Everything posted by zKars

-

A window regulator trick I learned by accident

There are subtle differences between the 240 and 74-76 280 regulators, guide channels and window guide frame that might explain that Nissan was also trying to improve the geometry. The regulator frame is about a 1/4 thicker and moves it away from the door frame by that amount. The final solution is the vastly different and much better window guide rails in the 77-78 doors that finally fixed the problem. Many modern doors still use this basic system of two vertical guide rails. The regulator is basically unchanged except in how it affixes to the glass. As usual, getting the basics right first, means fewer degrees of freedom for the other components. Good tight fitting felts in all the channels, and proper lube and free movement of the window in its guides. Once the window CAN move freely up and down without slop, THEN the guides can be tweeked to make it move in the geometry that makes it fit the frame when its up.

-

The blue 510

That is totally cool. A thing to hang on the wall and tell lies about for years.

-

What is this part

Another day, another new cool thing to learn about Z’s. I would have sworn up and down that was a user added part for an alarm or interior trunk light “upgrade”.

-

What's the most needed Z part that's currently NLA?

AM I crazy? (Ok, we all know the answer to that, but listen to me for a sec.) If I’m reading the original drawing thing, the diff moves back 35mm in the new “better” configuration. Like an 1-3/8 or better. Since the big steel cross member is not moving, the center M10 stud on the isolator has to be in the same spot, so it must be the two holes that bolt the isolator to the diff that are offset forward 35mm. Sure doesn’t look like that much when you compare the two isolators side by each. Or are you bolting through the “other” pair of holes on the diff to make up this massive difference? Or is the mount rotated one vs the other so the holes are at the front or rear of the cross member? That must be it... Clue me in!

-

Isolation Videos/Content to Keep Spirits High: Post Something (Non-Virus) for Entertainment of Others

Here is today’s contribution to your well being. A little bit of Zen tranquility to relax a troubled mind. Assume the lotus position, turn up the volume and put it on infinite loop. OHMMMMMMMMMMMMMMMMMMM ...... A5E5380B-4934-47F0-BFD5-927A0FEC5910.MOV

- Duffy's 1/71 Series 1 240z build

-

New Product Idea. Distributor Timing Plate Re-Design

That’s not a bad idea, I actually thought of that earlier. Trick with these is doing it in a straight line and with even spacing and rotation. Bit of a jig/wall/block could be made easily to help keep straight and square. Might just weld the 153624 together.... EasyTime... Dang, two E’s..... two sets. EasyTimy.....

-

New Product Idea. Distributor Timing Plate Re-Design

Unfortunately, being laser cut, they can’t do anything but cut right through. I asked. Same with water jet and plasma. I’ll call around and see if any engraving places are desperate for business.

-

New Product Idea. Distributor Timing Plate Re-Design

Wanted to be sure I thanked you for the kind words and positive report on my little gadget. Glad to hear it suited the purpose.

-

New Product Idea. Distributor Timing Plate Re-Design

So today, (Happy Easter by the way!) I was googling images of Datsun 510 idler arms (don't ask....) and what should I spy with my little eye while perusing the images? https://www.californiadatsun.com/distributors-and-parts/datsun-240z-280z-510-620-e1280-electronic-distributor-timing-plate-bracket-mount.html Seems I am late to the market. Now what the $)(*$&% do I do? And of all the people to do it first.....

-

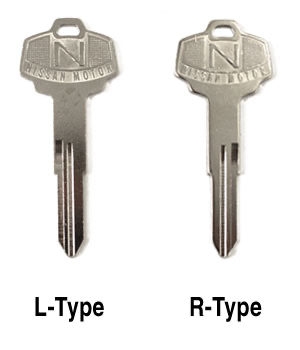

How to tell R or L hand cut key?

There really are two mirror image blank styles. And of course the early cars had the single edged keys. MSA has a nice description. https://www.thezstore.com/page/TZS/PROD/30-7457-58

