Posts posted by EuroDat

-

-

30 minutes ago, pogden said:

My wide ratio gearbox (the one in the pictures at the top of this thread) pops out of 2nd gear. Not always when upshifting, but always when downshifting. I've been reading everything I can on this site about overhauling one of these things, and I am going to give it a shot. I just received the rebuild kit from Rock Auto, which seems to be the exact same one sold by other places as described in @zKars's lengthy FS5W71B Rebuild Thread, and it was <$60. I also ordered a bunch of other small parts (seals, main shaft and countershaft nuts, detent springs/balls, oil gutter, Torx screws) that I might need from Courtesy Nissan. I did not order any of the big parts (gear sets, shafts) - I understand that many of those are NLA.

Regrading slipping out of gear, I have no idea why it's doing that, but I hope to find out. My *guess* is either a problem with the 1-2 baulk ring or maybe one of the detent springs. Thanksgiving project, I hope.

Might experience. Worn bearings and weak detent springs 32831N. Change the bearings or springs or both and you should solve the problem.

If it goes into 2nd gear without grinding, then there is nothing wrong with the balk ring or the springs 32602N in the hub. If those springs weaking they do not apply enough pressure to the baulk ring and release the hub too soon, before the gears can synchronise and then you grind gears.

-

2 hours ago, Jeff Berk said:

I'm trying to ID my transmission because I need to check if parts are still available. All I know is that it came out of a 280z or zx since it was installed in my 260 around '83. Based on the retaining bolt placement above the speedo cable and the two tabs on the tail end of the transmission housing it is likely a wide ratio FS5W71B. Is this the only potential transmission or do I need to dig deeper. There is an L3 on the housing if that helps.

Also, from talking to a transmission specialist, my problem of popping out of gear may be related to worn shoes or forks. If he is on the right track, are these components still available? I'm going to pull my center console out to see if something is blocking the shifter before bringing it in just in case it's a simple issue.

Thanks in advance...

Jeff

Hi Jeff,

It looks very much like a wide ratio FS5W71B out of a 280Z or a 280ZX 2+2. The L3 is a casting mark from the manufacturer and doesn't mean anything regarding type of transmission, ie wide or close ratio.

Popping out of third is caused by an accumilation of wear in several bearings in the transmission, but also springs in the selectors. This typically happens in third because the wear in the needle bearing between the input and main shaft, and third is the furtherest away from the adapter plate bearing. The selector springs loose tension over time and the extra stress caused by the worn bearings pushes it out of gear.

The spring is in the selector parts list in the link @Zed Head posted. 32831N is the part number. They can be replaced with the transmission in the car.

The springs cost a couple of dollars and with a good oil you should be able to drive trouble free for some time. GM or AC Delco make a very good oil for these transmissions. I would try this before doing an expansive rebuild.

-

Edited by EuroDat

The different types of 4 speed transmissions for the S30 cars in the north american region.

F4W71A is the early 240Z 4 speed transmission with the separate bell housing up to Aug 71 240Z.

F4W71B is the later 240Z, 260Z & 280Z 4 speed transmission. From Sep 71.

F = Floor selector

4 = 4 speed

W = Warner type synchros

71 = Distance between main shaft and cluster shaft

B = Version A, B & C

Where the 70 comes from, I don't know.

The seal you should be using 32136-U0100. It is the same seal as used in the 5 speeds through to the early 300ZX. Can you explain what the part nr #3771?

Can you post a photo of the metal shavings. Hard to say what they are without seeing it.

Here is a link with a lot of the part numbers you would need to do a thorough rebuild?

-

-

-

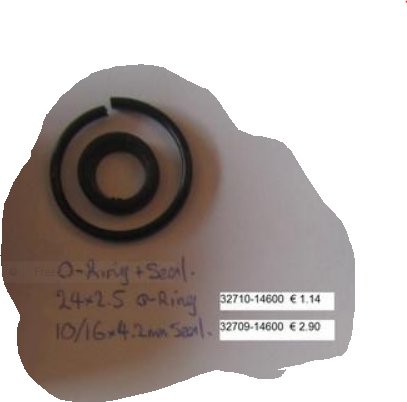

I take it you cleaned the switch it to determine that. If you disconnect the switch wires and unsrew the switch, you will find an o-ring seal at the shoulder end of the thread. You can see it in SteveJ photo. It is an easy fix,. I have the size I used somewhere. Ill look it up.

