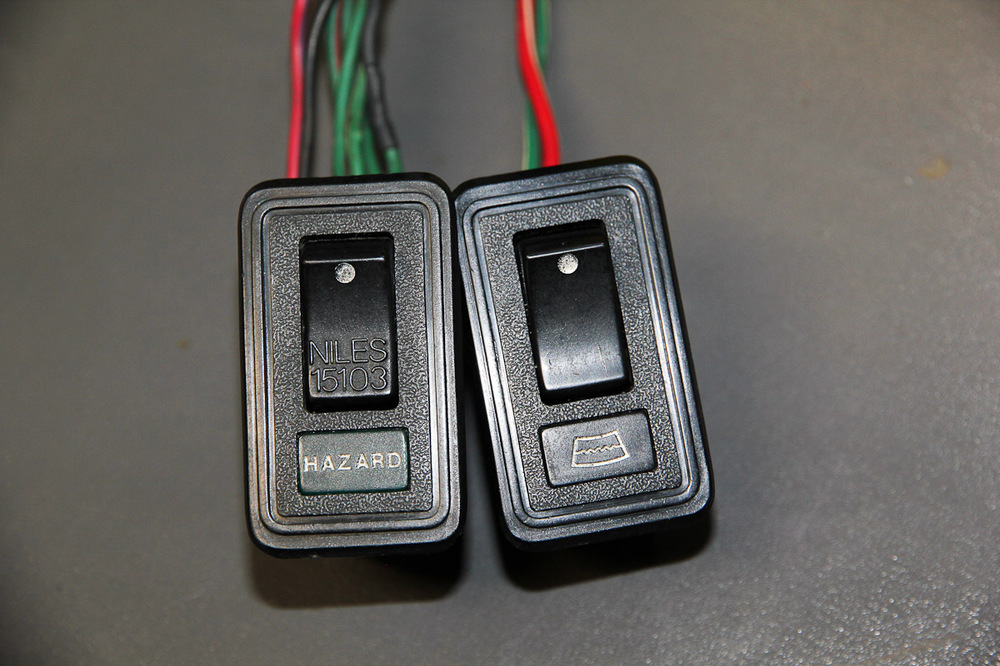

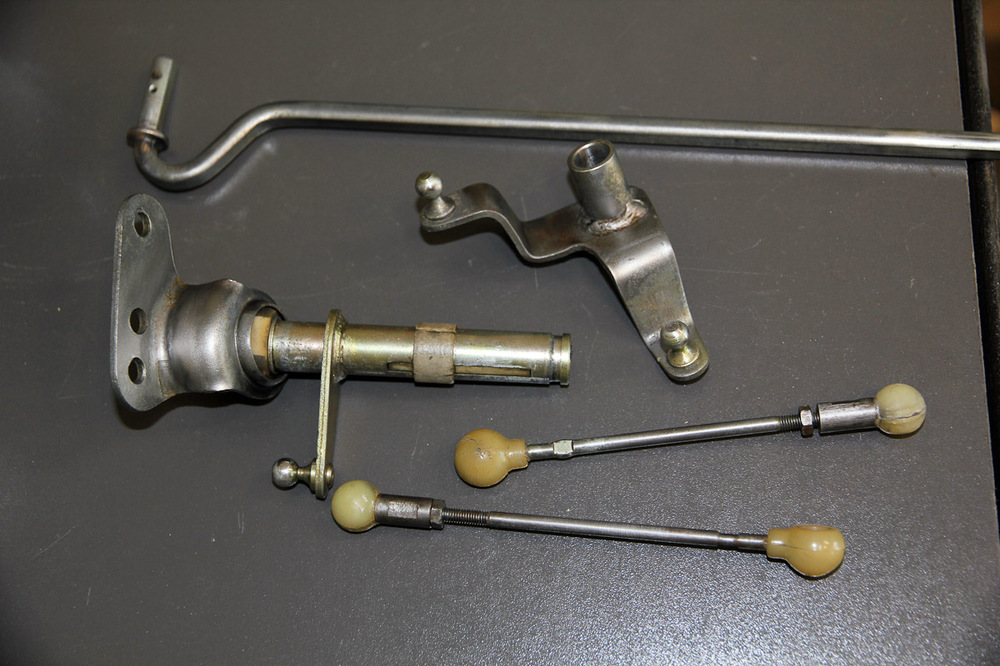

Been kind of a while without an update. Mostly dealing with some little things here and there whenever I can find some time. The throttle linkage had been giving me minor problems for a while, so I cleaned, straightened, spray painted, lubricated and adjusted everything and it's much better. Flushed the cooling system and added the coolant temp potentiometer.

