Everything posted by inline6

-

1973 Rebuild

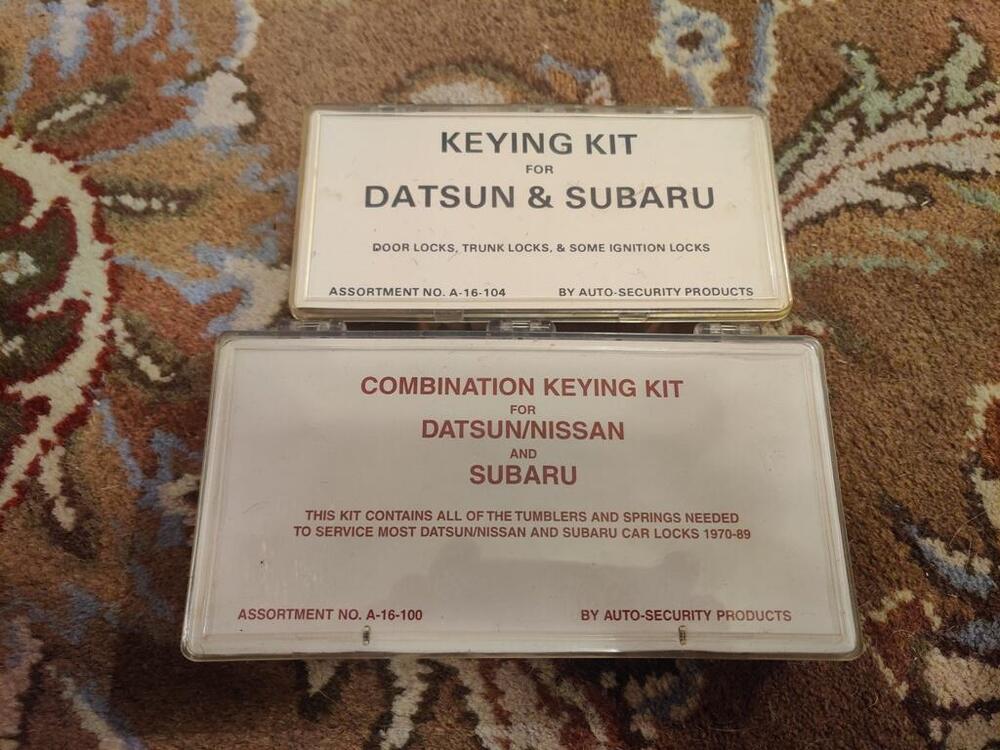

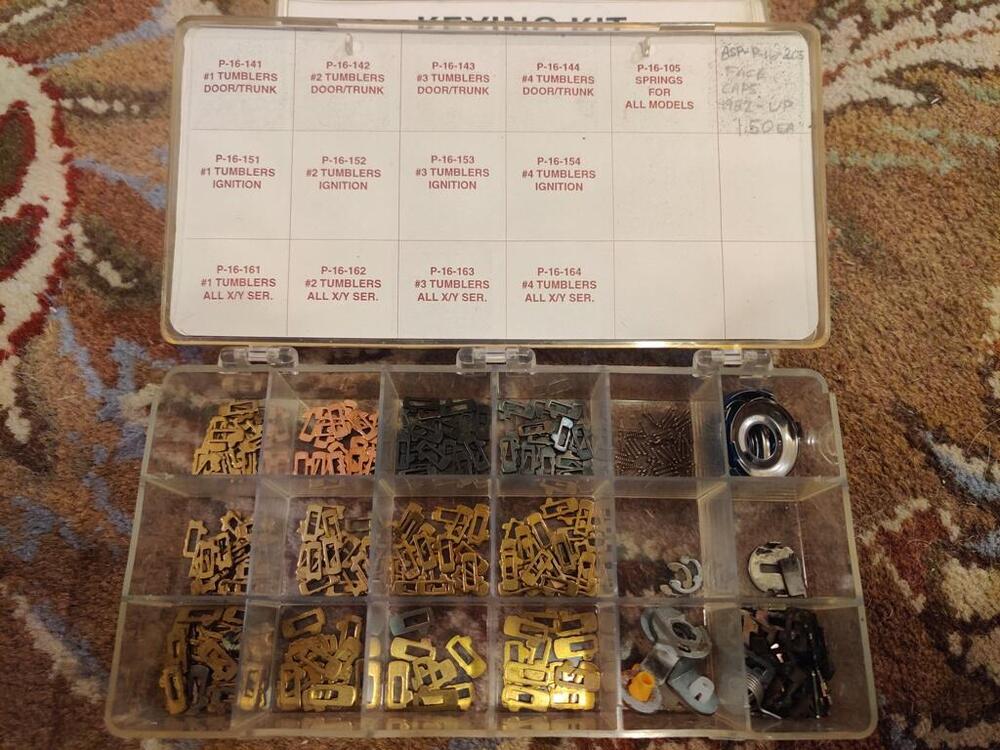

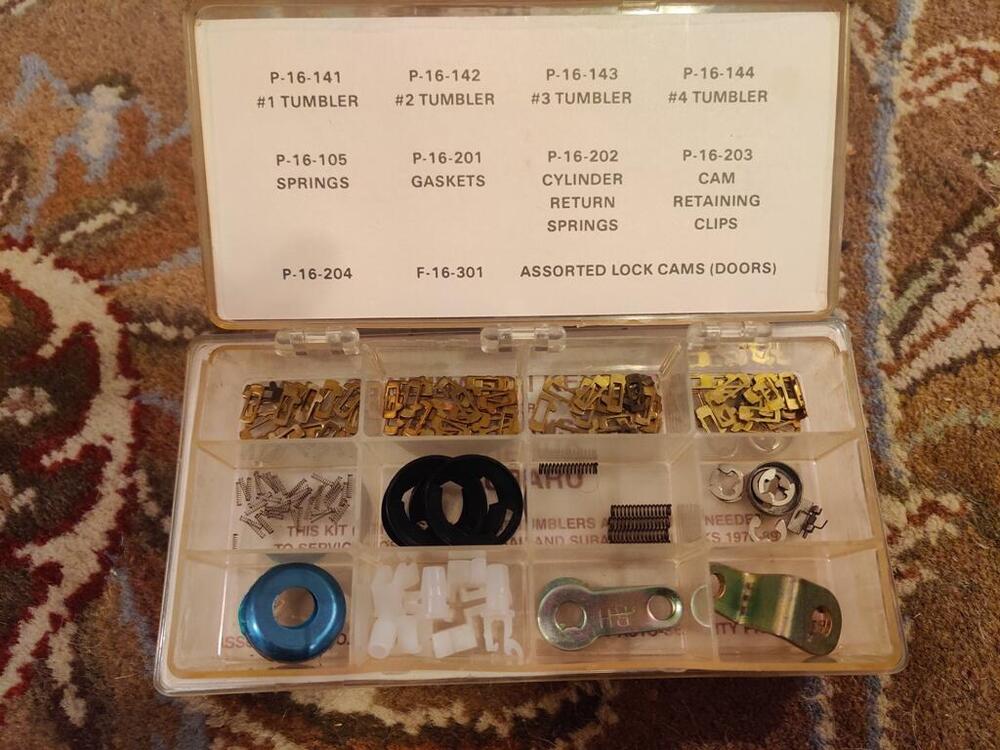

All of the locks on the car use wafers, but the wafers for the ignition are slightly different. These are the kits I bought and their contents. The A-16-100 has both types of wafers. The A-16-104 only has the wafers for the locks other than the ignition.