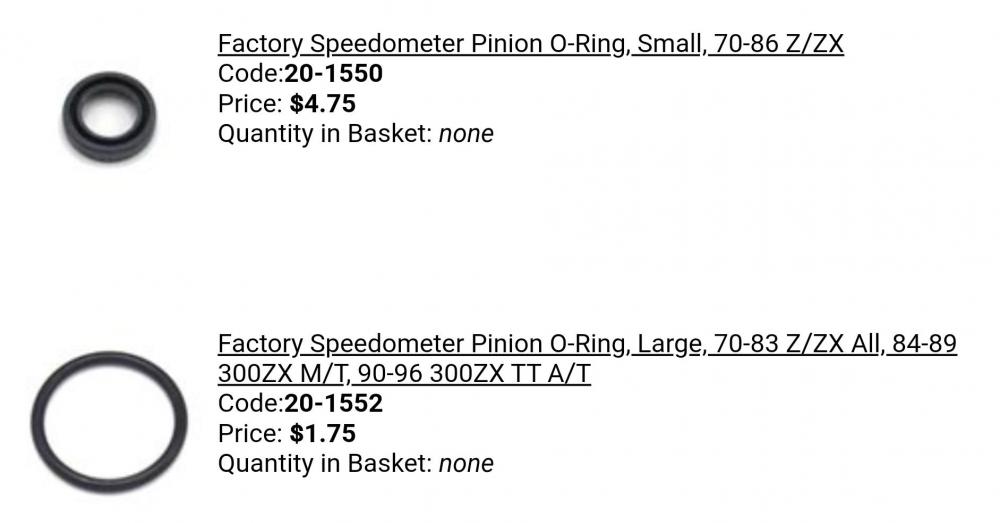

The speedo is two seals. You should replace both. You can get them at most at most auto dealers. Here is a sreenshot from The Z Store.

-

Edited by EuroDat

The first thing I would do is degrease all the areas of concern and check regulary after each drive to determine where the leaks are coming from. Oil can spread and give the impression it's leaking from one spot, but accually coming from another.

Pay attention to where exactly the leak is.

1. Reverse switch: Is it leaking out the side between the transmission case and switch or out through the rubber boot where the wires are? Leaking through the side is s gasket. Leaking past the wires is a worn out switch.

2. Speedo: Leaking through the cable or leaking out between the speedo "adapter" and transmission casing? Leaking past the adapter is an o-ring seal. Leaking through the cable is a inner Lip-seal and is a little more difficult to change. If either one is leaking, I would replace both seals.

3. Slave cylinder: If it leaks replace it. If you buy a new one, strip it apart and clean it before installing it. The new units often have metal shavings left over from manufacture and that can destroy the new seals.

All the parts you mentioned are common leak areas and easy fixes with basic tools.

-

Edited by EuroDat

AK260 and Zed head are on the mark.

"Pressure will build up when the pads and shoes make contact. The harder you press the pedal the more pressure applied."

