I have already posted all over the forum, so I will add links to work I've already done as much as possible to avoid double-posting. This will be to consolidate the work. Should have done this from the start back in the Spring, for whatever reason I didn't notice the Build Thread section back then.

My "toy" car has been a Bertone / Fiat X1/9 (mid engine) since around 2007. That car evolved over the years. The last major revisions were a Dallara replica wide body conversion (2016-2018), and then a Honda K24/AST5M drivetrain conversion (2018-2020). I do all my own work. Now that is essentially 'done' (not in need of major changes or constant fiddling) & really only needs to be driven, I needed a new long term project to keep me busy.

In one thread on the X1/9 forum, a member brought up the Datsun 240Z, can't remember what the topic was, but anyway, I have loved the styling of the Z since I was a kid in Malaysia during the mid 70's, where I bought one of the Tamiya FairLady Z model kits.

I decided to focus on looking for a 280Z after seeing just how much the 240Z's were going for, and knowing that this would not be a stock build. I'm not one who cares about keeping or using original parts just because. Settled on this 75 280Z from inland CA based on price & overall condition of the sheet metal & one owner. Bought back in early Spring.

At this point, I've installed or modded, not in order (I'll convert the list below to hyperlinks):

Note- many, many thanks to all the ppl on here whose existing threads/work I have tapped for ideas and ongoing assistance 😊

Front & rear skinny bumpers. Installed a Skillard grille, Xenon front spoiler, fixed the louvre mounting system.

New seat foam & Upholstery, w/heated seat grids. Honda seat belt shoulder guides

Honda wiper motor conversion, Cowl refresh (actual paint),

Replaced all opening/glass seals.

Repaired the driver's door panel, glass winder mechanism & inner release mechanism.

Replaced exterior rear view mirrors.

Rebuilt the entire front & rear suspension, Rear Strut Brace

updated the Front & Rear brakes,

Modified Steering wheel,

Front & Rear wheel well liners & stone guard & undercoat refresh,

converted the rear axles, replaced trans & diff fluid

replaced the dash,

console & carpeting,

rebuilt the AC system,

Ford Heater Core Install, SS heater pipe, AN bulkhead fitting

Kia Blower Motor Install

Water Pump, Front crank seal

3" SS Exhaust, custom DP

Replaced Fuel pump & bay fuel Ines, ProTunerZ fuel rail + High imp. Bosch Inj.

added a Bosch Idle Control System,

replaced the EFI harness on the engine,

Added 2.2K Pot for ECT circuit enrichment

Replaced the fusible links with 2 fused power supplies in the engine bay,

replaced the fusebox with a ATC fuse & relay panel, added auxiliary relay panel & power/ground expansion panels.

Added a starter relay.

Converted to HEI ignition module.

Added the Headlight Relays. H4/LED headlamps. Converted to LED exterior lighting.

Repaired rear tail panels, replacing light gaskets.

Headlamp covers.

Volvo horns.

Reverse light relay.

Lights On Buzzer.

Voltage Regulator Adj.

Clock Repair

Bunch of odds & ends I can't recall right now that only got posted in my Fiat forum thread, because I didn't make on here 🤪 - I'll try to add some of that as time goes by.

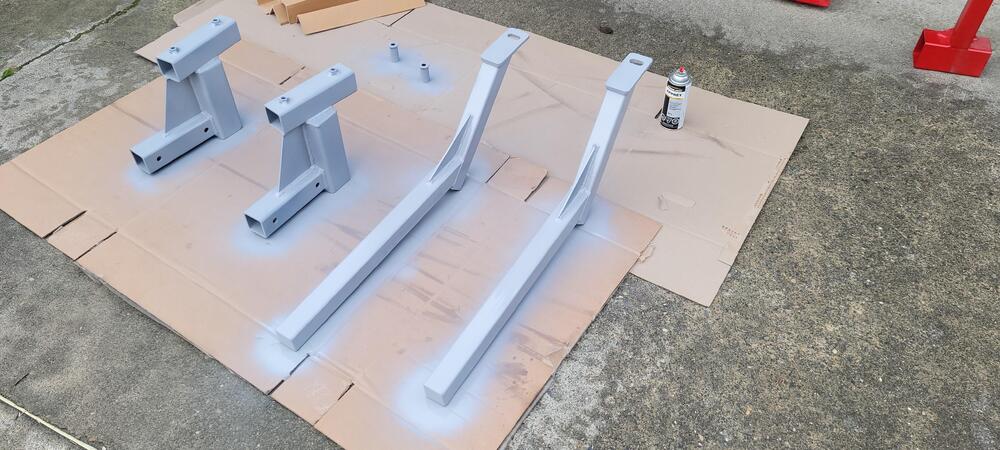

First long term project on this will be the drivetrain conversion. With this chassis, I wanted to keep it Nissan. I already did one major conversion with the X1/9, and am doing a Chevy V8 conversion with my '91 Volvo pickup, so I don't need that kind of extra flavor on this project. I settled on the VQ35DE/CD009 after doing some research on the various older drivetrains commonly used - RB series, etc., most of which if available are $$$$, and not so easy to find parts for moving forward, given that I want this to be reliable for DD fair weather use. The 350Z drivetrain uses readily available service parts & can be modded if I choose to go that route. Stock, it has around 300BHP, so using the stock 350Z EMS the car should be more than enough performance wise. I may change my mind about that DTR, however I've done an excessive horsepower build in the past, so I really don't need to do that again.

I'm going to be driving it 'stock' for the next year or so, until that V8 conversion is done.

350Z Drivetrain Conversion Thread

Work I still need to address to make it complete (not necessarily in this order):

Deal with heat soak / fuel vaporization issue (installed billet fuel rail & composite injectors)

3-5 sec fuel pump primer circuit

Replace L& R door panels, fix pass outer handle release rod, get door adjustment so they don't need to be slammed so hard

Drop the gas tank address the vapor system (leaks if filled)

Install Xenon rear spoiler (maybe painted first, haven't decided whether I prefer body-color for F&R spoilers or keep the contrast)

Additional floor / rear tub sound damping

Replace L & R door 'sashes' w/ later channeled versions

Install 350Z leather seats (reference HybridZ thread)

Add/incorproate switch for fan speed 1 (using Volvo 5 speed resistor, Datsun 3 speed fan switch )

New console lid has really annoying squeak if you use it as armrest - need to address

Go over whole body to address surface rust areas (no pitting or perforated concerns at it stands)

Then & Now pics

more recent