Everything posted by Zed Head

-

1970 datsun #6106

X-acto knife or similar, a metal pick tool maybe, to pull them back out? m One of those 90 degree metal picks would probably grab an edge. Or a broad sharp chisel to lift the edges and just break them apart. Just to be sure, you do know that the small center pin, the one mm wide part, is the part that pushes through? Leaving a loose fastener in the hole.

-

What rear end is this ?

It could be a 300ZX R200. That' what they look like. Bit so do all of the other R200's. Loosen the locknut and turn the end link. I think that's a custom-made control arm setup. Looks pretty well-made though. Decent welds and stout design.

-

What rear end is this ?

It looks like an R200 by size, shape, and the lack of the bolt-on plate on the sides. But the internals and the back cover are all interchangeable so you won't really know what type of limited slip, assuming it is, unless you take the cover off and look.

-

Engine Burning Oil

#4 looks like the only oily cylinder in your first picture. from the picture of the head. Odd problem. Your valves don't look like they're getting very hot either. Have you had it out for a good run at temperature or are you babying it because it's new? Could be a stuck oil scraper ring. It happens, from what I've read. The cure for stuck rings is hard usage of the engine. These engines like to be used.

-

Engine Burning Oil

I think that he's had his car for a while and drives it often. Maybe the relief valve in the pump did get jammed. Who knows. But he's in the "might as well" zone now. Might as well do some work on the head while it's off. Might as well check that oil pump for wear. Might as well put a high performance cam in it. Might as well buy another engine so I can work on this one....

-

Engine Burning Oil

So, "now what?" is the question.

-

Engine Burning Oil

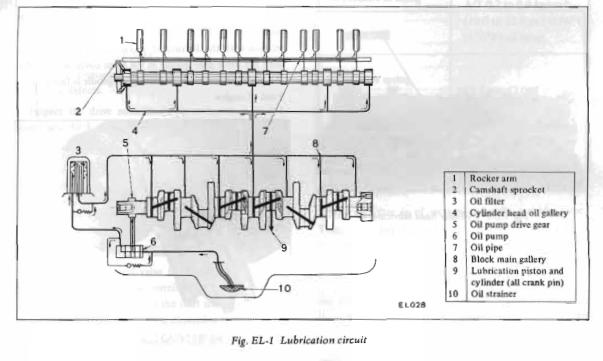

It might help to get in to the basics of the engine and its lubrication system. There is no "pressure" that would force oil in to the combustion area. High oil pressure might lead to high oil volume, flooding the top of the cylinder head, but there is plenty of room for the oil to flow back to the crankcase. You could have excess oil flowing through the main bearings, splashing up n to the cylinder walls as it gets thrown off, but the oil scrapers would have to be seriously overwhelmed to have that oil get ni to the combustion area. In short, oil pressure and smoke from the exhaust are not connected. It's actually more likely to see low oil pressure and smoking on a worn engine, with worn valve seals, than on a low mileage engine with high pressure and good valve seals. The two problems could be coincidental but there's probably no cause-effect relationship.

-

Engine Burning Oil

Could be that the guage in the dash wasn't reading right. It seems possible that the oil pressure was never really too high. When you installed the gauge on the engine block you disconnected the dash gauge. The high oil pressure reading might be a coincidental distraction from the real problem.

-

Engine Burning Oil

You didn't give any "higher" numbers so the 60 psi that follows has no point of reference. It is possible for oil to pass the rings and still get good compression. The oil scraper rings and the compression are two different sets of rings, with different functions. Not really clear what the "problem" is. High oil pressure or running rough or smoking. Seems like you're assuming that high oil pressure is going to cause problems. Reminds me of all of the effort I spent trying to solve a "problem" on an old muscle car in high school. In the end it just need a new set of plugs and points. No offense, you described several things happening but they might not be connected.

-

Nationwide Pick and Pull Junkyard Search

Coincidentally, this ZX came up in my email this morning. "Datsun" 280ZX. https://row52.com/Vehicle/Index/JN1HZ04S3BX273855

-

Intake manifold interchangeability.

Put them on the manifold and check functionality. I wonder if there are different versions of the ZX TB's. I spent some time looking at this same type of project and remember finding more reasons it might not work. My TB came a from a 1981 280ZX 2+2. I was using a 78 TB to compare.

-

Cylinder head flatness - is milling really necessary

As I mentioned above it really doesn't take much force to flex the head. Experiments with longitudinal clamps might show something. If it's bowed up on the ends then it might be as simple as tightening the center bolts first. If it's bowed up in the middle, clamp it from end to end and drive some wedges under the middle of the clamp. Who knows, it might actually be simple to do. https://www.harborfreight.com/1-2-half-inch-pipe-clamp-3813.html

-

280z won’t start

This could be a bad connection at the T plug on the back of the alternator. Seems like you partially realized that something is wrong there. Or, and I think this is rare, and I can't remember if there's not a second L circuit, the bulb in the voltmeter could be blown. That will also kill the charging circuit, assuming that it is the only L wire power source. Looks like they added a second L circuit in 78, with the internally regulated alternator. What year is your car?

-

78 280z turns off with turn signal/reverse lights

How many ohms? What does "good" mean? What does "ground" mean? "That ground looks clean". I can only offer clues. You decide how to run with them. Think in terms of circuits. Current flow. You're losing current flow somewhere.