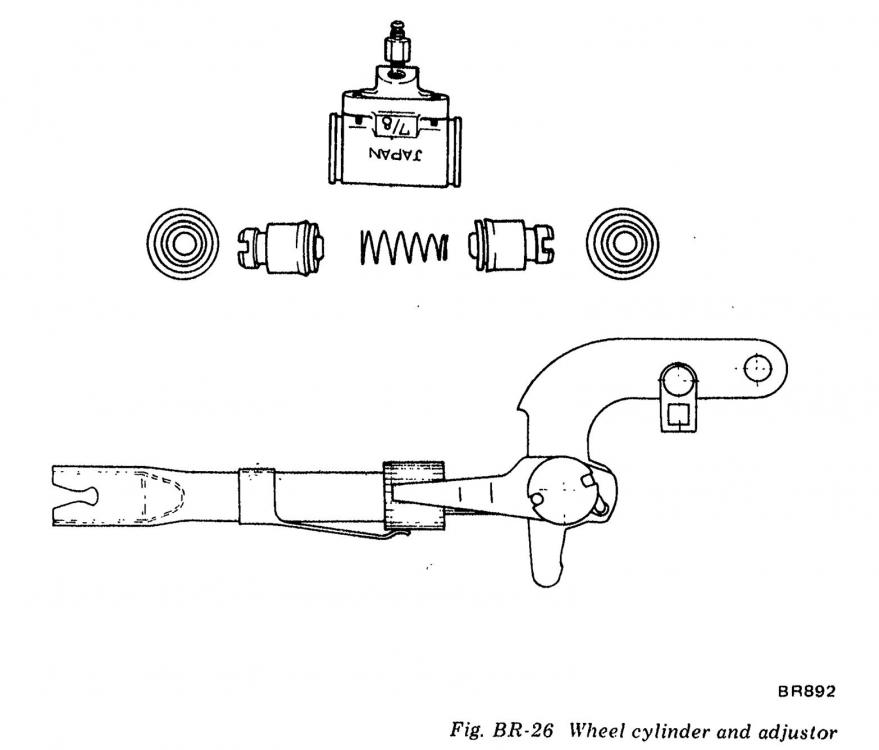

The front and rear system is balanced in volume. If the volumes needed to apply the brake are different the pressures will be different as well. In this case, the shoes are not adjusted correctly and the distance is excessive you will get an inbalance in pressure because you need more volume for the rear system.

This system has a self adjusting mechanism that is activated by the hand brake. When you park the car, pull the hand brake on and release it several times. That should correct the distance or the rear shoes.

Sometimes the adjusters will seize over time. You can check this by watching the levers at the backing plates and comparing them. If one moves more than the other then you have a seized adjuster.

When I rebuilt my brakes and after the run in I noted how many clicks the handbrakes makes. If it needs more than two extra clicks, and it doesn't correct itself by applying the handbrake several times, I know I have an issue with the adjusters.

-

Edited by EuroDat

If your brake switch is activating when "fully" depressed, then you have an inbalance when the system is under high pressure.

Basically at rest the mastercylinder is open to the reservoirs and the system is atmospheric. Once you press the pedal the ports to the reservoirs are closed and fluid in the front (closest to pedal) is transfered to the calipers and rear to the drum wheel cylinders.

The two systems (front and rear) are balanced and pressure will build up when the pads and shoes make contact. The harder you press the pedal the more pressure applied. Both systems pass through the switch and then the proportioning valve.

If the systems become unbalanced the shuttle in the switch will activate the switch. AK260 posted a good video explaining how it works.

What could cause this pressure difference?

1. A low level in a reservoir allowing air to enter the system or the brakes were not bled enough to remove all air after repairs. The pedal should feel spongy depending on how much air is jn the system.

2. A leaking seal in the mastercylinder allowing fluid to leak back to the reservoir. The pedal should sink to the floor when you hold pressure on it, but the reservoirs don't loose fluid. Engine running when testjng this.

3. A leaking component in the system: caliper seal, wheel cylinder or brake line. Does it use fluid and are their visable wet spots around the calipers, brake backing plate or lines?

Fair chance it is a master cylinder seal and likely one of the two primary seals.

-

Edited by EuroDat

The oil leak from above is most likely from one of two places.

