Everything posted by Zed Head

-

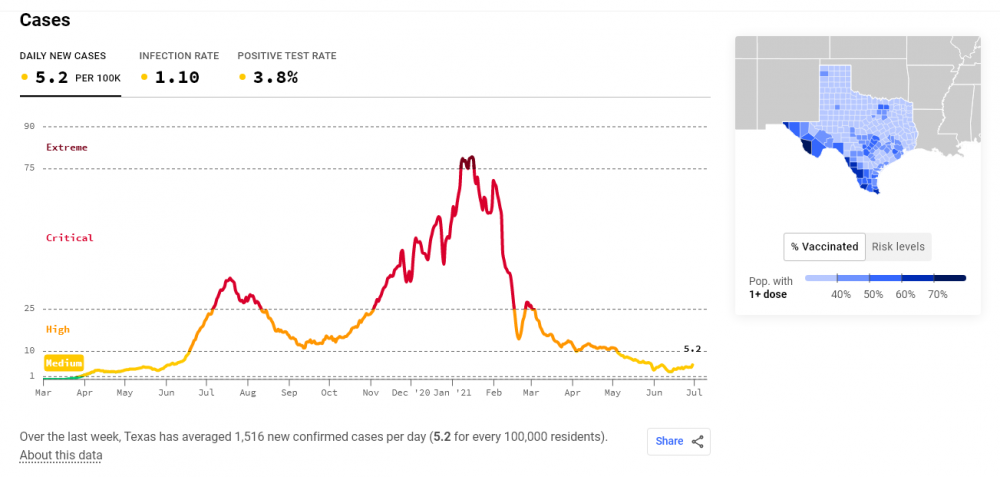

COVID-19

- COVID-19

- It had one job...

Looks like they made some assumptions about what they were dealing with. Somebody misread the x-rays? https://www.latimes.com/california/story/2021-06-30/lapd-responds-to-explosion-at-scene-of-confiscation-of-illegal-fireworks Officers also found improvised explosive devices with simple fuses — about 40 the size of Coke cans and 200 smaller objects of similar construction — and conducted X-rays to determine their contents. Less than 10 pounds of the devices were transferred into a semitruck, which Moore said was rated, with its outer containment shell, to handle 18 pounds.- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

