Everything posted by Zed Head

- Hesitation during acceleration

-

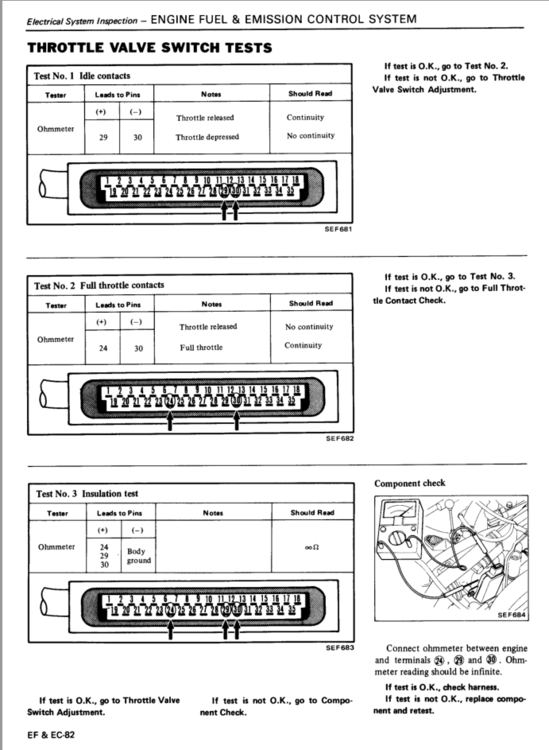

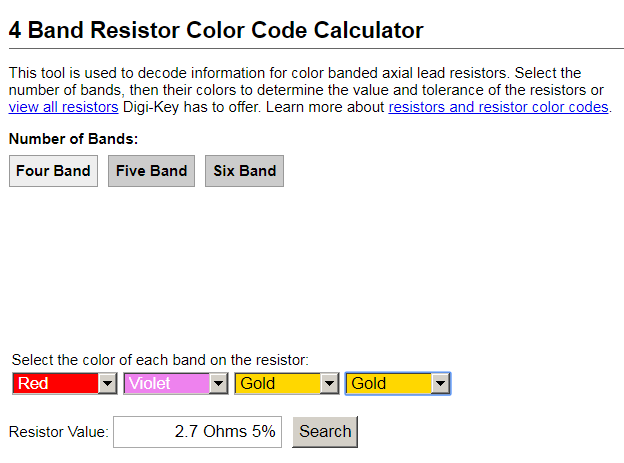

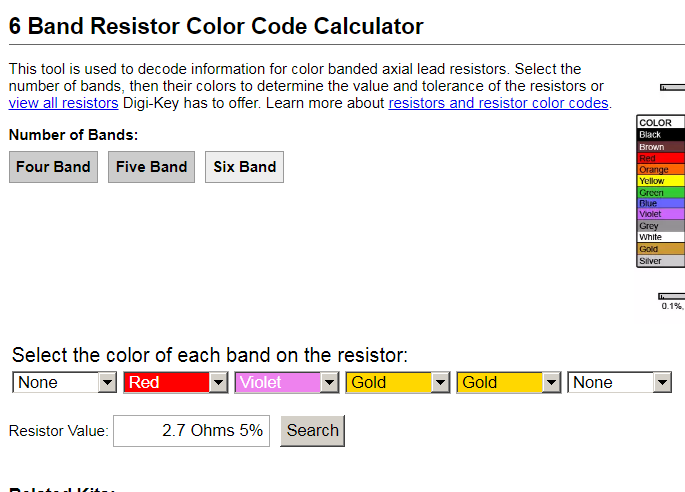

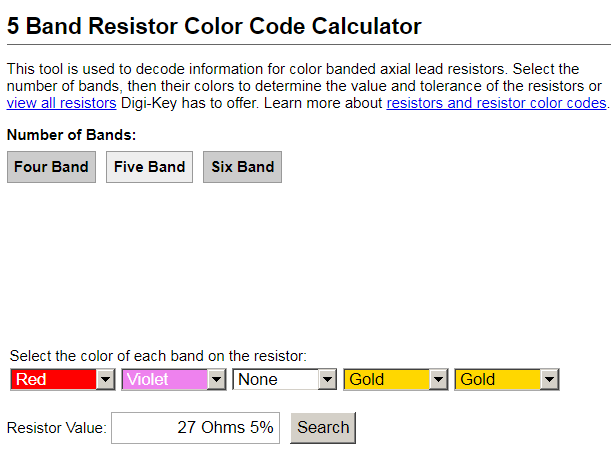

Fuel injection relay internal resistor value?

