high friction and metal to metal contact. The key probably needs to be strong enough to resist the torque transmitted through the bolt head in to the damper. You can sit and imagine where the loads go, if you want to, and figure out what to clean and what to lubricate. Lots of surfaces involved. Lubricate under the bolt head and washer, clean the space between the damper and crankshaft. Choose the right oil for the threads. Say a prayer...

-

How many threads on coilover to be safe?

I see the difference now, with Stance's inverted shock technology. Still, the "sleeve" would be used to adjust shock travel range, and the spring perch to adjust ride height. If you're adjusting the sleeve to get the shock stroke where you want it and running out of threads at the desired ride height, I think that would mean that you need a longer shock. Stance's design is an adjustable spring perch AND an adjustable shock perch. Basically, it's an external shock. You adjust the sleeve to determine where you want the shock piston to start its travel from. You have to consider wheel travel. https://stance-usa.com/about/faq/#toggle-id-1

-

How many threads on coilover to be safe?

Looks like an interesting problem. Not sure of your terminology though, can't really figure out what you mean. "Coilover" is a word with broad meaning, often incorrectly used. It's just short for coil-over-strut. I think the more correct term is MacPherson strut in the front, adn Chapman strut in the back. What people commonly call coil overs, are actually adjustable spring perch struts. Or mixing wrongness, adjustable coilovers. It's not clear how yours work though, because the tube that seems to thread in to the remnant of the original strut tube should only be adjusted to fit the shock insert inside, to create the tight rigid structure necessary to allow the spring and shock to work correctly. The spring perch should be used to adjust ride height. Seems like you're asking about the tube that sets the length of the shock insert portion of the strut. If that's what you're asking about. Maybe take a picture with a finger pointing at the threaded area you're worried about. https://en.wikipedia.org/wiki/MacPherson_strut https://en.wikipedia.org/wiki/Chapman_strut

-

280Z's going up in value!