-

Restoration of BringaTrailer 240z - HLS30-35883

Thanks Keith. Do you have any thoughts or concerns about the flap being only 2" deep and the and the additional distance that flap needs to be pulled down to reach (within hog ring reach) of the wire running across the bottom of the Pirelli straps? Also, I went looking for Imperial Army green, but only found some acrylic hobby paint. Do you recall what you actually used? I'd like to use it in a couple of places on my seat rails to improve their appearance a bit. Garrett

-

1973 Rebuild

I was able to find kits on eBay and rekey my locks. I did all of them including the glove box. In my case, I bought a new ignition lock because mine was worn... and I bought a new hath lock that came with the original black keys. Then I rekeyed the ignition and the doors and glove box to match. At and following posts here provide some details. More are elsewhere in my build thread. Here is another, for example. Be careful when buying new door cylinders as most I have seen come with their own key - they do not use the same key for both. You have to find two locks that come with one key which seems to be rare.

-

Restoration of BringaTrailer 240z - HLS30-35883

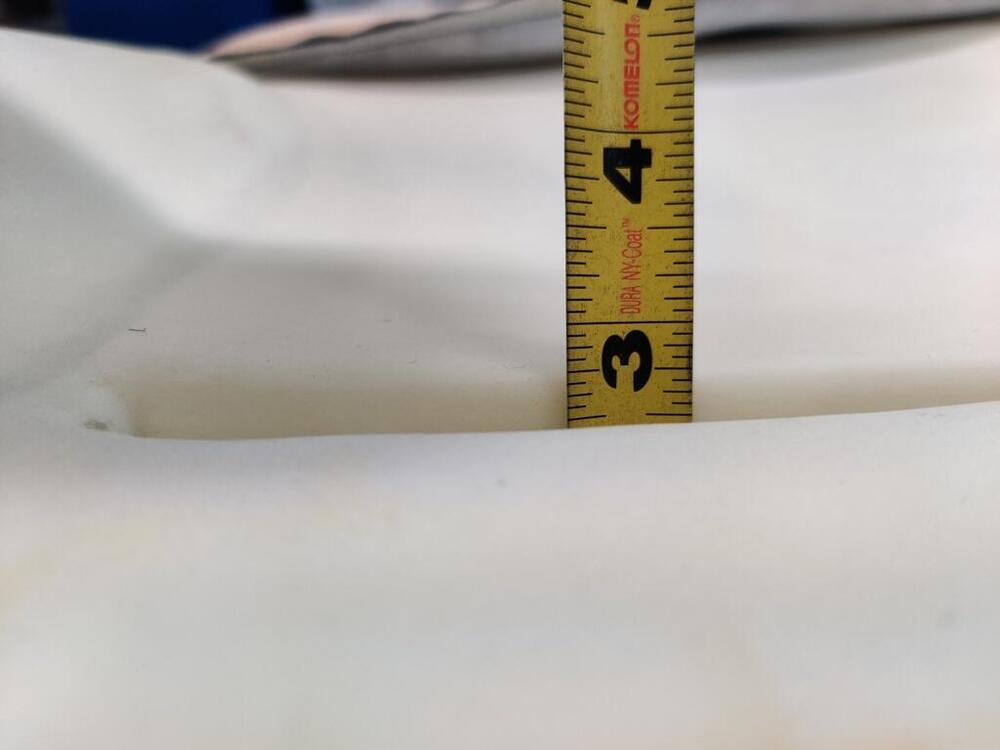

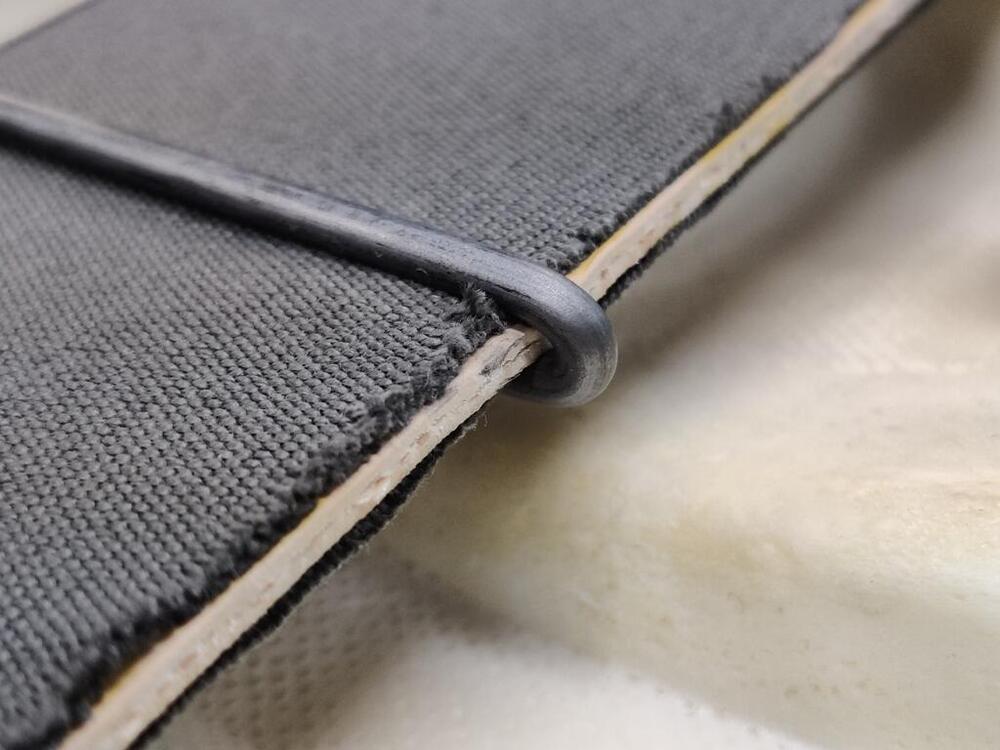

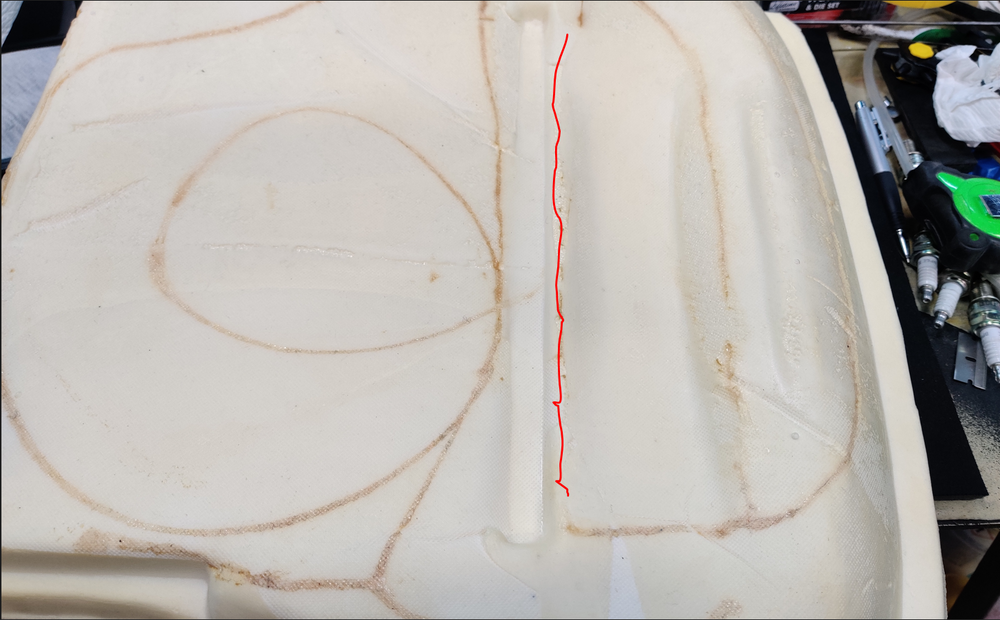

For some reason, the valve spring retainer tool didn't get here on time. It will be next week before I can pull the retainers from the exhaust valves. So, I switched back to the seats today. I spent a couple of hours doing research because I don't see how I need to proceed. The first issue I have is I don't know how to attach the flap to (or through) the seat foam. My seats do not have springs - they have Pirelli straps. The replacement foam has a slot in it. This slot is not cut all the way through the bottom of the cushion. I measured the depth of the slot at 2 nd 3/4" inches. Looking at the underside of the cushion, the bottom of the slot is offset to the right of the impression (long, skinny rectangle) you see here. I drew a red line approximately where the bottom of the slot is in this picture. There is a thickness of about a quarter of an inch of foam at the bottom of the slot. But, the seat upholstery flap that goes down into the slot is only about 2 inches deep. As I understand it, there should be a wire that is inserted in this flap and hog rings should be used to