Everything posted by Zed Head

-

Misfiring while cruising

One... https://www.taylorvertex.com/faqs/#ohmsonwires http://www.ngk-sparkplugs.jp/english/techinfo/resistor-wire/01/index.html

-

Misfiring while cruising

Seriously? This advice is not good enough? I don't see how it could be better. Not clear that Jalex really wants to fix the problems. I have to admit that sometimes I miss my car's old problems. It was something to work on. Good luck. https://www.zcar.com/forum/10-70-83-tech-discussion-forum/418272-spark-plugs-3-4-getting-sooty-black-my-1972-240z.html

-

Misfiring while cruising

He's so close, right now, to figuring out the poor idle in the heat problem. Those two center plugs and the dirty one next to it are huge clues. Much more informative than many of the previous posts. The clean plugs, 1, 2 and 6, tend to remove any choke setting, or carb-tuning, or fuel percolation, or Far311 camshaft issues. Unless, the fuel overflow runs straight down the 3 and 4 intake runners. With that focus a bunch of new ideas come to mind. But we need to know if the plugs are getting their voltage or not. Gotta test those plug wires.

-

Misfiring while cruising

Depends on how much oil is entering the cylinder and whether or not it's burning with combustion. You need to work on the simple checks so that you can zero in on what it really is. Focus on those spark plug wires. Here's another possibility - the newish spark plug wires aren't fully seated in the cap. That would give a sporadic misfire if there's no contact between wire and cap contact. That will show up in the multimeter test, which I'm sure you're doing while also searching the internet.

-

Red Crinkle Valve Cover and New Gasket

"Powder coat" is not inherently excellent. Like all coatings, surface prep, application, and curing determine the quality of the final product.

-

Misfiring while cruising

Yes, the center electrode should have a good path back to the contact in the distributor cap. You might see high resistance since you probably have resistor wires, but all six plugs and wires should show the same number. Wiggle the wires around once you get your meter set up, for each wire but especially 3 and 4, to be sure that you don't have an intermittent break in the circuit.

-

Where is the Fuel Vapor Check Valve Located

Just a loose end. This is why I haven't bought a new cap. Trying to figure out how to fix that gasket instead. https://www.courtesyparts.com/oem-parts/nissan-cap-filler-17251n4501

-

Misfiring while cruising

That's what Mark was saying to do. Put the plug in the end of the wire then measure from contact inside the cap to the center electrode of the plug. He said body but I think he meant center electrode. Do it for all six so that you have a good comparison.

-

Misfiring while cruising

Cap and rotor. Circling back... Oil rings don't show up in a cylinder pressure test. This a California Datsun engine after all. Valve seals can leak a lot of oil also. Focus on the plug wires and spark for now though. If you can show that it's definitely not spark related then you can move on to other possibilities. Eliminate one possible cause at a time.

-

Misfiring while cruising

That's a good test. But, does Jalex have a meter?

-

Misfiring while cruising

Another quick test of the wires would be to swap 2, 3, or 4 for any of the clean cylinders. It might be a stretch because the wires are custom fit but should be doable. Or just buy a single new plug wire and replace 3 or 4. If it's the wire, the problem will follow the wire. You're in to the process of elimination now.

-

Misfiring while cruising

That is a great picture. It shows a lot. We might all ponder the various causes of fouling for a short while. As I recall from much past experience with poor running engines, a fuel fouled plug often looks like 3 and 4 here, but then when it fouls, it gets wet with fuel. And it fouls quickly and the carbon coat is not so smooth. These plugs look fairly dry, and the other plugs look almost lean, like they're not even close to fuel fouling. Weak spark fouled plugs typically look wet also, like they were wet from the beginning of missed sparks. These plugs look like they were firing well, with a good even coat of sooty carbon on everything exposed, until the spark started shorting to ground through the carbon. In short, they look like they had great spark until they didn't. #2 (or maybe #5) looks like it is fouling also. But the other three look very clean. Considering how the carbs and manifolds are set up it doesn't seem like it could be a fuel problem, unless fuel is running down the intake runners and in to those cylinders. Is that possible? Is there a path for raw fuel in to the center runners? If he parks the car on a slant so the fuel runs away from the cylinders would that be a clue? If the spark is good and the fouling is fuel or oil related, and fuel is discounted, that leaves oil. Which could be rings or valve seals. It could also be valve lash, possibly, causing poor combustion. Just some thoughts on other possible causes. On situations like this, I tend to go around in a big circle on all of the possible causes until one wins. There's definitely a cylinder specific problem though, which narrows the possibilities down.

-

Misfiring while cruising

What is the idle speed of the engine? Engines with performance cams do better with a higher idle RPM.

-

Misfiring while cruising

Reply to Mark in #86 - I meant giving up on looking at all six. That would have made the 3 and 4 problem more clear. Which is why it was asked. Jalex's problem on the forum has always been that he doesn't do what people ask him to do. You asked for the other four and he only gave you one. Should have had a picture of all six in a row two days ago.

-

Misfiring while cruising

And #5 could be a lean misfire. Who knows.

-

Misfiring while cruising

Could be valve seals too. Weird that you guys gave up on "all 6" and accepted the addition of #5 as close enough. ? #1 is somewhat difficult but 2 and 6 are wide open.

-

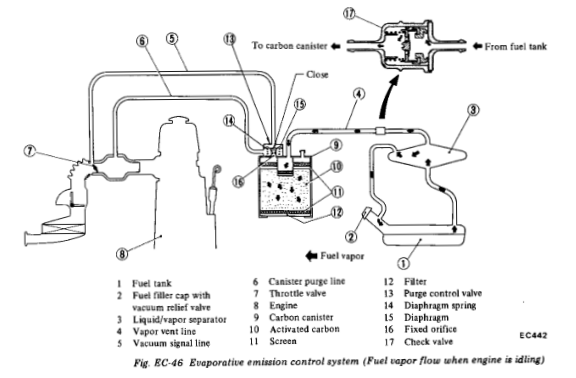

Where is the Fuel Vapor Check Valve Located

I wouldn't do the vacuum cleaner again. The motors are not sealed and could ignite fumes. Some pressure in the tank is not a bad thing. The system is designed to be sealed to the ambient atmosphere, to keep gas fumes in, and moisture out. Both ends are spring-loaded, with a spring in the check valve and a spring in the vacuum relief valve in the filler cap. Your fuel rail works on pressure differential so doesn't even know that the tank has pressure. If it was mine, I'd be happy to have some pressure. My filler cap vacuum relief gasket is shot so I don't get any whoosh, and I'm sure that my carbon canister isn't getting the workout it should. Sounds like everything is working right with your system. You could take a look under the car at the tank to see if the tank is bulging. If it's not, the pressure probably isn't very high. The whoosh might be more volume than pressure.

-

Where is the Fuel Vapor Check Valve Located

I think it's behind the panel. But you might check the end of the vent line in the engine bay, where it connects to the carbon canister, before you go too crazy. It might be clogged or blocked there. You should be able to suck some gas fumes through the hose after you disconnect it from the canister.

-

No spark, where to start?

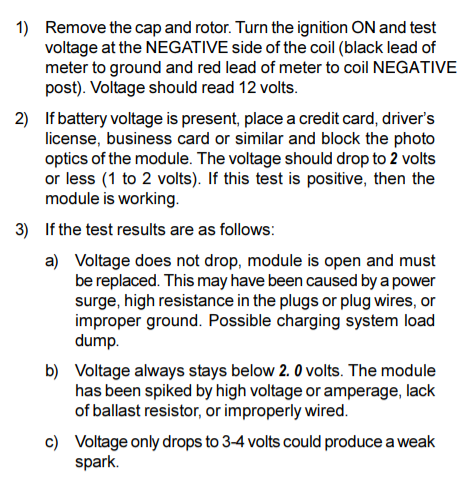

Just going through the basics, the next question might be "why would a functioning module not create a spark?". Does the distributor shaft turn when you crank the engine? Does the bottom of the rotor have the optics blocking part intact? Was there anything loose under the cap when you took it apart that might have been blocking the optics? Another common ignition module problem is that they overheat, fail, then come back to life when they cool down. You might find that the engine starts now if you put it all back together. Your testing shows that it should work. Edit - forgot to say...other parts can overheat also. Coils, wire connections, maybe the ballast resistor. If it starts then dies again you'll be farther down the troubleshooting path.

-

Misfiring while cruising

This is the old fuel percolation problem from way back, I think. Never got solved. How hot was it on Sunday?

-

No spark, where to start?

Coincidentally, one of the old Unilite threads just popped back up. It's a floater. https://www.classiczcars.com/forums/topic/60072-misfiring-while-cruising/?page=2

-

No spark, where to start?

That's right. The test described in that pdf file I linked to will tell you a lot though, for much less money than a $150 scope.. Can you take a picture of your distributor and engine bay? Might be some clues there.

-

alternator rebuilding-78 280Z

The FSM, even 1978, has excellent instructions for tearing down and testing the parts. Looks like fun. I tore one down but found that one of the big diodes was bad and couldn't be sourced. Held on to the parts for a while but eventually threw them in the recycle bin. I'm pretty sure that a person could buy most of the rebuild parts in the past. Probably find some NOS on eBay. (Shouldn't it be old new stock? ONS?)

- 76 280z Restoration

-

No spark, where to start?

Actually, I just read the Unilite instructions, and depending on where your probes were placed and how fast you moved, you might have been close to the proper test procedure. I think that the module times out after a short time though, so you have to have it open as shown, and use the optics blocking technique to get consistent results.