Everything posted by HusseinHolland

-

Dave W 1971/240Z rebuild

Those floor panels look like a really good fit! I bought one of those flanger/hole punch tools - it was essential for the roof junction on my Volvo pickup truck conversion. I used Lord Fusor & a spot welder through the sunroof opening to join it though, no panel distortion that way.

-

75 280Z - Updating fuel feed & return lines in the engine bay

Replacement rail came today. Center port was no different than the first one, so I cut a chamfer with a countersink drill. Just went deep enough that the o-ring compresses without any squeeze-out

-

vintage dashes 280z

Had one of the new LED bulbs fail - the one in the AMP/Fuel started pulsing on/off. Swapped it out after confirming the power, ground & rheostat wiring to the gauge assembly were all not the issue. Interesting that they appear different color cast in the photo - they are all the same bulb. Secondary gauge pod have standard incandescents.

-

Wiper Woes

Sorry, Steve, is that an American cultural reference? Being English, perhaps I'm missing it 🤪

-

Wiper Woes

-

Replacing All Large Opening Seals & Hatch Small Seals

Meaning that the mount screws sit on top where they are less visible? Sounds better. I wonder if the mechanic who did mine was the same meathead who did the AC install. Neglected to review any provided directions 😞 Replaced the pass door handle over the weekend, and the belly pan today. I broke my phone last Friday, so no pics of the work

-

1973 Rebuild

Thanks for the clear detail pics here. I need to remove the gas tank in my 75 to fix the leak that occurs when the tank is full. I figure I may as well remove the vapor tank & do all the hoses, and/or delete it. I've read that Nissan used more than 2 sizes of hose for the lines to/from the tank & canister. Is that correct? As an aside, I also find it odd that they came through the trunk floor with the hoses, instead of in the side well area. Not having dropped the tank, perhaps there is an obvious space limitation that required this routing? Just seems out of character with the overall design flow of the car's mechanical layout & construction. Did you pressure test or otherwise verify the cannister's integrity was solid? I've heard they can leak vapor. I do not have any fumes in the cabin that would suggest I have an issue in that regard. Finally, what brand & thickness of sound matting did you use in the pics above?

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

That's true - much more room to wire over on the pass side. Perhaps I'll just do that. I was planning on just triggering the AFM signal to switch the stock relay. I don't know what load this timer relay can carry, however it should be sufficient to power the pump for a short duration.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

For me, this can be cheap and effective. The point is, wiring is required. Anything remotely plug & play is going to cost more, since you are paying the creator. The only additional element is figuring out the settings for the timer relay.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

That's not cheaper than the $5 programmable relay. It still has to be (self) wired into the car, it's not plug & play

-

Replacing All Large Opening Seals & Hatch Small Seals

Redid the Louvre outer edging/seal The channel I bought worked, however it's not pliable to the extent of the original, so I had to cut slots where it wraps around at the top. I reversed it so the wide strip is on the inside, and works as a isolator to prevent the louvres from whacking the glass trim as it has been doing for the past 48(?) years

-

280Z 2+2 Rust damage on interior floor pans - how severe/bad is this?

Do you have better quality/clear pics of the floor? The shots you posted are either unfocused or poor quality, so it's really hard to tell what's perforation & rust vs. shadow/tar etc., since we can't zoom in & get any clarification. For the underside, unless you remove the undercoat you mentioned as being added, you are not going to know how extensive the rot is. It's been my experience it's always worse than what is apparent. In this pic, it looks like the rust & perforation goes all the way across the from of the floor beneath the pedals. In one of the other pics, it looks like coffee can under the seat rail. If you are doing it yourself, and have some prior MIG/TIG experience, it's really just a question of stripping all the undercoat, cutting out all the obvious rust back to clean metal, then evaluate whether you can patch or if you need to replace entire panels. The metal used on these seems to be very thin gauge, I'm surprised how easily the outer panel flex on my 75.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