attach this wire... to something. I just don't know what. This picture of @kats seat appears to have a wire running under the Pirelli straps. I have attempted to replicate that, bending hooks in the wire to locate it around the straps, however, I just don't know how to proceed from here. I am thinking about making a matching wire and putting it in the fabric flap on the seat upholstery and then using hog rings to pull the two wires together. But, I am concerned about the difference in measurements (2" depth of the flap vs. 2.75" depth in the slot). That may be ok though, as clearly, there has to be some tension on this flap to pull it down for the proper appearance. Perhaps when the wire placed inside the flap is hog ringed to the wire that runs under the Pirelli straps and is pulled down about the three quarters of an inch, the "compression" of the seat foam will be about right? I set that aside for now and worked on cleaning up the seat tracks. They were gummed and I could hardly get them to move. I used copious amounts of WD40, as brass wire brush, compressed air, and paper towels. To assist with cleaning, I moved the tracks back and forth repeatedly. For the track that has the handle, I disengaged the spring so that the track could move without latching. Bending tab at the end allows the spring to move away so the tang can be slipped out of position. This allows the handle to free float. Then, the track can be moved back and forth without the handle engaging the slots I am going to think about how to best proceed. If anyone has any guidance, let me know.

-

Reference 1970 Grapefruit Alternator Pictures

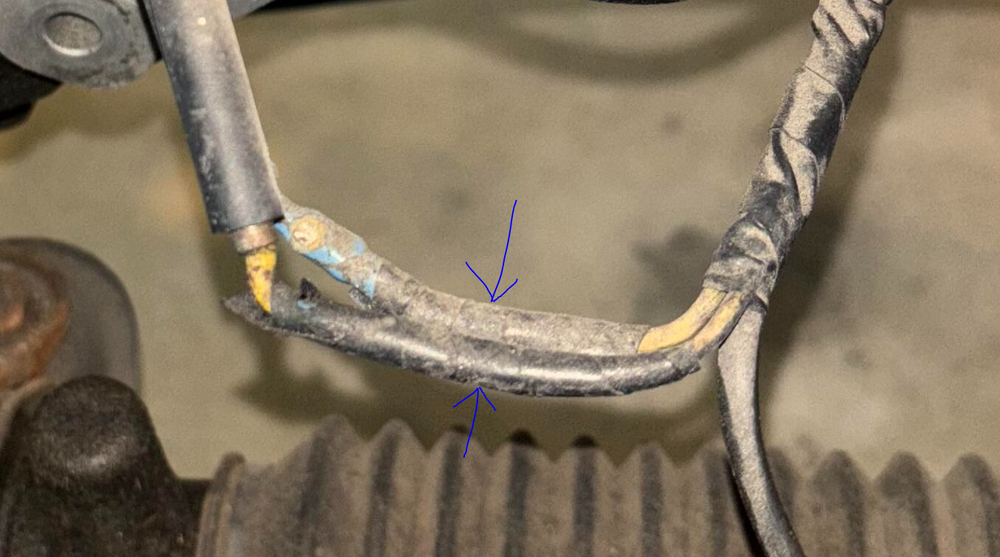

Because both of the wires coming out of that alternator case are yellow... with no other color stripes, they do not look factory to me. Neither do the connectors which appear to have been spliced into the wires on the harness. I suspect some wiring modifications were made.

-

Z's on BAT and other places collection

"This 240Z is now offered on dealer consignment in Oregon". Some sellers hire BAT specialists. I believe 911R is just a specialist who does the photography and perhaps handles working with the person from BAT assigned to the car.

-

Z's on BAT and other places collection

So... if the market is soft, it is a very interesting time for the "Franklin Mint" car to come back to BAT: https://bringatrailer.com/listing/1970-datsun-240z-128/