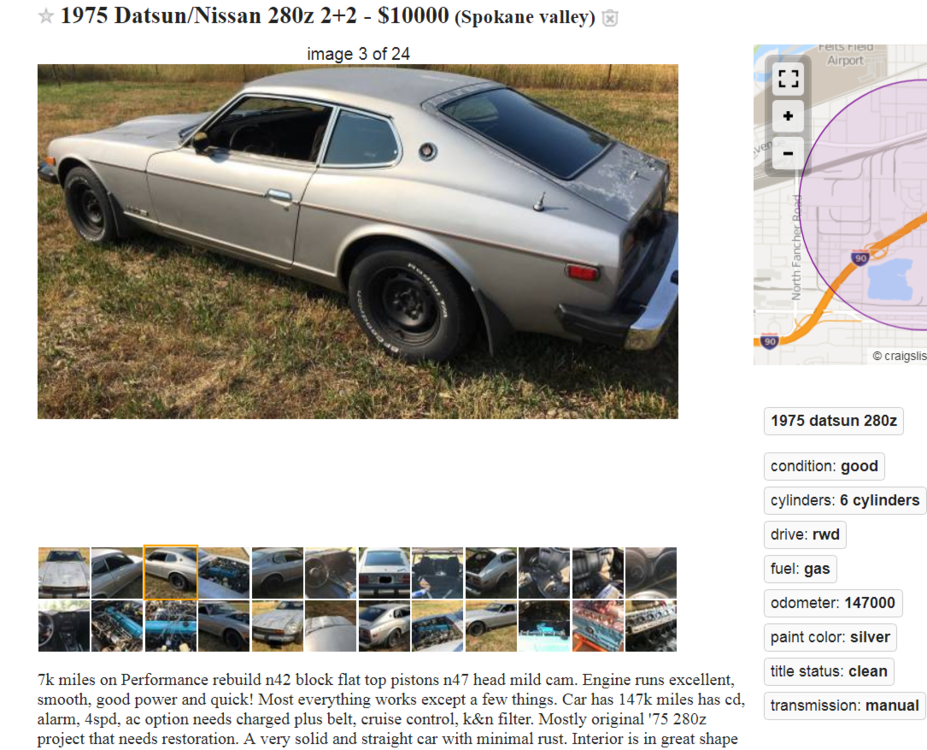

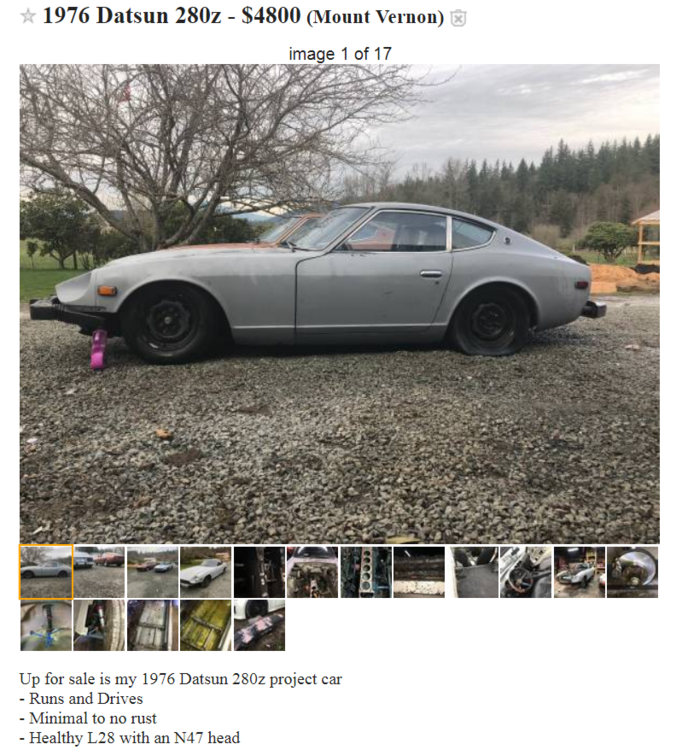

Sorry if these are members. Just amusing. https://seattle.craigslist.org/see/cto/d/1976-datsun-280z/6476674686.html https://seattle.craigslist.org/est/cto/d/1975-datsun-nissan-280z-22/6496718058.html

-

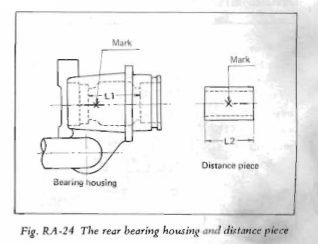

Rear Hub bearing uneven resistance

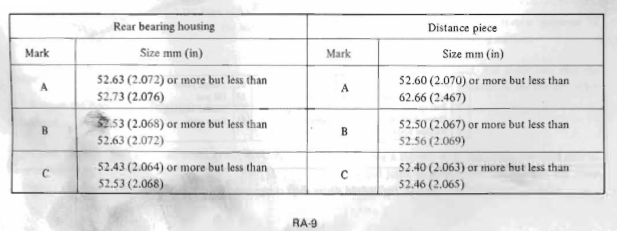

A funky distance piece would do it. Or a strut casting. Or a combination of funk in both. The distance piece is supposed to get the balls centered in the races but it sounds likes yours is a bit short for the casting.

-

Ignition help needed on '78 280z

Are you trying to get everything back to the way it should be or just get the engine started again? You said that you ran it with the fuse box jumpered for a while. You might just reset your thread with a description of what you're trying to achieve, right now, and what the status of things are , like the coil power, and whether you've checked for spark, or tried to start it with fluid. It might be that you actually have an ignition module or distributor problem, and the jumper wire to the fuse box didn't really do anything. It was just a coincidence. A red herring, as they say, or maybe a red herring that swam away. One sequence of troubleshooting that many of use use is - Turn the key to start. Engine turns over. Turn engine over, check for spark. Getting spark, check for fuel. Check for injection. Unsure on fuel or injection, try starting fluid. It should start for a short burst because there is spark. If it starts, then dies, with starting fluid, then troubleshoot injection system. This is a good sequence because those things are in the order that the EFI system would use them. We already know that the engine turns over, and you have power at the coil. Time to do the next step. Spark.

-

Resister tweak for fuel injection

Think I mentioned this in your other thread but you should be able to kill the engine by turning the resistance up. Flood it with fuel. I got the impression over there that you're not seeing any response at all. Maybe you have it plugged in to the wrong circuit. There's a bunch of bullet connectors in the same area, I think. Have you verified a resistance change on the circuit, at the ECU connector? That's what I'd do.