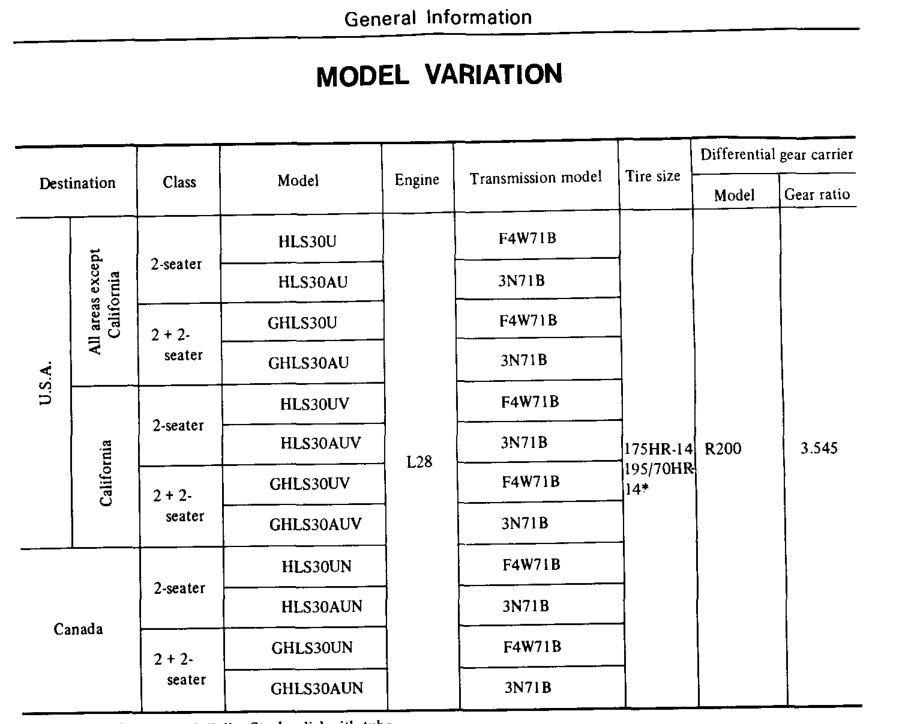

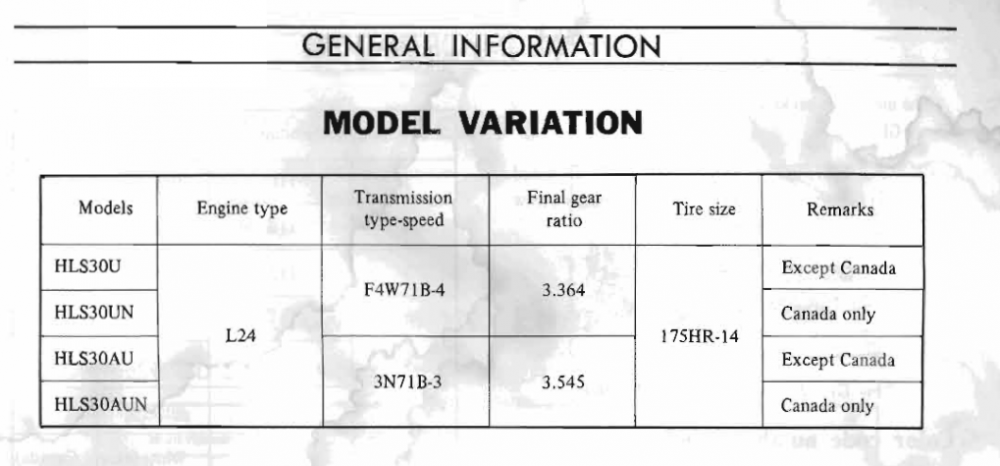

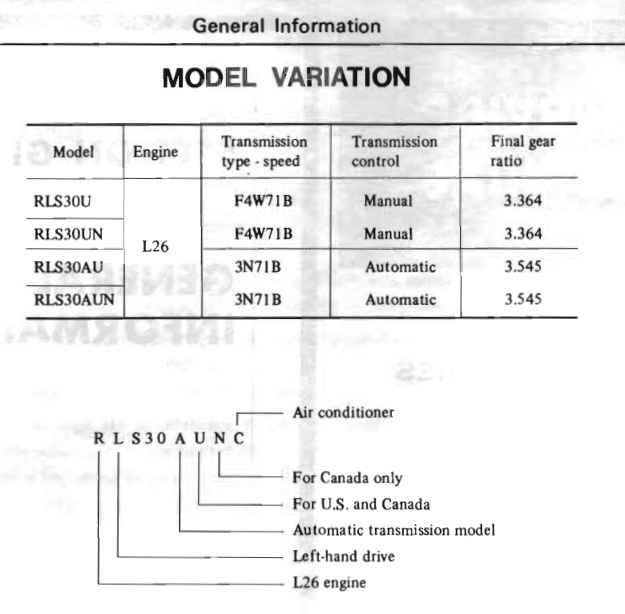

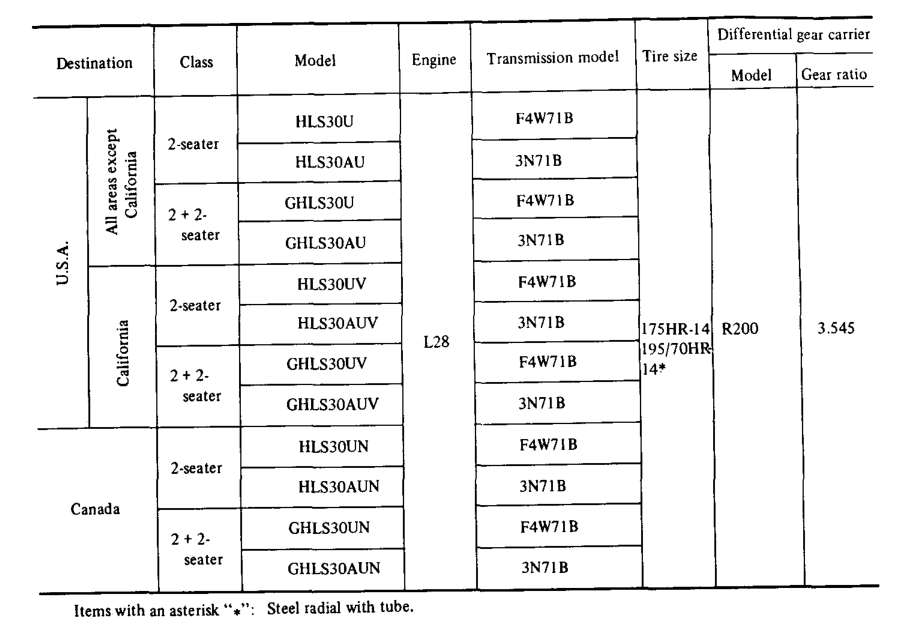

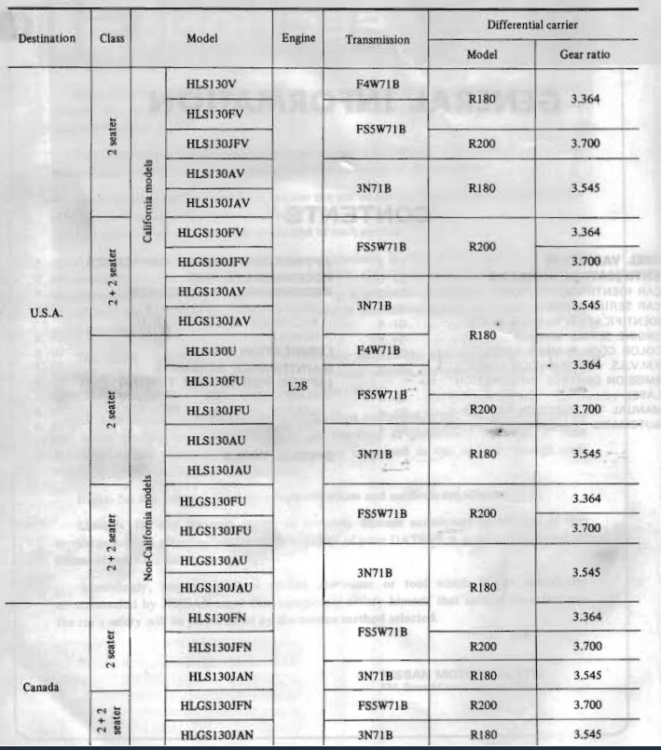

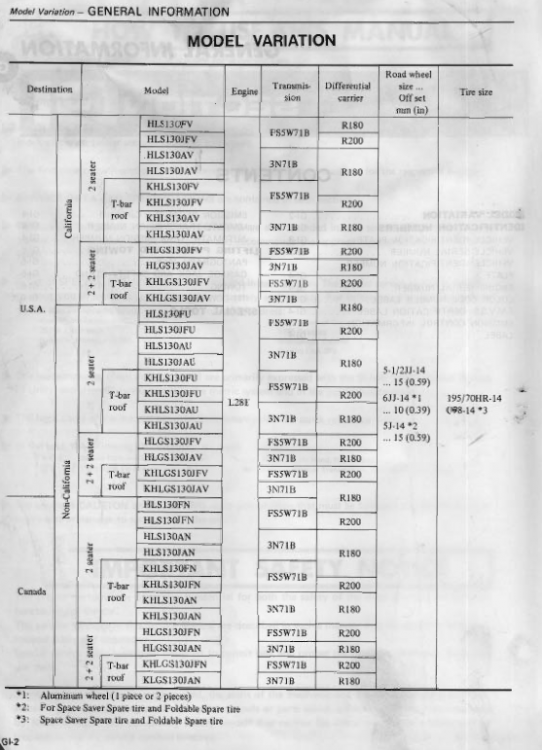

- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

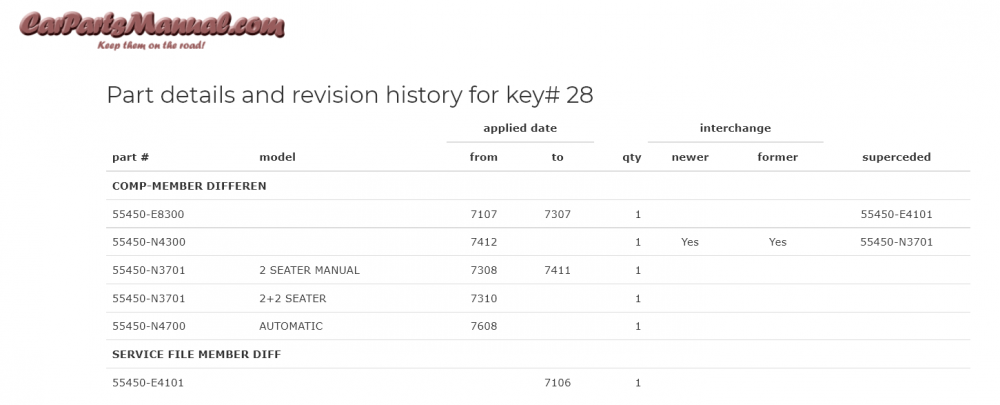

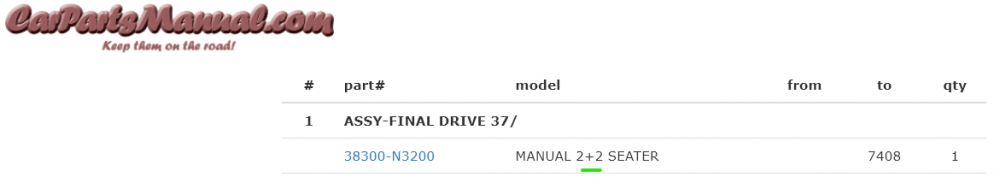

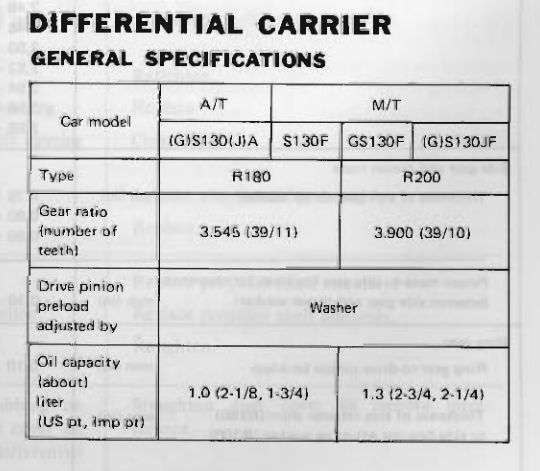

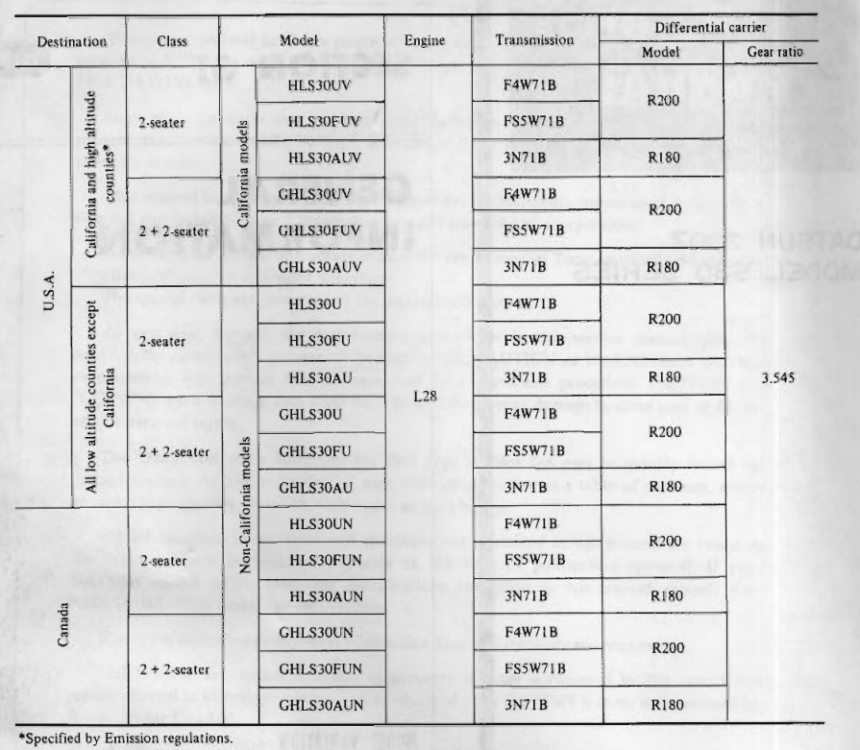

Here's a part that continued through the R180 to the R200. Kind of suggests that October 1973 was when "something different" happened