-

Restoration of BringaTrailer 240z - HLS30-35883

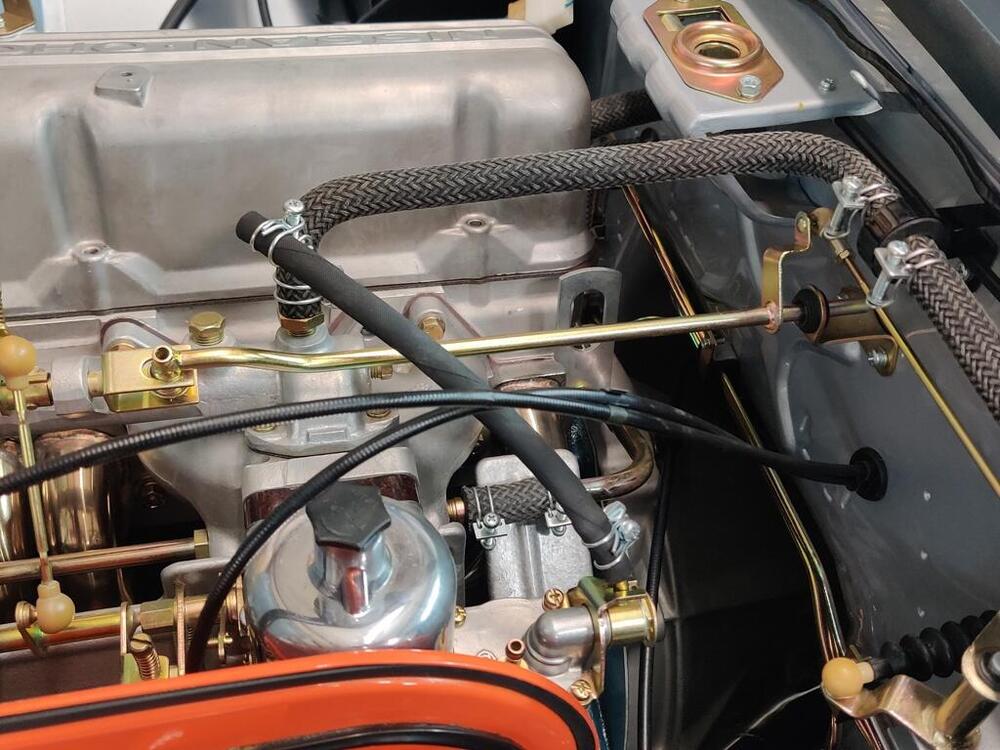

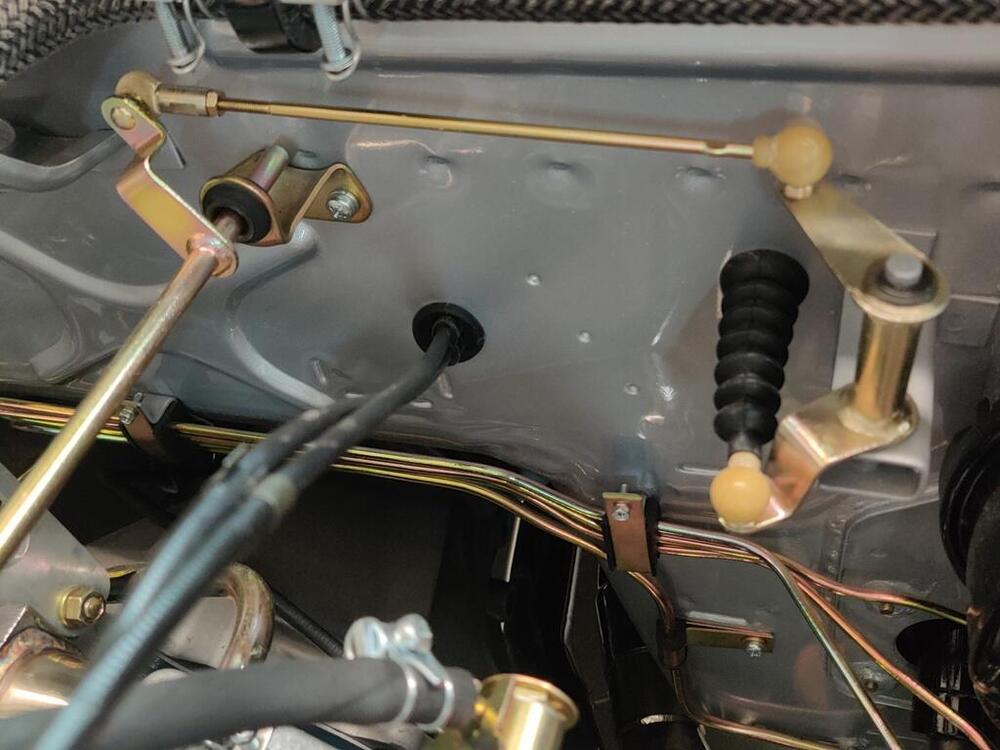

I attempted to remove the valve spring retainers from my exhaust valves this weekend with the homemade valve spring compressor tool I have use successfully before. However, this time, it didn't work as well as I recall it did last time. After futzing with it for a couple of hours and only getting one retainer off, I gave up and ordered one from Zcardepot.com. My homemade one interferes with the came towers and extracting the collets out is a real pain. Hopefully the new one will be a lot easier to use. In the meantime, I am working on what there is left. One of those things was installing and adjusting the throttle linkage arms. While I am familiar with this part (see red arrow), I never knew what its purpose was - do you know? Well, I may have figured it out. I think it is a linkage "stop". As I was assembling the linkage, it seemed logical to me that the little wings on this part may have been intended to contact the back of the rubber bellows that attached to the firewall. As I worked to set the lengths of the rod (this short one and a longer one have one threaded ball socket end) the location of this piece fell naturally to a position that eliminated all of the "slop" in the linkage after the throttle plates in the carburetors had just contacted their screw stops. In other words, you can then set the depth of this "winged" piece to contact the back surface of the bellows just at the point where the throttle plates in the carburetors have closed. Doing this, you will prevent introducing slop in the linkage which occurs after the throttle plates are shut but you continue to release the gas pedal as far as the pedal return spring will pull it from the floor. After setting the winged piece, I confirmed that even the slightest movement at the pedal caused carburetor shaft (and thus, throttle plate) movement. When releasing the gas pedal I now have a muted "thud" as this piece hits the back of the rubber bellows... and allows no more movement in the linkage beyond the throttle plates in the carburetors' seating. Kind of cool! It will be interesting to see how that all feels when driving the car. While I was doing all this, I ensured that I got full throttle opening at (both) carburetors by pressing only on the gas pedal inside the car. I am never all that surprised when I check and find that pressing the pedal to the floor does not fully open the throttle at the engine! The plastic ball sockets on the linkage turned white during the plating process. To address, I used a propane torch and very carefully heated them. The heat causes some type of reaction which restores the color of the ball socket. But, you have to get it hot enough that melting starts to occur. After heating, I went over them with some fine grits of sand paper to restore areas that has melted a tad. White socket... and my throttle linkage stopper in action (though I think I need to flip it around 180 degrees): Throttle linkage detail: I have read about getting dinged at Zcon for valve covers which have been glass bead blasted. I also know that there is quite a bit of variance in finish with glass bead blasting. You can use different media, different pressures, and even do vapor blasting which uses media along with water. For my valve cover, I tried cleaning it really well with #0000 steel wool and degreaser. And then I tried some Aluminum Brightener. After those efforts, I still had darkish areas that looked like stains on my valve cover: So, I started experimenting with glass beads set at very low pressure. The glass beads I was using have seen may work cycles and I was using only 20 psi. However, I was getting pretty good results. In this first pic for example, I concentrated efforts on the area at the top of the valve cover between the oil cap hole and the casting bump (for the spark plug wire holder). In the second picture I was concentrating in the area between the two bolts. In the third picture you can see the area of transition (darker, not blasted area on the right). In this first picture below, I had hit the N and and the I in Nissan and some of the area above and below the N. The downside is that it takes a lot of time at 20 psi. But, it did make a big difference in lightening the valve cover. I got a little more aggressive in a few areas with 25 psi, but I think that started to look unnatural. Anyway, I was pleased with the overall result. A note, if you do this, you have to seal the vapor compartment in the valve cover, or remove that plate inside the valve cover like I did so that you don't leave glass beads in there.

-

How should I price these? NOS front seat cushions

I have seen some cars with original backs in very good condition, but the bottoms not. And I have seen some where the bottoms have been replaced but not the backs, like this one on Bringatrailer a while back. https://bringatrailer.com/listing/1970-datsun-240z-101/ For the right person, they will be valuable. But, quality aftermarket ones from Distinctive Industries exist also for about $600 (in black). If they are the early type (can you take a pic of them outside the bag?) I'd put their value around $600 - figuring if I had good original backs (rare), I'd be will to spend that much to try to keep the seats original.

