Everything posted by Dave WM

-

280z 78 Wont idle, Running Rich, out of ideas.

Don't know if this has been mentioned but wet plugs.. leaking fuel pressure regulator thru the vac holes /regulator not working. check for fuel at the vac hose/ use a pressure tester for fuel pressure test. stuck open cold start valve CTS (temp sensor) or wiring from it. throttle position working correct. leaking injectors, check with bleed down test how long does the fuel pressure hold after engine off. fouled up AFM (test with a voltmeter and battery for function, not a test for calibration but at least checks for gross function) hope its not been fooled with on the big main spring. ECU, not sure how to test. I have though about doing a scope test in a controlled environment to see the waveform generated when operating normally under stated parameters (heat rpm throttle position sensor). That would give a base like results to be compared with on problem engines. What would be great is a test stand that you could plug in a ECU and feed it inputs then scope the output under an inductive load to simulate the injectors. sounds like a Capt. Obvious project to me...

-

5 speed worn bushing prevents reverse?

I could not see a video of the problem, clicked on a link, but it just came back as a blank screen.

-

5 speed worn bushing prevents reverse?

oh and the assumption is you have the correct shifter for the trans. I know they are different, length of the short side of the pivot, the spring loaded one, etc... there maybe interference with the actual shift shaft that requires some grinding if you have the wrong shifter. to know for sure once you get into 5th or reverse does the shifter feel tight? it should not, there should be some play since the shift rod is locked in by the balls (ha). if its tight the shift rod may not be getting enough throw from the striker lever, so the balls are fulling seated into the notches on the shift rod. the result is a rod that is pulling on the striker lever constantly keeping everything in tension, result in a tight feel at the shift knob.

-

5 speed worn bushing prevents reverse?

I am lost. there should be ZERO play in the shift rods, they are all held fast with the springs and balls in the plate. the Striker rod and lever are responsible for pushing/pulling the shift rods. I recall a guy had the shift dogs in backward on the rear syncro, caused a lot of problems for him. this is the video I did for that

-

280z 78 Wont idle, Running Rich, out of ideas.

another thing to keep in mind when you are checking that notch, make sure you have the timing chain tight side tight (the tight side is the distributer side). That is you must not reverse the crankshaft if you overshoot TDC, if you do you will have slack on the chain where you don't want it for reading the marks.

-

280z 78 Wont idle, Running Rich, out of ideas.

if the U matches the mark then you are fine on the cam timing. get a pic of the dist drive (distr off look down to see the drive tang) with the crank set at TDC.

-

280z 78 Wont idle, Running Rich, out of ideas.

I am a little lost on this. You need to make sure the dist drive slot is set at 11:30 (see FSM for a better explanation) when you are at TDC compression stroke piston #1. You may want to confirm the timing mark on the harmonic damper to the actual TDC just to make sure its correct. I set my single coil setup at 10 degrees advance at idle (no vacuum from ported vacuum). If everything is setup right you should be right about in the middle of the range of adjustment on the distributer when done. On the cam timing, generally you check a slot and a v cut on the top cam chain sprocket, however from looking at your sprocket is may not have the V notch cut in it to allow for a visual inspection. I am mentioning this since you spoke about moving a tooth down to fix timing.

-

Anyone using Amsoil with zinc additive?

you west coast guys have the nicest places to drive. One of the reasons I want to leave florida is the exceptionally BORING drives. Still hoping for at least some action up in NW Ga as soon as it stops raining every other day.

-

Anyone using Amsoil with zinc additive?

check the FSM or owner manual on viscosity, 20/50 is for warm climates. Zinc is prob a good idea I use Valvoline 20/50 VR-1 (hot climate) but I am sure there are lots of oils that would be fine.

-

280z AFM lead?

roger that. been working just fine since I disconnected that suspect added by PO ground.

-

AC Condenser Leak?

Its a pretty simple setup, everything under the hood is easy to get to. Try to stay with R12. Mine only needed the new condenser, I was lucky found a NOS OE one. That and a new drier is all it took to get it back to working great, and its been at least 2 yrs with no noticeable loss of Freon. It still has the original compressor, which is pretty amazing, its a big heavy brute of a compressor, but clearly well made.

-

AC Condenser Leak?

oily residue = leak. best bet would be to buy a new condenser. IIRC you can still buy new, some vendor was supplying them. There are used ones all over, but unless tested for leaks that's a gamble, plus it could be corroded or plugged. You can try a local AC shop, I don't think it would be hard to rebuild by either finding the leak and brazing up. OR you could get a generic condenser that is about the same size and fab up some mounts. You would prob need to make up new hoses and fittings to match type and location to fit back to the compressor and drier. 1st thing I would do is pressurize it with nitrogen and get out a spray bottle with some soapy water, put about 90psi in it and spray everything in site, cond, fittings, compressor, hoses.... look for any other leaks and find out for sure what needs to be fixed. Not easy to check the evap, but it lives in a pretty safe place so likely no leak there. The only issue maybe a stuck exp valve, esp if its been to air for a long time. If that is the case you maybe able to save it, if it has not lost its charge. But start with the leak test of stuff under the hood with the nitrogen.

-

Water Pump Bolt Washers

nope I mean the stuff designed for thread sealing. I replaced a pump and used old bolts (they still had junk on the threads) no issue with leaks. On another Z I used BRAND NEW OE pump bolts, and like you, anti seize, and I had a leak. After that I used some designed for thread sealant, no more leak. My guess is the water works past the anti seize and thru the bolt hole of the pump, from there it leaks. The old bolts had enough junk around the threads to prevent this.

-

Water Pump Bolt Washers

be sure to use some sealer on the long bolt threads, use the liquid kind that comes in a can like a thick white paste.