The colors are definitely red, violet, gold, gold. Seems like a pretty big gap between 2 and 3. That's why I picked "none" in a 5 band. But, apparently, the bands start and end on the bumps at the ends of the resistor. I'm learning. So, pick 4 or pick 6 and you get the same 2.7. I went ahead and measured it with a Fluke and got a 3.1 ohm reading. Minus the .3 to .4 lead resistance gives 2.7 to 2.8 ohms. Minutiae.

-

Fuel injection relay internal resistor value?

Did you add an extra "0" by accident? I got a different number. If I go with a four band the number gets even smaller. So, with a more time for the subconscious to think, I'm thinking the resistor is to reduce sparking at the fuel pump relay switch contacts in the AFM. They are so tiny.

-

Fuel injection relay internal resistor value?

Just remembered that I have a fried 76 relay sitting in the vicinity of me. Here's a picture. Don't know the color codes off the top of my head. It's the only one in there.

-

Fuel injection relay internal resistor value?

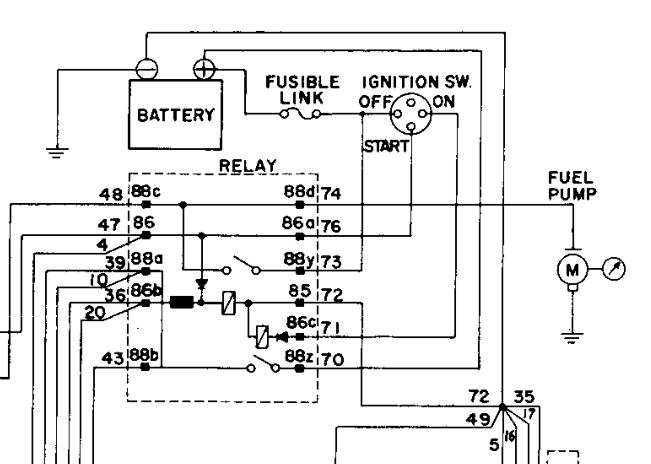

Not sure it's hugely critical. It just needs to pass enough current to close the fuel pump relay. Pin 36 is power back (to ground) from pin 39 through the fuel pump relay contact switch, if I read the diagram right. Not an electrics guy but the relay coils usually have about 50-60 ohms resistance. I think that they pull about about 0.3 amps. Just working from memory on past current draw problems, through relays. That combined relay is a weird mamajama. After hurting my brain looking at it I decided that I don't even know why that black rectangle is there. Seriously, why is it there. The relay coil provides resistance. Beside that, I think that somebody would have to disassemble a relay to measure its resistance. I'm assuming the black rectangle is what you're talking about.

-

ignition wiring

Download away. Sorry if all you have is a phone. They're not as smart as the phone makers make them out to be. http://www.classiczcars.com/files/category/11-240z/

- ignition wiring

-

ignition wiring

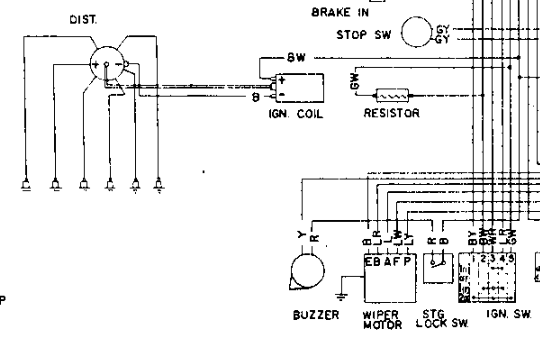

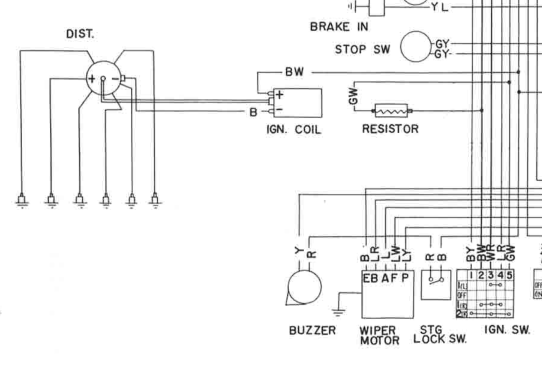

Here's the diagram from the Body Electrical chapter, from the downloadable file on the site. BE-4. Sorry to be so in-your-face but it really was in my face as soon as I looked at it. It's from 1970 though.