- 1970 HLS30-06521 Re-Restoration

-

Restoration of BringaTrailer 240z - HLS30-35883

3 mm. I have some suitable items to take place of the red washer in my cart, but have to buy way more than I need. And, I would like that black plastic piece too.

-

Restoration of BringaTrailer 240z - HLS30-35883

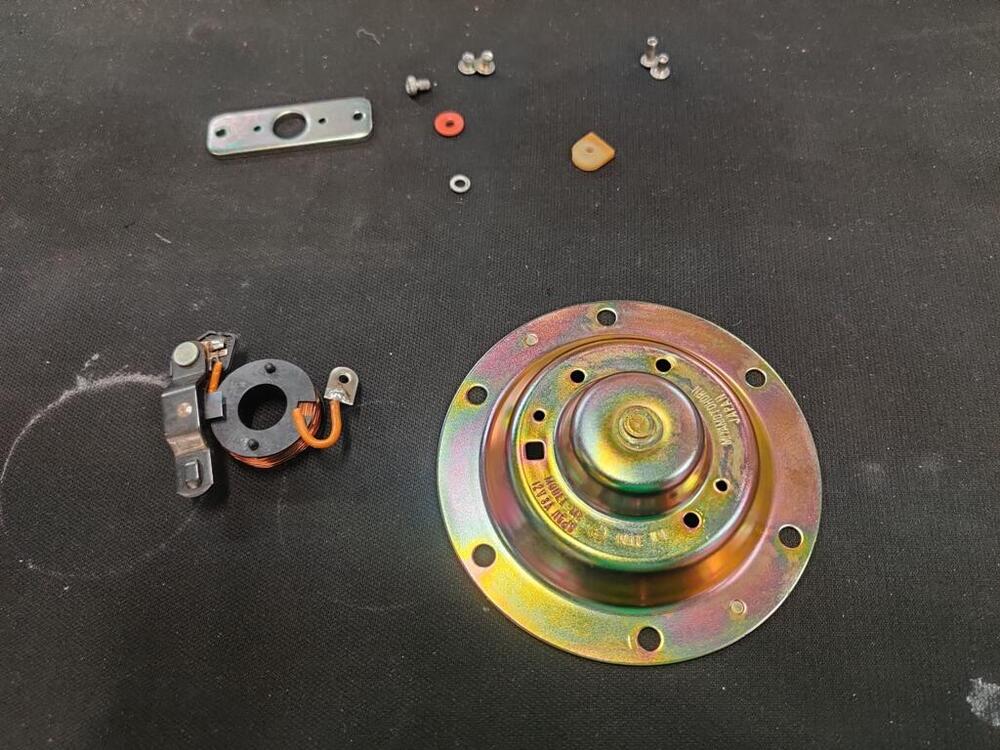

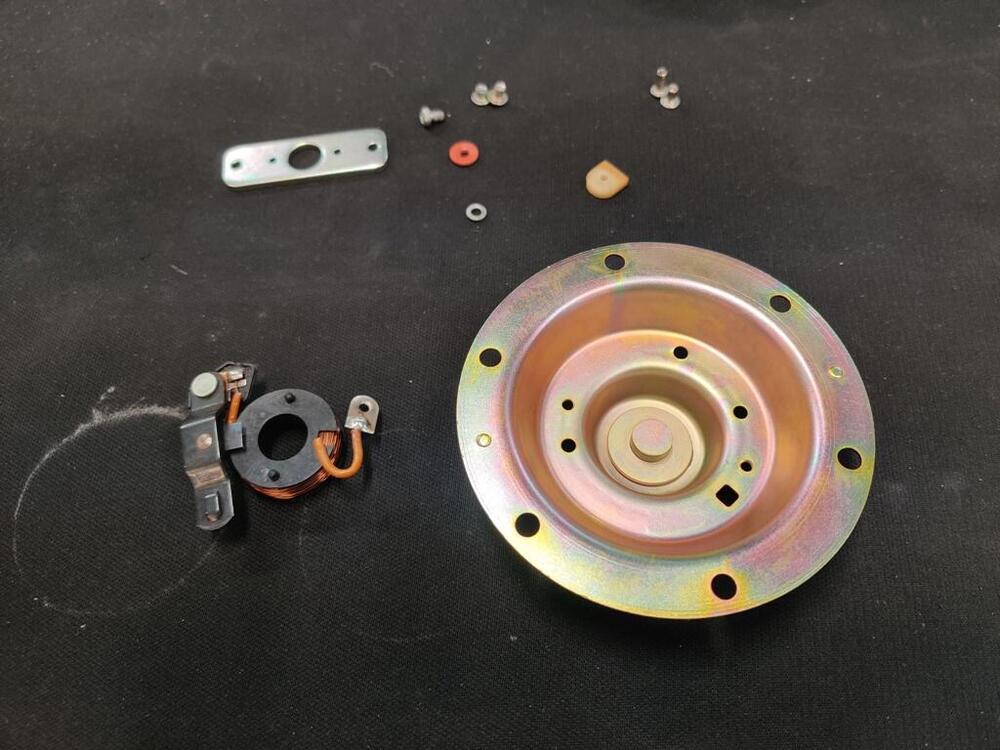

I have been saving a lot of money on shipping since I started using Stamps.com. I had no idea that using them, I could get much better than over the counter shipping rates. All I did was create an account, and fund it with like $50. I put in the address, dimensions and weight of the package (box or padded envelop), print out the label and drop off at a UPS store. I bet shipping a horn would be less than $8. Anyway, I managed to lose one of these red washers: And, I'd like another of these black plastic parts. However, both are only accessible after drilling out the rivets and they are easily damaged if you are not careful. I'd rather pay for the shipping and do that part myself.

-

Restoration of BringaTrailer 240z - HLS30-35883

Anyone have a 240z horn they'd be willing to part with for cheap? I need one to cannibalize from.

-

Restoration of BringaTrailer 240z - HLS30-35883

-

1973 Rebuild

Date code on that block indicates manufacture date is May 12, 1972. Stock head at that time would be an E88. Some parts may be of value to the stock restoration crowd. Air galley pipe, air pump... the fuel pump if a "Nikki". Block may be of interest to vintage racers. E31 heads still have value as people restoring the early VIN cars need those.