with the mustache bar for the 2+2. Maybe I should be looking at small bumper 2+2's also. Edit - actually I did when I looked through BAT. Only one guy showed the diff. https://bringatrailer.com/datsun/260z/?q=260z http://www.carpartsmanual.com/datsun/Z-1969-1978/axle/rear-suspension/28- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

- It had one job...

https://jalopnik.com/fireworks-explosion-destroys-la-police-bomb-disposal-tr-1847210186- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

I found a big bumper 2+2 manual on BAT with an R200. It's been modded but a diff change isn't mentioned. Who knows. The other listings don't have any diff pictures. https://bringatrailer.com/listing/1974-datsun-260z-22-6/- Haltech wiring ignition basic questions

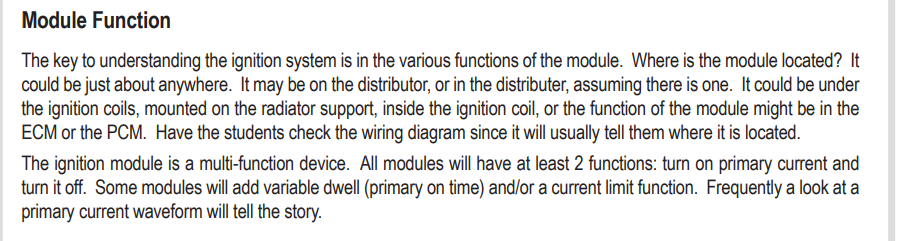

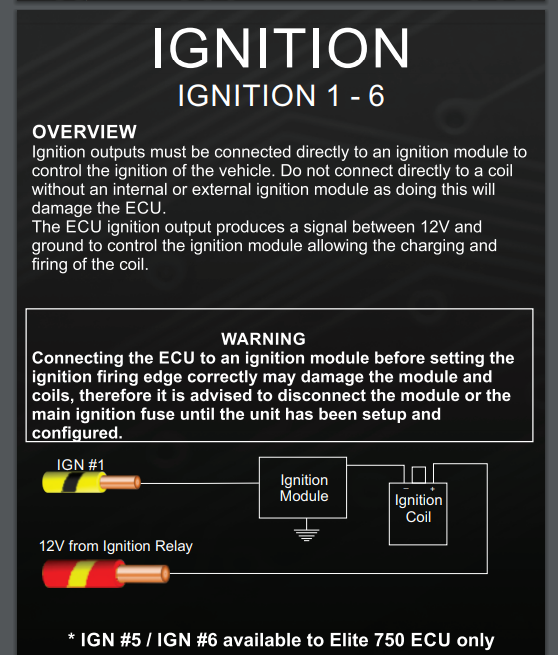

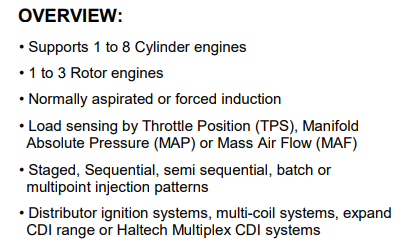

I think that you'll be just setting dwell in the software with the coil and power transistor (another name for ignitor, more correct) that you're planning to use. There are probably recommended values to for the Denso PS coil. Your setup will be like the system used on the 280ZX turbo engines. Very common, used well up in to the 90's (my 95 Pathfinder had that system), probably still used today on some engines. The dwell settings do the job, the most basic one, that the ballast resistor was designed to do.- Fuel pouring out the front of the carbs

Seems like a good reference for people looking for aftermarket electric pumps. I haven't had a carbed Z but if I did I'd probably get rid of the restrictor and use an FPR on the return line set to 4.6 psi if I went electric. It's probably already been discussed a few hundred times. Just filling my brain for future possibilities...- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

