Everything posted by 240260280z

-

It Ain't Running Right!

For initial it is just the timing at idle (800 to 1000rpm) using the timing light. Do you need to set up the carbs too?

-

It Ain't Running Right!

Try 15 degrees initial timing with no vacuum advance. Don't go over 38 at max. Do you know what the mechanical advance is on your distributor?

-

Durability Of Led Bulbs

Here are products. http://www.mgchemicals.com/products/protective-coatings/conformal/ You could melt wax over the parts too as a quick and dirty,

-

Beta Checkers Needed For Revised Engine Planning Tool

Hi All, I have revised the engine planning tool on our club's website (attached). Please take it for a spin and if possible, provide corrections to the data and also suggestions for more data. It is attached below. You should be able to save to your desktop and open with your browser. FYI just type in the green blocks if you want to manually override any value. Philip S30 Engine Modeller V2 Beta 1.html

-

Anyone Have A Torque Plate For Sale?

Yup. I'm planning to start building some Z motors. We have quite a few in our Z barn so if the 88mm piston works out then it should be a reasonable build. The race shop that will do the machining has an engine dyno so I'll get some benchmarks.

-

Durability Of Led Bulbs

Some pictures of a 71 and 73 here. http://www.classiczcars.com/topic/40844-1971-240z-license-plate-lamp-photos/

-

Welding On The Strut Housings Without Removing Bearings?

I bet it was painful! btw I have a mustang TB for you. Want me to mail it or wait until you and Rene visit us or we go there

-

Durability Of Led Bulbs

you could coat it with polyurethane or silicon to seal it.

-

Welding On The Strut Housings Without Removing Bearings?

That should be in every automotive and aerospace welding manual. No one will forget it

-

Anyone Have A Torque Plate For Sale?

Kurby, CCA are just making their first L28 plate next week. I may purchase it. Steve yup the machinists have measured differences with and without the plate installed. Newer techniques even pump the block with hot water to operating temperature. I plan to do quite a few 88mm and 89mm over bores over the next few years and sell some motors so it is a needed investment. ZH, for the head, the cam can be relieved by the tower bolts when it is torqued to the block. Not much else can be done w/o a long boring tool and boring new towers when installed on the block or over-boring and sleeving existing towers. Yup BHIP are très cher ($$$$)

-

Anyone Have A Torque Plate For Sale?

~500-600 locally. I'm looking at one of these ~450 and probably better made: http://www.ccaracing.com/product1.htm

-

Welding On The Strut Housings Without Removing Bearings?

I think you will be ok with temperature. Just let it cool between hits and make sure the electrical path is not through the bearings.

-

Anyone Have A Torque Plate For Sale?

Diving head first into a few motor builds. Trying to do it right. I figured I'd ask around before approaching a machine shop. Thanks!

-

Early Vin Project Car $3K Portland

https://portland.craigslist.org/mlt/cto/4966042617.html

-

New Volvo On Ice

- [2015] What Did You Do To/with Your Z Today?

Beautiful Moelk! Blue w White is pretty. Looks like Dunlop Princess Margaret wheels? The front valence with blanked lights and the upper turn indicators on the bumpers is unique. I guess the lack of Datsun on the fenders/wings is also Euro spec. ? What is the device on the rear bumper below the plate? What about all of the electrics on the passenger inner fender? Looks interesting.- [2015] What Did You Do To/with Your Z Today?

- AutoZone and crap from China

- Fyi Cool Autozone Tools

Some interesting tools now seem to be available from autozone. Example: http://www.autozone.com/test-scan-and-specialty-tools/valve-spring-tester http://www.autozone.com/test-scan-and-specialty-tools/top-dead-center-stop-tool http://www.autozone.com/test-scan-and-specialty-tools/piston-ring-tool/proform-12-volts-electric-piston-ring-filer/525530/?_requestid=10232353 http://www.autozone.com/test-scan-and-specialty-tools/valve-seal-tool/comp-cams-valve-seal-installation-tool/892690_0_0/- Cam Wear?

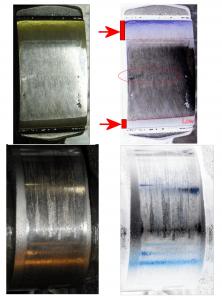

Remove valve cover, pull plugs, then crank with remote starter. Watch oil flow to rule it out. If you are getting good oil on that lobe/rocker, then it is most likely the rocker. This sadly happened to me not so long ago: http://www.classiczcars.com/topic/47101-cam-wear/ Here are some observations: Contact area is OK and it is "cheated" for more lift. As the lobe rocks across the rocker surface, it starts parallel (raising valve) but finishes (lowering valve) with more pressure on the firewall side of the rocker. The radiator side seems to be ground lower from the middle of the contact patch to the passenger side of the contact patch and the finishing pattern is not parallel to the starting pattern. This is also evident in the wear on the cam lobe's valve lowering face being more to the firewall side.- Triple Oer Carburetor Troubleshooting - Help

What emulsion tube do you have?- 1973 240Z Wiring Harness Info

- 1973 240Z Wiring Harness Info

- 1973 240Z Wiring Harness Info

- 1973 240Z Wiring Harness Info

- [2015] What Did You Do To/with Your Z Today?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.