-

Restoration of BringaTrailer 240z - HLS30-35883

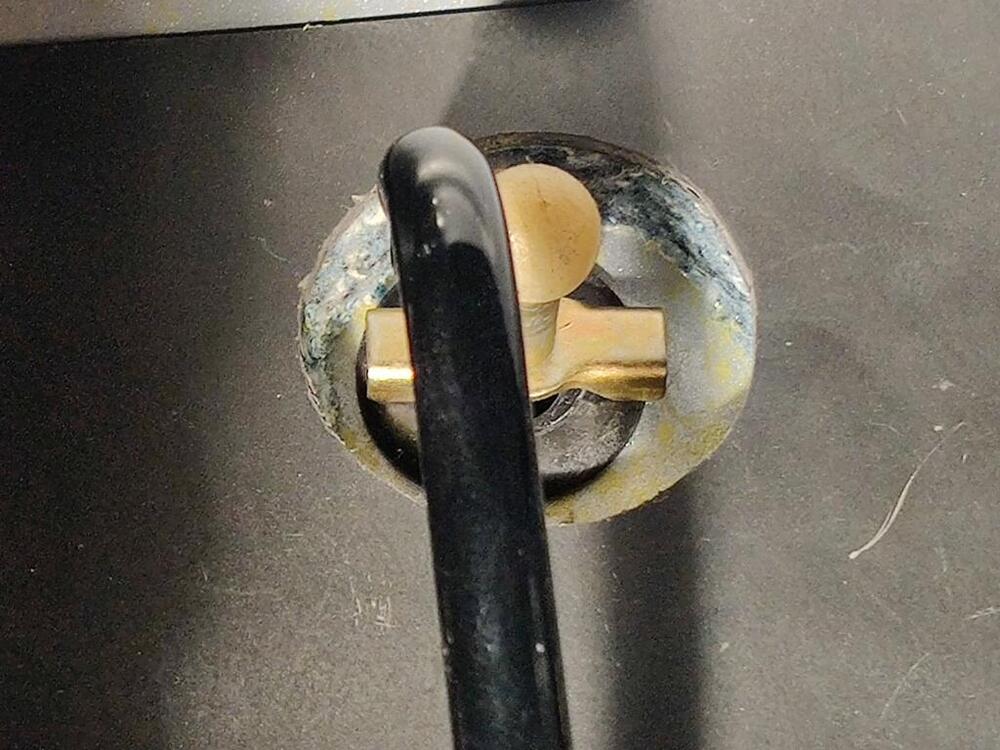

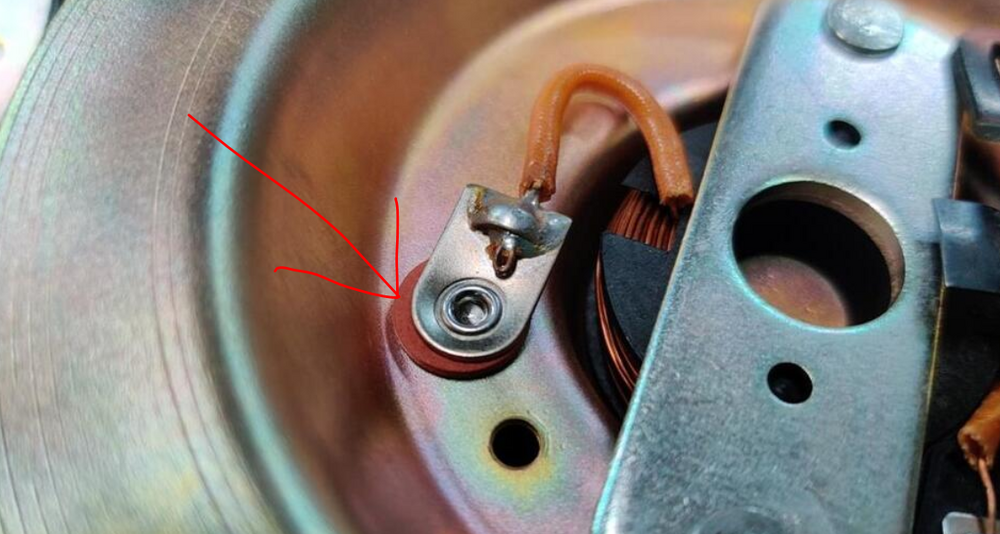

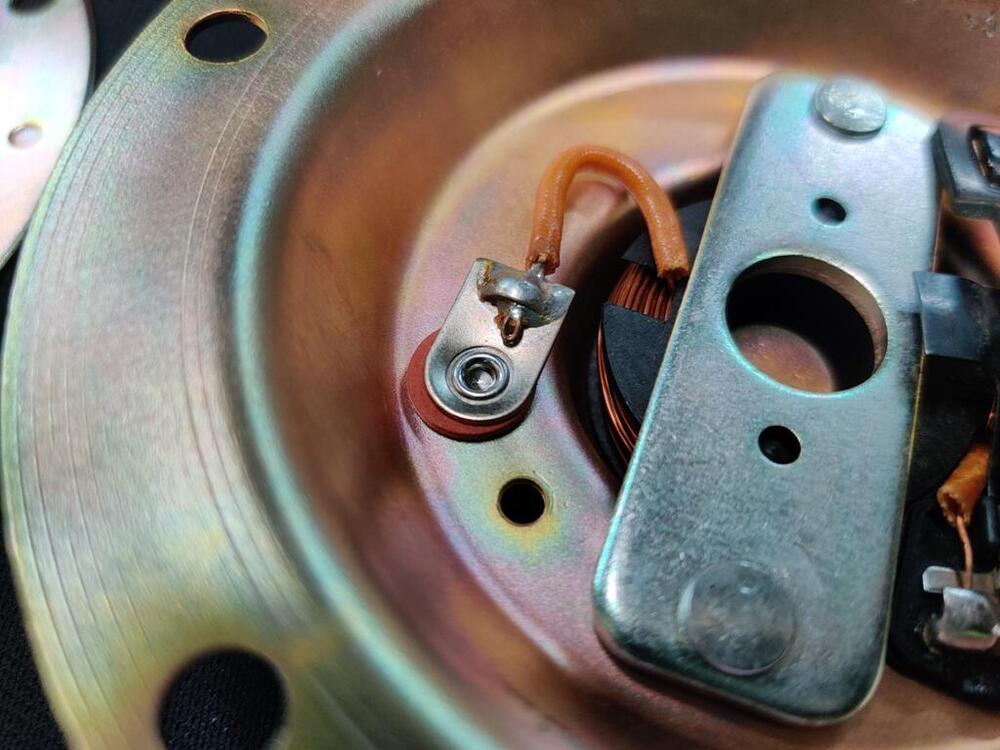

Recently, I sent off a small box of hardware for plating. Unknown to me, the place I sent the parts to had gone out of business, and my box got hung up in the UPS/USPS system for quite a while. But, I was successful in getting the box of parts back finally, after many weeks. I found another plater, and sent the parts off again. He got them done literally over a weekend and got them back to me already. For the horns, the first plater I sent them to wouldn't do them. So, this time, I drilled out the rivets holding the electrical parts to the back plate and sent the back plates off for re-plating. I had to order "semi-tubular" rivets and "rivet curling punches" to set the new rivets. Today I experimented a bit with those. The rivets for the "bridge bar" need a bit more work, I think: The rivet for the spade connector looks perfect: Didn't have much time to work on them tonight, but should be able finish them up this weekend.

