Everything posted by Zed Head

-

Z's on BAT and other places collection

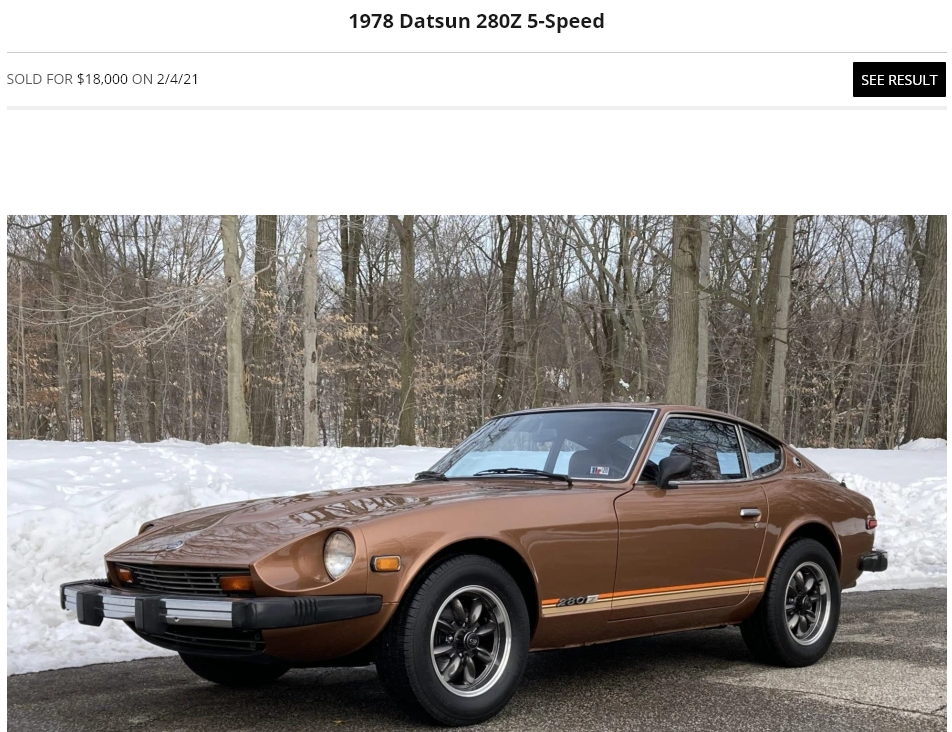

The 78 with the nice paint job sold for $18,000. https://bringatrailer.com/listing/1978-datsun-280z-82/

-

Z's on BAT and other places collection

I don't know, the guy seems scary. Look at that shoe. p.s. people still use checks?

-

carparts.com New parts site - disappointing

9/30/2019 Company formed right before the pandemic started. https://bostechauto.com/blog/bostech-growing-expanding/

-

carparts.com New parts site - disappointing

I did find a new company though. Never heard of them before now. Bostech. https://www.carparts.com/fuel-injector/bostech/bosmp4210?&vehicle[cylinders]=6&vehicle[liter]=2.8&vehicle[submodel]=Base&vehicle[model]=280Z&vehicle[make]=Nissan&vehicle[year]=1976 https://bostechauto.com/