-

Jack handle refinishing

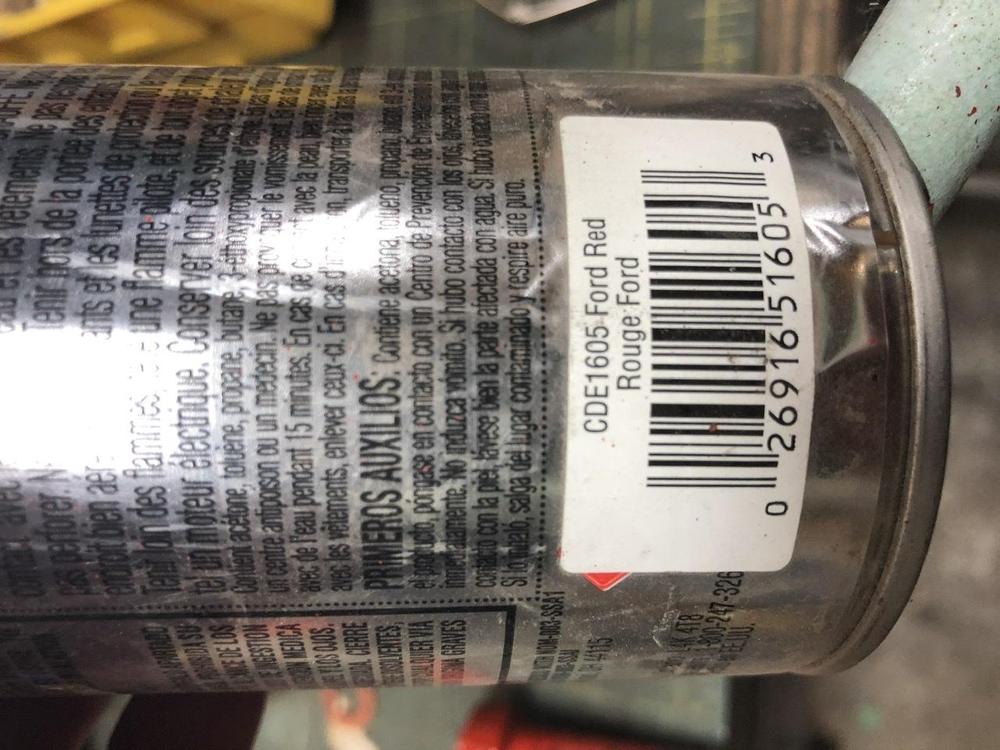

They definitely more red than the air cleaners. Very red. Just did a little test. Ford Red from Duplicolor is VERY close. The hue and overall shade feels really close to the original. Fresh spray on the right, old patina on the left of the square drive hole...

-

The positives of quarantine

I’m beginning to worry about the length of the shutdown, and how many yard based chores the royal “we” are starting to think about. Expanding the garden, moving a garden shed full of parts (someone please come buy some parts!) etc etc etc..... I’m definitely going to have a major yard sale of Datsun parts this spring/summer. Motivated seller, let me tell you....

-

Checking correct fuel level at Round Top 3 screw SU CARBS Float bowls

The top of the rectangular block on the side of the bowl is very close.

-

Checking correct fuel level at Round Top 3 screw SU CARBS Float bowls

No simple task to mount a flush style sight glass into the side of a curved fuel bowl, with a float very close to the inside of the wall. Too bad the correct level is at the top edge of that flat rectangular area, rather than in the middle..... If I could find the couple that Philip gave me about 5 years ago when we discussed this last, I’d actually go try this....

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

All good ideas. Sourcing the metric parts was easy, no need to bring any “outsiders” to the party. The original wing bolt is definitely two pieces, no sign of any brazing or soldering, maybe just a tight fit. Red loctite might just do it. I’ll do one and see what kind of torque it can handle.I can’t use more than about three threads or I start taking up too much of the cavity for the wing bolt. TIG’ing that bolt in there is the hot tip (haha) but I need to practice. Best thing I got was a face shield with a magnifying lens. Old people....

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

I initially bought M8 wing nuts, but they are quite a bit bigger than the M6 which are pretty much identical to the OEM wings (other than the silver zinc finish). I can these as an option however, as they would be much easier to tighten and loosen than the stock size wing nuts. I must be spending too much time with my Grand daughter and the Disney+ movies. All I see is

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

Proof of concept. top is OEM, center is my forgery, bottom is the component parts that you start with. The wing nut is an M6 x 1.0 so I remove the hex head of a bolt, turn it down then run a die over it to thread. Today I will experiment with ways to permanently affix the wing nut to the bolt. Red Locktite, welding, silver soldering are all options. Sort of the same issue about the lower bolt that forms the threaded leg of hex coupler. It is threaded in 3 threads, then presently a thin nut is used to lock it in place. I would prefer to weld that in. I will likely TIG it on, then turn it smooth over the weld area.

-

New Product Idea. Distributor Timing Plate Re-Design

Another TV series I had completely forgotten about! Clearly “It’s About Time” will be the catch phrase or slogan I’ll use in the marketing materials. Brilliant.

-

COVID-19

There are no stupid questions about this. At the very end, the doc says some stuff about what happens with this virus long term. The detail I picked out is that all the viruses, including all the variants of the common cold, become weaker with time, and simply enter the rotation of viruses we already have anti-bodies to, and if you do get it, it will be no more severe than the average cold. This particular one is just new, so NO ONE has immunity yet (well, some do now....) and it’s a bit of a nasty one, spreads easily (no kidding), and it’s killing lots of folks. So until we control it short term (distancing, wash hands, NTDF (no toucha da face)), a vaccine finally gets distributed, and enough time passes, the danger persists. As to origin, good luck ever learning the truth about that one. Viruses have been coming to reality for a long time with no Intentional human interference. The whole mutation thing. New ones pop up all the time. Very few get out into the general population the way this one did. Hopefully we are learning what to do (And not do) next time.

-

COVID-19

Here is common sense advice from a real doctor with real front line experience to help you and those close to you. All the details you need to know, and answers to all the questions I've had. Best I have seen by far, in every possible way. I have a new hero, Dr. Dave Price

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

That is a candle holder, but now you’ve got my mouth watering for some proper Irish whiskey.

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

-

Series 1 Choke Hand Throttle Cable Assembly Mechanism

Man if he can $10 for those dirty brittle random connectors, I’m gonna be really PO’ed that I’ve tossed so many of those.....

-

Source for the Cup washers on the SU Air cleaner Wing Bolts

If my plan comes together I won’t have to machine much of anything, let alone threads. I’m not aiming at a perfect or even a Really close forgery of the originals, just something that looks pretty close and functions properly, and that is cheap to create. My hardest machining task is to make a pointy ended bolt out of a regular one for the wing bolt, and cutting the head off of bolts to supply threaded stock. Raw parts costs will be in the $5 dollar range. I’m not even planning on getting the hardware plated, although that’s always an option. I’ll keep the few sets of OEM hardware I have for the proper restorationists, the rest of us just want to keep our air cleaners on!

Subscriber

Subscriber