-

Restoration of BringaTrailer 240z - HLS30-35883

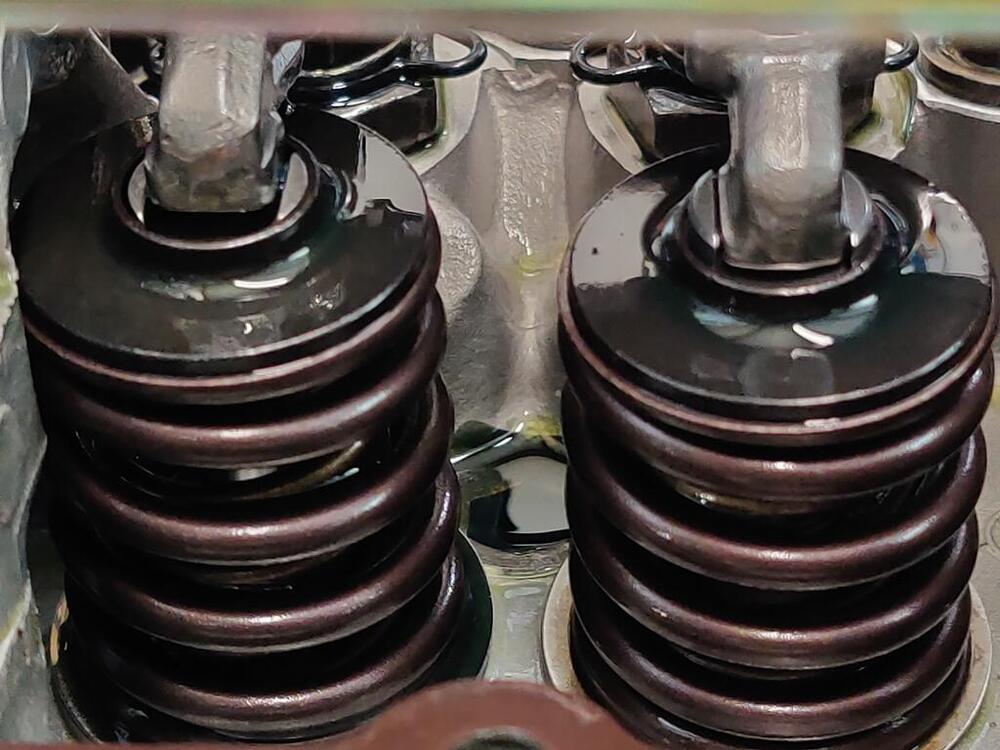

I plan to use zip ties to around the stems to hold them up. I will rotate the engine to top dead center for each cylinder and use a leak down tester to input the compressed air. That will allow me to remove the spring retainer. Then I will put zip ties around the valve stem at the valve seal. This should keep the valve from dropping while I rotate the engine to the next one. I will need to do that for all six exhaust valves.

-

Restoration of BringaTrailer 240z - HLS30-35883

While it is true that the tip of the valve is going to be in the same location... and the lash pad will sit on top of that in the same location, the location of the upper spring perch is different between the stock and the Isky retainers. Therefore, just swapping out the retainer to a stock one is going to to change the location of the upper spring perch and the installed pressure of the springs. It may be possible to remove or add shims. I will have to investigate more closely. Here is a link and brief description of the retainers I bought. Chrome moly valve spring retainer set "Made in the USA by Isky cams. These will fit Datsun L series engines found in the 240Z, 260Z and 280Z. High quality parts made for racing or street use. Includes 12 retainers. These retainers will alter the installed height, for use with Isky high pressure springs PT# 800-1374."

-

Restoration of BringaTrailer 240z - HLS30-35883

I do not know offhand if the Isky retainers and the stock retainers are the same on the underside. They might be. I think that swapping to the stock retainers will alter the installed heights because the keepers lock in a different location relative to the spring seats. I will explore the possibility of using them this weekend when I pull off the Isky retainers.

-

Restoration of BringaTrailer 240z - HLS30-35883

Ok, it seems the exhaust valves have been "sunk" deeper than is "typically done". And, it is likely I now have a situation where installing the .175" lash pads which were recommended by Isky is not going to work like it would as designed/intended. So, what I am very likely about to do here (machine the retainers) is not "normal". I get it: going far astray from what is usual may not be wise. The Isky retainers can be used with a broad range of cam regrinds, but the one I am using in this engine is very mild when considering the spectrum of available options. Modifying the retainers to use these thinner lash pads in this instance doesn't seem all that radical to me.

-

Restoration of BringaTrailer 240z - HLS30-35883

"If the engine machinist picked the lash pads and declared the wipe pattern "correct", then he must have overlooked a real problem!" - I think that is accurate. I am willing to forgive this mistake. I've got incredible amounts of value from talking with him over the years, and he has done a lot of great work also. I think I consider myself fortunate that no significant damage was done, and we'll get it sorted out pretty quickly.

-

Restoration of BringaTrailer 240z - HLS30-35883

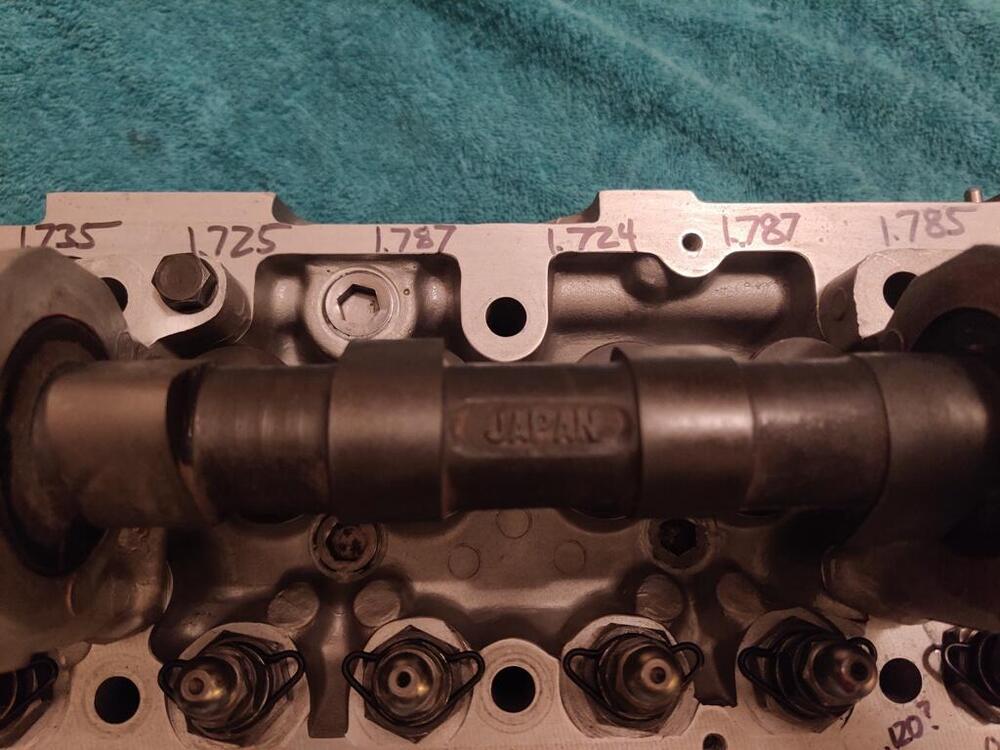

I will see if he will provide some info. I believe the main issue was the transition from the combustion chamber roof into the exhaust valve and that putting the exhaust valve deeper was done to improve flow out of the chamber. Here is a picture of the number 1 exhaust: And some of the installed heights. The 1.78 ish numbers are exhausts. The plan to fix is changing to removing the tall shoulder on 6 of the Isky retainers. My engine builder passed this along to me: "Your exhaust valve tip height is .050-.060 taller than the intake tip heights. This is reflected in the taller preliminary installed heights on the exhausts. It took lash pads that were .055-.060 thinner on the exhausts to get the cam sweep pattern centered, to match the intakes with the .175 pads. If you try to use the .175 pads on the exhausts, it may remedy the interference with the retainers but I believe it will screw up the sweep pattern. With use of a .118" lash pad, that shoulder protruding up on the exhaust retainers is only getting in the way, and not offering the support you would need with a tall pad."

