Everything posted by Zed Head

-

Random Wire!?

Sounds like the wire to the condenser/capacitor on the fender well. It would be hot when the key is on. See if the condenser is still in place, it's right across from the coil on the fenderwell.

-

240Z Distributor Questions

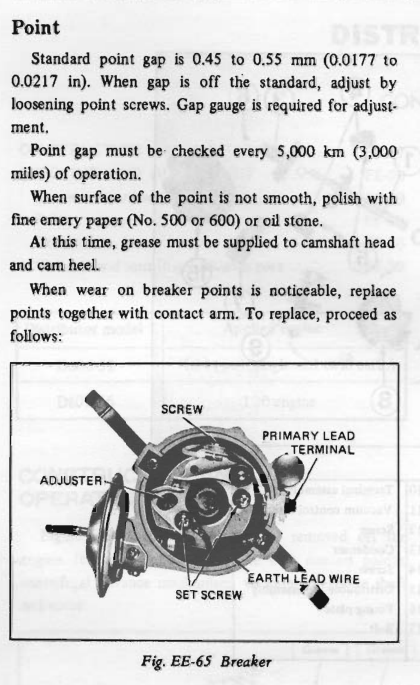

There is good stuff in the Service Manual. You should download it and look through the Tune Up chapter and the Engine Electrical chapter. Timing is set using a timing light. It's different from setting the gap of the points. It is normal for the rotor shaft to turn a few degrees. That is the mechanical advance mechanism working as it should.

-

Poly Bushings for Transverse Link and Spindle Pin

You might be able to hone out the bushing sleeves. I've used Scothbrite on the end of a suitably sized rod to hone things out. Cut s trip of Scothbrite, stick it over the end of the hole then jam it in with a rod on the end of a drill motor. Some WD-40 and a few million revolutions and the hole will get bigger. Surprising that the sleeve is too small. That's a bad product, since you have a new pin. Should be a perfect fit. Inside the casting, around the lock pin hole, there can be deformation. But I think you said that you already cleaned that up. The spindle pin should slide easily all the way through the casting hole.

-

New clutch...Noise when clutch is not depressed and trans in N?

This has the classic signs of noticing something that has always been there because you just did some work in that area. I had three different five speeds in my car that all made the bearing noise. Different sleeves, pressure plates, etc. but they all sounded about the same. Pedal down, noise gone; pedal up, noise there. Drive it for a few days and see if it changes. It will probably get a little louder when the oil is hotter and thinner.

-

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

Just a local news article. 192 mph. Pretty crazy, we have a lot of trees out here. https://komonews.com/news/local/impaired-corvette-driver-busted-going-192-mph-near-snohomish-wsp-says

-

COVID-19

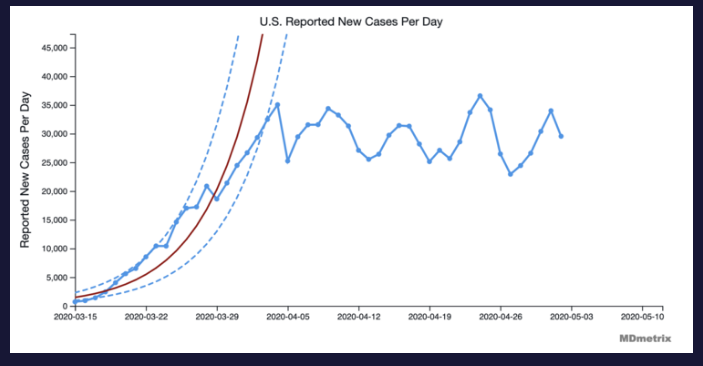

Overall, the infection rate has been pretty steady, with the distancing and closures. Not really seeing a trend up or down or any reason to think it will go any way but up, in the near future, unless summer weather balances out the reopenings. https://www.mdmetrix.com/covid-19-projections

-

COVID-19

I wish that they realized how stupid they look. Just a bunch of dumb idiots with guns and masks. Like 12 year olds playing army.

-

Poly Bushings for Transverse Link and Spindle Pin

You can see in your picture that the sleeve is narrower than the polyurethane bushing. People often just sand down the PU. But, as cgsheen1 implies, you can just compress the PU and squeeze it in there. It's elastic. Don't sand down any of the metal parts, it's only the PU that's a problem. I've used a thin paint scraper with lube on it to wedge the front bushings in to place. Use the thin piece of metal as a lubricated ramp to get over those edges. Once you get the edges started just squish it in there.

-

Dieing issue

That is odd. In order to create a spark the circuit through the coil needs to be completed then broken. It looks like the circuit is being "made" then being broken, maybe just due to overheating. I'm going to guess that your ignition module or the ignition coil is bad. When you turn the key on power flows through the ignition coil and the ignition module, something inside the module or the coil overheats and the circuit is broken, and a spark is created. It probably happens on #4 because the rotor just coincidentally was pointed at the #4 terminal in the cap. If you turn the rotor to a different spark plug you might get that plug to spark the same way. Feel free, anyone, to critique my guess. Since you already identified the coil as being out of spec. that's the easiest and cheapest part to try. If you have a spare coil of any type it will probably work for a test. If you want to try the GM HEI module there are some writeups on the site. It's just four wires and a place to bolt it to a good ground.

