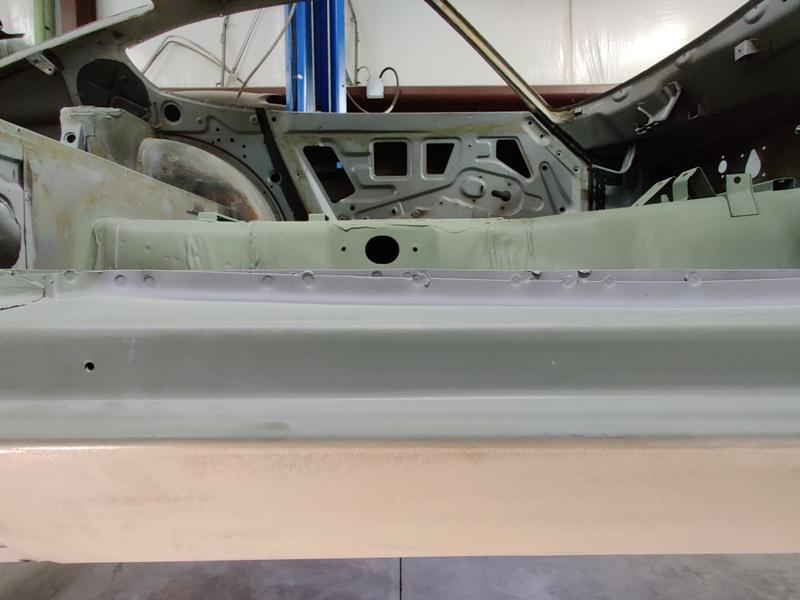

Work to straighten out the misaligned rocker panel (at the factory) has begun. In addition to the problem I already showed pictures of, the top of the rocker panel had some misalignment as well. The outer panel was noticeably low along the top edge, but only for the center portion of the rocker panel. This caused a dip in the top surface that the aluminum threshold goes over top of:

You can even see where the spot welder completely missed in attempting to join the inner and outer panels. Seems the workers at the factory had to adjust the welder downward to hit the outer panel, and even then, they could only pick up the top edge.

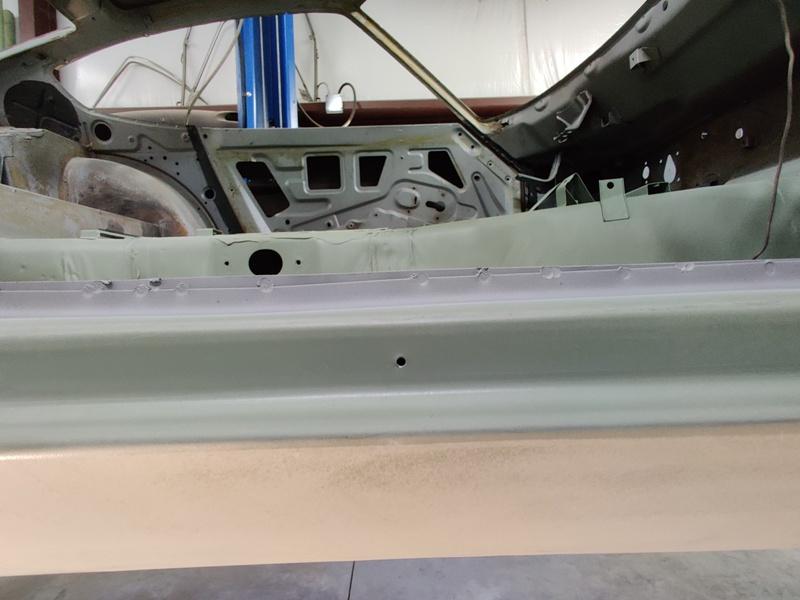

I didn't show how I corrected it, but I just drilled out the spot welds, then used the stud welder to put some pins on the weld flange, and then used a crow bar and piece of plate to protect the top surface of the rocker, while prying up on the pins. This allowed me to put enough lifting force on the weld flange to raise the low area of the rocker. I then welded, with my Mig, the holes left from cutting out the factory spot welds, and ground everything flat again with the surface of the outer panel's weld flange:

It's not perfect, but it is much better. Metal work like this is a big time suck. Lots of tedious grinding of welds. I finished them off with my hand held belt sander. I hope to experiment with the spot welder I bought on this flange, but the electrodes may be too large in diameter to align well on this flange. We'll see.