-

Restoration of BringaTrailer 240z - HLS30-35883

While talking with my engine builder last night, we discussed that he purposely sank the valves into the head to address problems with the combustion chamber's archaic design. The location of the top of the exhaust valve stem is the issue I am dealing with. If the .175" lash caps are too thick for me to use (I will put them in and check wipe patterns), then I will go with his suggestion to remove the valve spring retainers from the exhaust valves, and send them off to him to have the ridges on the tops of them turned down to work with the thinner shims.

-

Restoration of BringaTrailer 240z - HLS30-35883

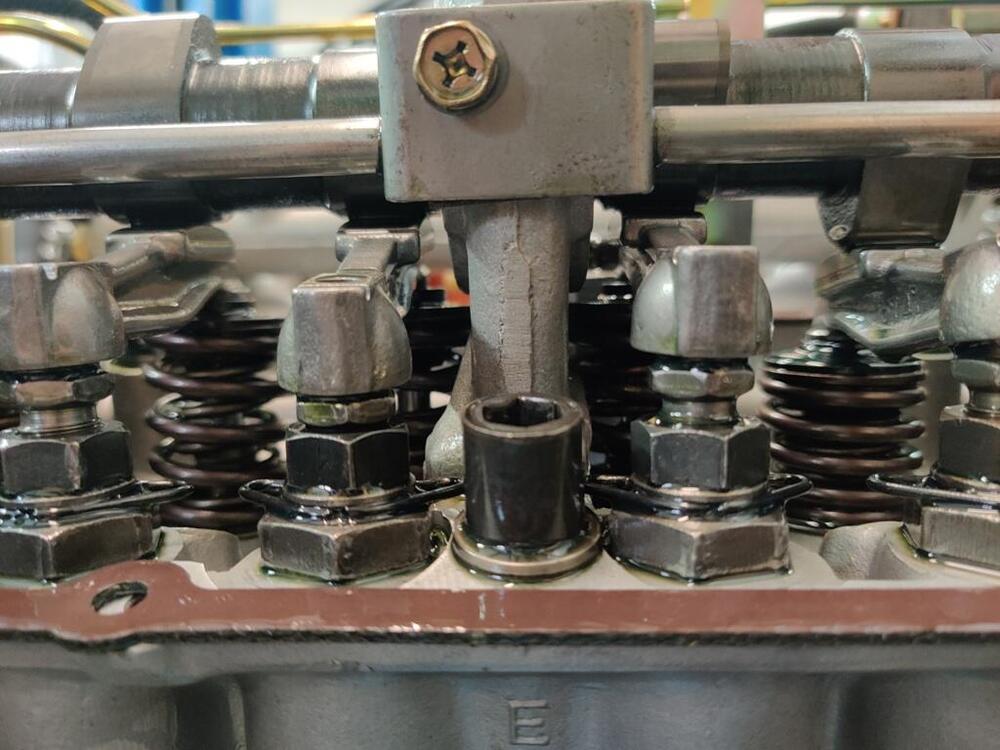

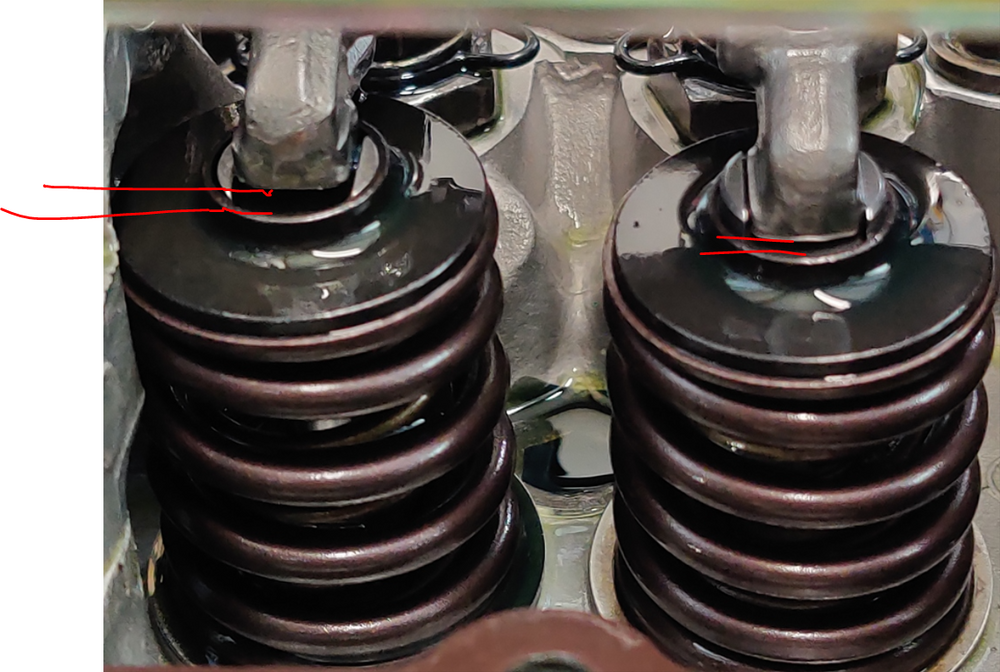

As I mentioned yesterday, the problem appears to be only with the exhaust valves. So, it is with interest that I made the following observation for valves 5 and 6 (with 1 to 12 being from the front of the engine to the back). These rockers are both actuating exhaust valves and are "adjusted to correct valve lash". Note the very different adjuster heights between the two: Wild - right? Well... have a look at this picture - the rocker on the left is the number 6 valve (exhaust) and the one on the right is the number 7 valve (intake): So... what is going on with the rocker on the valve on the left? Do you see how the tip of that rocker appears to be "floating"? And compared to the intake valve on the right, the rocker tip on the left appears to be sitting quite a bit higher (above the retainer) actually: Here is a picture showing the underside of the rocker - see the shiny part where the arm was contacting the retainer? Summarizing what I have found tonight, each of the 6 exhaust valves are hitting the top edge of the Isky retainers. When I was setting valve lash, I was setting it with the rocker arm sitting on the retainer instead of the lash pad. The rocker was floating above the stock .118" thick lash pads on each exhaust valve. During the total of about 1 to 2 minutes of engine operation at low revs, the cam was operating the exhaust valves, initially by rocker to retainer contact, but as the rotation continued, the rocker tip came into contact with the stock lash pad, and operated the valve. And note that the lash pads look very different. The ears on the lash pad of the intake valve (right) are sitting quite a bit further outside the retainer. I removed that rocker and took a measurement of the lash pad: Each gradient is .025". So the reading above is .177" and 7 tenths, or '.175'. These are the lash pads that came with the cam when I ordered it. I am hoping to get lucky here. My plan at this point is to put the .175 lash pads in each of the 6 exhaust valve locations and to modify the undersides of the rocker arms for clearance with the aftermarket Isky retainers. I'll just have to see if between the two, the rocker arms actually sit lower at the tip than before. If so, then I should be able to raise the height of the adjusters for these valves. Fingers crossed.

-

Restoration of BringaTrailer 240z - HLS30-35883

Ok. Yeah, I am going to pull all the rockers and look at wipe patterns, and measure lash cap thicknesses first.

Subscriber

Subscriber