-

New clutch...Noise when clutch is not depressed and trans in N?

One of the bearings in the transmission is known for making noise. I think it's the countershaft bearing. Doesn't hurt anything it's just annoying. There are stories of replacing the bearing with a new one and have ing the nosie come back within a very short time. Might be why Nissan went to a bigger bearing with the 71C transmission. What kind of "some noise" is it?

-

COVID-19

Now, on top of it all, we have the "Wuhan" hornet... C'mon! https://www.theguardian.com/environment/2020/may/02/murder-hornets-washington-state-bees-twitter

-

Dieing issue

You should hear all six injectors click at the same time. It's very hearable when the engine is not running or the starter turning. It might be that your ignition system needs some work. I think that you said it used to start then die, now it doesn't start at all? Maybe recheck spark, then tune the ignition system if it's gone. Do you still have the original ignition module? It might be that it is dying also. 75 was only the second year of electronic ignition and the modules are very old now. You're pretty close I think. Reconfirm what used to be. If you have lost spark there are some cheap and easy ways to upgrade to a better more powerful ignition system using a GM HEI module. That module also got rid of the tachometer issue on my car. Stronger spark and no injection problems.

-

Poly Bushings for Transverse Link and Spindle Pin

Sand, verb. Or grind.

-

Dieing issue

Actually, you're way ahead of most people new to EFI (no offense to most people). You have a meter, you're using it, and you're getting real numbers. 1975 was the first year of EFI so Nissan's book wasn't the greatest. Here's a later one that has tests for all of the years up to 1980, and has better numbers, than "small resistance". You have to pick through and find your year but they give more info. Your 185 would be about 150 in the newer book. Close enough I think. I would focus on the Pin 1 signal. Is the tachometer still in the car? I've found that the whole circuit from the coil to Pin 1 needs to be intact for the ECU to open the injectors. Sometimes the system own't work if the tach is disconnected. There is a simple trick for checking the Pin 1 circuit that lets the ECU know when to open the injectors. Connect a wire to the coil's negative terminal. Turn on the key. Tap the other end of the extra wire to ground. You'll get a small spark as the coil circuit grounds. Every third tap should cause the injectors to click. That's what the ECU does, it counts sparks then injects.

-

Poly Bushings for Transverse Link and Spindle Pin

Resizing the bushing is pretty common. Some people manage to wedge them in there with some lube and some trickery. Here's one thread that mentions it. It starts out on the other end, loose, but ends up at tight. There are other posts about the issue on the site, try some search words in the box at the top of the page.

-

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

Here's another. https://www.youtube.com/channel/UClvow1RFSyeh5CRwRB_m5sA

-

COVID-19

Just wait... Edit - I overlooked the first part of your comment. You're forgetting, maybe, about The Wall. Defense money was moved over to finance a few extra miles. "Emergency declaration" I think is the key phrase. https://www.vox.com/2020/1/14/21065352/trump-diverting-military-funds-border-wall-construction

-

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

Sports fans, soccer. There's probably others. NBC has a bunch of condensed and classic matches for free.

- Dieing issue

-

Dieing issue

Check resistance at the sensor itself. They don't really go bad often. Many get replaced for no reason. There are some bullet connectors in the harness between the ECU and the sensor that can come apart. The sensor is the small one with the injector-type connector, not the big one. The big one is the thermotime switch. They're both on the thermostat housing. You might pull a spark plug and see if it's gas-fouled. All of these small things add up. Keep knocking them down.

-

COVID-19

Seems fitting somehow. Pointless expensive military shows falling apart. https://www.nola.com/news/article_c2c9fb8c-8be6-11ea-a01c-03e9ac7cb93d.html

-

COVID-19

Shanghai'ed. https://www.theguardian.com/environment/2020/apr/30/no-end-in-sight-100000-crew-on-cruise-ships-stranded-at-sea-coronavirus

-

Dieing issue

There's no good reason for only one injector to lose power at the ECU connector. Power comes through the harness to the dropping resistors then through the injectors to the ECU connector. Could be a bad injector. Might explain the rough running. But the engine should keep running on five. Check the coolant (water) temperature circuit at the ECU connector, using the book as a guide. It might be that it's disconnected and the engine is flooding. If that sensor is bad or disconnected the ECU will add a lot of extra fuel. Like you're in the Arctic.

-

Dieing issue

Are you sure that the EFI harness wires are connected at the battery? They have plastic connectors and connect to the negative and positive posts. Don't get them mixed up. Check your fusible link connections. They get corroded and can lose continuity. I think that there are two under a single plastic cover on 1975s, plus the one in the wire to the positive terminal. Using your meter is the way to go though. Make sure you have power where it should be and check grounds also. Keep a list and record the actual numbers that you get. Something will show up. Most people with EFI have been where you are now.

- Dieing issue