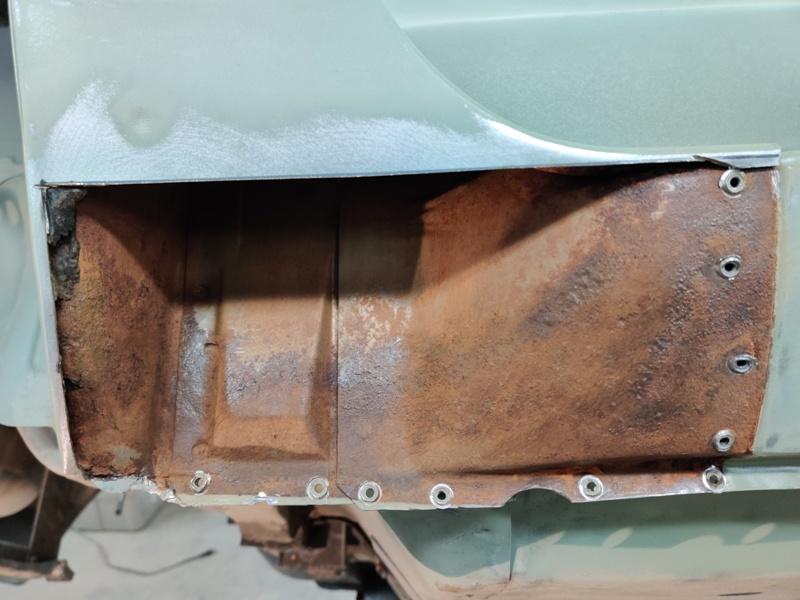

Next up was the part where the quarter panel folds over the rocker at the back.

Interesting to see what is inside.

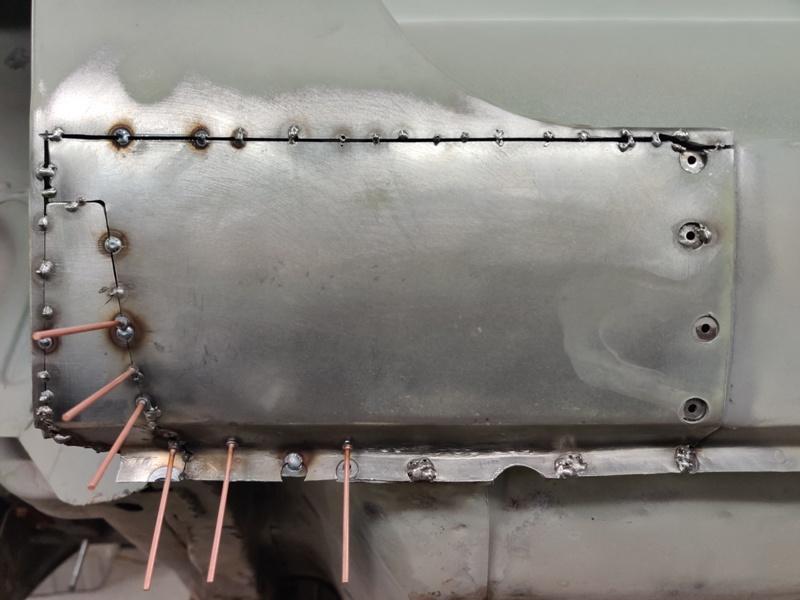

After a light dressing with wire brush... and the outer panel piece receiving some attention in the glass bead cabinet:

The sandblaster was again employed to remove corrosion and get to nice metal. Got several pictures while this area was seeing the light of day:

Close ups showing pitting (light pitting, in my opinion):

My first 240z was missing the entire dog leg corner (inner and outer). So nice to see this area in such nice condition.

Pic showing up inside (bare metal from the factory and the seam sealer they used in the wheel arch). A few more minutes in the glass bead cabinet with the panel. The dark corner (upper left in pic) was pitted too much, so I made a section to replace that.

Taping for application of weld thru primer. I've never used it before. It is kind of transparent (has been applied in second pic):

Tape removed and outer panel tacking in progress with new fabricated piece also (bottom left)

As the welding occurs, the panel wants to move around. I used the stud welder to yank on low areas, trying to keep alignment as best as I can as welding continues:

Alignment is not bad. Lots of time involved with keeping alignment, tacking, and eventually grinding. I easily have more than 30 hours of time with fixing the rocker and removing and reapplying this panel. The end result of the main effort, to straighten the bottom of the rocker panel/quarter panel along the bottom of the car is "better". Sometimes I can't get things good enough to my liking.

I've ground the welds in the last picture down and filled small voids etc. More pics will follow, but it's time to get out there and work on the car again. ?

Subscriber

Subscriber 3Points1,281Posts

3Points1,281Posts Subscriber

Subscriber 2Points381Posts

2Points381Posts

.thumb.jpg.5773de9e8b4fb1e6e8ae94ad9ca5638e.jpg)

.thumb.jpg.0e15ff6d68903030860de7e52c077255.jpg)

.thumb.jpg.d2bd9602f29cc4bd2e07e82ca8b5005c.jpg)

.thumb.jpg.c9c2b6eeca68b6a00fd82c717d6ddc83.jpg)

.thumb.jpg.2266c5e8920524521450406020fb6aa6.jpg)

.thumb.jpg.b054fec78b2be911938a6cf18f7c7c10.jpg)