-

280z AFM lead?

yep that's it. I will check but I think mine was a Apr build.

-

280z AFM lead?

it was right on top of the green lead under the block. already removed and discarded (when I was taking it off the poorly crimped on eyelet under the term cover fell off, def not OE). As far as grounding the green, it worked, I presume the signal wires are electrically isolated, so if only one lead was grounded it still works. I did note that with the ign on engine off, intermittent contact with the ground from the green signal wire would fire the spark. mentioned that a while back ZH speculated that it was just a slight change in the electrical potential from the grounding of the one lead. OR it was making no contact do to the poor crimp, but I doubt that. I have been driving it for years that way, and I am pretty sure when I started down this path of trying to figure out the issue, I did a resistance check of the green term to ground and it was a very low resistance reading that you would expect with a wire to ground connection. Pretty sure I verified the isolation by checking for resistance from the dizzy pick up coil to ground (completely open) same with the term block wires, no ground path on either red or green. That is with the non OE wire removed. I have no idea what the logic was from the PO on this hookup I am with ZH either a bad guess for just bad logic. Only think I can think may have been an attempt to ground the mount plate with the intent to connect to a body bolt near the term connector. Not needed of course since the correct OE ground wire was in place and attached in such a way as to ground it thru the chassis using the mount screw. Of course the idea of using the green term block as a ground makes no since at all but, that is the only thing I can come up with. its so obvious that no extra wire belongs there, even just looking at the rubber plug on the side of the tern block you can see cut outs for wires, and you can tell its not cut to allow 3 wires out of the block. Prob should have a thread for "Mystery Mods by PO's" :)

-

280z AFM lead?

ah now this is from a 76, so my 75 must have gotten the new harnes BE.pdf

-

280z AFM lead?

-

280z AFM lead?

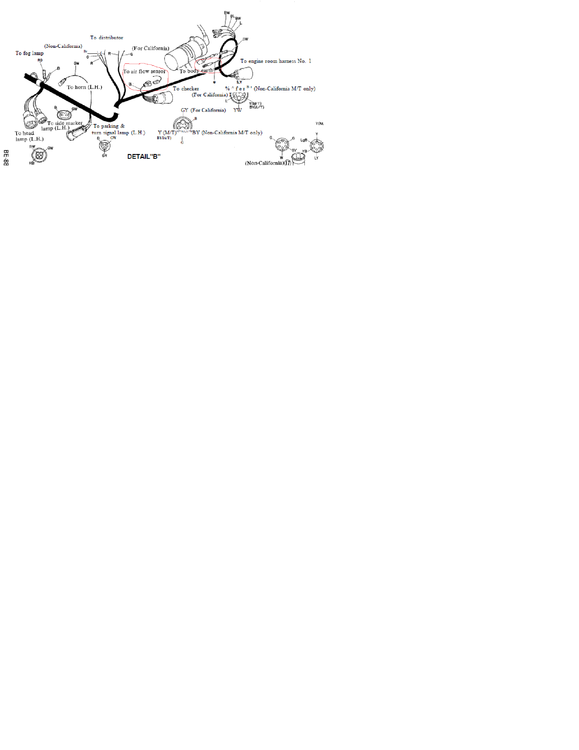

Ok now I am bugged, can you pls take a look at where that large white spade connector goes to? Not usre if that is a purple or black, black I assume. Another mystery, I do NOT have that ground connection shown attached to the nut under the term block. I have a place for it (the hole on the term block mount) but it is unused. I checked the FSM engine harness #2 detail B did not show those, but the FSM I am looking at was for 75/76

-

280z AFM lead?

I just checked my harness no sign of that purple lead with the large white locking spade connector. The harness looks complete with no signs of hacking. If you look at my 1st pic you can see it is missing. Wonder what that is for?

-

280z AFM lead?

I don't recall that large spade connector coming off the harness of mine (looks purple in the pic). I did remove the non OE ground, so far it works fine. The non OE ground may have been causing some issues, as I went to remove it, the poor crimp on the eyelet just let go. Could have been an issue if vibration setup causing spurious signals.

-

280z AFM lead?

well I went out today and tried it again, this time with extra ground (the non OE looking one that goes into the term block green lead) disconnected, and it started right up. Not sure why that was not the case before, but presume it was something else before causing the no start. Anyway I am going to keep that disconnected for now and get some drive time in!

-

280z AFM lead?

-

280z AFM lead?

ok that looks like mine, only diff is the extra ground wire from the green wire on the term block that mine has. A guess here, the AFM is electrically isolated from the chassis due to the use of the rubber gromments used to mount the plate to the chassis (I presume to damp vibrations). So with all that air flowing thru the alum body of the AFM it could build up a static electrical charge with out the ground lead. So that lead makes since but my grounding of the diff green wire does not. My play is to get one of the HEI modules as ZH has mentioned just as a backup, will wire it up and just control the coil by choosing which module is hooked up. I read some comments by ZH in another thread where he just left the OE stuff in place and would just disconnect the signal at the OE module and then hook this one up under the hood. All this is really just so I don't get stranded on one of my long road trips, so a tested backup system would be nice to have. oh btw my test stand engine does NOT have the AFM grounded, something I will take care of since I don't want to smoke an ECU.

-

280z AFM lead?

while I have been looking over what seems to be some non OE wiring around the dizzy term block I came across this pic in the FSM. I see the lead coming from under the AFM a single wire that looks like a locking spade connector. I think the PO replace this with a ground wire (has eyelets one side bolts to the bottom of the AFM the other side to the chassis ground thru a mounting bolt that secures the AFM mount to the chassis). Can someone confirm this is what this wire does? I could not find anything from the wire harness that looks like the pic at the top of the page. AFM lead.pdf