-

carparts.com New parts site - disappointing

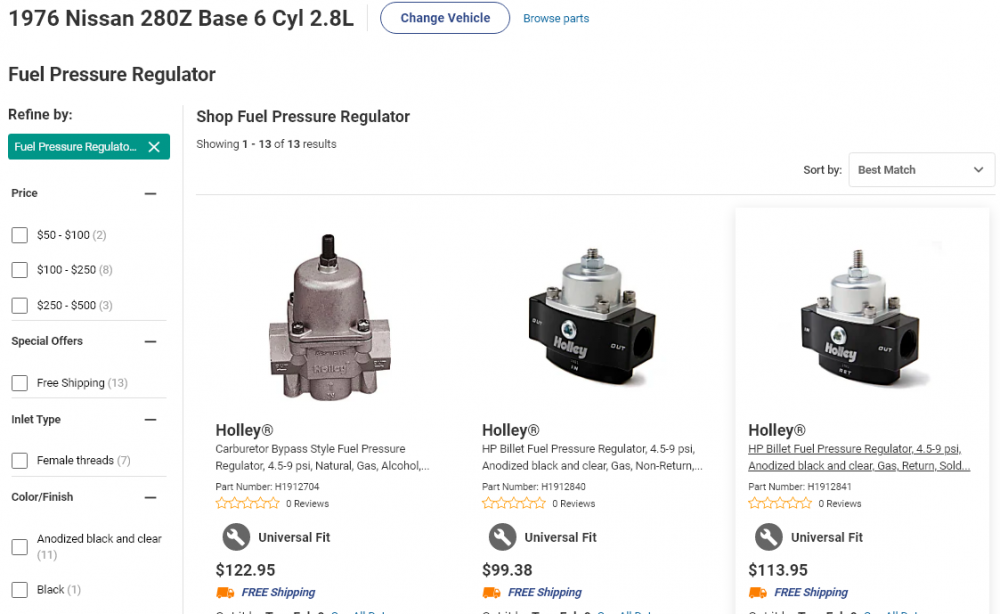

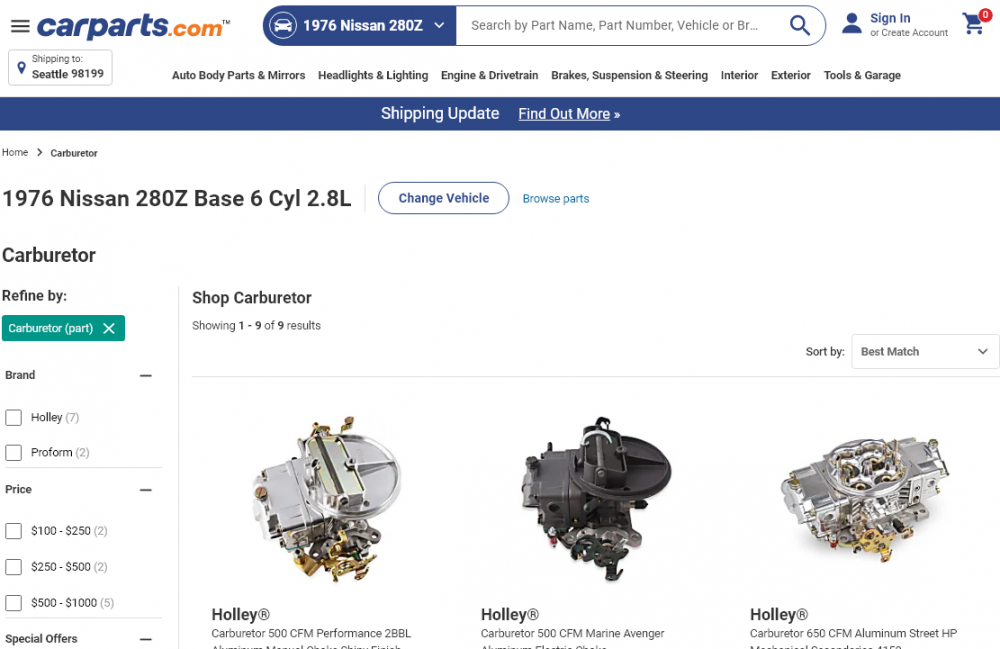

The site just shows the wrong parts overall, for a 280Z. It should be showing injectors instead of carbs, and a high pressure regulator. When I clicked "Fuel" on the site, for a 1976 280Z, the carbs popped up as an option. Basically, the site has lots of wrongness on it. It's just a messed up attempt to compete with Rockauto I think. I did see Injectors though, on the page. But how do I know they're the right ones? Maybe it will get better. https://www.carparts.com/fuel-systems-and-components?&vehicle[cylinders]=6&vehicle[liter]=2.8&vehicle[submodel]=Base&vehicle[model]=280Z&vehicle[make]=Nissan&vehicle[year]=1976

-

in-car crank removal

Those LD cranks seem to be worth a lot of money. Might be worthwhile to pull it just for resale.

