Everything posted by Zed Head

-

Odd facts/things about the transition to transistorized ignition systems on the 280Z

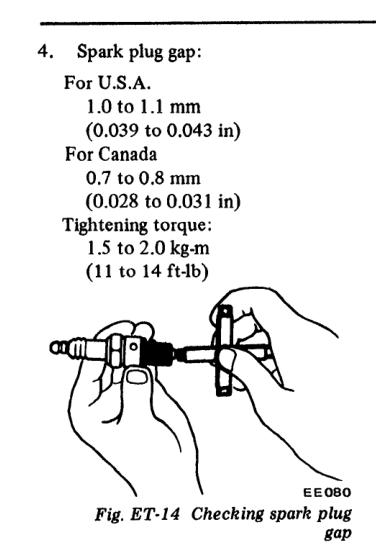

I learned something interesting in another thread about Nissan's move to electronic ignition systems, and thought it might be interesting to collect some stuff here. Nissan went from points to electronic ignition in 1974 with the 260Z. The coil still used a ballast resistor to limit current at long dwell times (low RPM). Spark gap was still specified at the gap used for points. 1975 and 1976 used the same basic system, an electronic module, a ballast resistor, and a coil, with spark plug gap set to the smaller points system gap. 1977 used the same basic system but opened the gap up to about .040" instead of the old ~.035". 1978 got rid of the ballast resistor and also kept the wide plug gap. Just collecting some thoughts while they're still in my head. I searched around the internet and found quite a bit of confusion about the ballast and 280Z's. Many people don't even realize that they have them, and assume that only points systems have a ballast resistor. Here is the carpartsmanual page for the ballast. The list doesn't quite match the picture, kind of confusing, the drawing says "to 74". So, does the 1977 ignition module pass more current than the earlier modules? Is that the difference that allows a wider gap? Interesting also that the first ignition boxes were aluminum with fins, to dissipate heat. http://www.carpartsmanual.com/datsun/Z-1969-1978/electrical/engine-electrical-fitting/3

-

1977, 280z with FS5W71B transmission

The 5 speed is basically the 4 speed with an extra gear engineered on. The parts should be interchangeable. You can tell by finding the part number on the carpartsmanual site and comparing diagrams. @Terrapin Z has a large collection of parts. You might want to disassemble further though to see what all you need. Looks like the 4 speed uses the same part. http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/transmission-gears/5-speed/44 http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/transmission-gears/4-speed/from-sep-71/27

-

1977 Cylinder #1 Mystery

It will be interesting to see what he comes up with. I think he likes the later ECM's with NISTUNE. @cgsheen1 Anyway, it's been an interesting discussion. I learned something about the 77's. Good luck.

-

1977 Cylinder #1 Mystery

- 1977 Cylinder #1 Mystery

It was a potential solution to the fouling plugs.- 1977 Cylinder #1 Mystery

- 1977 Cylinder #1 Mystery

I missed it, thanks. 77 is an odd year. So, they kept the ballast resistor, which is a current-adjusting device, and opened the gap for the plugs. So it's the intermediate step between 76 and 78. 76 had the same setup but a smaller gap. Electronic module with ballast. Who knows. I thought there might be an advantage to a more modern module. In the big scheme it just means he's still stuck with plug fouling, probably from the cam. Oh well.- 1977 Cylinder #1 Mystery

What about the FSM showing no ballast resistor and larger plug gap? The 77 FSM seems to show 78 material. The higher energy comes from electronic current limiting. The ballast should be unnecessary. Does the module number match the 1978 module? Does it have the plug or the terminal board for connecting it? I looked around the internet and can't find any E12 numbers, only LX. My basic point is that Nissan did not get everything done in time in 1977. It looks like they held on to the old style for a while.- 1977 Cylinder #1 Mystery

Doesn't @Captain Obvious have a 77?- 1977 Cylinder #1 Mystery

If his did he should not have the ballast resistor. That is the quandary. He said he has the ballast. If he has something he shouldn't then maybe he doesn't have something that he should. Post the number of the module. I think that that will tell you.- 1977 Cylinder #1 Mystery