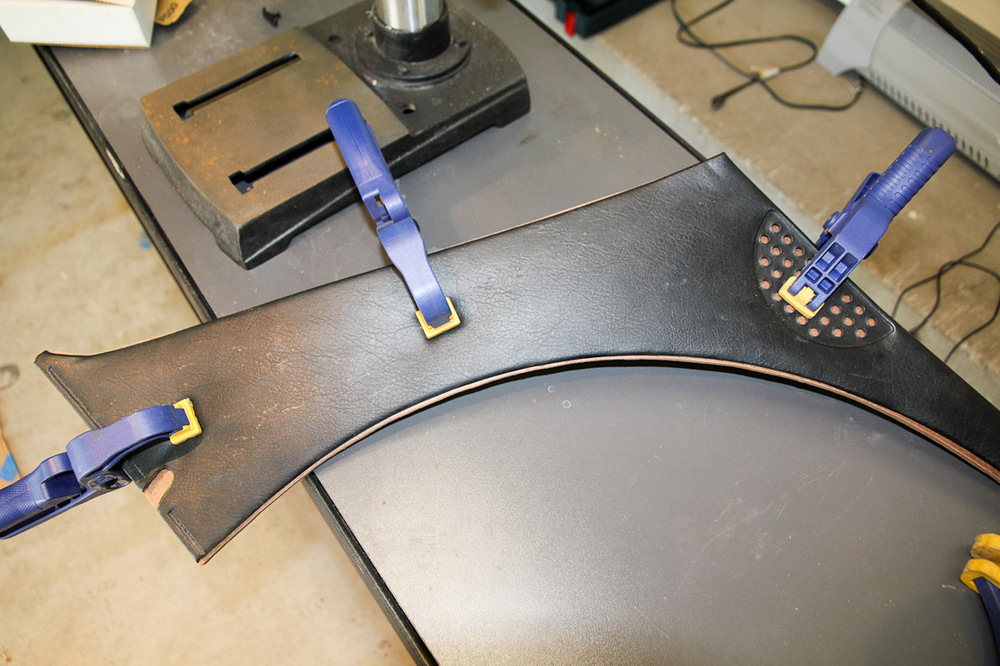

Also made a few interior bits. The B-pillar/dog leg pieces and the hatch finisher had all but disintegrated over the years. I always think I take plenty of photographs while I'm working on this stuff and then find out later that I usually don't even get a good before and after, so take my word for it that they were in rough shape The dog legs took two tries; the first go around I used the old one as a template without removing the vinyl since I didn't want the whole thing crumbling. That didn't fit well enough, so I made another pair (no vinyl on the old one this time) that fit significantly better.

The hatch piece actually took three tries. The first one wound up on the roadside somewhere between home and the office when I left it on the back window. The second one went in the trash, because it turned out that that piece isn't the simple rectangle that I thought it was. Third time's a charm! Everything was covered in the same vinyl that I used for the scuff plates, which is the closest to the original stuff I could find at Joann's.

And then the center console. The one I have is pretty well beat up -- aside from being dirty, it had some bad paint on it, the armrest was broken, ashtray rusty, etc. -- but I don't really want to spend my limited budget on a new one right now if I can get it to Good Enough, so that's what I did. The ashtray I cleaned up as best as I could with a wheel and sandpaper, then sprayed it with the wheel paint I used for the tail light panels. The sliding cover got a coat of Rustoleum.

The armrest was cracked along the middle, so that was glued and fiberglassed together. Someone covered it in the past with some foam rubber, which I left, but the studs for the screws had all been split open or broken off. Those were glued back together. I also stumbled upon a way to replace ones that were missing entirely: acid shop brushes dipped in ABS cement and cut to length.

The rest of the console got a thorough cleaning to remove as much of the old paint as possible. I glued/glassed some cracks back together and tried to fill in the choke slot, which was only a modest success. I sprayed the whole thing with Krylon Fusion and am hoping it holds up alright. It looks decent (and way better than it did), so if it lasts for a year (or even until I can do the dash) then that's good enough.