-

carparts.com New parts site - disappointing

-

carparts.com New parts site - disappointing

Just saw an ad for a new parts site. Thought it might be Rockauto type competition. Not. Carburetors for a 280Z. https://www.carparts.com/carburetor?&vehicle[year]=1976&vehicle[make]=Nissan&vehicle[model]=280Z&vehicle[submodel]=Base&vehicle[cylinders]=6&vehicle[liter]=2.8

-

in-car crank removal

What the heck are you working on? Is it in a wrecking yard? Is it in your driveway? Is it yours? Why do you want to remove a crankshaft from a Maxima? Are you going to repair something and put it back together? Stuff like that.

-

Z's on BAT and other places collection

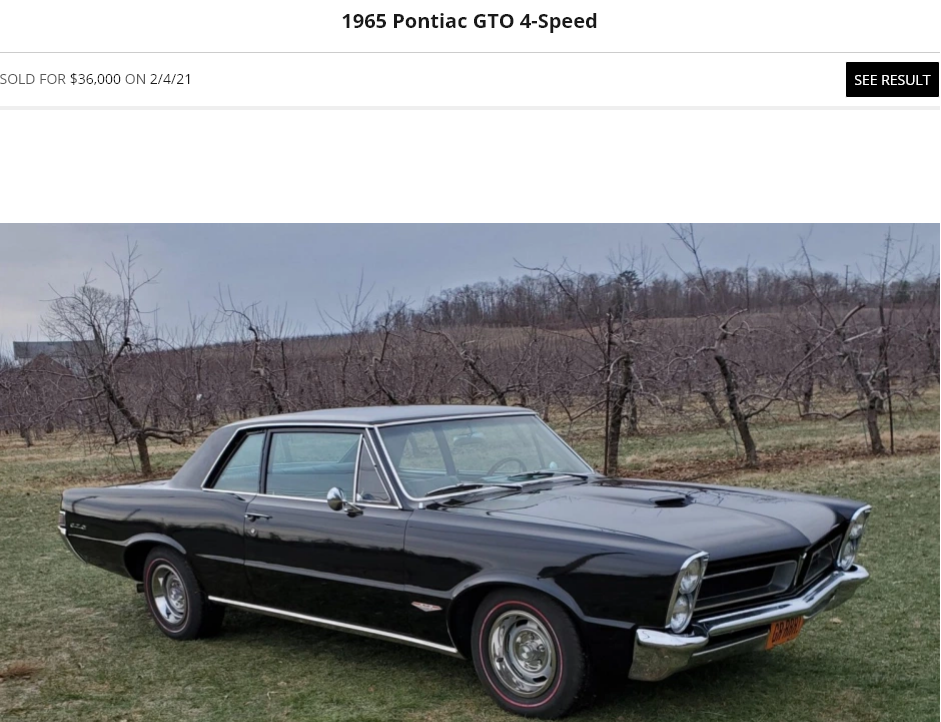

The 65 GTO is closing today, soon. Seems low, but it sold. $36,000. https://bringatrailer.com/listing/1965-pontiac-gto-41/

-

Z's on BAT and other places collection

The BAT post is another one of those weird ones where they don't seem to know how to show the car. No driving video and many questions about the sunroof. But no answers. The comments are interesting also. A few people saying that the sunroof actually adds value. Value defenders are active there. I'd want to see it working, and not leaking when water is sprayed on the car. I bet if it leaks it just ruins the headliner, among other things.

-

COVID-19

Just explain why. Pretty simple. Define "safe". https://abcnews.go.com/Politics/cdc-director-teachers-vaccinated-order-reopen-schools/story?id=75662299 "There is increasing data to suggest that schools can safely reopen and that safe reopening does not suggest that teachers need to be vaccinated in order to reopen safely," CDC Director Rochelle Walensky told reporters at a briefing. "Vaccination of teachers is not a prerequisite for the safe reopening of schools."