-

Bringing a 1977 Z back life

Forgot to mention the distributor. If the breaker plate bearings are good. A very common failure, especially when they sit. You should probably remove and clean your distributor before the little plastic bearing cage breaks. There are many little things that can be saved with a little preventive work. Clean the alternator air openings and oil the bearings, for example. Stuff most of us never did when we first started our old cars.

-

ignition wiring

Is it a 71 or does it have a 71 build date? Have you looked at the 72 diagrams? There aren't many wires. A multimeter would answer a lot of questions. The B/W wires are probably the Start and Run power to the coil. Y is probably the temperature sender. B is usually ground.

-

Bringing a 1977 Z back life

The AFM and ECU won't be "correct" for the year but they'll work in your car. Good to have for testing if you find running problems later. Depends on cost of course. The combined EFI/fuel pump relay also. The FPR if it's cheap. Check the injectors, they might be newish. Exhaust manifold if you can get it off without snapping the three studs. Clutch parts - the 225 mm flywheels are NLA now for the most part. Half-shafts if the u-joints are in good shape and they don't want too much. If you can pick up cheap parts they're good to have, just in case. Later, when you need to remove something and break a stud you'll have the replacement ready.

-

Bringing a 1977 Z back life

You might just use water for testing then let it run out or drain it when you're done. On the fuel, if you don't want to pull the injectors (nobody does but almost everybody ends up doing so) you could disconnect the return line by the filter and let the pump push whatever is in the rail and injectors out in to a container. See what was in there. The injectors and their hoses are dead zones in the flow path so after the initial purge you might reconnect everything and let the pump run. Diffusion will mix the old dead fuel in the injectors with good fuel and it will end up diluted in the tank. Otherwise, once you get everything electrical working right you'll be shooting old dead fuel in to the cylinders. Maybe even water. Another way to power the pump is to remove the AFM cover and move the vane's counterweight, with the key on. You should a click and then the pump will run. Or. You can pull the injectors and rail and give everything a good rinse. Seafoam has a following. But it's really just a mix of oil and stuff that burns. Makes mysterious smoke. Gasoline is a super solvent.

-

ignition wiring

Not clear which problem is the problem. The switch to manual or the wiring. Does the engine run and the car drive? Is there something that doesn't work? And where's the pictures?

-

Bringing a 1977 Z back life

That's a nice looking car though. Make sure you don't set it on fire. Get a milk crate or box or build a seat, then sit on that seat with a meter and the wiring diagram. Maybe with a little space heater in the car. Some beers. Your phone or laptop so that you can show us what you find. Take measurements and write down what you find or don't find. Since wiring has been removed (edit - had dash here), there are many many things that could be disconnected. The grounds are just as important as the power leads. Realized that your dash is still in place, which is good. But there are relays under the seat, and the Hazard switch in the console and stuff on the steering column that can be a problem.

-

Bringing a 1977 Z back life

It's a toasty 39 F here in the great northwest. Dave is right, you need to get a meter and make sure power is where power should be. The simple test for the fuel pump is to disconnect the starter solenoid wire and turn the key to Start. But apparently you don't have power to the starter solenoid. 107,000 is low miles for these engines. Assume that the engine is going to run fine once you get the other stuff sorted out. Spend your time on the small stuff. One short circuit causing melted wires will ruin things for you. I still remember taking the advice of a friend about using a Juicy Fruit wrapper to "fix" a blown fuse. Those wrappers can pass a lot of current.

-

Bringing a 1977 Z back life

A long comma, like a long pause? Very creative writing, I like it. Browse the categories on the right on this page, and download your FSM and other guides. Wiring diagrams, troubleshooting guides, they're all in there. http://www.classiczcars.com/files/ How did the fuel that you drained look? Is there rust in the tank? Does the fuel pump work? We love pictures here. What, exactly, are you trying to get out of it? You're trying to start it when it's probably full of crud that will get circulated through the various systems, engine, fuel system, cooling system, etc. Not good for long-term but you'll probably have fun before other stuff starts to break, if you get it running.

-

I don't know what this is

I wouldn't replace anything yet. Nothing you have described indicates a bad part. The hissing noise is normal, it's fuel passing through the FPR. Looks like you have a 75-77 280Z so it will have the fuel pump contact in the AFM. The engine probably dies because the idle speed is too low and the AFM contact switch is opening. You might also have some vacuum leaks which will cause the AFM vane to close at low RPM, opening the pump power switch. You can try turning up the idle speed to get it to idle while you're looking for leaks and other problems. There is no magic "one fix" that will make these cars tun better. It's a whole bunch of small things. Edit - actually that might be a 78 FPR. One inlet port. So, low idle and vacuum leak can still be a problem but there won't be a switch in the AFM. Still, small things first. It runs.