I'm going to add the relay - it's just a bit of a PITA to work with the relay end of the FI harness in the space under the dash. I really should have thought about this while the dash was out. Hindsight is always 20/20. I'm going to add a bridge harness to take the AFM pump trigger, run it through the timer relay, then back to the factory relay. So, I need to extract the trigger wire from the existing relay socket. The constant and switched power for the timer can also be drawn from the main relay, to avoid running lengths of new harness from other sources. It would be possible to make an entirely plug & play insert to redirect as needed from the factory relay sockets, however that would end up occupying much more space up under there, which I really don't have now that I added the 2 adjustable flasher relays. Working on my back and/or twisted up under the dash is not good for my lower back issues, so in part I am avoiding it for that reason. I will get to it eventually.

-

280Z 2+2 Rust damage on interior floor pans - how severe/bad is this?

Much better viewing inside. Got any pics of the underside where those rails & floor meet the bulkhead? The type of issue that can arise is where there are multiple overlapping panels. This was on my X1/9 Once I removed that perforated forward section: multiple layers to address. That would be my concern with your level of visible floor rot When you patch panels you have to consider how the new & old are joined - butt, lap, etc., you want to make sure you don't create water traps. In the end, I cut pretty much all of it out, so I could fit the panel inside at the leading and inner edge and under/outside along the rocker & seat frame area, to match the original flow of the panel welds. You do want to investigate what path makes the most sense. Your DS looks like most of it should go, depending on what it looks like under the seat frame rail....

-

75 280Z - Updating fuel feed & return lines in the engine bay

ProTunerZ is sending me another rail. They said they will send one with a more obvious chamfer, as they do seem to be variations. Apparently none of them have a significant chamfer on the ORB-6 port, and they said I am the first one to indicate it is a problem. The "chamfer" such as it is on mine is not uniform, and where the thread is visible close to the surface is where the o-ring pushed out. Perhaps most ppl block it off instead of using it as an active port? I dunno. Anyway, I'll swap it out when the new one arrives. The Allen heads are where the rail is bolted to the provided standoff brackets. The website illustrates the old brackets, which apparently bolted to the head/manifold studs (Yuk) - the new version bolts to the stock rail mount points.

-

Dave W 1971/240Z rebuild

Dang. That layered rust is giving me PTSD. Even my X1/9 rot pales in comparison. How do you get through all those layers without completely removing everything inside & out?

-

Replacing All Large Opening Seals & Hatch Small Seals

Finally found a rubber seal that should work to refurbish the rear hatch Louvre. Also found a thin U-channel that will work for the center ridge.

-

Designing A/C System Using Other Cars Parts?

Finally figured out how I can use all the 5 speed settings of the Volvo resistor pack. Been looking for a 4 speed switch without any success, ones I did buy listed as 4 speed, were not so. I decided to add one of the micro switches originally installed with the aftermarket AC. Modified the supplied bracket (sectioned, spot welded to correct the offset) so the microswitch lever sits behind the fan speed switch in the off position, and turns on between off & first speed detent

-

Voltage Regulator - Should I adjust it??

All the others I've seen are $80 or more, so it's still cheaper even with the higher shipping

-

Voltage Regulator - Should I adjust it??

Nice find - I searched for V/regs , and that one did not come up. For the price, I think I'll just get one. As I mentioned, mine has pitted contacts, so even with cleaning it is not perfect