-

COVID-19

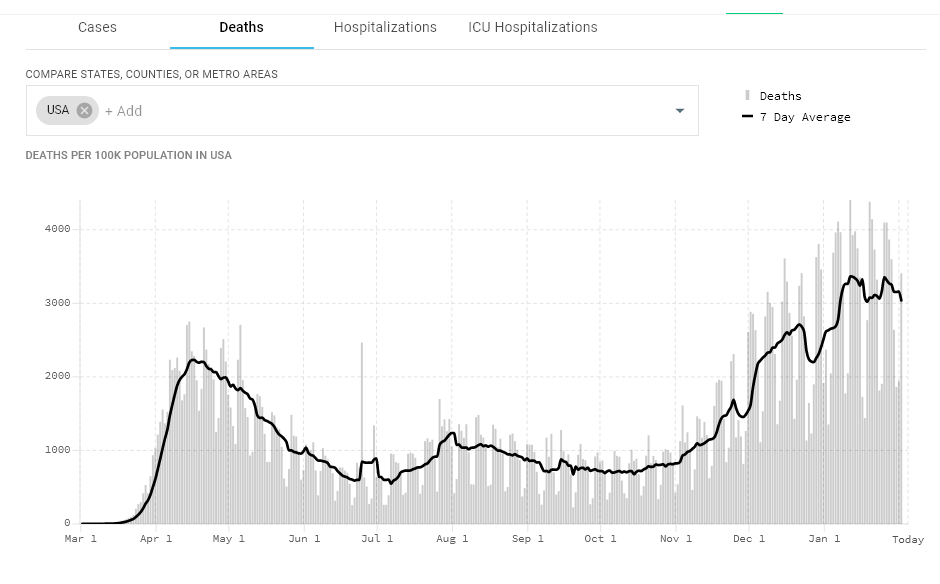

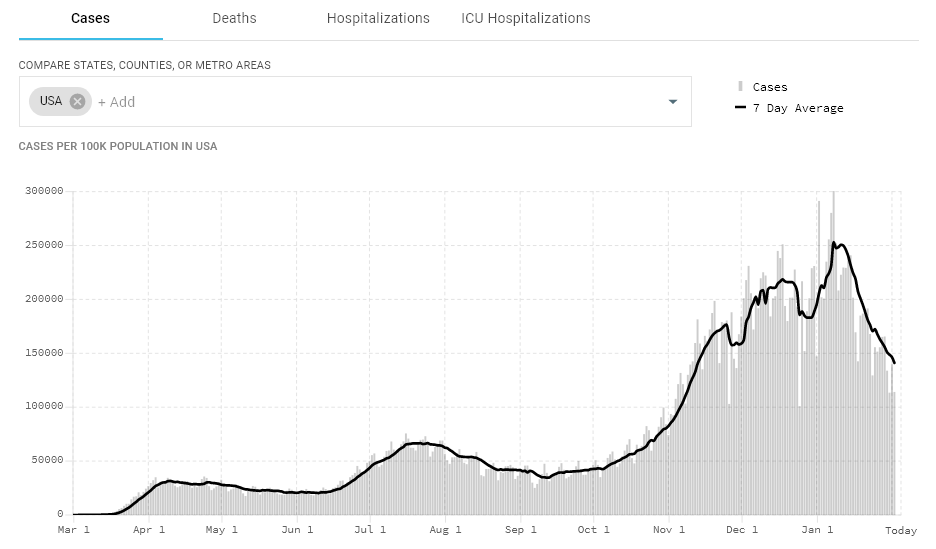

The data and news over the last few months seems a little bit contradictory. Supposedly the therapeutics are better, so fewer people that get sick are dying. But the dats plots show deaths as about level while cases and hospitalizations drop. Seems like the data gatherers are just collecting numbers and reporting them but not really examining what's happening. They're backsliding to poor messaging, I think. Like the demands that teachers get back in the classroom, but nobody can give a simple explanation about how the teachers are safer. The new head of the CDC seems tone-deaf about it. They're still talking about sacrificing teachers for students. They should just come out and say it, or show the data that shows that teachers are safer. Things change but they stay the same. https://covidactnow.org/?s=1575515

-

in-car crank removal

Are you going to tell us why?

-

Clutch Master Cylinder replacement

Another thing that I found that works on both the clutch and the brake is that you can use a pair of pliers to spin the rod without removing the clevis pin. Just loosen the lock nut, grab the rod with the pliers and spin it a quarter turn at a time. The end in the booster or clutch master is free to spin. You can gauge proper tightness by how the clevis pin wiggles in the hole. I just adjusted mine up until it was almost tight, to give maximum travel, and no pedal play. Much simpler than taking measurements, taking the pin out, and spinning the clevis.

