Everything posted by Patcon

-

1971 HLS30-14938 "Lily" build

I dont believe that is the same item. I believe there is supposed to be another seal a the bucket to fender joint Edit: checking car parts manual shows totally different part numbers #30 https://www.carpartsmanual.com/datsun/Z-1969-1978/body-240z/front-fender-hood #12 https://www.carpartsmanual.com/datsun/Z-1969-1978/electrical/head-lamp

-

1971 HLS30-14938 "Lily" build

Are there any pictures around for what they looked like? I might try to replicate them. I dropped off the remainder of my panels at the paint shop today. I suspect they will be ready next week.

-

Smoke coming from head light switch

Did anyone ever recreate the Nubbins? I know somebody was working on that

-

1971 HLS30-14938 "Lily" build

Any idea on a source for those? Those aren't the ones for the headlight to bucket are they?

-

1971 HLS30-14938 "Lily" build

What is part #30?? https://www.carpartsmanual.com/datsun/Z-1969-1978/body-240z/front-fender-hood

-

1971 HLS30-14938 "Lily" build

I stripped some headlights a little while back I had a pair of 280z lights and a pair of 240z lights. Even with the plugs off, it's a little hard to get them out of the headlight buckets

-

Quaife LSD Installation in R180 - With Questions About Installation Also

I can't answer most of your questions, but I do think you are correct to remove the excess paint

-

Wiper rebuild

Polished the pivots some today and bead blasted the wiper pivots I noticed a thin hard washer on all the short pivots. Very hard to see and I had to use a knife to separate them from the pivots. Three of these pivots have a broken bolt in them

-

L20b Cody's Goon

We have been working on getting the fuel tank back into the Goon. Noticed the filler neck is much smaller than the tank port Over a 1/4" different in diameter and the filler neck is pretty hard. So I bought some exhaust swagers I will expand them. Then heat. Then repeat. We'll see how that works

-

Black out areas

I think I found another I was taking headlights apart for plating buckets. I believe the painted ones are 240z and the unpainted are 280z The screw tabs for the lamps are also different They must have blacked them after assembly because the tabs and screws were all painted black

-

Better Than Bondo??

Maybe, the link worked for me

-

Wiper rebuild

I was very disappointed a few years ago when looking for 350z interior parts. Almost all of them were unavailable on a 14 yo car. I find that to be a poor business decision but it is what it is

-

Better Than Bondo??

Bondo ( plastic body filler) is really not a suitable material for dealing with rust holes. It is not water proof so moisture can travel through it and continue the rusting process. Grannyknot is correct that the hole is probably larger than you suspect once you get back to sound metal. I also agree with the sentiment that you need to get the metal clean. I would also add a step of treating the rust with a phosphating chemical. This chemically converts what minor rust is left. If I was going to try to fill a hole after this and didn't have access to a welder then I would use short hair fiberglass resin. Fiberglass resin is totally water proof after it's cured. But bare in mind that fiberglass resin gets much harder than filler! It's harder to shape and finish well. Once the hole is sort of filled and sealed up you can use filler over the primed resin to make it smooth.

-

Wiper rebuild

No I haven't checked the part numbers. That would be very surprising if they were available. The only part Im not sure how you would refurbish are the ball joint ends.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

https://www.ebay.com/sch/i.html?_from=R40&_trksid=p4432023.m570.l1313&_nkw=280zx+turbo+oil+cooler&_sacat=0

-

Wiper rebuild

Both, and recommendations on how to deal with them moving forward

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

The 280zx turbo had an oil cooler with an adapter plate. I have no idea what they cost used

-

Wiper rebuild

Some of the spindles were bound up in the bases, but we managed to get them all out Now for the questions... How do we think these were made?? I'm thinking the main body was yellow zinc by the looks of it, but the pivots almost look like they are hard chromed (??) then riveted through the main body? The drive pivot was tacked welded to prevent rotation maybe... Thoughts? I have some that are badly corroded. What do you do then? Clean and yellow zinc? @Captain Obvious@grannyknot