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

-

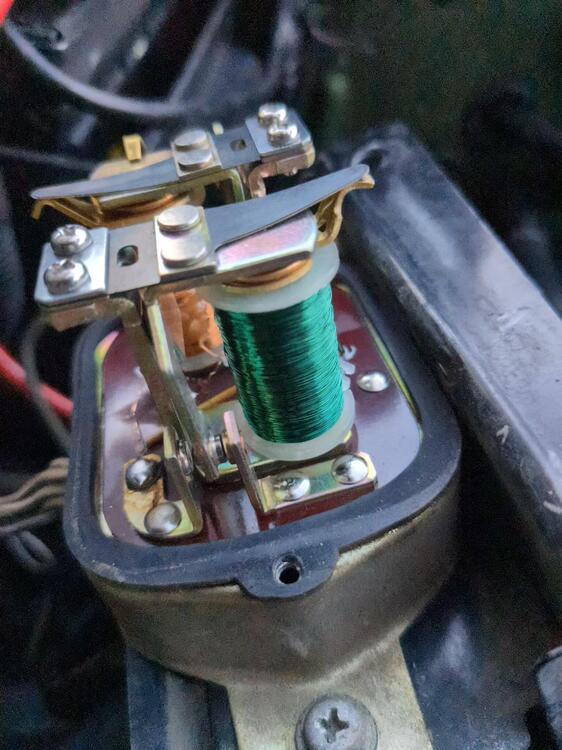

Voltage Regulator - Should I adjust it??