Looks like 77 already has the high energy ignition. I always get the change mixed up with the fuel pump control. 77 was kind of a mid-change year, it still has the old AFM pump relay switch, I think. Posting before I see ckurtz's reply... Weird! The FSM says you shouldn't. Probably a mid-year change. So, if you're using the FSM tuneup spark plug gap, you'd be using a wide gap on a weak ignition. What plug gap are you running? Migth be a small part of your problem. Either way, the GM module will give more energy and allow the larger gap.- 1977 Cylinder #1 Mystery

I just looked at the 77 tune up chapter and can't tell if you have the old style or the new style. I thought 77 used the ballast resistor but they don't show it there. Do you have a ballast resistor by the coil?- 1977, 280z with FS5W71B transmission

It might be that the 3rd piece is doing all of the work. Be careful. Do those two pieces have jagged edges like they broke off of something? I recognize the tooth pattern but can't tell where it would have come from.- 1977 Cylinder #1 Mystery

Multiple spark discharge ignition was kind of developed for race cams so they could get cleaner low RPM performance. MSD built their company on it. It might help. And raising your idle RPM will probably increase your vacuum reading. These are the small things the guys that get theirs to run just fine don't tell you. You could swap to a GM HEI module really easily for cheap and you'll get a stronger spark. Get rid of the ballast resistor and keep the Flamethrower. When you say rebuilt distributor you don't mean a ZX distributor, right? You're still using the module down by the fuse box. Here's some MSD history. https://en.wikipedia.org/wiki/MSD_Ignition- 1977, 280z with FS5W71B transmission

Wow, that is not a synchro ring, looks more like part of a coupling hub. I've only pondered the insides of a trashed 5 speed after I took it apart, so don't really have the memories of somebody who has rebuilt one. Looks significant though. You might start browsing the ads for another 5 speed, just in case. Always good to have spares. Even a 4 speed will get you by.- 1977, 280z with FS5W71B transmission

@EuroDat will have a better idea but it looks like the remains of a synchronizer/baulk ring, but kind of different. Can you take a picture of the teeth on the parts? They look wide. The other magnetic parts might be bearing parts, which might have caused the synchro ring failure. http://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/transmission-gears/5-speed https://www.nissanpartsdeal.com/parts/nissan-ring-baulk~32604-p0100.html https://www.ebay.com/p/1529633534 https://www.nissanparts.cc/oem-parts/nissan-ring-baulk-s12-z31-720-c31-c32-d21-r31-32604p0100- 1977 Cylinder #1 Mystery

Are you running the 1977 ignition system? 1977 was still using the weak electronic system. Your cam is going to cause variation in the gasoline/air ratio, especially if you try to maintain a low idle RPM, plus the batch fire nature of the old EFI system also causes variation across the cylinder. A better ignition system might help.- 1977 Cylinder #1 Mystery

Didn't know you were running a lumpy cam. That thread from zcar.com is interesting. A lot of what would be considered bad advice on how to get the 260 cam to run "right". Fiddle with the AFM, run direct vacuum advance, adjust the TVS so it's off-idle. wangsman's version of "runs great" seems to be pulling hard to 6000 RPM. Your issue is at idle. You can tell from the comments that some of the opinion might be more of an "I made it work" view. I'll bet their cars smelled like raw gas at idle. No offense to the two guys that said it can run just fine with the lumpy cam, but that's how the brain works. We probably all have memories of the guy in high school that thought his car was fantastic but nobody wanted to ride with him. @Jeff G 78 is one of the guys in the thread. He knows a bit about how to get these engines to "run right". It will be entertaining to see where you end up. How are you going to write a guide if you take it to a tuning shop? What goals will you set for the tuners? Today's tuners only know how to use computers to tune automotive computers (I just saw one of those car repair videos that the guy titled "millenial vs. carburetor" or something like that) . Take special note of the looks on their faces when they see what you're working with. Should be fun.- 1977 Cylinder #1 Mystery

From up north - http://www.atlanticz.ca/zclub/techtips/tempsensorpot/index.html- 1977 Cylinder #1 Mystery

The bucking sounds like the typical lean mixture problem. Solved with the potentiometer in the coolant temperature circuit to richen things up.- Barefootdan's 280z Build

Some people have problems with Eibach springs. It seems to vary, almost like the springs are coming from different sources. The common problem is that the front ends up higher than the back. Others have no problems.- 1977, 280z with FS5W71B transmission