-

Wiper rebuild

Some of the later mechanism had some different parts This mechanism has a rubber boot on the end of it. I believe Steve Nixon offers this part as a reproduction Here is it half disassembled Out of the 3 mechanisms only had the spring in this orientation, but I beleive this is the correct position The last one also had this little piece of plastic? I'm not sure of it's purpose

-

Wiper rebuild

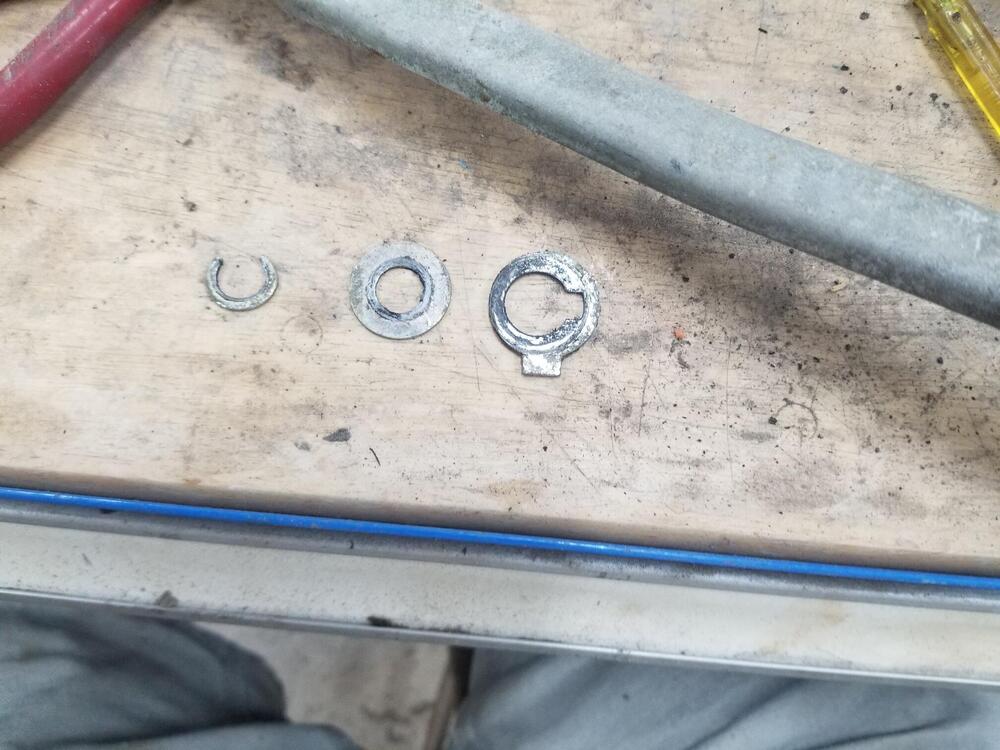

This is what the single side spindle looks like This is the drive end of the linkage Order of the top pieces Be careful when disassembling this! There is a spring under here and the first one I did the spring and washer went flying. Order of the lower pieces Another pivot

-

Wiper rebuild

On the wiper side of the pivot there is a tiny spring steel ring. Like a little bull ring. I need to find a source for these. Some of them were rusted away When you pull the wiper spindle out of the base there is a wavy washer at the bottom to prevent wear

-

Wiper rebuild

I have 3 sets of wiper mechanisms on the bench. I finally decided I would rebuild them and plate them since I have some other items that need to go to the platers. Since I didn't know of a comprehensive rebuild thread on CZC I thought I would make one I did the break down today So you need to be sure on reasssembly that it looks like this or you're gonna have problems!! I started on the single pivot end The little clips aren't spring steel. The bend open. I might go back with snap rings on reassembly Then the felt. I am working on replacements for these Also shows the rubber seal that is on the face of the wiper pivot base

-

Resurrecting my horn (the sans Viagra thread)

- Replacement External Door Scraper Molding (Silvermine)

Sometimes they rust and break off. The rest ends up in the bottom of the door.- Replacement External Door Scraper Molding (Silvermine)

Yes, designed to keep the glass from tipping too far out of the door - Replacement External Door Scraper Molding (Silvermine)

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber