Everything posted by ozconnection

-

Compatible shifter for Jatco trans

Don't expect dudes behind the counter to be able to imagine what could be done. If it's not written there in front of them, they have NFI. Speed shops may have what you want sitting on the shelf for you to look at and sus out. That way you're not relying on someone else to decide if it will fit or not. "Your current car"...is that the one with the 3n71b in it?? They don't have lock up TC's. My 4 speeder shifts beautifully, so throttle responsive. I played around with an adjustable vacuum modulator valve until I had it just the way I liked it. There is a short rod behind this valve, failing buying an adjustable valve, you could try different length rods (by a few mm's each way) yourself. I used nails cut down to the right length and thickness. Cheap mate....and easy either way you go!

-

Compatible shifter for Jatco trans

The luxury of my 4 speeder is that its a hydraulic box.....it doesn't need or use a computer to drive it! Its just like the 3 speeder in it operation except for the O/D which can be cut out via a toggle or rocker switch. Thanks for the website...only problem is its under construction!! Have a look around for the hydraulic version....personally I hate having to fiddle with wires and stuff if the trans. can be made to work just as well with a vacuum signal from the intake manifold!! Your call and good luck. Cheers.

-

Compatible shifter for Jatco trans

That L4n71B is a great box. I know. You'll be glad you got one with that tall overdrive ratio on board. The first two gears are lower in ratio but you can still chuck in some 4.11's for example and still have a good top end! Here in Oz, I was able to get one from an L Series 2.4 litre R30 Skyline. Bolted right up with the R30 flexplate (4 speed one, not the 3 speeder as it's different) and some mods to the tailshaft as the shaft and splines are bigger from the 4n71B. A newly fabricated crossmember was needed for it to fit my chassis, maybe yours too dunno you'd have to check that one out for yourself. Shifter issue as well. Just needed to drill a new hole in the linkage so I could manually shift into 1st....easy mod though. Yes, put the 4n71B box in....for sure. How many have done it????? :devious: ....and with a shift kit and high stall...... yeah baby!

-

Compatible shifter for Jatco trans

What do you want to do with one of those shifters anyway? The factory linkage setup is very simple and I've only ever experienced a failure once when a plastic bush gave out that made the t bar a little loose and rattley. Took about 10 minutes to get under the car and fix and cost so little that I can't even remember how much it cost. :stupid: The shifters you are talking about...you'll remember how much they'll cost you! If you want to do it properly, put a shift kit through the trans, put a high stall converter in it and go beat the troops! Cheers.

-

A new Holley for my L28

Hi there, I've just finished building a new four barrel carburettor for my next development phase on my L28. The Holley originally started off as a 'run of the mill' 450 cfm (list 4548) vacuum secondary four barrel. Since then, it has been extensively modified and upgraded to suit my requirements. Some of the features it has are: 4 corner idle mixture adjustment Downleg booster venturis Electric choke Reworked metering blocks to include adjustable power valve channel restriction and idle/off idle circuits via screw in jets Percy's adjustable metering blocks for primary and secondary main fuel Centre hung fuel bowls Quick change secondary spring unit and A blended 600 cfm 4 barrel base plate. The next phase of engine development includes a new cylinder head where I'm concentrating on improving low engine speed torque. The head will have a much better quench around the valves and will boost my compression from 8.3 to 9.9 to one. The ports are round exhaust with liners like the P79 heads and the intake ports are smaller than the N42. (30mm's versus 34.7mm's). The intake manifold is an older candilabra single carburettor type, Nissan code E30. This manifold will be adapted to suit the Holley carburettor and it has 30mm runners, matching perfectly the Y70 head which originally came off an L20A ET engine in Japan. The head is currently at a headshop being reconditioned with guidelines not to touch the ports other than to clean the bowl region and improve the valve seat areas for better flow. A special smooth radius valve job will be tried instead of the usual 5 angle. It came with strong recommendation so I said yes to that. The head should be ready fairly soon. I'm very curious (and committed!) to giving this a go. I will be doing a series of dyno runs soon to establish my baseline at the moment and then gradually change over to the new parts to see their effect on performance. Remember, my aim is to improve torque at low rpms, so talk about big ports, valves and camshafts may not be what is needed, unless you can convince me otherwise! Sure, I would still like it to rev to say 5000rpm, but it is what happens when you change to the next gear higher that interests me, what happens at between say 2000 to 4000 rpm's! Read Torque Monster! Your thoughts?

-

Ram air?

:classic: My understanding of this is that it's the temperature of the air that the engine sees which determines how much fuel to add. Cold air is more dense than hot air at the same elevation above sea level. It carries more oxygen by volume so therefore needs proportionately more fuel added to keep the same AFR's as before. Without adjusting or compensating for this added, colder air (because the mouth of the new ducting is usually placed outside of the hot engine compartment), the engine will run leaner than before with the possibility of some lost power. An overly rich carb calibration before the mod may actually run closer to optimum with the mod, picking up a little torque/power. Either way, it's important to realise that some minor adjustments could/should be made to the tune after fitting an effective cold air/ram air induction setup. There's a lot more to it than just a few lines written on a page and grad students could write a thesis on the topic!! However if you're going to the trouble of creating a cold air intake, make sure you place the mouth in an area of the car that experiences high air pressures! Mounting the air induction pickup in a low pressure area is counter productive. A good spot for high pressure is under the wipers on the front windscreen, for example. Just as a final point, 'ram air' induction really only works when driving at super high speeds. The effect from sedate around town speeds is minimal. Like I said before, it's the temp. of the air that has the greatest potential for more power and torque. (Have I put you all to :sleep:?) Cheers!

-

Question on modified E31 HEAD

What you say here makes good sense. However, can we attack this idea from a different angle? Replacing the valves in the head is a fairly involved procedure. Great for increasing the top end power potential of the engine but at what cost to the lower rpm torque band? If the head was to stay on the engine, would a change in cam profile be more cost effective in trying to achieve the desired flow through the heads and improve the top end horsepower rather than larger valves? I know enlarging the valves seems like the logical way to reduce aiflow restriction into the cylinders but if the new, larger valves were the 'right size' valves in the first place, wouldn't the factory have already installed them with all the necessary unshrouding to best effect? Apart from cost, what specific criteria do the OEM engineers use for determining 'optimal' cylinder head valve sizes in your opinion? As you've seen many times, ports are often too big or made that way by the owners wish to have bigger ports. The velocity of the intake charge drops and the engine becomes less responsive to the throttle at lower rpm's. What if a cylinder head was installed on an engine that had smaller ports than the original head, with correspondingly smaller valves that weren't at all shrouded and the characteristic airflow into the cylinders were governed more directly by the profile of the camshaft rather than the size of the ports or valves? Do you see where I'm heading with this? For a percentage of the drivers in this forum, most of their driving is done at sedate suburban speeds, ie less than 4K rpm. Smaller ports promote faster velocities in the intake so that improved cylinder filling is the result. Cam changes could be viewed as a preferred tuning method which wouldn't be as involved (or costly) as changing the valves, valve seats or hogging out the ports. There would also be flexability in the direction in which the owner could 'tune' their engines. The owner could run a small street cam or a much larger performance cam all on the same head! (with the appropriate attendance to things like valve springs, retainers, piston notching, suitable compression ratio's etc etc etc). Wow, wouldn't that be a revelation! So where would you find cylinder heads for an L series with smaller than original ports? I'm lucky that I have found several L20A cylinder heads that fit the above idea perfectly. I'm just toying with the idea and was looking for input from anyone else who may have thoughts on this. I was thinking of installing one of these heads on an L28 with a stock bottom end and a 2mm HG to boost compression to around 10:1 on 98 octane pump fuel. The intake ports are 30mm's and 1.5 inch intake valves and 1.3inch exhaust valves with liners. Torque below 4K rpm is my top priority! Your thoughts? PS Diseazd, I hope you don't consider this to be a thread jacking, I just was looking for input into my own thoughts and this comment by Phred struck a chord with me...!:embarrass:

-

Y70 Head

I have a Y70 head in my garage that was used on an L20AET engine. You could use it on an L24. The chambers are nice and closed, the 30 mm intake ports would keep gas velocity high promoting good mixture homogenisation and the compression ratio using a two litre head on a 2.4 would be a bonus. Team all that with a fairly healthy cam to take advantage of the head's features and I would think it would go quite nicely! I remember reading something about ports in general years ago. What was the bottom line here was that by using a head with stock ports, or even a head with smaller than stock ports, excellent torque could be gained by using a cam with high lift and a modest increase in duration. That way, the top end would still be good with great low speed tractability. I run L28's, so I have never actually done this mod. I think the head would need a lot of work to work on an L28, so it kind of negates the whole idea really. But for an L24, I think it would surprise! :classic:

-

E31 Head Gasket

Your engine wouldn't have overheated if the rest of the cooling system is properly maintained. I have seen this several times when some brands of headgasket block off some of the smaller vent holes in the head/block. A large percentage of the coolant should flow to the back of the engine to keep the rear cylinders 'temperature happy'. The 'small' holes are for the release of steam (and not bulk coolant flow), so steam pockets don't form and cause localized hot spots.

-

Cylinder Head Removal - Part Two

This has happened to me in the past. Couldn't understand it. But there is some logic to it if you stop for a minute to think about it. The bright links on the chain are not exactly the same number of links from each other. An example: Say there are 50 links total in the chain, and the bright links are separated by 17 links. Turn the thing over and it will take a while before all the 'bits' fall back to their respective positions. It would happen much more often if there were exactly 25 links of separation....do you follow? Get a bicycle and experiment with the chain and mark two links with paint and make sure they are separated like the example above. Give it a go and you'll soon see what is happening in your engine. Bottom line, doesn't line up with the bright links...who cares? So long as all of the other setup criteria is met, TDC, rotor pointing the right way, timing sprocket notches etc, you'll get it to run again properly. :classic: (Or you could have turned your motor when the head was still on with only the rocker cover off until the links were where they were 'supposed' to be).

-

Bob Sharp intake question

There are lots of throttle return spring setups out there. Holley's have been around for a long time. Go to a speed shop and see what they have. Or search online. I bought one from a performance parts shop for my Holley. Cheap, effective and easy to instal.

-

Replacing old spark plug leads

My L28 was beginning to experience some hiccups lately. It would start and run easily enough but would run 'flat' with poor throttle response and the thing would hesitate until the engine was fully warmed up. First thought that came to mind was the carby. Don't all investigations start with the carby? However, the engine had been running well a while ago and had only started to degrade recently. I had a good look at things under the bonnet. I asked myself the question...."How old are these guys?" The leads were the original L20AET ones I got from a Jap import motor I bought way back in 1990. They looked good and weren't crossfiring but were they up to scratch? Time to break out the multimeter! The results were: No 1 = 10.31 No 2 = 15.58 No 3 = 14.99 No 4 = 13.25 No 5 = 11.49 No 6 = 16.60 These values were read with my ohm meter set on the 20K position. The new leads that I had bought were: No 1 = 2.05 No 2 = 1.91 No 3 = 2.06 No 4 = 2.19 No 5 = 2.49 No 6 = 2.54 These values were also taken with the ohm meter set on the 20K position. I even tested the coil to distributor wire. The original L20AET wire had been cut, so I'd never used it. Instead I had an 9mm 'eliminator' series wire that measured 0.96 on my meter, again on the 20K position. The new wire I got with the set measured 1.26 :surprised So I kept the old eliminator wire on. Firstly, I guess one could conclude that the 'eliminator' series of leads would be better than the "Top Gun" 8mm leads I've just put on the car. Then it would boil down to cost vs performance etc. However, I think that with the new leads I have on the engine, I should see an improvement over what was in there originally!! I'll do some 'cruising' and let you guys know how I get on.

-

MSA 3 into 2 Headers and Twice Pipes

Please do a before and after dyno run......... Post your results here.

-

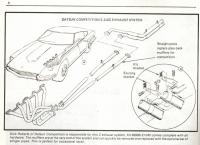

Roberts Competition's Exhaust

Don't sweat it Toxic. That exhaust system hasn't been available for what seems like a long time now but it doesn't look very hard to build either. Any good exhaust shop should be able to fabricate you a setup like that. They're mostly straight pipes with a few bends here and there. The suggestion to take the picture with you is good as it gives the exhaust fabricator some idea of what you want. Most headers that I've seen join the first and last three cylinders groups together already. Then they join the secondaries to form a single system. Just cut the seconary pipes before they merge into one pipe and continue on from there. Too easy. Oh, one more thing, I don't mind you using my picture, just say from where you got it from ok :classic:.

