Everything posted by Zed Head

-

74 260z distributor on wrong ??

The ballast is still broken if all three terminals don't have power. The way it's wired won't affect what you showed with your test light.

-

74 260z distributor on wrong ??

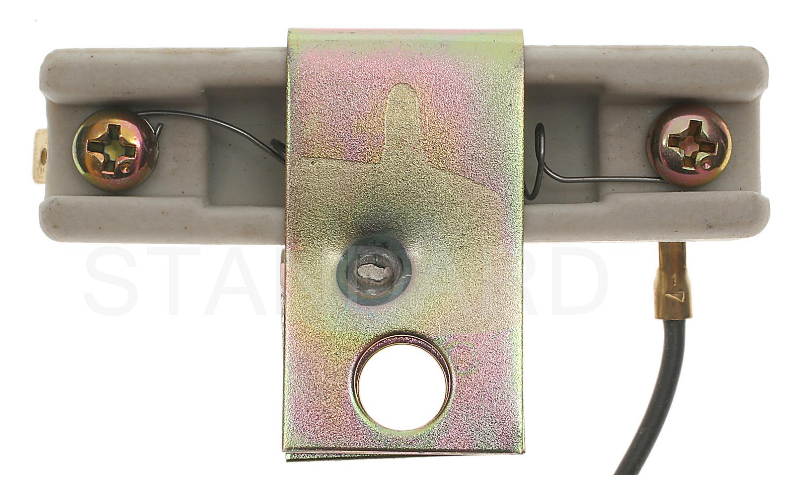

I'm not sure if the wiring is correct but if you have power to any of those three terminals you should have power to all of them, because of the way the ballast is designed. The last terminal in your ballast is not connected to the others. Either the wire broke or the screw came loose. You want a three prong ballast just to match what you have. It might be three prongs to protect the ignition module. Looks like they are hard to find though. Take yours off and see what's broken. Might just be a loose screw.

-

Blown Fuse Link and Now No Power at Ignition

With everything turned off, use a meter and test for a dead short from the fusible link terminal. You never described why or how the fusible link blew. Somehow you're on to hot wiring the solenoid.

-

74 260z distributor on wrong ??

C'mon it's still light out....

-

74 260z distributor on wrong ??

-

74 260z distributor on wrong ??

- 74 260z distributor on wrong ??

Disconnect the wires, remove the ballast resistor and turn it over. Looks like it might be damaged. The wire is probably broken.- 74 260z distributor on wrong ??

Once this part is figured out it's on to carburetors! 😀- 74 260z distributor on wrong ??

No, that is incorrect. You need a meter or a test light. It's an easy test.- 74 260z distributor on wrong ??

Two rotations. Four cycles. It will either be right the first time the piston comes up or the second time.- 74 260z distributor on wrong ??

If you get the valve cover off, and take all of the spark plugs out, you can put a wrench on the timing gear bolt to turn the engine over. Shine a bright light down the #1 plug hole and you'll see the top of the piston as it comes up. When you see it close to the top, look at the timing mark on the damper pulley and get it to zero. Look at the first two cam lobes at the front of the engine and make sure that they are pointed upward. That will be the compression stroke.- CLutch Kit

Fidanza has done a terrible job explaining what the green coating is and how it should be handled. They also refer to installation instructions on their web site but there are none to be found. They have videos on Facebook, but none on their Youtube channel. They're lucky that people like their product because their "media" presence is crap. They've created lots of confusion. This doesn't help you at all Wally. Make sure you get that throwout sleeve right though. Post the number of the kit you got, or a picture, and the parts that came with it. And the bearing/sleeve is just clipped on to the clutch fork, and the fork is clipped on to the pivot ball. They both just pull off by hand. Pull them out of your transmission and take a close look. they should be cleaned up anyway. https://www.facebook.com/FidanzaPerformance/videos/1583594301777341/ https://www.fidanza.com/ https://www.classiczcars.com/forums/topic/61251-is-my-clutch-seized-to-flywheel/- CLutch Kit

The "bearing" is actually the sleeve and a bearing. Two pieces. If you didn't get a tall pressure plate in your kit then the sleeve will not work right. You'll have to remove the transmission to fix it. The bearing is pressed in to the sleeve. If the bearing is worn or dry you will regret not replacing it.- 74 260z distributor on wrong ??

