Everything posted by Zed Head

-

What is this?

Thanks. This one - http://backissues.com/issue/Sports-Car-Graphic-February-1970 siteunseen had the best and most direct and informative answer, I think. And he didn't even add a comment.

-

1973 240Z Value

The key to the @ symbol is to type the first few letters of the person you want to notify right after the symbol. No space. Sometimes it takes a second for the dropdown menu. @Montezuma If you don't want to add your address, just type in 111 fake address on fake street in faketown, USA. That's what I do. You could also just add For Sale to the title of this thread. It will catch some eyes.

- 1973 240Z Value

-

1973 240Z Value

Do you have any paper work on who built the engine? The right engine builder could add a lot of value. Also, if the engine has no miles on it, it might be best not to get it tuned. The engines are very durable once they're broken in, but they occasionally will destroy some parts during break-in. If you have the paperwork about the rebuild that might be enough for a new owner to take on the risk. I went through something similar recently and got caught in a loop of breaking new things as I was fixing other things. Finally got to a stable point and left a few things "as-is" for the new owner.

-

Shifter question

That's a ZX lever. Remove the plastic bushing and you'll see the slot that the bushing rides in. It's essentially a self-adjusting hole that changes the bottom arm length through the range of its stroke. I've looked at it but never really figured out exactly what its intent was. There's a spring and it's meant to slide. You could raise the hole to the top of the slot and see if the bottom arm length is longer than the Z rod. I think I've written this before - maybe we should all be modifying ZX levers to work with our Z's instead of swapping Z levers in to our ZX transmissions. They put a lot of effort in to that design. It must have some benefit.

-

What is this?

Let's not get our trolling lines all tangled up. Where did you find that image? And what is the real question? Are you asking what a Fairlady Z 160 is? Exceedingly obvious that it's a picture aka image.

-

Pictures uploading different

Sorry Mike, you don't seem to understand what's happening. I've been using Incognito for 2 or 3 or 4 years. It has worked flawlessly for all web sites including classiczcars.com until a few days ago, when classiczcars,com stopped loading correctly and/or quickly. classiczcars.com is the only site that has a problem. Being a nerdy problem-solving type I went through a wide range of possible causes, looking at malware and viruses and purging old programs that load at startup, and finally decided to try using a "non"-Incognito Chrome window, even though it should have no affect on the loading side, only the end of a session, when cookies and history are removed. And it worked, and it's working right now as I type this. It doesn't really fit Google's description of what "Incognito" is or does, which is interesting by itself. There's more to Incognito than they're saying. I would guess that classiczcars.com loads a large batch of "stuff" on the first time that is then stored and accessed the next time a session is opened. That's why it's back to being fast now. So it's just a curiosity now, about how the internet and classiczcars.com works. I'm still trying to foil the tracking and spying because it's a free world and if I can run fast enough to get away, that's my prerogative. Google used to associate at least a full single session's worth of my personal browsing data to each of my individual classiczcars.com sessions now they'll just get no data. They went too far and exposed themselves. Pretty fascinating, really. I've dissociated my classiczcars.com activity from all of my other internet activity. They created their own problem. No offense. I had to do it, just to be able to get on to the site at all. Ironic! Of course, my ISP is probably selling every single thing I do on the internet to whoever pays anyway. So, a bit of a hollow victory. Edit - something to ponder - why would Google's Chrome in Incognito mode block Google's own ad-sense? Activate synapses....

-

78 280z Starts then dies (Have searched forum)

The charge light should go off as soon as the engine starts. Could be part of your problem. There are several "GM" "upgrades". Not all are upgrades though. An there are many "online" instructions. And don't forget that people like us are the ones putting those "instructions" about "upgrades" online. Air quotes galore...

-

Pictures uploading different

Seems to be the ticket. So, classiczcars.com gets its own window from now on.

-

Pictures uploading different

Got a new experiment going. A special Chrome session, using a normal window. Load up all those ads and cookies and stuff and see how things go. So far, I've been out and back in and it's pretty speedy. I'll have to go try an Incognito window to do a full compare, over multiple sessions (ever wonder why they call them sessions?)

-

78 280z Starts then dies (Have searched forum)

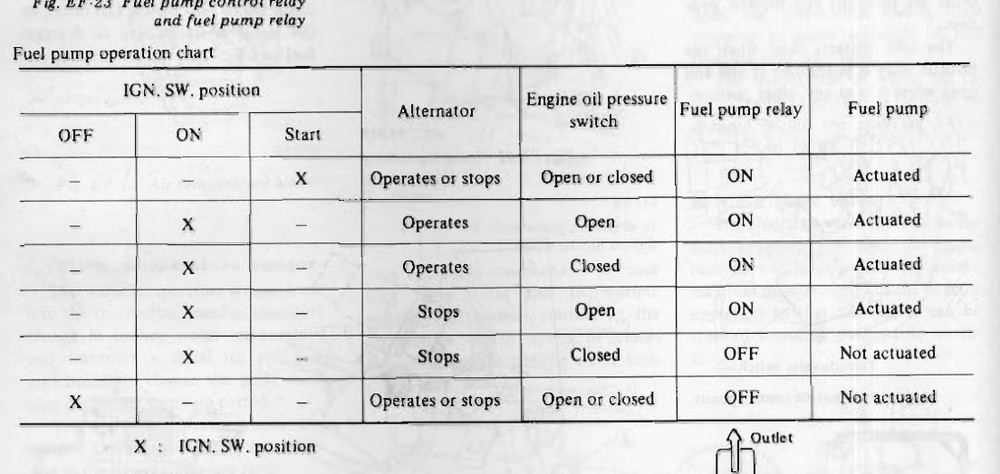

You've made some progress. Might have lost your train of logic though. Did you plug the sender back in while the engine was running? Or with the the engine off, then it wouldn't restart? And "the whole process" covers too much stuff. You don't need to do the Start tests becuase you already know that the pump runs and it will start, Seems like your pump control relay might have problems. It might be slow to react or defective. There are two circuits to activate the pump relay, one from the oil pressure switch and the other from the alternator power. Either will keep the pump running. If your oil pressure builds slowly and the alternator function isn't working, for example, you could have a problem like you have.

-

Shifter question

My mistake, I read "both pieces" as both ears, not the shifter and the ears. I just read the two followups and see my error. I don't have the patience to read properly anymore after waiting for the Google ads to load up. If that's what's really happening. I don't think that there's enough meat there to drill the shift lever, and maintain enough strength to last, though. Better have a spare lever handy.

-

Shifter question

You don't see how the top of the lever will move the same distance no matter where you put those holes? You'll be moving the lever and the fulcrum. You need to move the fulcrum relative to the lever. Not relative to the object being moved. The point of the short shifter is to move the internal mechanism the required distance (the required distance stays the same) with less movement at the top of the lever. If you don't change the ratio of the top of the lever to the bottom of the lever (moving the fulcrum) then by definition, it won't work. It won't have any effect.

-

Shifter question

The fulcrum is the pin in the hole in the lever. If you just move the holes you're moving both the fulcrum and the lever. No effect, except pressing on a different part of the same object.

-

Brakes stuck

Most tow companies have roll trucks, dollies, and all the gear they need to move that car without damaging it Probably cost less than $100. And you can rent a 15' U-Haul truck for about $60 to move the rest. Sometimes, time and convenience is worth the spending, even if it's only moving a few feet. With the truck blocking the garage entrance you can keep the riff-raff out too.

-

78 280z Starts then dies (Have searched forum)

Weird that you see the pressure drop while it's running but you said that the pump runs when the key is "On". The key should be On after it starts. Did you mean "Start"? There's no reason to remove the starter solenoid wire if you're turning the key to "On". The 78 cars are known for a flaw n the system. If you remove the oil pump sender wire, the fuel pump will run with the key at "On". If it does stay running when you do that then you can focus on the pump control relay and sender switch. The sender has two prongs, one is for pressure, the other is a switch. SteveJ replied while I was writing, hitting the button now......

-

Shifter question

You have to change the hole in the lever, not the ears, to change the ratio of travel between the top of the lever and the bottom of the lever.. Travel of the bottom of the lever will be the same, it will just be higher up, if you only drill the transmission ears. The bushing at the bottom of the lever slides up and down in a cylinder as the lever tip moves back and forth. Another way to get a shorter stroke is to cut the top of the lever down. You can simulate that by holding the lever lower when you shift, if you want to gauge the increase in force needed. The downside of the short-stroke.

-

Brakes stuck

If you're only moving it next door, a couple of cheap Harbor Freight dollies under the rear wheels might work. The BR chapter of the FSM shows how the brakes work (see link below). You can see the mechanism behind the rear wheel. if you crawl under the car It's usually the rear brakes, not the front. http://www.classiczcars.com/files/

-

Pictures uploading different

Ironic that the very thing Google wants to jam through my eyes in to my brain is the one thing keeping me away.. The internet is a strange thing.

-

testing heater core in car

Testing with pressure up to the cap limit plus a couple sounds like the way to go. If you wanted to get even more real-world you could dunk in a bucket of hot water, since a crack might open up when heated. Or you could just fill it with epoxy since you don't need heat. Or plug the inlet and outlet.

-

Pictures uploading different

I haven't tried it yet. I'm not really a big texter but sometimes I get in to the middle of a big textorama and have to try to keep up.

-

Pictures uploading different

I don't have any blockers or anything else added on. No extensions or plug-ins. It shows now. It was probably related to the other problem that I still have, just very slow loading classiczcars.com. The site just timed out on trying to load the image. The only thing that might be different is that my browsing history and cookies get deleted whenever I close my browser. I'd say that's probably the source of my problem. classiczcars.com loads either bunch of cookies, or it loads some that my system doesn't like, or it's loading something else. It seems to me, that with such a narrowly focused viewer base that you could forget about Google ad-sense, and the tracking cookies, and the spyware, and just choose your own ads. Solely focused on cars, and tools. It's the constant tracking and spying and following that slows down all of the internet sites. And for not much gain. Think about how much simpler things would be. And how much more comfortable we'd be, not seeing ads supposedly related to something we viewed on a completely different web site. Or that someone else here viewed on a different web site. K.I.S.S.

-

Pictures uploading different

- Pictures uploading different

I get the the white space in site's pictures even when clicked on, and there's a broken link in Mike's.- Installing a 1983 280zx 5 speed. Prep work?

You'll stir up the debris that would normally just sit on the bottom of the case, and disperse it through the various bearing surfaces. Flushing the transmission is not specified by any manufacturers as a maintenance procedure. - Pictures uploading different

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.