Here's another source of info. Most of the dates are in mid-1974, but they don't give the first "From". Ends in August 1974, but no start shown. It is a manual transmission 2+2 though. Maybe there is a USA/Canada 260Z with an R200. That would be opposite of later trends though where they used the R180 for the 2+2's. Part 37 shows the one year 1975 pinion flange, then no changes. http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/differential-gear/r200- differential insulator early one

It came out in August of 1973. Probably some minor design change. Maybe for the big bumper 1974 models. http://www.carpartsmanual.com/datsun/Z-1969-1978/axle/rear-suspension/16- Haltech wiring ignition basic questions

I don't want to overdo getting involved in your project. But I found another thing that shows a parameter that looks like it's in the Haltech tuning software. One of those things that could lead to problems if overlooked. The dwell setting. Depends on the module. Also, the word "module" could mean what they call an igniter. That would be the high speed relay that I mentioned above. Requires ECU control. That might be what your Denso coil has. This is from the RB30 page. All systems have similarities though. Good luck. https://support.haltech.com/portal/en/kb/articles/rb30-engine- Haltech wiring ignition basic questions

Here's some Haltech stuff. Describes "Auto-Dwell", AKA current-limiting, and "ECU-Dwell", which is essentially using the module as high speed relay. The module keeps the heat/current out of the ECU. It's a fun topic, very energizing. https://support.haltech.com/portal/en/kb/articles/ignition-modules- Haltech wiring ignition basic questions

Some ignition coils have their "dwell" controlled by the computer, like modern GM HEI coils which are almost zero ohms resistance. Other coils use independent modules that have current-limiting circuitry that maximizes "charge" then holds it. I did a Google and found an interesting article about coils and modules, below. There's a bunch out there. My basic point is that you should not even be considering keeping the ballast resistor for a modern ignition system. It is a relic, although a cool (as in neato, but also a pun) one, for keeping current flow controlled through a coil used for points. It only lasted three years after Nissan went electronic in 1974. 1978 did not use a ballast resistor. Each system is different. There should be details in the full installation manual about what you need for the coil; resistance, type of module, how to wire it, etc. My other post was pointing out that the system is designed for independent coils per cylinder. You only show one. Maybe the Haltech 750 can run one coil for six cylinders but it's not clear. That would be inthe manual also. https://www.consulab.com/files/ignitionHandoutV20181.pdf- Fuel pouring out the front of the carbs

I wonder how much pressure the original electric pumps for the carb'ed cars generated. The system started with the mechanical pump that relieves pressure at the pump itself through internal valving. They hit a pressure and just don't push anymore. What did Nissan specify for the pressure of the factory electric pump?- 260z horn, signals, wipers not working

Not sure fishing for wires is the same. Still, a good skill to have.- Haltech wiring ignition basic questions

Not really clear how Haltech does their ignition. Might want to dig in to that a little more. https://www.haltech.com/wp-admin/admin-ajax.php?action=ht_get_file&id=5d227b76506c252c8b7fb0d1&op=1 https://www.haltech.com/wp-admin/admin-ajax.php?action=ht_get_file&id=5d351552506c25377c49fae6&op=1- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

I am pretty sure that the R200 started with the 1975 280Z. It has its own unique pinion flange bolt pattern and bolt size. I have never heard of the different pattern for a 260Z diff. From 1976 on the pinion flange pattern and bolt size stayed the same until the 1984 300ZX's with the short nose R200's. You have to go by year because Nissan went away from the R180 then started using it again as I showed above for 1976 and 1978. The same body types used different diffs in 1978, according to the FSM. In 1976 they all used the R200.- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

- Datsun ( Nissan ) Z and ZX types of transmissions and differentials

I think that Carl Beck has a pretty good description on his zhome site. I'll see if I can find it. You can't generalize by just the type of car. You have to go by year. Here are four examples. 1976 USA/Canada 280Z FSM 1978 USA/Canada 280Z FSM 1979 USA/Canada 280ZX FSM 1981 USA/Canada FSM- 260z horn, signals, wipers not working

We're teaching how to wire a fish. It's complicated.- Haltech wiring ignition basic questions

Deleted some wrongness. I would just use the R, B, S, and IG to decide what to use to power your Haltech and parts. Believe Steve. That would be a great political slogan... - COVID-19

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.