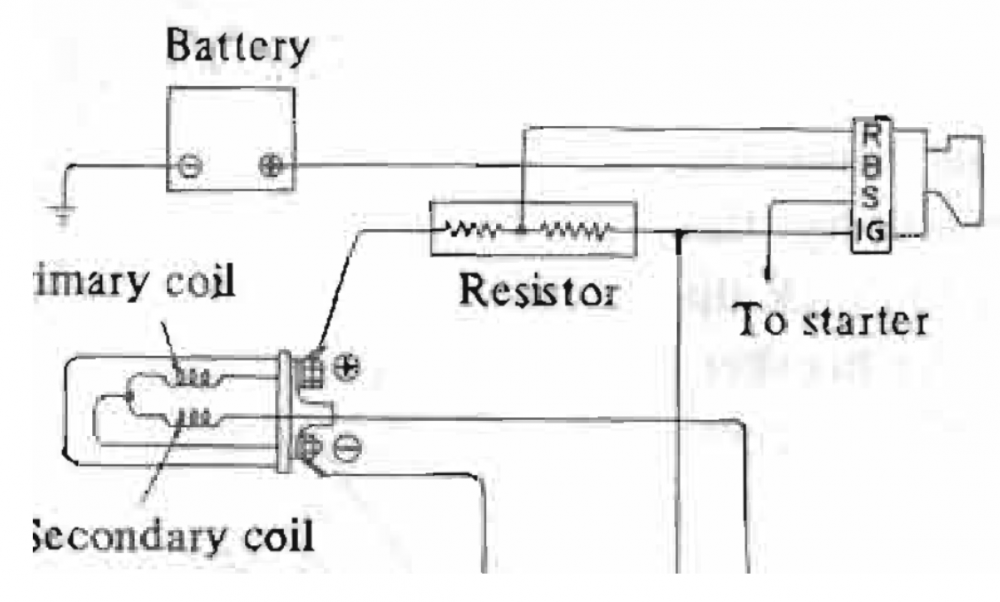

One rotation puts the engine on the opposite cycle or stroke. It's a four cycle engine. Compression (up), combustion (down), exhaust (up), intake (down). There are two cycles per revolution. The reason the small side needs to point a certain way is so that you can get the rotor in the distributor to point at the #1 cylinder on the compression stroke so that the spark will light the fire. If it's pointed the other way the spark happens during the exhaust stroke, where nothing will happen. https://en.wikipedia.org/wiki/Four-stroke_engine- 74 260z distributor on wrong ??

- 74 260z distributor on wrong ??

- 74 260z distributor on wrong ??

Wrong.- 74 260z distributor on wrong ??