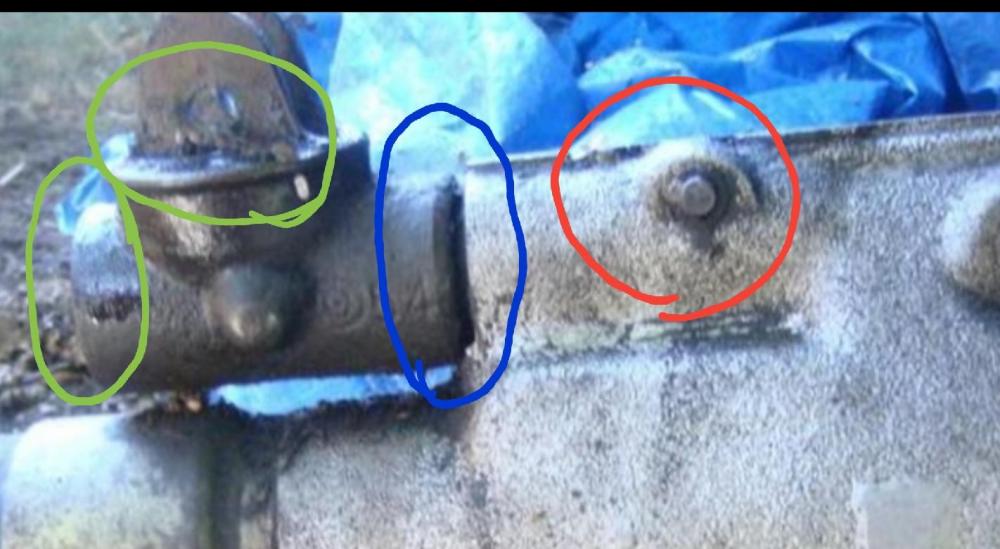

1. The cotter pin in "red circle" or the o-ring for the selector "blue circle". There is a third spot, the lip seal "green circle" in the selector mechanism, but them your selector stick would be leaking out the back or top where the gear stick goes.

Green circle is where it would leak fron. The lip seal is further in the selectors

-

Yep. There is a cotter pin for the selectors above the speedo cable adapter. It often leaks a little oil over a long period.

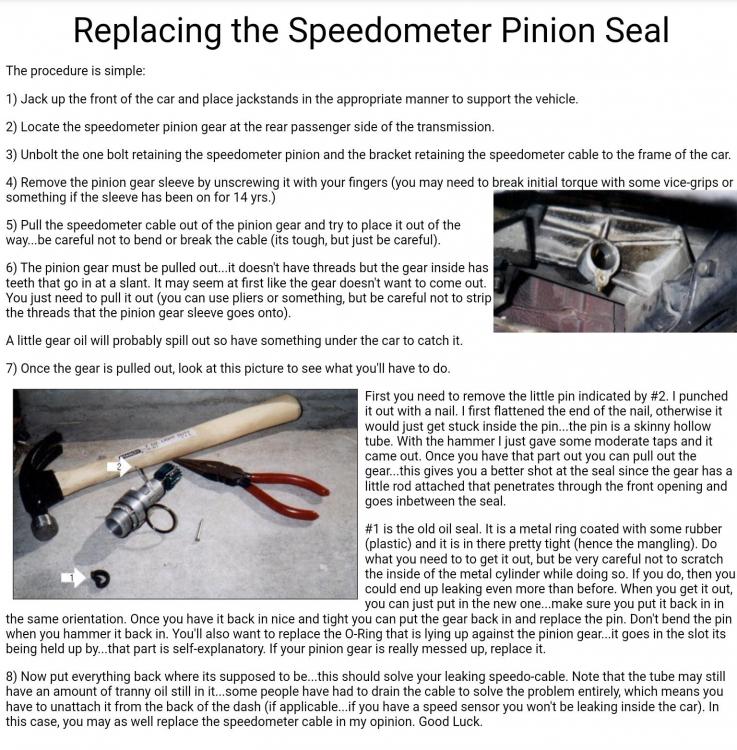

Yoer adaptrr is leaking through the pinion shaft seal. The o-ring seal looks like it is still ok, but you should always replace it too. They harden when they get old. Once you remove and refit them they start leaking.

I think I mentioned it earlier. To remove the adapter, just remove the M6 bolt and tab above it and the use a flat bladed screwdriver in the groove where the tab was to pry it out.

-

Hi Mat,

If you do plan on rebuilding the FS5C71 you might want to try contacting SW Motorsport in Sydney, Australia. They did have the 1st to 4th gear porche type synchros. They still have the 5th gear porsche type synchro for $145 Australian dollars which is about €95.

https://www.swmotorsport.com.au

https://www.swmotorsport.com.au/product_info.php?products_id=1150

-

-

Edited by EuroDat

I tried to buy the AC delco/GM Friction-modified oil here locally (Europe), but couldn't find it anywhere. There was a company in Italy, but he didn't stock it anymore.