-

Taste like Two Fingers to me!

I knew some guys in West Virginia that used to get pure ethanol from the local chemical plant. They knew people. Years ago. The ultimate moonshiners.

-

Loose wire

I can't remember which year car you have. But the wiring diagram in the FSM actually shows the top of the T and the post, with wire colors, if you find the right diagram. Start with Engine Electrical.

-

Fuel pump not working

You checked power at the pump itself? Back by the tank? Check the ground circuit also. If you used a convenient metal spot as your ground you might have overlooked the ground wire for the pump. And are you sure that the pump was not working? You could loosen a hose clamp at the filter and see if there's pressure. Looks like you just assumed there no pressure because you had spark.

-

Replacing a clutch

Yes, Nissan calls it a sleeve. We call it a collar. It must match the pressure plate finger height, nothing else. Even the parts makers get things wrong in their specs. Measurements are necessary unless you're a gambler.

-

Replacing a clutch

The only parts that need to have the transmission out to be replaced are the throwout bearing, the rear main seal of the engine, and the front cover seal of the transmission. And the clutch parts, of course. The clutch fork too, sometimes they're worn. The rest can be replaced piece-meal as necessary, or at better times, with the transmission installed. You might start your project by loosening nuts and bolts. Propeller shaft flange bolts at the diff, exhaust pipe bolts and nuts, exhaust system hanger bolts and nuts, fill and drain plugs on the transmission. It's that one nut or bolt that won't loosen or breaks that will stop a well-made plan. List all of the parts that you have and we'll tell you which ones to be careful with. The throwout bearing sleeve is the most common place that people go wrong. Some kits have it, some don't. You didn't mention it specifically.

-

Front Suspension not settling

Here's a thread from this year that kind of shows how things are still confusing. Some people like them, some people like them after they fix them, some people don't like them. Old Eibach doesn't seem like new Eibach. Nobody knows where they really come from. It's madness. But the name sounds good - Eibach. Like salsa.

-

Front Suspension not settling

I can't criticize writing if I can't do reading. But, "throughout" doesn't really tell the whole story. You're right though, if the front link bushings are polyurethane now, then that FSM passage doesn't matter. Back to Eibach springs. The're something weird about the Eibachs. Many people have problems, either too high or too low, but there doesn't seem to be much consistency. It's a dice roll as to what you'll get. Could be counterfeits, could be low QC on a low volume product. I'd never use Eibachs myself, too many people have problems. I'd post some links but there are so many stories. Some too high, some too low...general confusion. You can read the stories but none will have a solid answer.

-

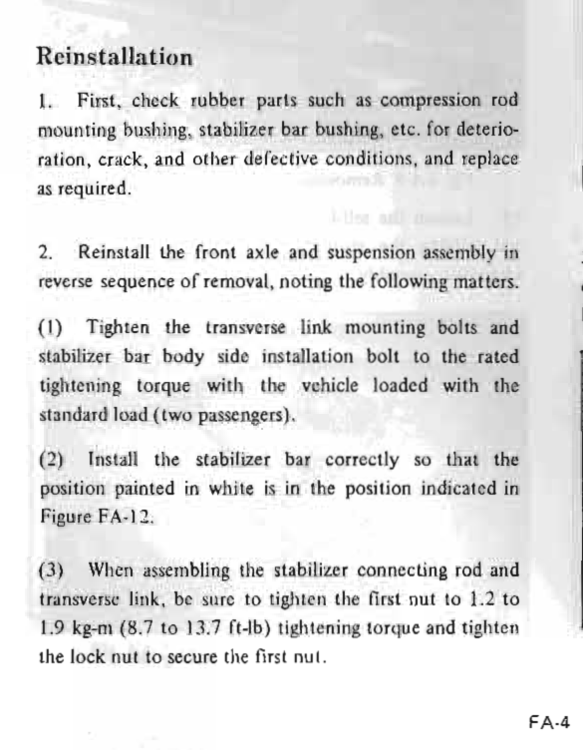

Front Suspension not settling

I completely overlooked the fact that the engine was not in. 400 lbs would make a difference, of course. CO has posted on this often - the bushing bolts need to be torqued when the suspension is loaded. Leave them loose until then. The factory bushing rubber is bonded to the metal sleeves and actually adds a small amount of elastic resistance to wheel or body movement, once the metal sleeves are locked in to place with final torque settings. It's described in the Service Manual. If that doesn't do it, it might be the springs. What kind are they? Progressive or straight rate? People have had problems with the progressive springs for many years.