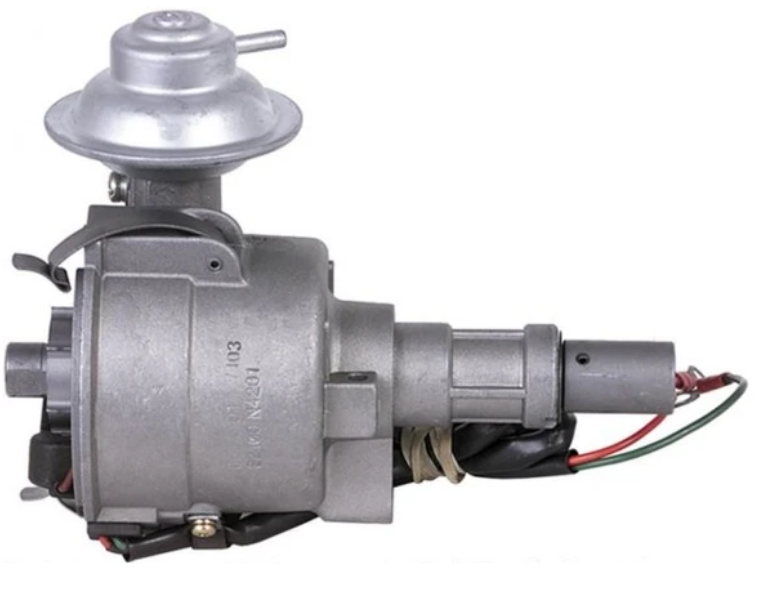

That distributor looks like a reman, or somebody did a really good job of cleaning it up. It seems like the plate on the bottom of the distributor might be upside down. If you install the distributor so that it looks like one of site's earlier pictures, that hole should be directly under the adjustment slot in the distributor plate. Take a picture of the bottom of the distributor and post it. After you confirm that piston #1 is on the compression stroke. Don't worry about the wires. Wires are easy. Honest. Get those mechanical parts right first.- 74 260z distributor on wrong ??

Was there a screw in this hole that held the distributor down? Or was the distributor free-floating? It's still unclear how the distributor was rotated so far away from where it should have been, as site/cliff/unseen noted in an earlier post. You're making progress...- 4-speed: No 1st 2nd gears

That is some nice detective work.- Z's on BAT and other places collection

- 4-speed: No 1st 2nd gears

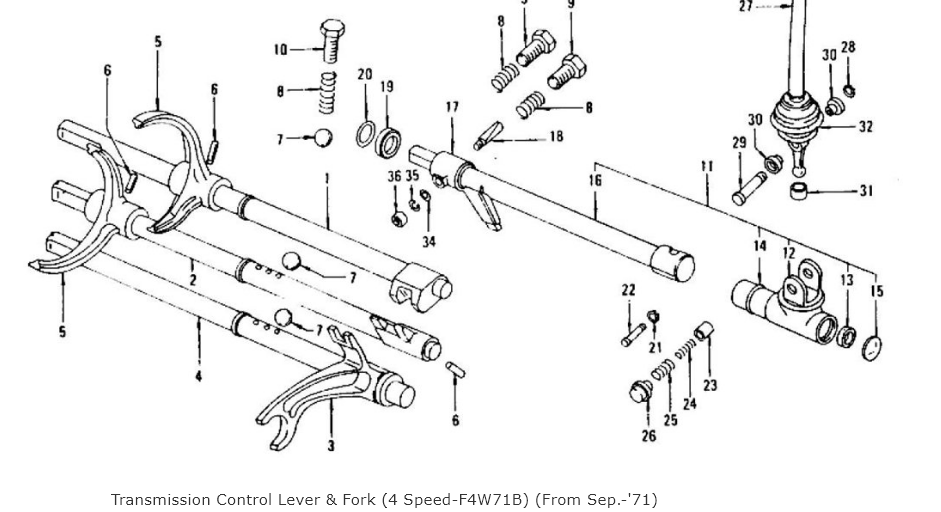

Here's another view. http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/transmission-control/4-speed/from-sep-71- 4-speed: No 1st 2nd gears

You should be able to grab that exposed rod by hand and just shove it back and forth to get in to gear, if the other two rods are in neutral. A simple test of the detents.- 4-speed: No 1st 2nd gears

Can you move the exposed 1-2 shift rod to get in to 1st and 2nd? Edited, re-read your first post.- COVID-19

People should keep in mind that the vaccines are not 100% effective. They just reduce the chance of getting infected, and reduce the chance of suffering severe effects if you do get infected. I am now seeing people in the supermarket acting like they are bulletproof and the risk is completely gone. I still mask up in the supermarket. Just calculating the odds, roughly, and why take a chance for a few minutes of mask-wearing inside. When the case numbers are way down I'll leave the mask at home. - 74 260z distributor on wrong ??

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.