I ended up ordering it from the states, but they cancelled and refunded the money because it was considered dangerous goods being flamable. Thats is going back 5 years ago, but I doubt much has changed.

-

-

-

Grats. Poor quality oil or low level can cause a lot of shifting issues. Yet another happy AC Delco/GM gear lube sucess story.

Speedo leak: Where exactly is the oil coming from? Leaking out the side of the adapter, then it's an o-ring seal between the adaptor and the transmission housing. If it is leaking through the cable itself, than it is a leaking lip-seal in the adaptor where the speedo pinion shaft goes through.

The speedo has an o-ring seal and a lip seal. It is easy to change both. They cost less than $10 for both seals. You will need to tap out a small roll pin, but with basic tools it's is not much work.

Simply unscrew the speedo cable and the 10mm hex (m6) bolt and locating tab. You can pry the adaptor out using a flat screwdriver in the locating tab slot. You will see the roll pin passing through to the side of the pinion shaft. It holds the pinion in place. You can tap it out with a small hammer and a blunt wood nail.

See tech article for the part numbers. You can also source the parts at a local (hydraulics) parts store. Make sure you ask for NBR, HNBR or Viton rubber. Don't use EPDM or Silicone.

-

10 hours ago, EuroDat said:

What can cause your problem:

1. The baulk ring is worm and under minimum tolerances. It can not synchronise the hub and the constant mesh gear. Result is grinding gears.

2. Poor quality oil makes the baulk ring inefficient. Oil does make a difference.

3. The teeth in the constant mesh gear and sleeve are blunt and rounded. That way the sleeve hits the blunt teeth and you require more force to engage the two. You have to force the gear a little left or right to get it home. Occasionally they will line up and it go in easily.

One other problem I rthought I would mention here. It could be playing a roll in this problem.

4. When the springs behind the inserts get old and weaken they don't apply enough pressure for the insert in the sleeve. When this happens, the inserts don't apply enough force on the baulk ring to synchronise the hub and constant motion gear. The sleeve slips over the inserts and hits the gear before it reaches the same speed as the hub. Result is gringing into gear and rounding the pointy end of the teeth.

A good quality oil with help this a lot and extend the usable life of the transmission.

-

8 hours ago, jfa.series1 said:

This is a highly recommended transmission oil, perhaps the same one referred to by @EuroDat

Yep. This is the one. Part nr 88900399.

I couldn't find that here in Europe, so I went with the Redline MT 75W-90. It works fine in these old transmissions.

-

-

Hi Red67,

Not seeing it, hearing it or feeling it happen makes it hard to diagnose. From your description I think you have a problem with the teeth on the side of first gear.

A little background on how a borg warner type synchro works. 1st gear: The FS5W71B Synchro mechanism consists of:

Hub (26), Sleeve (28), Baulk ring (29), 3x inserts (30/31), Constant mesh gear (19).

The hub is connected to the main shaft. In the hub are three grooves for the inserts and springs the push the inserts outwards towards the sleeve. The inserts have a tab on the outside so they will "centre" in the sleeve.

The baulk ring has three slots where the inserts fit into. This makes the synchro turn at the same speed as the hub.

The constant mesh gear has teeth on the side and a cone that fits neatly into the baulk ring.

Now how does that all work when you change from neutral to 1st gear. Basic description:

The sleeve moves over the hub and pushes the inserts and baulk ring onto the cone section of the constant mesh gear. The friction then causes the hub and constant mesh gear to synchronise by speeding up or slowing down the first gear to the same speed as the hub.

When you push further the sleeve slides over the insert tab and meshes with the teeth on the constant mesh gear. The teeth on the constant mesh gear are pointed to guide the sleeve into position.

Now first gear is connected through the constant mesh gear à Sleeve à Hub. The baulk ring and inserts have no function. The detent balls in the selector mechanism hold the sleeve in position.

What can cause your problem:

1. The baulk ring is worm and under minimum tolerances. It can not synchronise the hub and the constant mesh gear. Result is grinding gears.

2. Poor quality oil makes the baulk ring inefficient. Oil does make a difference.

3. The teeth in the constant mesh gear and sleeve are blunt and rounded. That way the sleeve hits the blunt teeth and you require more force to engage the two. You have to force the gear a little left or right to get it home. Occasionally they will line up and it go in easily.