-

Twice Pipes

Can you post a sound clip??? Cheers :classic:

-

Twice Pipes

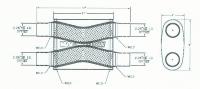

Got this from Magnaflow today. They were really quick in their response too. Thanks Magnaflow! It's the internal workings of the 11378 muffler. Seems to me that the two pipes are not separated but allow the mixing of gasses. What do you guys think? I like the sound of the twice pipes ZDemon!

-

Twice Pipes

Ron, great idea with the blower! :bulb: When do you think you'd get one of these mufflers? A very comprehensive list of features supplied by the manufacturer. Too bad it doesn't mention what happens inside the thing! I wouldn't mind getting one of the magnaflow mufflers myself if it is truely split. I still think that if you're going to all this trouble, you may as well do it 'properly' and get the most 'bang for your bucks!' :classic: I will go to their website and ask them. Perhaps you could too if you wanted to. They might be more inclined to respond if there are two people asking?!

-

Twice Pipes

Yes please Ron, you must post the sound of your machine here once it's done....it looks superb. I'm wondering if there is flow mixing (ie completely separated chambers or not) with that magnaflow pre-muffler you have? Do you know, can you tell?

-

Twice Pipes

Unfortunately nor do I have any 'proof' with the L series as yet. As soon as my current single system expires, I'll be doing some dyno testing to establish differences. V8 engines are a different kettle of fish. Different number of cylinders, different firing order and therefore work to a different 'tune' to our sixes. We cannot compare what works on an eight to what works with our engines however much we try. I'm curious, why don't you throw your machine on the dyno now and after the pipe change? Give us all a taste of things to come for those who are going to do this to there cars in the future. (and post an "on the dyno" sound clip too, please!)

-

Twice Pipes

There was a comment by one of the posters that all the pipes merged into one pipe and then split again into two pipes and this was a good thing. Wrong!! This is pointless and isn't a true twice pipes setup. The interaction of the exhaust pulses at this point will negate any advantage the system could have provided the engine with. Group cylinders 1,2,3 and 4,5,6 together and keep them separate all the way through...no interconnecting pipes or any form of merging. Check out the attachment to see what I'm talking about.

-

Twice Pipes

I guess that's the value of forums like this. With our collective and shared knowledge we could probably go to the exhaust shop and tell them what we wanted on our cars. Knowledge is power:geek:

-

Myth or Reality, low backpressure=low torque

Look, I'm no real expert here and a lot of this stuff belongs in the physics lab in some university. What I do know is that there are powerful pressure waves travel up and down the exhaust system while the engine is running. A hole somewhere in the exhaust system (where it shouldn't be) then dampens this 'good' pulsing. Also, a hole creates turbulent flow in the exhaust pipe or muffler. This turbulent flow will reduce the exhaust flow out of the engine, decreasing its performance.

-

Myth or Reality, low backpressure=low torque

If that were true, the car should've run better not worse. I believe its more to do with the proper pulsing inside the exhaust system which was restored by plugging the hole.

-

Twice Pipes

Arne, I have reseached this topic myself for quite a while now. What I have found is it's not just the diameter of the exhaust pipe that's important. Exhaust system tuning can reap substancial power and torque dividends if done correctly. There are a number of textbooks that promote the idea of dividing the exhaust system into two separate banks for a six cylinder engine with a firing order of 1,5,3,6,2,4. Just like the intake side of things where there are dual plane, single plane, tunnel ram, individual runner etc type configurations, there should be insight given to these possibilities where the exhaust is concerned. There's lots of 'theory' on the topic. May I suggest you grab a book like "Scientific design of Exhaust and Intake Systems" by Smith and Morrison and have a litte read. I haven't done this yet on my car, but I've already made the promise in another thread that as soon as my system needs replacement, this is the path I'll be taking.

-

Myth or Reality, low backpressure=low torque

Yes, that might hold some truth with forced induction.