-

'78 280z Running Lean?, lack of power

If the plugs are new you can't really tell if it's running lean. EFI engines are designed to run clean, the plugs don't brown up like an old carb'ed engine might. Could be several things. You need to know fuel pressure at the rail while the problem happens. Leave a gauge on and check it when it loses power. Take the black cover off of the side of the AFM and make sure the counterweight is moving with air flow. It might be stuck. Usually when these engines run lean you get popping back through the intake manifold. Popping and bucking, very annoying. Just a lack of power sounds more like air flow. You can check the coolant temperature sensor with an ohm-meter, at the ECU connection. There's a chart in the FSM. Don't forget the EGR system. I think that it is actuated after the engine warms up.

-

78 280z turns off with turn signal/reverse lights

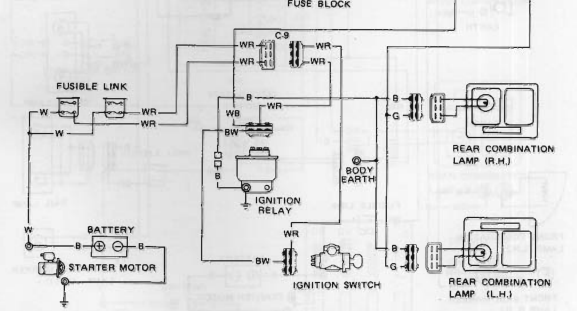

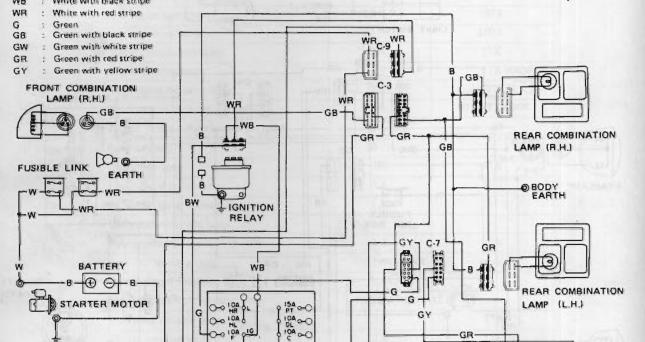

So you can unplug a single bulb, either side, and power comes back? I don't have a solution in mind but do see that the ground wire for the bulbs is back at the ignition relay. Same for the signal bulbs. You might find that ground wire and either replace it with a better ground wire or clean up the connection. My latest guess is that the ground circuit is opening due to heat from the extra current. Similar to how the bad battery connection open up. Find that ground wire and make sure it's right. It could be the connection at the relay mount or the connector shown in the diagrams.

-

78 280z turns off with turn signal/reverse lights

Are you unplugging each light individually, at the socket, or unplugging the reverse switch on the transmission? You said "them" which implies both, but you have to unplug each individually if you're actually unplugging the lights at the socket.

-

78 280z turns off with turn signal/reverse lights

Do you lose power to the ignition system also? The coil. You're focused on the tail of the problem instead of the head. Go all the way back to the battery. You might even have a bad battery connection. You haven't really said that everything else maintains power, only that certain relays lose power. And don't assume that voltage equals current. Seeing voltage on a circuit just means that it has the potential to do something. Without a ground nothing will happen. Be the electrons...

-

78 280z turns off with turn signal/reverse lights

This is actually a good thing. Now you can look elsewhere for the source of the problem. Try to determine if you're losing ignition power, fuel pump power, or both. That will be a clue.

-

Intake manifold interchangeability.

My mistake on the TB fitting. It must have been the hoses between the AFM and the TB that I was thinking of. The ZX hose and TB inlet is smaller. I thought that there was a bolt pattern issue but apparently not. p.s. edit - although I do also vaguely remember a throttle linkage problem. Worth double-checking, but kind of pointless if you have the other parts. Just like when swapping any of the EFI parts there's always a way to make it work. It's a crude system. The engines all have about the same power from 75-83.

-

Intake manifold interchangeability.

Are you assuming that the larger plenum will flow more air? Your throttle body will not fit if it comes from a 280ZX intake manifold. They're different, the ZX TB's and manifold opening are smaller.

-

78 280z turns off with turn signal/reverse lights

Don't assume that continuity and low voltage mean the relay contacts are making good contact. Sounds like you have a bad relay. The test I described will show you if that's the case. The measurements only get you so far, typically showing what's working correctly. Your measurements have shown you that something is not right in the relay. The next step is testing.

-

78 280z turns off with turn signal/reverse lights

You just described a bad relay. Not sure why your fabbed-up relay didn't work. You're saying that the coil is energized but the switch is not transmitting power. Be the relay. Short across the circuit in the relay that you think is losing power. If it fixes the problem then the relay is bad, either the contacts are dirty or the solenoid isn't working. If it doesn't fix the problem then you can move on from the relay.

-

78 280z turns off with turn signal/reverse lights

It's not clear why the engine needs to be running for this problem to manifest itself. Also not clear that the fuel pump power is the main reason the engine dies. Seems more like you're losing all ignition relay power, not just fuel pump power. Do other things shut down? Radio, heater blower, windshield wipers, etc. Those are accessory items but I think that they use the same supply line to the ignition relay. Also, voltage to the coil should go away if it's an ignition relay problem. Maybe connect a test light or two to your ignition relay's input and output then put it in and out of reverse and see if something different shows up. And don't forget the Hazard switch. It is the cause of many mysterious electrical problems.

-

78 280z turns off with turn signal/reverse lights

The 280Z's have the relay in a bad spot. Gets wet if there's a leak. They're easy to take apart, just bend the crimped lock tabs back and pull the cover off.