From your description, I would think the 3rd problem is the main issue and maybe some of it comes from the other two problems.

I would try changing the oil for starters. The rest will require dismantling the transmission.

A member on this forum "Chickenman" recommends an oil from AC Delco or GM. The part numbers are AC DELCO USA part number is: 88900399. GM USA part number is: 12377916. I can not order the GM or AC delco oil here in Europe so I have no experience with it. I'm using Redline MT 75W-90 and find it very good. Here is a thread on the oil subject

https://www.classiczcars.com/forums/topic/51698-how-should-a-71-240-4-speed-feel/

I don't think your selectors are an issue atm.

-

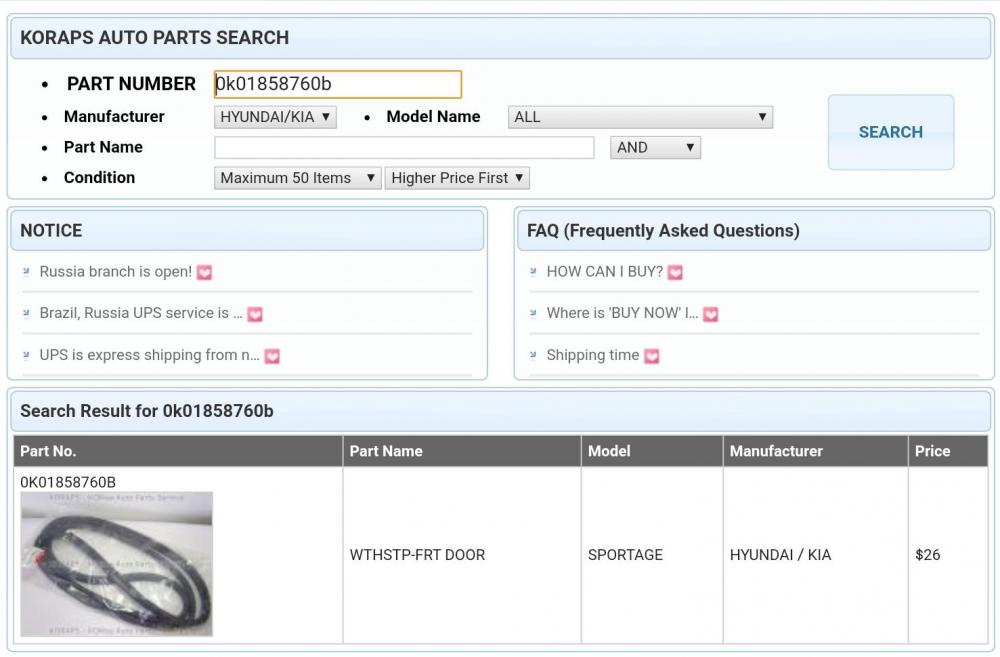

Why don't you go to www.koraps.com and buy two new ones.

0k01858760b right

0k01859760b left

Left and right. I could tell the difference. The most people that have used them find they fir very well as an alternative to finding originals this in usable condition.

I have to admit they are darn expensive at $26 each an $6 shipping. They were $12.50 each when I bought mine.

-

-

Oh crap. Wrong photos. Now Ill try that again.

You are wrong on with your comments about not fitting well. They do pull in with a little persuasion. I used a block of wood and a trolley jack to compress them enough and start the nut. See second photo.

Another point. My kit was 4 rubbers and washers, simple bolt, nyloc nut and a spacer tube. If you tightened down hard , you could crush the rubbers completly. I tighted the nut until the rubbers started to bulge slightly. Checked them aftrr a couple of monthes and retightened a little where needed.

I hope that makes some sense.

FS5W71B transmission identification (close-ratio vs. wide ratio) - with pictures

in Engine & Drivetrain

·

Edited by EuroDat

Here is a photo where you can just see the two side detents in the red circle ( 3rd/4th and 5th/reverse) the other one (1st/2nd) goes in from the top and is the hardest to replace. It helps to lower the rear transmission mount and crossmember to give yourself more room. You will also need a small pencil style magnet to remove the spring and ball.