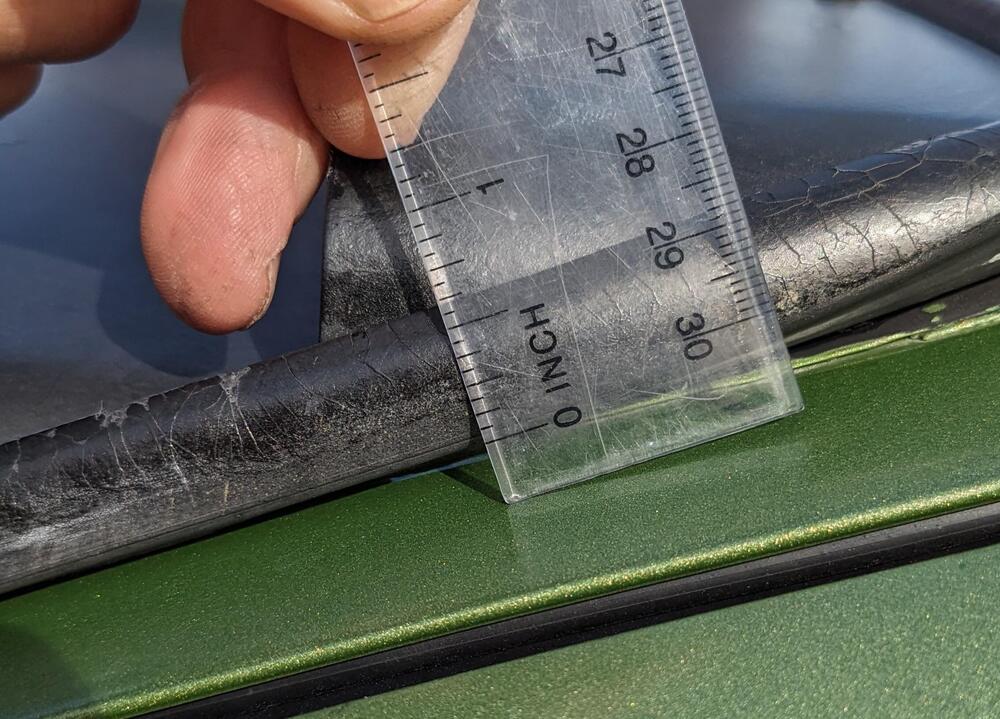

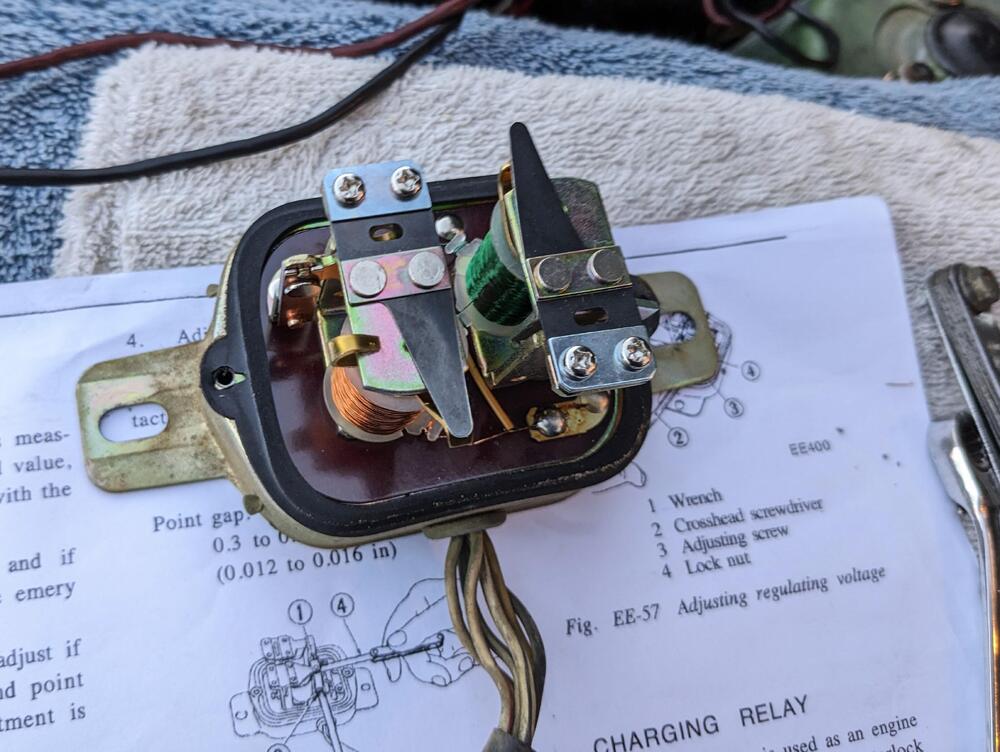

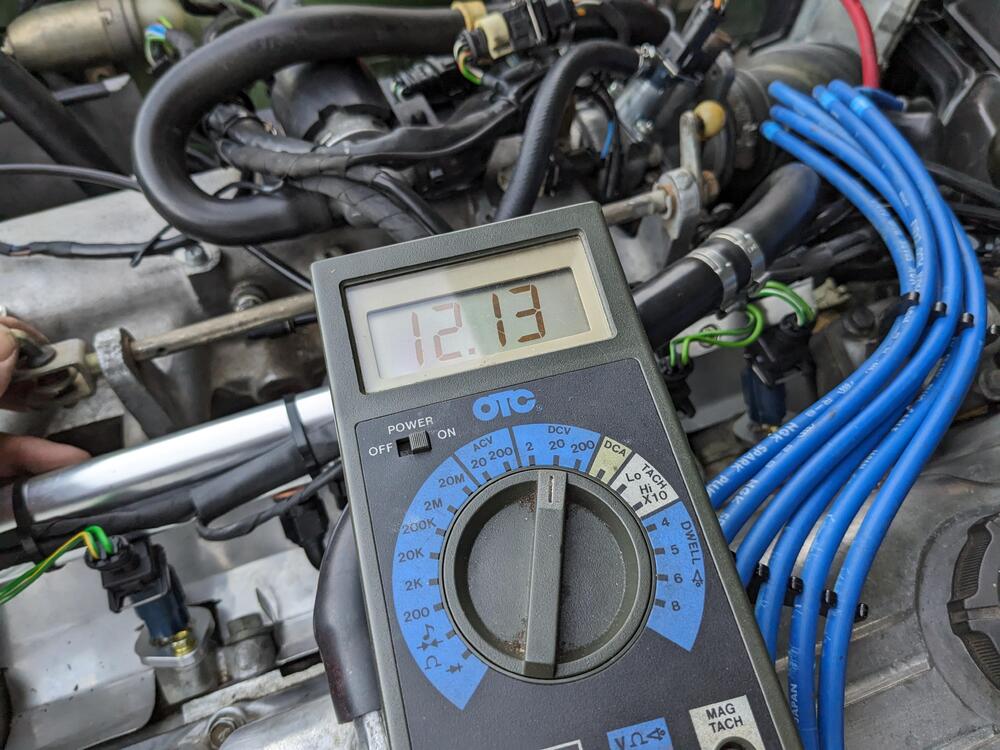

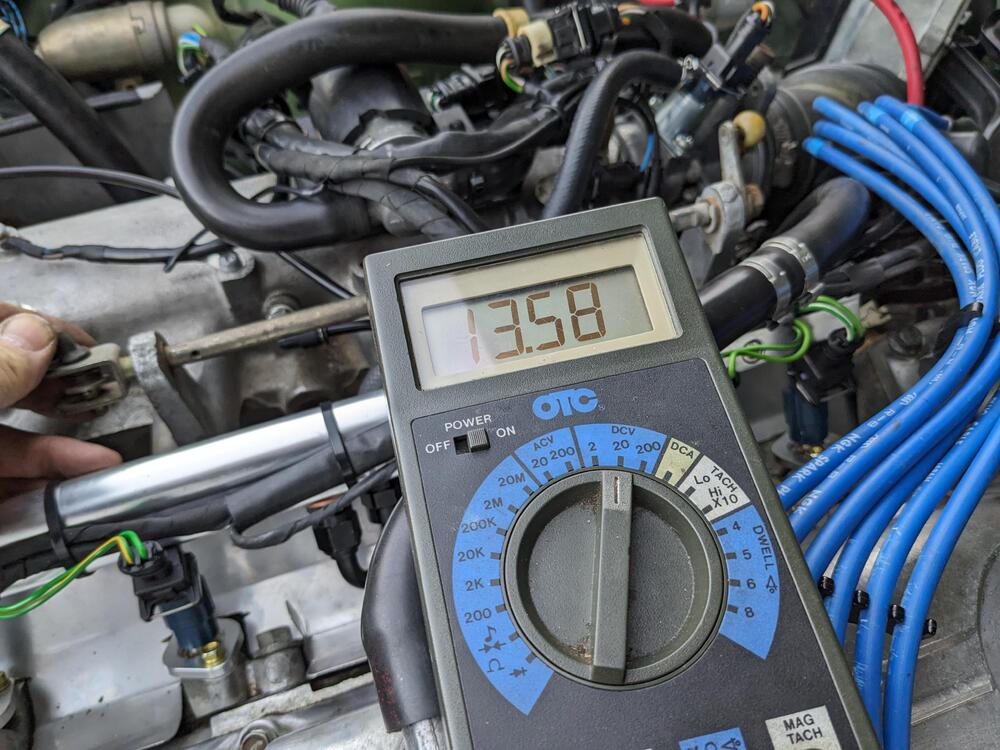

Adding to this rather than start a new similar thread. My system puts out 15.5-16v as soon as the engine is revved over 2500rpm, regardless of load. Sometimes it spikes to that off idle. Seems hair-raising to me. I'm used to 14.1-14.5V being optimal on my Swedish & Italian cars. This was around 1800rpm I read how to adjust it in the service manual, however mine did not match the diagrams. I had to adjust the point gap by loosening the two top screws. It was unclear which side of the points was supposed to be checked @ .012". After initial adjustment I was only getting 12V any any rpm, so I decided to adjust it while running - that way I was able to check idle & high rpm values for consistency. I settled on 13.8-14.5 range, as tweaking it outside that just need up with either too low or back to 16V range. My points do have some pitting, so I sanded them to remove the peaks at least. core gap on left, point gap on right Point gap seems to be the left side standoff on mine. When I set the larger gap on the right side, it didn't charge at all initial adjust final setting - goes from this to about 14.5-7 max. Seems good to me

-

Replacing All Large Opening Seals & Hatch Small Seals

I did see that - however the chrome on mine is burnished/marred where they sanded the car for paint 30 years ago. I don't throw things away, so I was planning on saving the old ones in case the new construction doesn't past muster.

-

75 280Z winder mechanism & release mechanism

ZcarDepot

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

To conclude this for me at least, using the GM-branded module, the symptom has not returned. I've been driving and commuting in the car everyday (except a couple of rainy days) and have had no break up / cut out. Other issues, but those are fueling related 🤪