I'm going to guess that the jolt was a ball cage/retainer on one of the adapter plate bearings. People often find pieces of the retainer when they do a fluid change. The transmissions seem to just keep going though, it's amazing how destroyed they can look but still do just fine when new parts are installed. Draining the fluid will probably tell you something. Look for metal shavings and flat pieces of metal. https://www.researchgate.net/figure/Main-parts-of-ball-bearing_fig1_289540744- 1977 Cylinder #1 Mystery

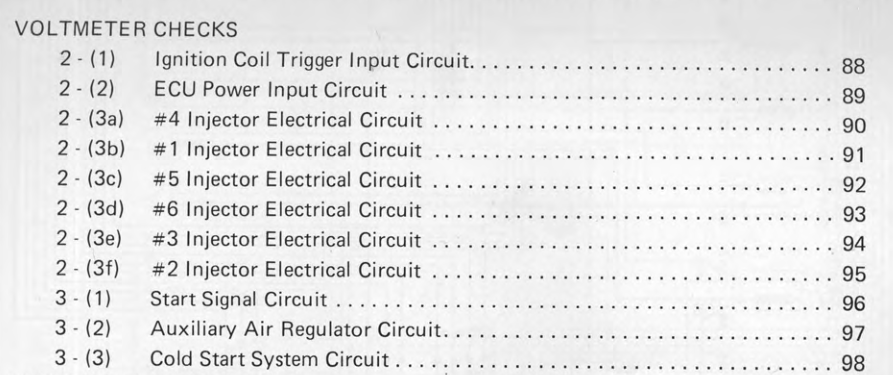

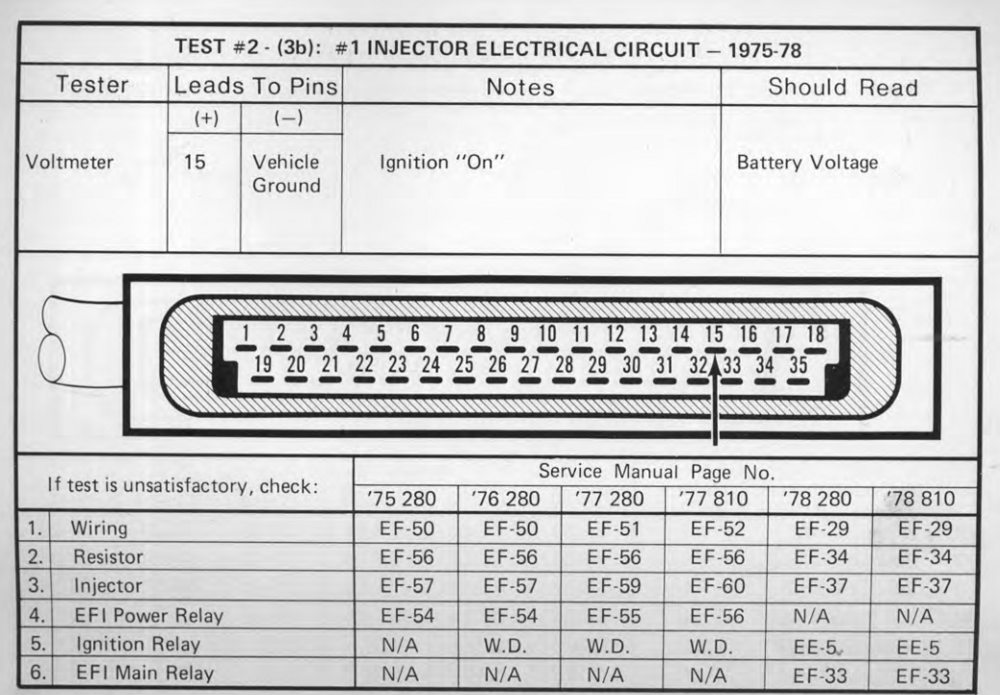

You guys are reminding me of something I see on some of these youtube repair videos. You can see proper voltage but it's best to put a load on the circuit to make sure the current is there. The guys that seem to know make up their own test lights with a headlight bulb. A cruddy connection might show proper voltage, especially with today's digital meters. But it disappears when a load is on.- 1977 Cylinder #1 Mystery

- 1977 Cylinder #1 Mystery

But you do bring up a good point about the grounding part of the circuit. You could have power but no ground. You can measure voltage at the ECU connector also. That will test the whole circuit. If you have voltage there then your theory about the ECU fits. Then you can get out your magnifying glass and check the trace back to the transistor. - 1977 Cylinder #1 Mystery

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.