-

COVID-19

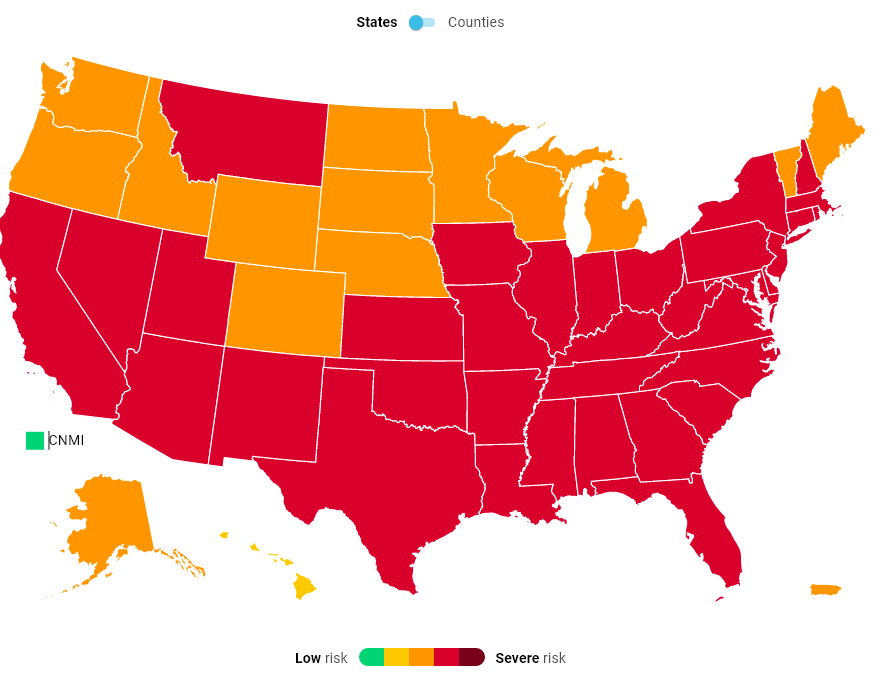

Actually, cases are getting better. But it looks like the risk is spreading across the country again. Not so localized. https://covidactnow.org/?s=1575515

-

COVID-19

People are excited about the vaccine rollout but overall things are still getting not getting better yet. A few weeks ago only Arizona was red in this States map. For anyone planning that big celebration party. Super Bowl weekend will probably start another wave, with variants included. My daily PSA and dose of happy sunshine news. https://covidactnow.org/?s=1575515 https://www.worldometers.info/coronavirus/

-

in-car crank removal

Might be that he's just picking up a crankshaft from a car in a wrecking yard. We've all probably seen what people will do to get their parts there. Pretty common to see a Z engine leaning against the firewall, on the valve cover. I'm sure the details will come out.

-

in-car crank removal

People do crazy things, see attached link. With an automatic you might even have room to drop it with the flex plate attached. Who knows. It will be heavy. https://forums.hybridz.org/topic/81528-replacing-piston-rings-with-the-engine-in-the-vehicle-l-series-faq/

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

Another 71. Over-riders, shiny mag wheels, and... an L26. Might as well just drive it to the wrecking yard. Ruined! 💀☠️↘️ Chassis: HLS3005807 https://bringatrailer.com/listing/1971-datsun-240z-167/

-

Z's on BAT and other places collection

One of the orange 72's didn't get bid very high. $20,750. Seems like original is the key on the early ones. Keep those old parts.

-

Help Hint of the Day, Transmission mount Direction

Pretty cool. So my "snow plow" thought, from the drawings, was correct.

-

suspension parts

There is a ton on the forum about "PU" bushings. They're all about the same. It all depends on what you're trying to do. Nobody can say if you should or shouldn't without knowing that. And you can get them cheaper on Amazon. https://www.amazon.com/Prothane-14-2001-BL-Black-Total-Kit/dp/B003AVWMN4

-

suspension parts

Must be one of those stealth upgrades.